Technical Contents

Engineering Guide: Aluminium Injection Molding

Engineering Insight: Precision in Aluminium Injection Moulding

Aluminium injection moulding, often referred to as cold chamber die casting, represents a critical intersection of material science and high-precision engineering. At Wuxi Lead Precision Machinery, we define this process not merely as a manufacturing technique, but as a discipline where micron-level accuracy directly influences structural integrity, thermal performance, and long-term reliability of end components. In high-stakes applications such as aerospace, defense systems, and Olympic-grade equipment, even sub-millimeter deviations can compromise functionality, safety, and compliance.

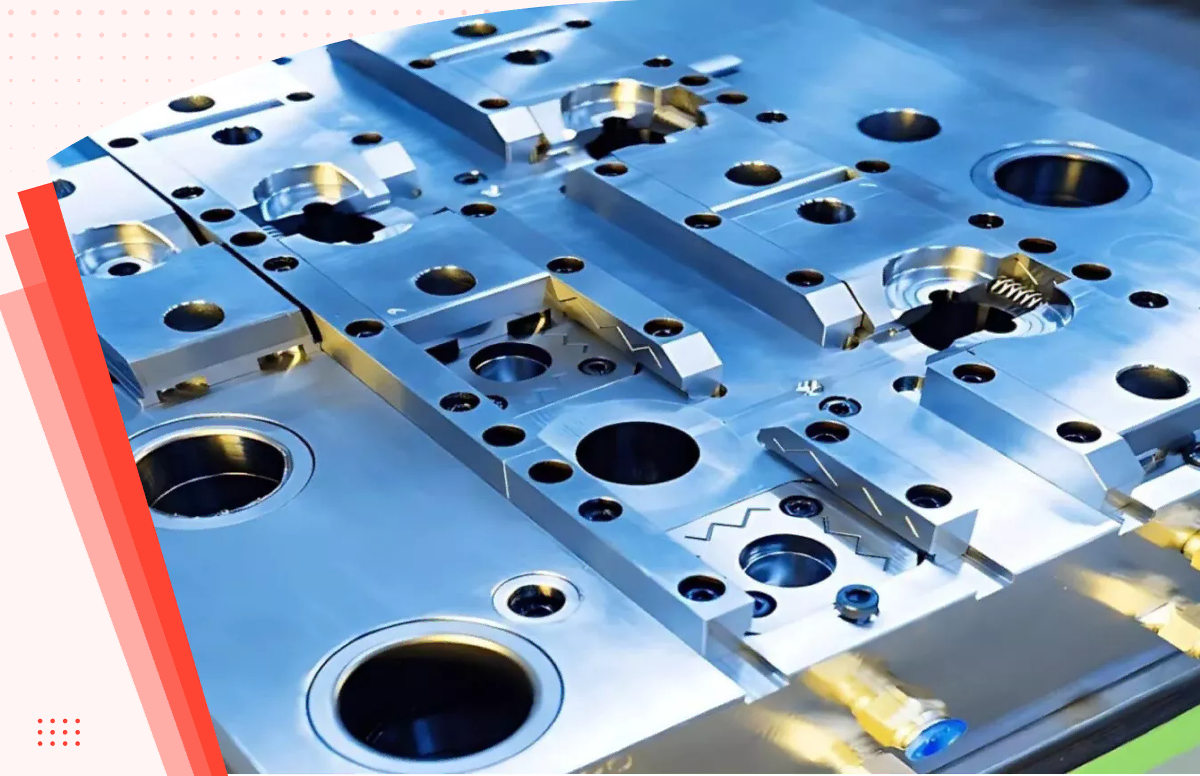

The process involves injecting molten aluminium into a precision-engineered steel die under high pressure, where it rapidly solidifies into complex geometries. Unlike plastic injection moulding, aluminium’s high thermal conductivity and reactivity demand exact control over temperature, pressure, and cycle time. Any inconsistency in tooling geometry or process parameters results in defects such as porosity, warpage, or incomplete fills—failures that are unacceptable in mission-critical systems.

Precision begins with the mould design. At Lead Precision, our engineering team utilizes finite element analysis (FEA) and computational fluid dynamics (CFD) to simulate metal flow, cooling gradients, and stress distribution prior to manufacturing. This predictive modeling ensures optimal gate placement, venting, and cooling channel layout, minimizing distortion and maximizing repeatability. Our in-house CNC machining centers, equipped with 5-axis capabilities and laser probing systems, achieve tolerances down to ±0.01 mm, ensuring that each cavity and core aligns with the original CAD model within microns.

