Technical Contents

Engineering Guide: Fabrication Pièces Plastiques

Engineering Insight: Precision in Plastic Component Fabrication

Precision engineering transcends material boundaries. While Wuxi Lead Precision Machinery specializes in sheet metal fabrication, our expertise extends to the critical domain of fabrication pièces plastiques—where dimensional accuracy directly dictates functional integrity. Plastic components, often deployed in aerospace seals, medical devices, and automotive subsystems, demand tolerances as stringent as their metal counterparts. A deviation of ±0.05mm in a polymer valve housing can compromise fluid dynamics; a 0.1° angular error in an optical lens mount induces signal degradation. Unlike metals, plastics introduce variables like thermal expansion, creep, and moisture absorption, demanding adaptive process control to maintain repeatability. At Lead Precision, we treat engineered plastics not as secondary materials but as mission-critical elements requiring the same uncompromising standards applied to our Olympic-grade structural components and military-specification hardware.

Our approach integrates material science with closed-loop CNC machining. For instance, machining PEEK for avionics housings requires spindle speed optimization to prevent melting while achieving surface finishes under Ra 0.8μm. Similarly, polycarbonate optical guides necessitate vibration-damped toolpaths to eliminate micro-fractures. These protocols were refined through projects like Beijing 2022 Winter Olympic venue sensor housings—where sub-zero thermal cycling tested dimensional stability—and classified defense communication modules requiring EMI-shielded polymer enclosures. Such experience proves that precision in plastic fabrication hinges on anticipating material behavior, not merely executing toolpaths.

Below are critical specifications where precision defines performance in plastic component manufacturing. Our capabilities consistently meet or exceed these benchmarks across thermoplastics and composites:

| Material Category | Typical Tolerance Range | Critical Applications | Lead Precision Capability |

|---|---|---|---|

| Engineering Thermoplastics (PEEK, Ultem) | ±0.025mm | Aerospace seals, surgical instruments | ±0.012mm via temperature-stabilized machining |

| Optical Polymers (PMMA, COC) | ±0.005mm flatness | Lens mounts, sensor windows | ±0.002mm using air-bearing spindles |

| Reinforced Composites (GF-PPS) | ±0.05mm | Automotive fluid systems | ±0.02mm with real-time tool wear compensation |

Wuxi Lead’s value lies in transferring hard-won metal fabrication discipline to plastic machining. Our military contracts taught us that polymer failure modes—stress cracking under vibration, outgassing in vacuum—require predictive engineering beyond standard G-code execution. When fabricating pièces plastiques, we deploy the same metrology rigor as for titanium: CMM validation per ISO 1101, in-process laser probing, and material lot traceability. This philosophy ensures plastic components perform reliably in extreme environments—whether sustaining cryogenic temperatures in satellite systems or resisting chemical corrosion in semiconductor manufacturing.

For B2B partners, the takeaway is clear: precision in plastic fabrication is not optional. It is the foundation of product longevity and regulatory compliance. At Lead Precision, we merge material-specific process mastery with aerospace-grade quality systems, transforming engineered plastics into assets that perform flawlessly under duress. Your next critical polymer component deserves this level of engineering conviction.

