Technical Contents

Engineering Guide: Aluminum Injection Molds

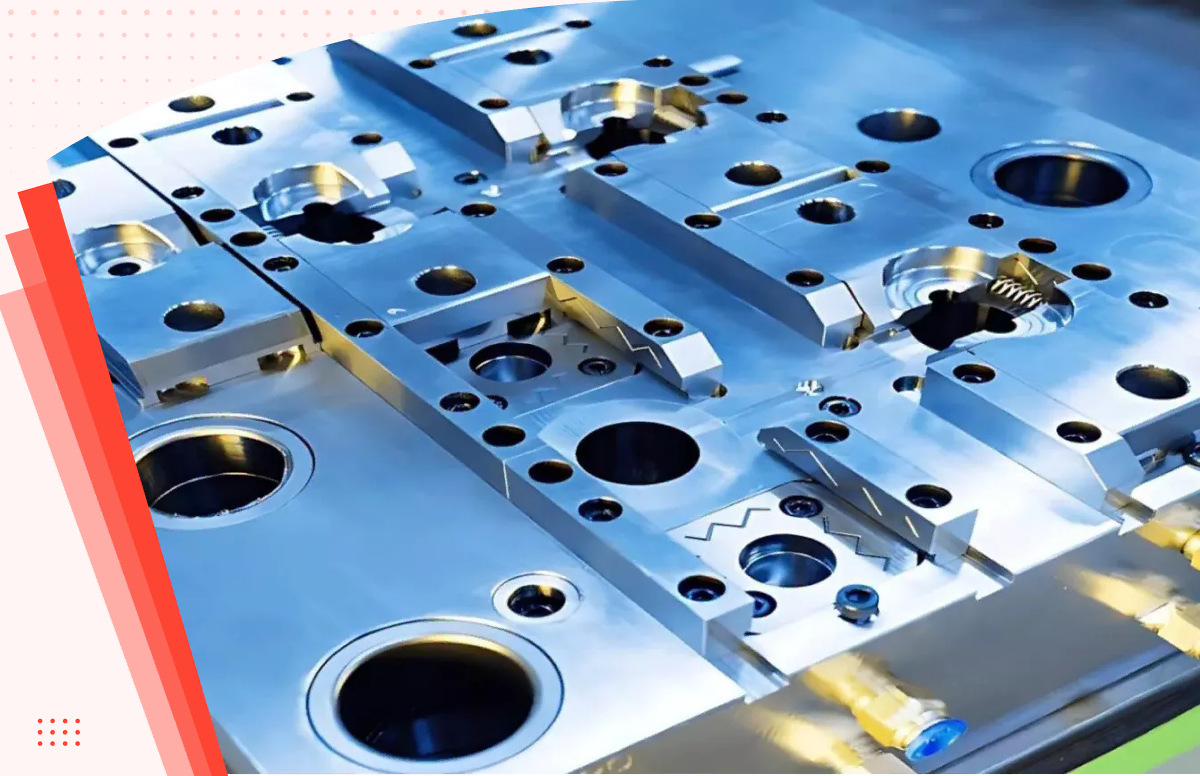

Engineering Insight: The Critical Role of Precision in Aluminum Injection Molds

In the realm of custom metal manufacturing, aluminum injection molds represent a convergence of advanced engineering, material science, and ultra-precision machining. Unlike conventional molding processes, aluminum injection molding demands exceptional dimensional accuracy, thermal stability, and surface integrity to ensure consistent part quality and extended mold life. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is the foundation of reliability, efficiency, and competitive advantage in high-stakes industrial applications.

Aluminum injection molds are engineered to withstand repeated thermal cycling and high-pressure material injection, often under conditions that push the limits of material performance. Even microscopic deviations in cavity geometry or cooling channel alignment can lead to warping, incomplete filling, or premature mold failure. This is especially critical in sectors such as aerospace, defense, and high-performance automotive, where component tolerances are measured in microns and failure is not an option.

Our expertise in precision aluminum mold manufacturing has been rigorously tested through projects for Olympic-grade equipment and military-spec components. These assignments required adherence to ISO 2768-mK and AS9100 standards, with geometric tolerances held within ±0.005 mm and surface finishes reaching Ra 0.2 µm. The success of these programs underscores our mastery in integrating CAD/CAM optimization, high-speed CNC machining, and real-time in-process metrology to deliver molds that perform under extreme conditions.