Material selection for the mould itself is equally vital. We employ premium-grade H13 tool steel, treated with advanced nitriding processes to enhance wear resistance and thermal fatigue life. This allows consistent production over thousands of cycles—essential for clients requiring high-volume output without degradation in part quality.

Our track record in delivering components for Olympic athletic equipment and military-grade electronics enclosures underscores our commitment to precision. These projects demanded not only adherence to ISO 2768-mK and AS9100 standards but also rigorous first-article inspections and full traceability from raw material to final shipment. In each case, dimensional stability under thermal cycling and mechanical load was validated through third-party testing.

The integration of automation and real-time process monitoring further elevates consistency. Our die casting cells feature closed-loop control systems that adjust injection speed, pressure, and shot monitoring dynamically, compensating for minor fluctuations in alloy temperature or viscosity. This level of control ensures batch-to-batch uniformity, a prerequisite for clients in regulated industries.

At Wuxi Lead Precision Machinery, we recognize that excellence in aluminium injection moulding is not achieved through isolated improvements, but through a holistic approach—where design, materials, machining, and process control converge. It is this integrated precision engineering philosophy that enables us to serve the most demanding sectors with confidence and consistency.

Typical Process Specifications – Aluminium Injection Moulding

| Parameter | Specification Range |

|---|---|

| Alloy Types | A380, A360, ADC12, AlSi10Mg |

| Tolerance Capability | ±0.01 mm to ±0.05 mm |

| Surface Finish | Ra 0.8 µm (as-machined), up to mirror polish |

| Minimum Wall Thickness | 1.5 mm (standard), down to 0.8 mm (optimized) |

| Clamping Force Range | 400 to 2,500 tons |

| Production Volume Capability | 1,000 to 500,000+ units annually |

| Secondary Operations | CNC machining, heat treatment, surface coating |

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Die Casting & Machining

Wuxi Lead Precision Machinery specializes in high-integrity aluminum die casting and precision machining for mission-critical industrial components. Contrary to common terminology, aluminum is processed via high-pressure die casting (HPDC), not injection molding, which applies to polymers. Our integrated workflow begins with proprietary HPDC processes using A360, A380, and ADC12 alloys, followed by advanced 5-axis CNC machining to achieve geometric complexity unattainable through casting alone. This dual-capability approach eliminates secondary operations, ensuring dimensional stability and reducing lead times by up to 40% versus conventional methods.

Our 5-axis CNC machining centers (DMG MORI and Makino) feature sub-micron positioning accuracy and integrated probing systems for in-process verification. Complex geometries—including undercuts, organic contours, and thin-walled structures down to 0.8mm—are machined in a single setup, minimizing datum errors and thermal distortion. All equipment operates under strict environmental controls (20±1°C), with real-time tool wear compensation and coolant-through-spindle technology to maintain surface finishes of Ra 0.8µm or better. This capability is essential for aerospace brackets, hydraulic manifolds, and medical device housings requiring hermetic sealing.

Quality assurance is anchored by Zeiss CONTURA CMMs with 2.5µm volumetric accuracy, performing 100% first-article and batch inspections per AS9100 and ISO 13083 standards. Automated GD&T analysis validates critical features against CAD models, while X-ray fluorescence (XRF) spectrometry confirms alloy composition. Statistical process control (SPC) monitors cavity pressure, shot speed, and cooling rates during die casting to preempt porosity or shrinkage defects. Every component receives a traceable digital certificate documenting all inspection points, thermal treatment parameters, and material certifications.

The following table details our standard and enhanced tolerance capabilities for machined aluminum components post-casting:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Hole Diameter (Ø6-50) | ±0.015 mm | ±0.005 mm |

| Positional Accuracy | ±0.030 mm | ±0.012 mm |

| Flatness (per 100 mm) | 0.025 mm | 0.010 mm |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm |

Wuxi Lead’s technical infrastructure guarantees repeatability for volumes from 50 to 50,000 units annually. Our engineering team collaborates with clients during DFM stages to optimize gate design, ejector placement, and machining sequences—reducing scrap rates by 22% on average. For sectors where failure is not an option, we deliver certified precision from molten metal to finished part, backed by 15 years of aerospace and energy sector validation. Partner with us to transform complex aluminum component challenges into reliable production outcomes.

