Technical Contents

Engineering Guide: Best 3D Printing Services

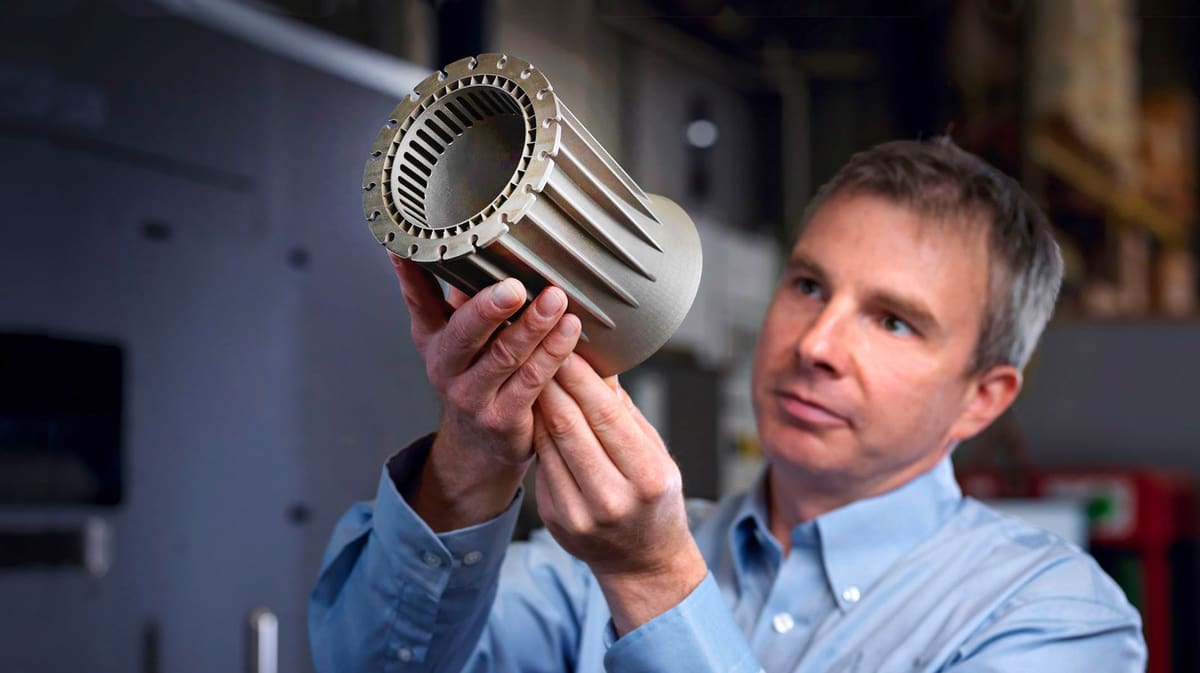

Engineering Insight: Precision as the Non-Negotiable Foundation of Industrial 3D Printing

In high-stakes custom metal manufacturing, 3D printing transcends rapid prototyping to become a critical production solution. However, its true industrial value is unlocked only when precision is treated not as a desirable attribute, but as the absolute foundational requirement. Surface finish and geometric accuracy directly dictate part performance, fatigue life, and functional integration within complex assemblies. Tolerances measured in microns determine whether a turbine blade survives extreme thermal cycling or a medical implant achieves osseointegration. Compromising on precision introduces latent failure points, escalating lifecycle costs through maintenance, recalls, or catastrophic in-service failures – risks unacceptable in aerospace, defense, energy, or advanced medical applications. This is where the distinction between generic printing services and engineered additive manufacturing becomes starkly evident.

At Wuxi Lead Precision Machinery, we operate at this precision frontier daily. Our engineering protocols are forged in environments where failure is not an option. We have delivered mission-critical titanium components for propulsion systems adhering to stringent military aerospace standards, where dimensional variance beyond ±0.02mm jeopardizes flight safety. Similarly, our involvement in supplying high-precision structural elements for the Beijing Winter Olympics infrastructure demanded thermal stability and geometric fidelity under extreme cold – tolerances maintained despite complex lattice structures impossible with traditional machining. This experience ingrains a singular focus: every micron controlled is a potential failure mode eliminated. It necessitates rigorous process validation, in-situ monitoring, and post-processing expertise that transforms raw printed parts into certified, reliable components.