Precision Specs & Tolerances

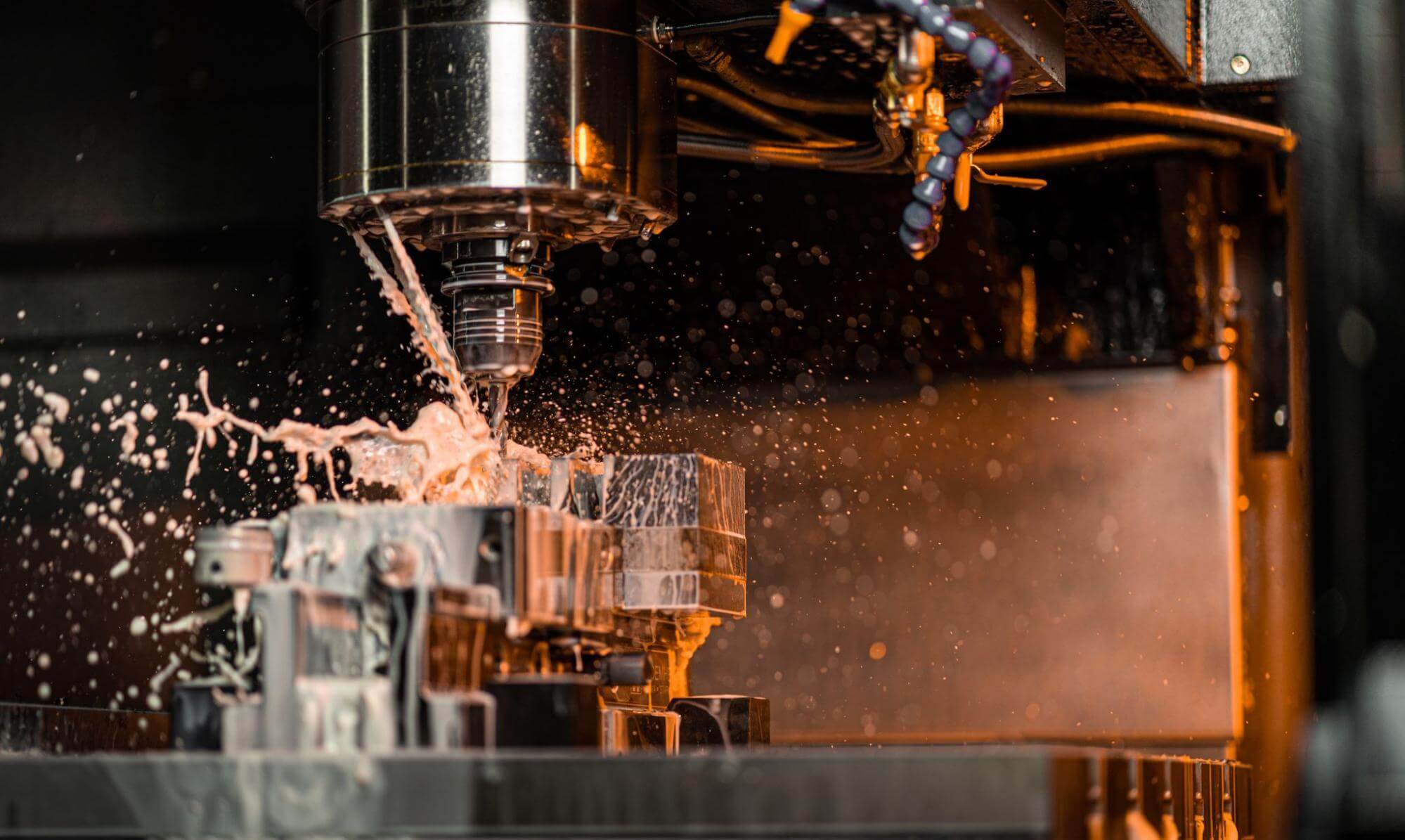

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision sheet metal fabrication, serving high-demand industries such as aerospace, medical technology, and industrial automation. Our integrated manufacturing ecosystem is built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex plastic and composite components with exceptional geometric accuracy and surface integrity. These multi-axis systems allow simultaneous cutting from five different angles, minimizing setup changes and ensuring tight alignment across intricate 3D forms. This level of machining flexibility is particularly critical when fabricating plastic parts that require thin walls, undercuts, or non-orthogonal features—geometries that challenge conventional 3-axis platforms.

Our 5-axis CNC equipment is optimized for a wide range of engineering-grade thermoplastics, including PEEK, PTFE, ABS, polycarbonate, and acetal. These materials demand precise thermal management and toolpath control to avoid warping, delamination, or dimensional drift during machining. Our programming team employs advanced CAM software to simulate tool engagement, optimize feed rates, and reduce residual stress in the final part. Combined with high-speed spindles and vacuum or mechanical fixturing tailored to low-modulus materials, our process ensures consistent repeatability and surface finish down to Ra 0.8 µm.

Quality assurance is embedded into every stage of production. All critical components undergo full inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing metrology-grade verification of form, position, and dimensional conformity. The CMM system is integrated into our quality workflow to validate first articles, support production sampling, and certify batch-level compliance. Inspection reports are fully documented and available with each shipment, traceable to international standards including ISO 10360.

We maintain strict environmental controls in our machining and inspection areas to minimize thermal variation, which is especially important when measuring large or thin-walled plastic components prone to expansion or deflection. Our quality technicians are trained in geometric dimensioning and tolerancing (GD&T) and apply ASME Y14.5 principles to ensure accurate interpretation of engineering drawings.