Material & Finish Options

Material Selection for High-Performance Aluminum Injection Molding Components

In precision manufacturing, especially within aluminum injection molding, material selection directly impacts part performance, tooling longevity, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions where the choice between aluminum, steel, and titanium is guided by application demands such as strength, weight, thermal conductivity, and corrosion resistance. Each material offers distinct advantages and must be paired with appropriate finishing processes like anodizing to maximize durability and functionality.

Aluminum is the primary material used in injection molding applications due to its excellent thermal conductivity, lightweight nature, and machinability. Grades such as 6061 and 7075 are commonly selected for mold cores, cavities, and inserts. Aluminum reduces cycle times by enabling faster heat dissipation, making it ideal for high-volume production runs. However, its lower hardness compared to steel requires careful consideration in high-wear environments.

Steel, particularly tool steels like P20, H13, and S136, provides superior hardness, wear resistance, and longevity. It is best suited for molds requiring high dimensional stability under prolonged thermal cycling. While steel molds have longer lead times and higher initial costs, they are optimal for ultra-high-volume production where tool life is critical. Steel components often require surface treatments such as nitriding or chrome plating to enhance performance.

Titanium alloys, such as Ti-6Al-4V, are employed in specialized applications demanding exceptional strength-to-density ratios and corrosion resistance. Though rarely used for full mold structures due to cost and machining complexity, titanium finds use in critical inserts or components exposed to extreme conditions. Its biocompatibility and performance at elevated temperatures make it suitable for aerospace and medical sector tooling.

Anodizing is a key surface treatment for aluminum components, significantly improving wear and corrosion resistance. The process creates a durable oxide layer that can be dyed for identification or aesthetic purposes. Hard anodizing (Type III) is particularly effective for mold parts subject to friction, increasing surface hardness up to 600 HV. This treatment extends service life and maintains dimensional accuracy under repeated thermal loading.

The following table summarizes critical properties and applications for each material:

| Material | Typical Grade | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Primary Application in Molding |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 95 | 167 | Mold cores, prototypes, low to medium volume production |

| Aluminum | 7075-T6 | 572 | 150 | 130 | High-strength inserts, performance tooling |

| Steel | P20 | 950–1100 | 280–320 | 30 | High-volume mold bases and cavities |

| Steel | H13 | 1550 | 230 | 34 | Hot-runner systems, high-thermal cycling molds |

| Titanium | Ti-6Al-4V | 900 | 360 | 7 | Critical wear inserts, aerospace tooling |

Material and finish selection must be aligned with production volume, part complexity, and environmental exposure. At Wuxi Lead Precision Machinery, we support clients in optimizing these choices to ensure precision, efficiency, and long-term reliability in aluminum injection molding systems.

Manufacturing Process & QC

Precision Aluminum Die Casting: The Zero Defects Production Pathway

Wuxi Lead Precision Machinery clarifies a critical industry distinction: aluminum components for demanding applications utilize high-pressure die casting (HPDC), not injection molding, which is specific to polymers. Our advanced HPDC process delivers the complex geometries, structural integrity, and surface finishes required for aerospace, automotive, and medical sectors, underpinned by an unwavering Zero Defects mandate. This rigorous pathway ensures every component meets exacting specifications from concept to volume shipment.

The process initiates with collaborative Design for Manufacturability (DFM) engineering. Our team integrates client CAD models with deep material science expertise, focusing on optimal gate placement, runner system design, and thermal management simulation. This phase proactively addresses potential issues like air entrapment, shrinkage porosity, or die erosion, significantly reducing downstream risk. Material selection (e.g., A380, A360, ADC12) is meticulously matched to performance requirements, corrosion resistance, and post-casting operations. Comprehensive mold flow analysis validates the thermal and fluid dynamics model, ensuring the design is inherently capable of zero-defect production before tooling begins.

Prototyping transitions the validated design into physical reality using rapid tooling techniques. Initial castings undergo rigorous dimensional inspection via CMM and critical feature validation. Material properties are verified through destructive testing per ASTM standards. Crucially, this phase includes real-time process parameter optimization and in-mold pressure/temperature monitoring. Any micro-porosity or surface anomaly triggers immediate DFM feedback, refining both the part geometry and the process window. This iterative loop, typically completed within 10-15 days, certifies the process capability (Cpk > 1.67) essential for flawless mass production.

