Technical Contents

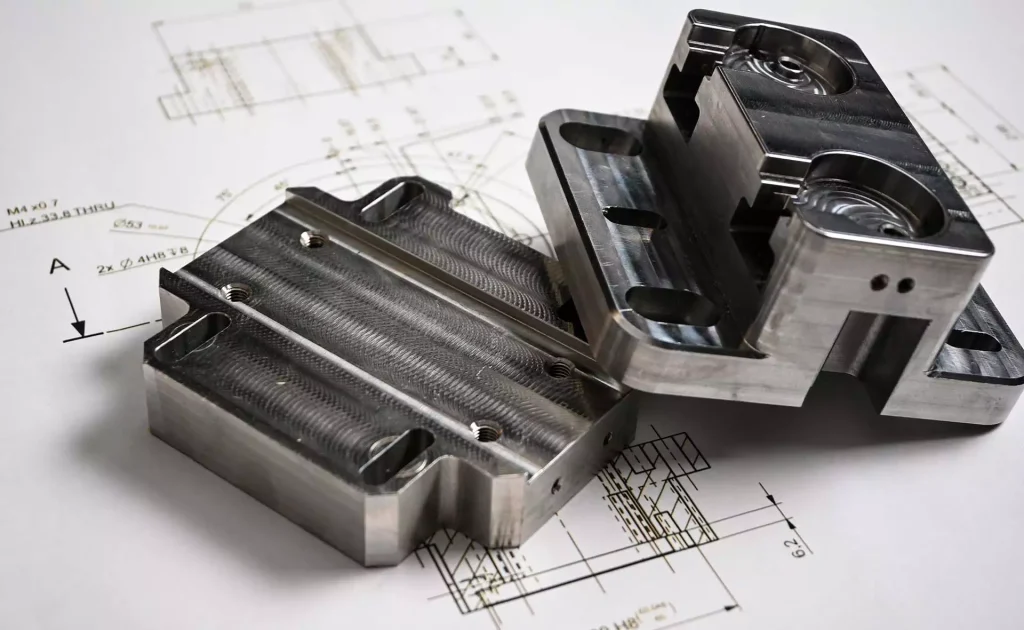

Engineering Guide: L Molding

Engineering Insight: L Molding Precision in Critical Applications

L molding profiles represent a fundamental yet exacting component in advanced structural and enclosure systems. While seemingly simple in geometry, achieving true dimensional integrity in L-shaped metal forms demands exceptional process control. Variations in leg length, angle deviation, or surface imperfection directly compromise assembly fit, load distribution, and long-term performance. At Wuxi Lead Precision Machinery, we recognize that precision in L molding transcends basic specification compliance; it is the cornerstone of system reliability in high-stakes environments.

Our engineering approach begins with material science understanding. Aluminum alloys like 6061-T6 and 7075-T73, alongside stainless steels such as 304 and 17-4PH, exhibit distinct thermal and mechanical behaviors during forming. We meticulously model springback and residual stress to counteract deformation, ensuring the final profile meets exact angular tolerances and leg straightness. This is non-negotiable when L moldings integrate into assemblies requiring micron-level alignment, such as satellite deployment mechanisms or precision optical benches. Our proprietary CNC bending sequences and in-process metrology systems actively compensate for material inconsistencies, delivering repeatability where standard fabrication processes fall short.

The critical nature of this precision is underscored by our project history. Wuxi Lead supplied mission-critical L-profile structural elements for Beijing Olympic venue infrastructure, where thermal expansion differentials across vast spans demanded angular tolerances tighter than ±0.1°. Similarly, for classified military communication shelters, our L moldings achieved flatness tolerances of 0.05mm per meter across 3-meter lengths, ensuring RF shielding integrity under extreme environmental stress. These projects exemplify how precision L molding directly enables structural resilience and functional performance in applications where failure is not an option.

Material selection and process stability must align with end-use demands. The table below outlines key precision parameters we engineer for high-integrity L molding production:

| Parameter | Standard Tolerance | Lead Precision Capability | Critical Application Impact |

|---|---|---|---|

| Dimensional Tolerance | ISO 2768-mK | ±0.05mm | Ensures seamless multi-part assembly |

| Angle Accuracy | ±1.0° | ±0.1° | Maintains structural load paths |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Reduces fatigue initiation points |

| Straightness | 1.0mm/m | 0.05mm/m | Guarantees sealing surface integrity |

| Flatness | 1.5mm/m | 0.03mm/m | Critical for EMI/RF shielding |

For Wuxi Lead, precision L molding is never merely dimensional conformity. It is the integration of metallurgical expertise, adaptive process engineering, and relentless validation. When your application demands profiles that perform under extreme thermal cycling, vibration, or load, our experience delivering for Olympic-scale infrastructure and defense systems ensures your L moldings become assets, not liabilities. Contact our engineering team to discuss how our precision forming protocols can be tailored to your specific structural requirements.

