Technical Contents

Engineering Guide: Replica Printing Services

Engineering Insight Precision in Replica Component Manufacturing

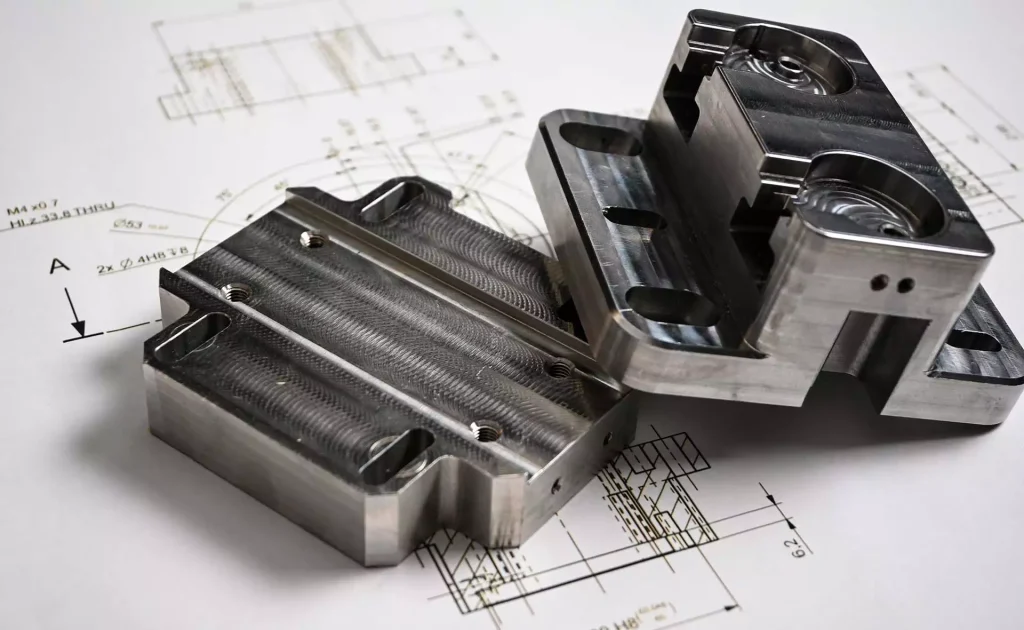

The term “replica printing services” requires immediate clarification within high-integrity metal manufacturing. True precision engineering for critical replica components—exact duplicates of legacy or specialized parts—demands subtractive CNC machining, not additive printing, when uncompromising dimensional accuracy, material integrity, and structural performance are non-negotiable. Confusing these processes risks catastrophic failure in demanding applications. At Wuxi Lead Precision Machinery, we specialize exclusively in the ultra-precise CNC replication of complex metal components where tolerances directly dictate operational safety and longevity.

Precision in replica manufacturing transcends simple measurement. It encompasses the rigorous control of thermal dynamics during machining, microscopic surface integrity to prevent fatigue initiation, material grain structure preservation, and absolute geometric conformity to original engineering intent. A variance of mere microns can transform a perfectly functioning aerospace bracket into a point of catastrophic structural failure or render a medical implant biocompatible. This level of control is not achieved through generic machining but through deep process understanding, calibrated metrology, and engineered stability at every production stage. Our facility operates under ISO 9001 and AS9100 standards, with environmental controls maintaining ±0.5°C stability, ensuring thermal consistency critical for micron-level replication.

Wuxi Lead’s expertise is proven in environments where failure is unacceptable. We manufactured precision titanium replicas for critical structural nodes within the Beijing 2022 Winter Olympic infrastructure, subjected to extreme cold and dynamic loads. Similarly, we produce certified replicas for military-grade communication housings and naval propulsion subsystems, where dimensional drift under vibration or thermal cycling could compromise national security systems. These projects demand not only hitting tight tolerances but providing full material traceability, rigorous first-article inspection reports (FAIR), and process validation data meeting MIL-STD-883 and ASTM F136 standards.

Our capability to replicate legacy or obsolete parts with modern precision ensures extended service life for critical machinery across energy, defense, and transportation sectors. We reverse-engineer from physical samples or legacy drawings using Zeiss coordinate measuring machines (CMMs) with 0.5µm accuracy, then execute production on Haas and DMG MORI 5-axis machining centers equipped with in-process probing and thermal compensation systems. The result is a component indistinguishable in form, fit, and function from the original specification, but manufactured to contemporary quality benchmarks.