Precision manufacturing demands capabilities calibrated for industrial reality. Generic service bureaus often prioritize speed or cost over repeatability, lacking the metrology infrastructure or material science depth for true production-part consistency. True precision requires integrated control from digital design through final inspection. Our dedicated metal additive facility utilizes aerospace-grade systems with certified material traceability and environmental controls, ensuring layer-to-layer consistency. The table below outlines the core precision capabilities underpinning our production workflow for demanding sectors.

| Specification Parameter | Capability | Industrial Significance |

|---|---|---|

| Standard Build Tolerance | ±0.02 mm per 100 mm | Ensures dimensional stability for critical fits and assemblies |

| Minimum Feature Resolution | 0.1 mm | Enables complex internal channels and fine lattice structures |

| Surface Roughness (As-Built) | Ra 8-12 µm | Provides baseline for precision post-machining to Ra 0.8 µm |

| Layer Thickness Range | 20-50 µm | Balances resolution, build time, and material density |

| In-Process Monitoring | Melt Pool Thermal Imaging | Real-time defect prevention and parameter adjustment |

| Post-Processing Capability | Precision CNC Machining, HIP, Stress Relieving | Achieves final aerospace/medical grade tolerances and material properties |

Achieving this level of precision consistently requires moving beyond printing to engineered manufacturing. It demands understanding how support structures influence residual stress, how scan strategies affect microstructure, and how thermal post-processing alters final dimensions. At Lead Precision, our engineers collaborate from the initial design phase, applying decades of metallurgical and manufacturing insight to optimize for both printability and end-use performance. We don’t just print parts; we guarantee precision-engineered solutions where every micron contributes to operational success and safety. For industries where performance is non-negotiable, precision isn’t a service feature – it’s the core product.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for performance-critical industries including aerospace, medical, energy, and high-performance automotive. At the core of our technical capability is a fully integrated 5-axis CNC machining platform that enables the production of highly complex geometries with exceptional precision and surface finish. Our 5-axis systems utilize simultaneous multi-axis motion, allowing for intricate part features to be machined in a single setup, minimizing human intervention and reducing cumulative error. This capability is essential for components requiring tight tolerances, organic contours, or internal features that are inaccessible with conventional 3-axis methods.

All machining operations are supported by industry-leading CAD/CAM software, ensuring optimal toolpath generation and process simulation before any material is cut. Our engineering team works closely with clients during the design-for-manufacturability phase to optimize part geometry, reduce cycle times, and improve structural integrity—resulting in faster time-to-market and lower total production costs. Materials routinely processed include titanium alloys (Ti-6Al-4V), Inconel 718 and 625, stainless steels (316L, 17-4 PH), aluminum alloys (7075, 6061), and specialty alloys such as tool steels and cobalt-chrome.

Quality assurance is embedded throughout our manufacturing workflow. Every critical dimension is verified using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems, ensuring compliance with international standards such as ISO 9001 and AS9100. Our CMMs are calibrated to NIST-traceable standards and operated by certified metrology technicians. Full inspection reports, including first-article inspection (FAI) documentation per AS9102, are provided upon request. Additionally, we perform in-process inspections and final quality audits to guarantee consistency across production runs.

Surface finish, edge break control, and geometric dimensioning and tolerancing (GD&T) are rigorously maintained to meet the demands of high-reliability applications. Our facility supports secondary operations including precision tapping, thread forming, heat treatment coordination, and surface treatments such as anodizing, passivation, and coating application through certified partners.

The table below outlines the standard technical specifications achievable across our 5-axis CNC and inspection platforms:

| Parameter | Capability |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machining) | ±0.010 mm (±0.0004″) |

| Geometric Tolerance (GD&T) | Down to ±0.005 mm (form & position) |

| Surface Finish (Ra) | As low as 0.4 μm (16 μin) |

| Maximum Work Envelope | 1,200 x 800 x 600 mm |

| Minimum Feature Size | 0.5 mm diameter (drilled/tapped) |

| Inspection Resolution (CMM) | 0.001 mm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver custom metal components that meet the most demanding engineering requirements. Our technical capabilities are designed to support innovation in additive hybrid manufacturing, where 3D printed near-net shapes are precision finished using our CNC systems—ensuring dimensional accuracy and surface integrity required in mission-critical applications.