Mass production leverages Wuxi Lead’s fully automated HPDC cells and proprietary Zero Defects System. Every casting cycle is governed by tightly controlled parameters monitored by in-die sensors. Real-time data feeds into our AI-driven analytics platform, comparing actuals against the validated prototype window. Deviations trigger automatic die correction or part rejection before secondary operations. Statistical Process Control (SPC) charts for critical dimensions, tensile strength, and porosity levels are maintained continuously. 100% automated visual inspection (AVI) combined with selective X-ray for internal integrity ensures absolute conformance. This closed-loop system, certified to ISO 9001 and IATF 16949, guarantees batch-to-batch consistency and eliminates escape defects.

Critical Aluminum Die Casting Process Specifications

| Process Phase | Key Parameters | Tolerance Control | Validation Method |

|---|---|---|---|

| Design & Simulation | Gate velocity 40-60 m/s; Fill time 20-100 ms; Solidification time 1-5s | ±0.05mm (critical features) | Mold flow analysis (Autodesk Moldflow) |

| Prototyping | Shot pressure 80-120 MPa; Metal temp 620-680°C; Cycle time 30-90s | ±0.025mm (Cpk > 1.67) | CMM, Tensile test, X-ray (ASTM E505) |

| Mass Production | Real-time pressure ±2 MPa; Temp ±5°C; Cycle time ±2s | ±0.01mm (SPC monitored) | AI analytics, 100% AVI, SPC, X-ray QA |

Wuxi Lead Precision Machinery’s integrated approach transforms aluminum die casting from a manufacturing step into a guaranteed quality outcome. By embedding Zero Defects principles into each phase—design validation, prototype refinement, and intelligent production—we deliver components where reliability is non-negotiable. Partner with us to achieve manufacturing excellence for your most critical metal components.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Aluminum Injection Molding Solutions

When it comes to high-performance aluminum injection molding, precision, consistency, and engineering excellence are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions that meet the exacting demands of industries such as automotive, aerospace, medical technology, and industrial automation. Our expertise in aluminum injection molding—also known as squeeze casting or semi-solid metal processing—enables us to produce complex, high-integrity components with exceptional mechanical properties, reduced porosity, and superior dimensional accuracy.

Choosing the right manufacturing partner is critical to your product’s success. At Lead Precision, we combine state-of-the-art equipment with decades of metallurgical and process engineering experience to ensure every component meets or exceeds international quality standards. Our facility in Wuxi, China, is equipped with advanced hydraulic presses, temperature-controlled die systems, and real-time monitoring technology to maintain tight control over every phase of production. From prototype development to full-scale serial manufacturing, we offer a seamless, scalable partnership built on transparency, responsiveness, and technical mastery.

We understand that each client brings unique challenges and performance requirements. That’s why our team of engineers works closely with you from initial design consultation through final inspection. We provide comprehensive DFM (Design for Manufacturability) analysis, material selection guidance, and mold flow simulation to optimize part integrity and reduce time-to-market. Whether you require low-volume, high-mix production or high-volume runs, our flexible manufacturing systems adapt to your needs without compromising quality.

Our commitment to innovation and customer success has made us a trusted partner for global OEMs and Tier-1 suppliers. By integrating lean manufacturing principles and ISO 9001-certified processes, we ensure every project is delivered on time, within specification, and at competitive cost.

Below are key technical specifications that define our aluminum injection molding capabilities:

| Parameter | Specification |

|---|---|

| Maximum Clamping Force | 2,500 to 6,000 tons |

| Shot Weight Range | 500 g to 15 kg (Aluminum) |

| Wall Thickness Capability | 1.5 mm to 8.0 mm (typical) |

| Tolerance Accuracy | ±0.05 mm (standard), up to ±0.02 mm (precision) |

| Surface Finish | Ra ≤ 0.8 µm (as-cast), polishable to mirror |

| Alloy Compatibility | A380, A360, ADC12, AlSi10Mg, AlSi7Mg, custom |

| Secondary Operations | CNC machining, heat treatment, surface coating, assembly |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer long-term partnerships. Our mission is to become an extension of your engineering and production team, providing not only manufacturing capacity but also technical insight and continuous improvement.

Contact us today to discuss your next aluminum injection molding project. Reach out to our engineering team at [email protected] and discover how we can help you achieve superior performance, reliability, and cost-efficiency in your metal components. Let Lead Precision be your trusted partner in advanced manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.