At the core of our process is a systematic approach to precision engineering. We begin with finite element analysis (FEA) to simulate thermal and mechanical loads, followed by multi-axis machining using hardened aluminum alloys such as 7075-T6 and 6061-T6. Each mold undergoes rigorous CMM inspection and mold-flow validation to ensure conformity to design specifications. This end-to-end control allows us to achieve repeatable accuracy and cycle times that meet the demands of high-volume production.

Our proven track record in mission-critical manufacturing reflects a deeper commitment: to deliver not just molds, but engineered solutions that enhance our clients’ operational performance.

| Specification | Detail |

|---|---|

| Material Options | 7075-T6, 6061-T6, AlSi10Mg (additive) |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (polished/texture) |

| Max Mold Size | 800 mm × 600 mm × 500 mm |

| Machining Accuracy | ±0.003 mm (after thermal compensation) |

| Inspection Standards | ISO 2768, AS9100, GD&T compliant |

| Cooling Channel Precision | ±0.01 mm positional tolerance |

Wuxi Lead Precision Machinery continues to set benchmarks in aluminum injection mold manufacturing by combining cutting-edge technology with decades of hands-on engineering excellence. For industries where performance is non-negotiable, precision is the only acceptable standard.

Precision Specs & Tolerances

Technical Capabilities for Aluminum Injection Mold Manufacturing

Wuxi Lead Precision Machinery delivers exceptional precision and efficiency in aluminum injection mold production, leveraging advanced manufacturing infrastructure specifically engineered for the demanding requirements of prototyping and low-to-medium volume production. Our core strength lies in integrating high-speed, multi-axis machining with rigorous quality control protocols, ensuring molds meet exacting dimensional and surface finish specifications critical for successful injection molding cycles. Aluminum molds require superior thermal management and geometric accuracy to validate part designs and processes before committing to hardened steel tooling; our capabilities are optimized to fulfill this pivotal role in accelerating product development.

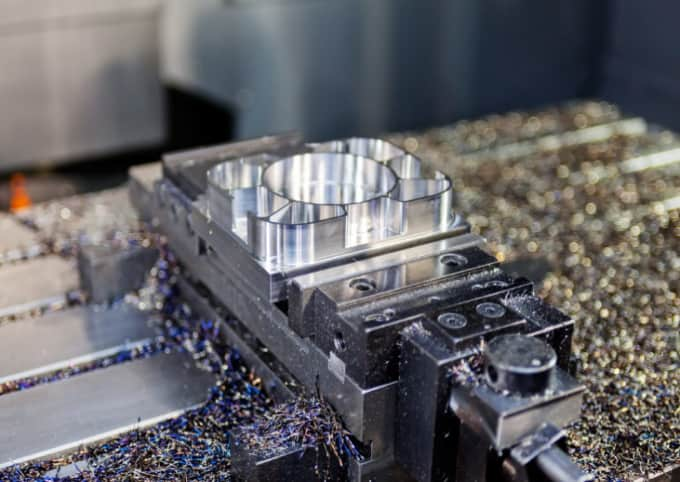

Central to our process is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems, featuring high-torque spindles operating up to 24,000 RPM and sub-micron positioning accuracy, enable the complete machining of complex mold cavities, cores, and intricate runner systems in a single setup. This eliminates cumulative errors inherent in multi-setup processes, significantly reducing lead times while achieving superior part-to-part consistency. Our programmers utilize advanced CAM software to generate optimized toolpaths that maximize material removal rates for aluminum alloys like 7075-T6 and 6061-T6, minimizing cycle times without compromising surface integrity or critical feature definition. The ability to machine undercuts and deep ribs without secondary operations is fundamental to producing functional, high-fidelity aluminum molds rapidly.

Quality assurance is non-negotiable. Every critical mold component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMMs), including Zeiss and Hexagon systems with sub-5-micron measurement uncertainty. Our inspection protocol covers all geometric dimensioning and tolerancing (GD&T) requirements specified by the client, verifying cavity dimensions, core alignment, cooling channel placement, and parting line flatness to ensure seamless mold assembly and performance. First-article inspections generate detailed reports with full traceability, providing clients with documented proof of conformance before mold shipment. This systematic approach to quality control mitigates risk and guarantees the mold will perform as intended during initial production trials.