Precision Specs & Tolerances

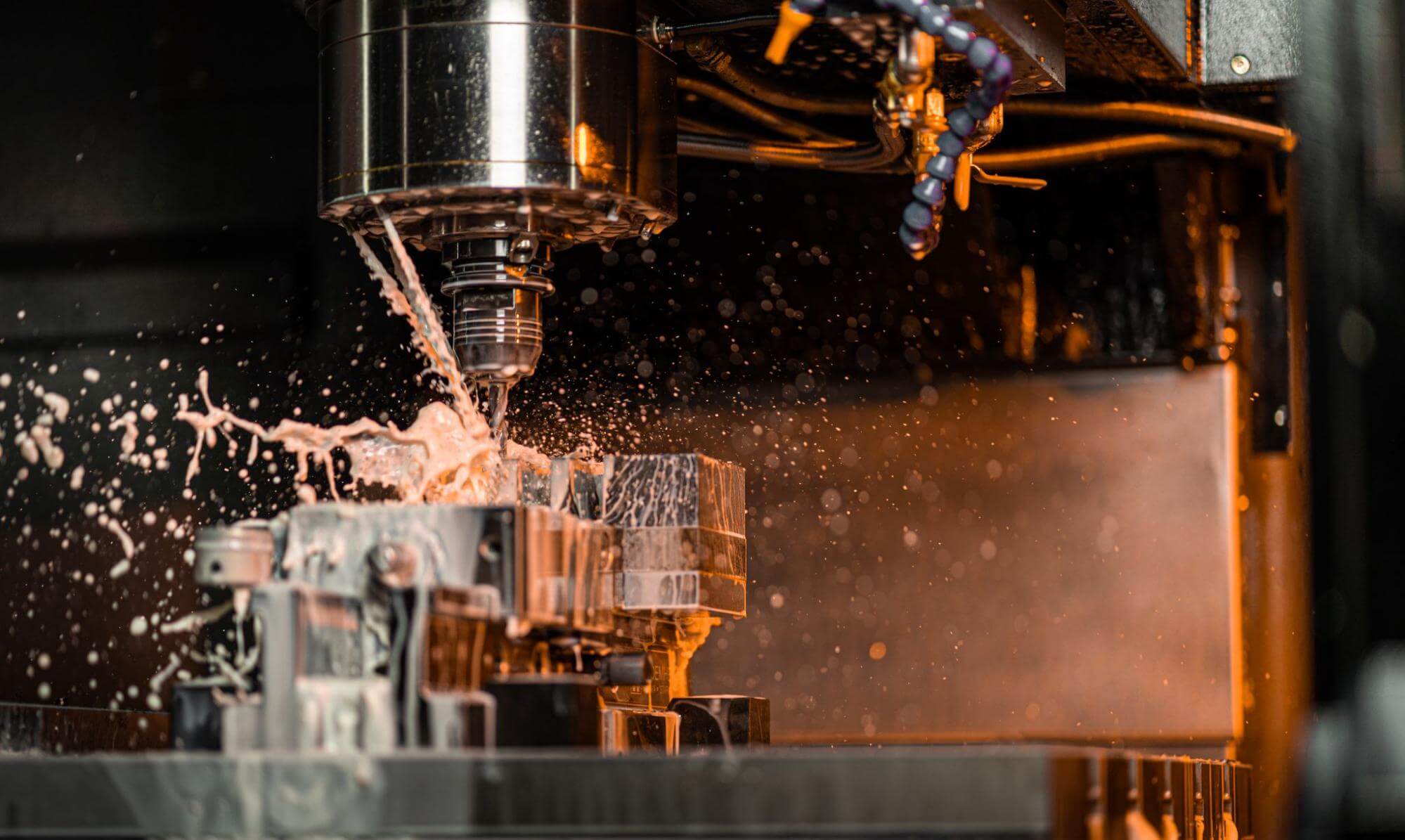

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the most demanding specifications of high-performance industries such as aerospace, medical, automotive, and industrial equipment. At the core of our precision manufacturing workflow is our state-of-the-art 5-axis CNC machining technology, which enables us to produce complex geometries with superior accuracy, surface finish, and consistency. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five planes, dramatically reducing setup time, minimizing human error, and ensuring tight tolerances across intricate features. This level of precision is essential for components requiring multi-faceted contours, deep cavities, or undercuts—common in l-molding applications where form, fit, and function are interdependent.