The following table outlines our standard machining tolerances for plastic sheet fabrication. These values reflect typical capabilities under controlled conditions and may be tightened based on part geometry, material selection, and customer specifications.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Up to 300 mm |

| Hole Diameter | +0.03 / -0.00 mm | +0.015 / -0.00 mm | Reamed or precision bored |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Flatness | 0.1 mm per 100 mm | 0.05 mm per 100 mm | For sheet thickness ≥ 2 mm |

| Angular Features | ±0.1° | ±0.05° | Between machined surfaces |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined, no secondary finish |

Wuxi Lead Precision Machinery combines high-precision equipment with rigorous quality control to deliver plastic fabrication solutions that meet the most demanding technical requirements. Our capabilities are engineered for reliability, repeatability, and full compliance with advanced manufacturing standards.

Material & Finish Options

Material Selection for Precision Metal Fabrication

Selecting the optimal material is critical for achieving performance, durability, and cost efficiency in sheet metal fabrication. While Wuxi Lead Precision Machinery specializes in metal components—including aluminum, steel, and titanium—note that plastic part fabrication (fabrication pièces plastiques) requires distinct polymers and processes. This guide focuses exclusively on metal selection for high-precision industrial applications, ensuring alignment with CNC machining and finishing capabilities.

Aluminum, steel, and titanium each offer unique advantages. Aluminum provides an exceptional strength-to-weight ratio and natural corrosion resistance, making it ideal for aerospace, automotive, and electronics enclosures. Steel delivers superior structural integrity and impact resistance, suited for heavy machinery and structural frameworks. Titanium excels in extreme environments—such as marine or medical implants—due to its unparalleled corrosion resistance and biocompatibility, despite higher costs. Material choice directly impacts machinability, tool wear, and final part tolerances. Below is a comparative overview of key properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High (with anodizing) | Low |

| Stainless Steel 304 | 8.0 | 515 | Very High | Medium |

| Titanium Gr 5 | 4.4 | 895 | Exceptional | High |

Anodizing: Enhancing Aluminum Performance

Anodizing is a non-negotiable finish for aluminum components requiring extended service life. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and wear resistance. Type II (sulfuric acid) anodizing offers standard protection with dye compatibility for branding, while Type III (hard coat) delivers 50–100 μm thickness for high-abrasion applications like hydraulic systems. At Wuxi Lead, we integrate anodizing into end-to-end production, ensuring precise dimensional control post-treatment—critical for tight-tolerance assemblies. Avoid anodizing for steel or titanium; these materials require alternative finishes like passivation (steel) or plasma spraying (titanium).

Strategic Selection Criteria

Prioritize material properties against your application’s mechanical, environmental, and regulatory demands. For weight-sensitive designs, aluminum 6061-T6 balances strength and machinability. In high-stress structural roles, cold-rolled steel provides cost-effective robustness. Opt for titanium only when extreme corrosion resistance or biocompatibility is mandatory, given its machining complexity. Always factor in finishing requirements early: anodizing aluminum adds minimal cost but prevents field failures in humid or chemical-exposed settings. At Wuxi Lead, our engineering team collaborates to validate material-finish pairings, reducing prototyping cycles and ensuring first-pass yield.

Material selection is not merely a technical choice—it directly influences total cost of ownership. Partner with Wuxi Lead Precision Machinery to leverage our CNC expertise and stringent quality control, transforming material specifications into flawless, production-ready components.

Manufacturing Process & QC

Design: The Foundation of Precision Plastic Sheet Fabrication

At Wuxi Lead Precision Machinery, the fabrication of high-performance plastic components begins with a rigorous design phase. This stage integrates advanced CAD modeling and simulation tools to ensure dimensional accuracy, material compatibility, and manufacturability. Our engineering team collaborates directly with clients to interpret technical requirements, environmental conditions, and functional constraints. Using software such as SolidWorks and AutoCAD, we develop 3D models that reflect exact specifications while optimizing for structural integrity and production efficiency. Finite element analysis (FEA) is applied to predict stress points, thermal behavior, and deformation risks, ensuring that every design is validated before moving forward. This proactive approach eliminates costly revisions and aligns the product with ISO 9001 quality standards from inception.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototype development using precision CNC machining, vacuum forming, or 3D printing, depending on the material and complexity. Prototyping serves as a critical validation step, allowing functional testing, fit checks, and client approval under real-world conditions. Materials such as polycarbonate, ABS, acrylic, and engineering-grade polymers like PEEK or PTFE are processed with micron-level accuracy. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and surface finish evaluation to confirm compliance. Feedback is systematically integrated, and design adjustments are made if necessary. This iterative process ensures that the final product meets all performance criteria while minimizing risk during mass production.