Material & Finish Options

Material Selection for Industrial 3D Printing: Aluminum, Steel, and Titanium

Selecting the optimal material for metal additive manufacturing is critical for achieving performance, durability, and cost-efficiency in high-end applications. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your functional requirements and operational environment. Aluminum alloys offer an exceptional strength-to-weight ratio, making them ideal for aerospace brackets, automotive heat exchangers, and lightweight structural components where weight reduction is paramount. Their inherent thermal conductivity also suits thermal management applications. Stainless steel variants, particularly 17-4 PH and 316L, deliver superior corrosion resistance, high strength, and biocompatibility. These are indispensable for demanding sectors like medical implants, chemical processing equipment, and marine hardware requiring long-term reliability in aggressive environments. Titanium alloys, especially Ti-6Al-4V, represent the pinnacle for extreme conditions. Their outstanding strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility make them the standard for critical aerospace components, high-performance motorsport parts, and permanent surgical implants where failure is not an option.

Material properties directly dictate part success. Below is a comparative overview of key industrial alloys used in our precision metal 3D printing services:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Primary Applications |

|---|---|---|---|

| Aluminum AlSi10Mg | 2.67 | 480 | Aerospace brackets, heat sinks, lightweight structures |

| Stainless Steel 316L | 8.00 | 620 | Medical devices, chemical valves, marine parts |

| Titanium Ti-6Al-4V | 4.43 | 950 | Aircraft engine components, orthopedic implants, racing parts |

Surface finish and protection are equally vital. Anodizing is the preferred post-processing treatment for aluminum components produced via additive manufacturing. This electrochemical process significantly enhances surface hardness, wear resistance, and corrosion protection. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, while Type III (Hard Anodizing) delivers a much thicker, denser, and harder ceramic-like coating essential for parts subjected to severe abrasion or extended outdoor exposure. Our certified anodizing lines strictly adhere to MIL-A-8625 and ASTM B580 standards, ensuring consistent, high-integrity finishes that meet aerospace and defense specifications. We precisely control coating thickness, pore structure, and dyeing for both functional performance and aesthetic requirements.

Choosing the right material and finish requires deep technical understanding of additive processes and end-use demands. Wuxi Lead Precision Machinery leverages extensive metallurgical expertise and certified material batches to ensure your 3D printed components meet the highest performance benchmarks. Partner with us to transform your complex designs into mission-critical parts with guaranteed material integrity and surface quality. Our engineers provide full consultation from material selection through to final certification, reducing prototyping cycles by up to 30% while ensuring compliance with ISO 13485 and AS9100 standards.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production journey begins with meticulous design engineering, where functionality, manufacturability, and material performance converge. Our engineering team collaborates closely with clients to translate conceptual designs into production-ready 3D models using advanced CAD software such as SolidWorks, Siemens NX, and Autodesk Fusion 360. Every geometric feature is evaluated for structural integrity, thermal behavior, and compliance with industry standards. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations are routinely employed to validate performance under real-world conditions. This phase ensures that the final component not only meets dimensional specifications but also performs reliably in its intended application, whether in aerospace, medical devices, or high-performance automotive systems.

Prototyping: Validating Design with Zero Defects

Once the design is finalized, we proceed to prototyping using state-of-the-art metal 3D printing technologies, primarily Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These processes enable the fabrication of complex, lightweight, and high-strength components directly from digital models. Prototypes are produced using the same materials intended for mass production—such as titanium (Ti6Al4V), stainless steel (316L, 17-4PH), Inconel 718, and aluminum alloys—to ensure accurate evaluation of mechanical properties and surface characteristics. Each prototype undergoes rigorous inspection using Coordinate Measuring Machines (CMM), optical scanning, and metallurgical analysis to verify dimensional accuracy, material density, and absence of internal defects. This validation phase is critical in achieving our zero-defect philosophy, allowing design refinements before committing to full-scale production.