Our machining centers are operated by certified CNC engineers with extensive experience in high-mix, low-volume production environments. Each machine is maintained to OEM standards and equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure continuous performance and process stability. Materials are carefully selected based on application requirements, including aerospace-grade aluminum alloys, stainless steels, titanium, and high-temperature superalloys. Our 5-axis capability supports both prototyping and full-scale production, offering scalability without compromising precision.

Quality control is integrated at every stage of production. All critical dimensions and geometric features are verified using Coordinate Measuring Machine (CMM) inspection, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Our CMM systems provide full traceability, generating detailed inspection reports for each component. These reports include point-cloud analysis, GD&T verification, and surface profile measurements, which are essential for audit readiness and customer validation. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate dimensional integrity across both first-article and in-process inspections.

The following table outlines the standard and precision tolerances we consistently achieve through our 5-axis CNC and quality assurance systems:

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Angular Dimensions | ±0.1° | ±0.05° | Measured via CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Includes hole patterns |

| Flatness | 0.05 mm | 0.01 mm | Per 100 mm² |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved with fine finishing passes |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or honed |

These capabilities are backed by a certified quality management system compliant with ISO 9001:2015. Wuxi Lead Precision Machinery is committed to delivering not only precision but also reliability and repeatability—ensuring every l-molding component meets the functional demands of its application.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting optimal materials is foundational to achieving performance, longevity, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical demands, environmental exposure, and finish requirements. This guide details critical considerations for aluminum, steel, and titanium alloys, alongside anodizing as a premier surface treatment.

Aluminum alloys dominate aerospace, automotive, and electronics due to their high strength-to-weight ratio and excellent thermal conductivity. Grade 6061-T6 offers balanced machinability and weldability for structural frames, while 7075-T6 delivers superior strength for high-stress components. Aluminum’s natural corrosion resistance is enhanced through anodizing, which creates a durable, non-conductive oxide layer. Anodized finishes support color customization and improve wear resistance without dimensional compromise—critical for precision-molded parts.

Carbon and stainless steel variants provide unmatched hardness and load-bearing capacity. AISI 4140 excels in high-tensile applications like shafts and tooling, whereas 304/316 stainless steels are indispensable in corrosive or hygienic environments (e.g., medical devices, marine hardware). Steel components often require plating or painting for corrosion protection, though passivation suffices for stainless grades. Note that steel’s higher density increases weight and machining costs versus aluminum.

Titanium alloys (e.g., Grade 5 Ti-6Al-4V) are reserved for extreme conditions—think aerospace actuators or biomedical implants—where exceptional strength, near-zero corrosion, and biocompatibility justify premium costs. Titanium’s low thermal conductivity challenges machining, demanding specialized CNC parameters and tooling expertise. Anodizing is less common here; plasma electrolytic oxidation (PEO) or bare finishes typically suffice.

Critical Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Index | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (with anodizing) | Excellent (9/10) | Low |

| Stainless 304 | 8.0 | 515 | Excellent | Moderate (4/10) | Medium |

| Steel 4140 | 7.8 | 655 | Fair (requires coating) | Good (6/10) | Low-Medium |

| Titanium Ti-6Al-4V | 4.4 | 900 | Exceptional | Poor (2/10) | High |

Anodizing remains the finish of choice for aluminum components requiring enhanced surface durability, electrical insulation, or aesthetic control. Type II (sulfuric acid) anodizing offers standard protection, while Type III (hardcoat) achieves 50–75 μm thickness for severe abrasion resistance. Crucially, anodizing must be specified early in design—hole tolerances and critical dimensions require pre-treatment allowances to avoid post-process rework.

Material selection directly impacts manufacturability, lifecycle costs, and functional success. Wuxi Lead Precision Machinery leverages decades of CNC expertise to match your project’s exact needs with optimal material-finish combinations. Partner with us to transform specifications into precision-engineered reality—where metallurgical insight meets uncompromising execution.

Manufacturing Process & QC

Design Phase: Precision Engineering as the Foundation

At Wuxi Lead Precision Machinery, the L-molding production process begins with an intensive design phase that integrates engineering excellence with advanced simulation technologies. Our design team collaborates closely with clients to interpret technical drawings, 3D models, and functional requirements. Utilizing CAD/CAM software such as SolidWorks and AutoCAD, we generate precise digital blueprints tailored to the application’s mechanical, thermal, and structural demands. Finite Element Analysis (FEA) is applied to simulate stress points, deformation risks, and thermal behavior under operational loads. This ensures that every L-molding profile is not only dimensionally accurate but also optimized for performance in real-world environments. Design validation includes tolerance stack-up analysis and material selection based on environmental exposure—such as corrosion resistance for outdoor applications or high-strength alloys for structural support.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using CNC precision bending and forming techniques. Prototypes are manufactured in-house using the same tooling and materials intended for mass production, ensuring accurate representation of final part quality. Each prototype undergoes rigorous inspection via coordinate measuring machines (CMM), laser scanning, and optical comparators to verify dimensional accuracy within ±0.05 mm. Functional testing—including load-bearing trials, fitment checks, and surface finish evaluation—is conducted to confirm compliance with client specifications. Feedback from this stage is incorporated into final design adjustments, minimizing risk during full-scale production. This iterative approach ensures that form, fit, and function are fully validated before release.