Our precision machining and inspection capabilities translate directly into superior mold performance and extended service life, even under the thermal cycling inherent in aluminum mold applications. The following table details our standard and enhanced tolerance capabilities for critical mold features:

| Parameter | Standard Capability | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.005 (Critical Features) |

| Angular Tolerances (°) | ±0.1 | ±0.05 |

| Flatness (mm/m) | 0.05 | 0.01 |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm (Cavity Surfaces) |

| Hole Position (mm) | ±0.02 | ±0.008 |

| Profile of Surface | ISO 2768-mK | ISO 2768-fine |

This commitment to dimensional excellence, combined with rapid 5-axis machining throughput and stringent CMM validation, positions Wuxi Lead Precision Machinery as the strategic partner for manufacturers requiring reliable, high-performance aluminum injection molds to de-risk product launches and optimize time-to-market. We transform complex mold designs into precision-engineered reality with measurable speed and accuracy.

Material & Finish Options

Material Selection for High-Performance Aluminum Injection Molds

When engineering aluminum injection molds for precision manufacturing, material selection is critical to ensuring durability, thermal efficiency, and long-term cost performance. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that balance operational demands with material science. The primary materials used in mold construction—aluminum, steel, and titanium—each offer distinct advantages depending on production volume, part complexity, and thermal requirements.

Aluminum alloys, particularly 7075 and 6061, are widely favored for prototyping and low-to-medium volume production. Their high thermal conductivity enables rapid cooling cycles, significantly reducing cycle times. Aluminum is also easier to machine than steel or titanium, allowing for faster lead times and complex geometries. However, aluminum’s lower hardness makes it less suitable for high-volume runs or abrasive materials. For enhanced surface durability, anodizing is recommended. Hard anodizing (Type III) increases surface hardness up to 60 HRC, improves wear resistance, and provides excellent corrosion protection—ideal for maintaining mold integrity in repeated injection cycles.

Steel remains the standard for high-volume production molds. Alloys such as P20, H13, and S136 offer superior hardness, wear resistance, and longevity. While steel molds require longer machining times and higher initial costs, their extended service life justifies the investment in large-scale operations. Steel molds are less thermally conductive than aluminum, which can increase cycle times, but this is often mitigated through optimized cooling channel design.

Titanium, though less common due to cost and machining complexity, offers an exceptional strength-to-density ratio and outstanding corrosion resistance. It is typically reserved for specialized applications where weight reduction or extreme environmental resistance is required. Its use in standard aluminum injection molding is limited but may be considered in niche aerospace or medical applications.

Surface finish selection further influences mold performance. Anodizing not only enhances aluminum’s durability but also allows for color coding and improved release properties. Other finishes such as chromate conversion coating or polished surfaces may be applied based on part aesthetics and ejection requirements.

Ultimately, the choice of mold material depends on a clear understanding of production goals, material compatibility, and lifecycle costs. Wuxi Lead Precision Machinery provides expert consultation to match your project requirements with the optimal material and finish combination, ensuring precision, efficiency, and reliability in every mold we produce.

| Material | Typical Alloys | Hardness (HB) | Thermal Conductivity (W/m·K) | Best For | Common Finish Options |

|---|---|---|---|---|---|

| Aluminum | 7075, 6061 | 150–200 | 130–200 | Prototyping, low/medium volume runs | Hard Anodizing, Polishing |

| Steel | P20, H13, S136 | 280–450 | 25–40 | High-volume, long-life production | Nitriding, Polishing, Coating |

| Titanium | Ti-6Al-4V | 300–360 | 6–7 | Specialized, corrosive environments | Anodizing, Passivation |

Manufacturing Process & QC

Aluminum Injection Mold Production: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, we execute aluminum injection mold production as a rigorously controlled sequence where design integrity, prototyping validation, and mass production consistency converge to achieve Zero Defects. This integrated approach is fundamental for high-value B2B applications demanding rapid deployment and exceptional part quality.

The process begins with Advanced Design Engineering. Our team utilizes integrated CAD/CAM/CAE platforms, focusing on mold flow analysis specific to aluminum’s thermal properties and lower melting point compared to steel. We optimize cooling channel geometry, gating systems, and structural supports to mitigate warpage and ensure uniform solidification. Critical to Zero Defects is the concurrent engineering phase where manufacturability, tool longevity under thermal cycling, and final part tolerances are validated digitally before any metal is cut. Material selection prioritizes high-purity, vacuum-degassed aluminum alloys like 7075-T6 or 6061-T6, balancing thermal conductivity, strength, and machinability.