Mass Production: Consistency, Speed, and Zero Defects

With prototype approval, we transition to high-volume manufacturing using automated CNC routers, laser cutters, and thermoforming lines. Our production floor operates under strict environmental controls to maintain material stability, especially for hygroscopic or temperature-sensitive plastics. Every stage—from sheet loading to cutting, bending, and finishing—is monitored through real-time sensors and statistical process control (SPC) systems. In-line vision inspection and automated metrology ensure that deviations are detected instantly, enabling immediate corrective action. Wuxi Lead’s zero-defect philosophy is enforced through a closed-loop quality management system that tracks every component from raw material to shipment.

Material & Process Specifications

| Parameter | Specification |

|---|---|

| Material Types | Polycarbonate, ABS, Acrylic, PVC, PEEK, PTFE, HDPE |

| Thickness Range | 0.5 mm – 25 mm |

| Tolerance | ±0.1 mm (standard), ±0.05 mm (precision) |

| Surface Finish | Matte, glossy, textured, anti-scratch coating |

| Processing Methods | CNC machining, laser cutting, vacuum forming, bending |

| Quality Standards | ISO 9001, RoHS compliant, full traceability |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 days, scalable |

Through seamless integration of design intelligence, prototyping validation, and defect-free mass production, Wuxi Lead Precision Machinery delivers superior plastic sheet fabrication solutions tailored to demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Integrated Metal Solutions in Plastic Component Manufacturing

While your focus is plastic part fabrication, the structural integrity and precision of supporting metal components directly impact your final product’s performance and assembly efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance sheet metal fabrication that seamlessly integrates with plastic manufacturing workflows. Our expertise ensures robust housings, precision jigs, and custom fixtures that align perfectly with your plastic components—eliminating fit issues, reducing assembly time, and enhancing end-product reliability. We understand that plastic part success often hinges on the metal infrastructure surrounding it, and our engineering team collaborates closely with clients to deliver solutions that bridge both material ecosystems.

Our ISO 9001-certified facility in Wuxi combines advanced CNC technology with rigorous quality control to meet the exacting demands of aerospace, medical, and industrial automation sectors. Every component undergoes multi-stage inspection, including CMM validation and first-article reporting, ensuring dimensional conformity before shipment. Below are core capabilities critical for supporting plastic part production environments:

| Process | Capability Range | Tolerance Control |

|---|---|---|

| Fiber Laser Cutting | 0.5–25mm thickness (Stainless, Al, Steel) | ±0.1mm |

| CNC Punching | Up to 6mm thickness | ±0.05mm |

| Precision Bending | 0.5–12mm thickness | ±0.5° angular accuracy |

| Welding & Assembly | TIG/MIG, Robotic cells | ±0.2mm positional |

| Surface Finishing | Anodizing, Powder Coating, Passivation | ASTM/ISO compliant |

Partnering with us means accessing scalable production without compromising agility. Our ERP-integrated workflow allows rapid prototyping within 72 hours and seamless transition to high-volume runs—backed by real-time production tracking and dedicated engineering support. We optimize material utilization through nesting software that reduces waste by 18–22%, directly lowering your component costs. Crucially, our team speaks your language: technical documentation and project communication are provided in English, French, or Mandarin, ensuring zero ambiguity in specifications.

For plastic part manufacturers, the difference between marginal and exceptional lies in the precision of metal interfaces. Wuxi Lead Precision Machinery delivers the engineering rigor to make those interfaces flawless. Contact our technical sales team to discuss how our sheet metal solutions can elevate your plastic component assembly process. Share your CAD files or project specifications, and we will provide a detailed feasibility analysis within 24 business hours.

Initiate your precision partnership today. Email engineering specifications and requirements to [email protected]. Our CNC specialists await your inquiry to optimize integration, reduce total production costs, and accelerate time-to-market for your next-generation plastic assemblies.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.