Mass Production: Zero Defects Through Process Control

Our mass production phase is built on a foundation of lean manufacturing and Six Sigma principles, engineered for zero-defect output. Automated CNC press brakes, robotic handling systems, and real-time monitoring ensure consistent forming accuracy across high volumes. Each L-molding component passes through a defined quality gate at every stage—raw material inspection, in-process checks, and final 100% visual and dimensional inspection. We implement Statistical Process Control (SPC) to monitor key variables such as bend angle, leg length, and surface integrity, enabling immediate correction of deviations. All finished parts are traceable through batch coding and digital records, supporting full auditability.

Material and Production Specifications

| Parameter | Specification |

|---|---|

| Material Types | Aluminum 6061, 6063; Stainless Steel 304, 316; Mild Steel Q235 |

| Thickness Range | 1.0 – 6.0 mm |

| Leg Length Tolerance | ±0.2 mm (standard), ±0.05 mm (precision) |

| Bend Angle Accuracy | ±0.5° |

| Surface Finish Options | Mill finish, anodized, powder-coated, galvanized |

| Production Capacity | Up to 50,000 units per month |

| Quality Standards | ISO 9001:2015, GD&T compliant, RoHS |

Through seamless integration of design intelligence, prototype validation, and disciplined production controls, Wuxi Lead Precision Machinery delivers L-molding solutions that meet the highest standards of precision and reliability in custom metal manufacturing.

Why Choose Wuxi Lead Precision

Elevate Your Precision Metal Manufacturing Partnership

In the demanding landscape of high-precision metal component production, selecting a manufacturing partner transcends transactional procurement. It requires an engineering ally capable of transforming complex design intent into flawless physical reality while mitigating supply chain volatility. Wuxi Lead Precision Machinery operates at this critical intersection of advanced capability and strategic partnership. We specialize in mission-critical metal fabrication where tolerances, material integrity, and repeatability directly impact your product’s performance and market success. Our facility integrates 5-axis CNC milling, precision turning, and multi-axis grinding with rigorous in-process metrology, ensuring every component adheres to aerospace, medical, and industrial automation standards. Unlike commodity suppliers, we embed our engineering team within your development cycle—from DFM analysis to first-article inspection—reducing time-to-market and eliminating costly redesign iterations.

Our technical infrastructure is engineered for uncompromising quality. The table below outlines core capabilities relevant to precision metal molding and forming applications. These specifications represent baseline capacities; our engineers routinely exceed these parameters for specialized projects through adaptive process refinement.

| Capability Category | Specification Range | Industry Standard Compliance |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.025 mm | ISO 2768-mK, ASME Y14.5 |

| Surface Finish (Ra) | 0.1 µm to 1.6 µm | ISO 1302, ASME B46.1 |

| Material Expertise | Titanium Gr5, Inconel 718, 17-4PH SS, Aluminum 7075, Tool Steels | AMS, ASTM, EN standards |

| Max Work Envelope | 1200 x 800 x 600 mm (XYZ) | Custom fixturing available |

| Process Certifications | ISO 9001:2015, IATF 16949, NADCAP (pending) | PPAP Level 3, FAI reports |

This technical foundation is augmented by proactive risk management. We maintain dual-sourced raw material channels for critical alloys and implement real-time SPC monitoring across all production cells. Our facility operates under a closed-loop corrective action system, ensuring deviations are resolved before impacting your shipment schedule. For projects requiring rapid iteration, our digital twin validation process reduces prototyping cycles by up to 40% compared to traditional methods.

Partnering with Lead Precision means accessing engineering rigor without geopolitical or logistical friction. We navigate complex international certification requirements so you don’t have to, providing full documentation traceability from billet to shipment. Your success hinges on partners who treat your specifications as non-negotiable commitments—not suggestions.

Initiate your precision manufacturing partnership with actionable engineering dialogue. Email [email protected] with your project specifications, target tolerances, and timeline constraints. Our technical sales team will respond within 4 business hours with a preliminary process assessment and feasibility analysis—no generic quotations, only engineered solutions. For urgent RFQs marked “ENGINEERING REVIEW REQUIRED,” expect direct engagement from our lead CNC applications engineer. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.