Mass Production: Scalable Precision with Full Traceability

With design and prototype approval, we transition seamlessly into mass production. Wuxi Lead leverages a scalable network of industrial-grade metal 3D printers, CNC post-processing stations, and automated quality control systems to maintain consistency across high-volume runs. Each build is monitored in real time using in-situ process monitoring, including layer-wise imaging and thermal tracking, to detect anomalies during printing. Post-processing includes stress relief, heat treatment, precision machining, and surface finishing—tailored to meet exact functional and aesthetic requirements. Every component is serialized and tracked through our digital manufacturing execution system (MES), ensuring full traceability from raw material to final shipment.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Materials | Ti6Al4V, 316L, 17-4PH, Inconel 718, AlSi10Mg |

| Layer Thickness | 20–50 μm |

| Build Volume | Up to 250 x 250 x 325 mm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Passivation |

| Quality Standards | ISO 9001, AS9100, GD&T Compliance |

Through this disciplined progression from design to mass production, Wuxi Lead Precision Machinery ensures every component meets the highest standards of quality, performance, and reliability.

Why Choose Wuxi Lead Precision

Elevate Your Production with Certified Metal Additive Manufacturing

In high-stakes industries like aerospace, medical implants, and energy, component failure is not an option. Generic 3D printing services often lack the metallurgical rigor and process validation required for mission-critical applications. At Wuxi Lead Precision Machinery, we bridge the gap between rapid prototyping and certified serial production. Our ISO 9001:2015 and AS9100D-certified facility combines industrial-grade metal additive systems with decades of CNC engineering expertise to deliver parts that meet exacting aerospace, medical, and industrial standards. We don’t just print metal—we engineer solutions with full traceability from raw powder to final inspection.

Our integrated workflow ensures zero compromise on integrity. Every build undergoes in-process monitoring via melt pool analytics and laser power calibration, followed by mandatory post-processing in our vacuum HIP (Hot Isostatic Pressing) chamber to eliminate internal porosity. All components receive full metallurgical validation, including tensile testing, microstructure analysis, and 100% dimensional verification against your CAD model using 5-axis CMM systems. This end-to-end control minimizes scrap rates and eliminates supply chain vulnerabilities—critical for low-volume, high-value production runs.

Key Production Specifications

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Materials | Titanium Ti6Al4V, Inconel 718, Maraging Steel M300, Stainless 17-4PH | AMS 7000, ASTM F136, AMS 5832 |

| Accuracy | ±0.02 mm (as-built), ±0.005 mm (post-machined) | ISO 2768-mK |

| Max Build Volume | 500 x 500 x 500 mm | – |

| Surface Finish | As-printed: Ra 12.5 μm; Machined: Ra 0.8 μm | ISO 1302 |

| Lead Time | 7–15 days (including NDT and certification) | PPAP Level 3 |

Why do global Tier-1 suppliers trust Lead Precision for production-critical components? We integrate additive manufacturing with subtractive finishing under one roof. Our engineers collaborate from DfM (Design for Manufacturing) through final assembly, ensuring complex geometries—such as conformal-cooled molds or lightweight lattice structures—achieve both functional performance and regulatory compliance. Unlike outsourced print farms, we control the entire value stream: powder recycling, stress-relief annealing, precision milling, and non-destructive testing. This eliminates third-party variables that compromise repeatability.

Your next project demands more than a printer—it requires a manufacturing partner with deep metallurgical intelligence and process ownership. Contact our engineering team to discuss material certifications, build orientation optimization, or achieving ASME NQA-1 requirements for nuclear applications. We provide detailed process documentation, including SPC charts and first-article inspection reports, to streamline your qualification process.

Initiate your certified metal additive project today. Email detailed requirements to [email protected] for a technical consultation within 4 business hours. Include your target application, material specifications, and volume needs to receive a tailored production plan with timeline and cost analysis. Let Wuxi Lead Precision Machinery transform your most demanding designs into flight-ready, life-saving, or energy-critical components—with precision you can measure and trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.