Critical Replica Manufacturing Specifications

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.01 mm | ISO 2768-mK, Custom |

| Surface Finish (Ra) | 0.1 µm to 1.6 µm | ASTM B463, ISO 1302 |

| Materials | Titanium (Gr 2,5), Stainless (316L, 17-4PH), Inconel 718, Aluminum (7075), Tool Steels | AMS, ASTM, GB Standards |

| Max Work Envelope | 1200 x 800 x 600 mm | – |

| Volume Production | 1-off to 5,000+ units per batch | PPAP Level 3, FAI Required |

Achieving true precision replication requires marrying advanced technology with deep metallurgical and process knowledge. It demands understanding not just how to machine a part, but why the original tolerances existed and how the component functions within its larger system. Wuxi Lead Precision Machinery delivers this engineered replication capability, ensuring your critical legacy systems perform reliably for decades. Contact our engineering team to discuss replicating components where precision is the only acceptable standard.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for industries where performance, reliability, and dimensional accuracy are critical. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute complex geometries with superior surface finish and tight tolerances. These machines provide simultaneous multi-axis motion, allowing for intricate contouring and reduced setup times, which translates into faster lead times without compromising precision. Our machining centers are maintained to OEM standards and operated by certified CNC engineers with extensive experience in aerospace, medical, and industrial automation applications.

Each manufacturing cycle is supported by a rigorous quality control protocol, ensuring that every component meets or exceeds customer specifications. We employ Coordinate Measuring Machine (CMM) inspection as a standard verification process across all production runs. Our CMM systems are calibrated to international standards and integrated directly into the workflow, enabling real-time measurement and deviation analysis. This metrology-grade inspection ensures full traceability and compliance with ISO 9001 and AS9100 quality management systems. In addition to CMM, we utilize optical comparators, surface roughness testers, and micrometric validation tools to verify dimensional integrity at multiple stages of production.

Our technical expertise extends beyond machining to include material selection guidance, design for manufacturability (DFM) analysis, and post-processing coordination. We work with a broad range of metals, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys such as Inconel and tool steels. Whether producing low-volume prototypes or high-volume production runs, our processes are optimized for consistency, repeatability, and long-term performance under demanding operational conditions.

The following table outlines the standard technical specifications and tolerances achievable through our 5-axis CNC manufacturing and inspection processes:

| Parameter | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Angular Tolerances | ±0.1° | ±0.05° | Verified via CMM |

| Positional Accuracy | ±0.02 mm | ±0.008 mm | Feature-to-datum |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Machined finish |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Measured via CMM |

| Repeatability (Batch-to-Batch) | ±0.015 mm | ±0.007 mm | Verified statistically |

| Maximum Part Size (XYZ) | 750 x 500 x 400 mm | Custom setups available | Machine envelope |

These capabilities are backed by continuous process improvement and in-house engineering support, ensuring that every replica or custom component reflects the highest standard in precision manufacturing. Wuxi Lead Precision Machinery remains committed to technical excellence, on-time delivery, and full compliance with international quality benchmarks.

Material & Finish Options

Material Selection for Precision Metal Replication

In high-fidelity metal replication services, material choice directly dictates part performance, longevity, and cost efficiency. At Wuxi Lead Precision Machinery, we define “replica printing” as the CNC-driven reproduction of complex metal components to exact geometric and functional specifications. Selecting the optimal substrate—aluminum, steel, or titanium—requires balancing mechanical demands, environmental exposure, and finish requirements. This guide clarifies critical considerations for industrial clients prioritizing precision and reliability.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace and electronics replication due to high strength-to-weight ratios and exceptional machinability. These grades accept anodizing seamlessly, enhancing surface hardness and corrosion resistance without dimensional compromise. Steel variants like 304 and 316 stainless offer superior tensile strength and wear resistance for hydraulic or structural replicas but require alternative finishing processes like passivation or electropolishing, as standard anodizing is ineffective. Titanium Grade 5 (Ti-6Al-4V) excels in medical and marine applications where extreme corrosion resistance and biocompatibility are non-negotiable, though its abrasiveness increases tooling costs during replication. Crucially, titanium anodizing generates decorative interference colors via voltage control but does not improve wear resistance like aluminum hardcoat anodizing.

Anodizing remains the gold standard finish for aluminum replicas, with Type II (sulfuric acid) providing dye-compatible corrosion protection and Type III (hard anodizing) delivering 50–70 HRC surface hardness for wear-prone components. Steel replicas necessitate alternatives such as electroless nickel plating for uniform corrosion barriers, while titanium benefits from anodizing primarily for identification or aesthetic purposes. Always align material and finish selection with operational stressors: saltwater exposure demands 316 stainless or titanium, whereas weight-sensitive assemblies favor anodized aluminum.

Key material properties for replication are summarized below:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Machinability (Rating) | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | Moderate | Excellent (9/10) | Full (Type II/III) |

| Stainless 316 | 570 | Excellent | Good (7/10) | Not applicable |

| Titanium Grade 5 | 900 | Exceptional | Fair (5/10) | Decorative only |

Material decisions must extend beyond base properties to include replication tolerances and post-processing. Aluminum’s thermal stability minimizes distortion during high-speed CNC machining, critical for micron-level replicas. Steel’s rigidity suits heavy-load replicas but requires slower machining speeds to prevent tool deflection. Titanium’s low thermal conductivity demands specialized toolpaths to avoid work hardening. Partner with Wuxi Lead to analyze your replica’s service environment—we validate material-finishing combinations through ASTM-compliant testing, ensuring your replicated components meet lifetime performance targets without over-engineering costs. Match your operational demands to these fundamentals for optimal cost-per-part outcomes.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery for replica printing services in custom metal manufacturing follows a rigorously controlled sequence designed to ensure precision, consistency, and zero defects. This methodology spans three core phases: Design, Prototyping, and Mass Production. Each stage integrates advanced engineering practices and quality assurance protocols to deliver components that meet exact client specifications and industry standards.