Precision Prototyping is non-negotiable. We fabricate the first mold cavity and core using our 5-axis CNC machining centers, achieving micron-level accuracy on critical surfaces. This prototype mold undergoes rigorous in-house testing on our dedicated injection molding presses. We conduct systematic trials with the client’s specified aluminum alloy, meticulously measuring fill patterns, cycle times, part dimensional stability, and surface finish against the original CAD model. Every deviation is analyzed; tool geometry or process parameters are refined iteratively until the prototype consistently produces defect-free parts meeting all specifications. This phase validates the digital design and establishes the exact process window for volume production.

Zero Defects Mass Production leverages the validated prototype parameters. Our production cells employ automated 5-axis CNC machines with in-process probing for real-time dimensional verification during mold fabrication. Each finished mold undergoes comprehensive metrology using CMMs and optical comparators against the master CAD file. During molding, we implement Statistical Process Control (SPC) monitoring key variables: melt temperature, injection pressure, cooling time, and clamp force. Fully automated part handling and vision inspection systems perform 100% dimensional and surface checks on every component, rejecting any unit outside the strict tolerance bands. Preventative maintenance schedules for both molds and presses are严格执行 to eliminate unplanned variation.

Our commitment to Zero Defects is quantifiable through the precision achievable in aluminum mold construction and molding:

| Critical Specification | Wuxi Lead Precision Standard | Industry Typical Standard |

|---|---|---|

| Mold Cavity Dimensional Tolerance | ±0.005 mm | ±0.012 mm |

| Part Flatness (per 100mm) | ≤ 0.015 mm | ≤ 0.030 mm |

| Surface Roughness (Cavity) | Ra 0.2 – 0.4 µm | Ra 0.8 µm |

| Thermal Distortion Control | < 0.01 mm @ 300°C cycling | Variable / Unspecified |

| First Article Pass Rate | ≥ 99.5% | 95-98% |

This seamless transition from validated design through proven prototyping to tightly controlled mass production, underpinned by Wuxi Lead’s advanced CNC capabilities and obsessive process control, delivers the reliability and quality essential for demanding aluminum injection molding applications. We engineer out defects at every stage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Aluminum Injection Molds

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance aluminum injection molds tailored to the exact specifications of advanced manufacturing operations. As a trusted name in custom metal manufacturing, we understand that precision, durability, and repeatability are non-negotiable in today’s competitive industrial landscape. Whether you are scaling production, optimizing part complexity, or reducing cycle times, our engineering team is equipped to design and produce aluminum injection molds that exceed expectations.

Aluminum molds offer distinct advantages over traditional steel, including superior thermal conductivity, faster cooling cycles, and reduced weight—making them ideal for rapid prototyping, low-to-medium volume production runs, and applications requiring frequent design iterations. At Lead Precision, we leverage advanced CNC machining, EDM processing, and strict quality control protocols to ensure every mold meets micron-level tolerances and long-term performance standards.

Our collaborative approach begins with a deep analysis of your component requirements, material selection, and production goals. From initial concept to final delivery, our team provides full technical support, including mold flow analysis, design optimization, and post-production validation. We work with a range of high-grade aluminum alloys—including 7075-T6, 6061-T6, and AlSi10Mg for additive applications—ensuring compatibility with your injection process and end-use environment.

What sets us apart is our integration of engineering excellence with scalable manufacturing capacity. Located in Wuxi, China, our ISO 9001-certified facility combines cutting-edge equipment with decades of mold-making experience, enabling us to deliver complex molds with lead times that support agile production schedules. We serve clients across aerospace, automotive, medical devices, and consumer electronics—industries where precision and reliability are paramount.

When you choose Wuxi Lead Precision Machinery, you’re not just sourcing a mold—you’re gaining a long-term manufacturing partner committed to innovation, quality, and operational efficiency.

Contact us today at [email protected] to discuss your aluminum injection mold project. Our engineering team is ready to review your CAD files, provide a detailed quote, and support you through every phase of development.

Key Specifications and Capabilities

| Parameter | Specification |

|---|---|

| Material Options | 7075-T6, 6061-T6, AlSi10Mg, ADC12 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 1.6 µm (polishing, texturing, EDM) |

| Max Mold Size | 800 x 600 x 500 mm |

| Tool Life | 50,000 – 100,000 cycles (depending on alloy and use) |

| Machining Equipment | 5-axis CNC, Wire EDM, High-Speed Milling |

| Quality Standards | ISO 9001:2015, Full First Article Inspection |

| Lead Time (Average) | 15–25 days (based on complexity) |

| Supported File Formats | STEP, IGES, X_T, SolidWorks, AutoCAD |

Reach out now to elevate your manufacturing capability with precision-engineered aluminum injection molds from Wuxi Lead Precision Machinery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.