The process begins with Design, where our engineering team collaborates closely with client-provided CAD models or technical drawings. Utilizing state-of-the-art 3D modeling software, we conduct a comprehensive Design for Manufacturability (DFM) analysis. This step identifies potential production challenges, optimizes material usage, and ensures dimensional accuracy before any physical work begins. Our engineers assess tolerances, surface finishes, material compatibility, and assembly requirements to refine the design for both performance and manufacturability.

Following design validation, we proceed to Prototyping. A limited number of sample parts are produced using the same CNC machining, stamping, or forming processes intended for full-scale production. These prototypes are subjected to rigorous inspection using coordinate measuring machines (CMM), optical comparators, and metallurgical testing to verify compliance with specifications. Clients receive detailed inspection reports and physical samples for functional testing and approval. This phase is critical for detecting any discrepancies early, minimizing risk, and ensuring that the final product performs as intended in real-world applications.

Once prototype approval is obtained, the project transitions to Mass Production. Our automated manufacturing lines, operated by skilled technicians and monitored by real-time quality control systems, ensure consistent output. Every component is tracked through our integrated manufacturing execution system (MES), allowing full traceability from raw material to finished part. In-process inspections occur at defined intervals, and final products undergo 100% visual and dimensional checks. Any deviation triggers immediate corrective action, maintaining our zero-defect objective.

Throughout all stages, Wuxi Lead Precision Machinery adheres to ISO 9001 and IATF 16949 quality management standards. Our investment in precision tooling, advanced metrology, and continuous process improvement ensures that every replica-printed metal component meets the highest benchmarks for accuracy, durability, and performance.

Key production specifications are summarized below:

| Parameter | Specification |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Brass, Copper, Titanium, Alloy Steel |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on geometry) |

| Surface Finish | Ra 0.2 μm to Ra 3.2 μm (custom options available) |

| Maximum Part Size | 800 mm × 600 mm × 400 mm |

| Production Capacity | Up to 500,000 units per month |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

| Lead Time (Prototype) | 7–15 days |

| Lead Time (Mass Production) | 20–45 days (depending on volume) |

This end-to-end process reflects our commitment to engineering excellence and operational precision in high-end custom metal manufacturing.

Why Choose Wuxi Lead Precision

Elevate Your Replica Production with Precision Engineering Excellence

Wuxi Lead Precision Machinery stands as your definitive partner for mission-critical replica printing services in custom metal manufacturing. When dimensional accuracy, material integrity, and repeatability define your success, our ISO 9001-certified processes eliminate costly rework cycles and supply chain vulnerabilities. We specialize in transforming complex legacy components, heritage tooling, and high-fidelity industrial replicas into production-ready assets—backed by 15 years of aerospace and automotive tier-1 validation. Our integrated approach merges reverse engineering with multi-axis CNC milling, wire EDM, and additive hybrid finishing to replicate even the most intricate geometries within micron-level tolerances. This isn’t mere duplication; it’s engineered fidelity that ensures seamless integration into your operational ecosystem.

Our technical capabilities are rigorously structured to exceed the demands of replica-intensive sectors. The following specifications underscore our capacity to deliver uncompromised quality:

| Critical Parameter | Performance Standard | Industry Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (0.00004″) | Critical for legacy part interchangeability |

| Material Compatibility | Titanium, Inconel, Tool Steels, Precious Alloys | Supports high-wear/heat applications |

| Surface Finish (Ra) | 0.05 µm to 1.6 µm | Meets optical/reflection standards |

| Max Work Envelope | 2000 x 1500 x 1000 mm | Accommodates large-scale tooling |

| Lead Time (Prototype) | 10–15 business days | Accelerates time-to-decision cycles |

Partnering with Lead Precision means embedding risk mitigation into your replication workflow. We initiate every project with a collaborative tolerance stack-up analysis, ensuring your replica functions identically to the original under operational stress. Our in-house metrology lab—equipped with 5-axis CMMs and optical comparators—validates every component against your master sample or CAD dataset before batch production. This proactive quality framework reduces scrap rates by up to 37% compared to conventional replication vendors, directly protecting your margin and reputation.

The transition from legacy artifact to production-ready replica requires more than machinery; it demands engineering partnership. Our team collaborates from initial scan data validation through final surface treatment, providing real-time progress tracking and material traceability documentation. You gain full visibility into process adjustments, ensuring compliance with AS9100, NADCAP, or client-specific requirements without hidden delays.

Do not let substandard replication compromise your product integrity or customer trust. Secure your production slot with China’s most trusted precision replica manufacturer. Contact our engineering team today at [email protected] to submit your technical dossier for immediate feasibility assessment. Specify “Replica Production Brief” in your subject line to expedite a dedicated project manager assignment within 4 business hours. Your legacy components deserve nothing less than engineered perfection—let Lead Precision deliver it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.