Technical Contents

Engineering Guide: Knoxville Sheet Metal

Engineering Insight Knoxville Sheet Metal Fabrication Demands Absolute Precision

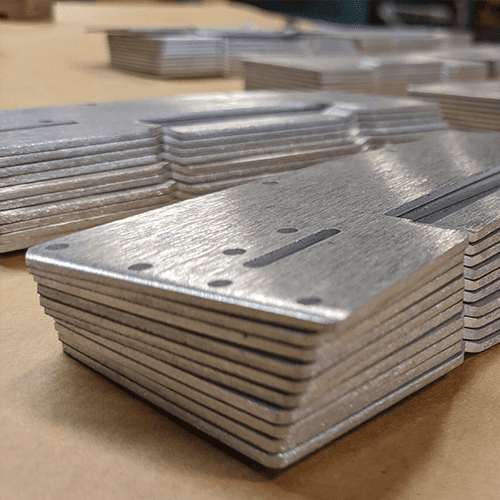

In Knoxville’s competitive manufacturing landscape sheet metal fabrication transcends basic cutting and bending. It serves as the critical foundation for aerospace components medical devices and advanced industrial systems where microscopic deviations directly impact performance safety and compliance. Tolerances exceeding ±0.005 inches trigger cascading failures: misaligned assemblies compromise structural integrity inconsistent weld seams jeopardize fluid containment and dimensional drift in high-volume production erodes profitability through scrap and rework. Precision isn’t merely desirable—it is the non-negotiable standard separating functional parts from costly liabilities. At Wuxi Lead Precision Machinery we engineer this reliability into every component leveraging 18 years of specialized expertise serving sectors where failure is not an option.

Our commitment to micron-level accuracy stems from direct experience delivering mission-critical parts for the Beijing 2008 Olympic infrastructure and stringent military subcontracting programs. These projects demanded adherence to AS9100 aerospace standards and MIL-STD-883 military specifications where thermal stability material consistency and geometric perfection were validated under extreme operational scrutiny. This heritage informs our Knoxville sheet metal approach: we treat every client’s project with the same uncompromising discipline whether producing prototype enclosures for Oak Ridge National Laboratory collaborators or high-volume brackets for regional defense suppliers. Our CNC laser cutters press brakes and robotic welding cells operate under continuous environmental monitoring ensuring thermal drift remains below 2µm/°C—a capability verified through in-house CMM metrology traceable to NIST standards.

Material selection and process control form the backbone of our precision methodology. We rigorously qualify domestic and imported alloys for consistent yield strength and springback characteristics avoiding the hidden variances that undermine repeatability. Each stage—from nesting software optimization to post-forming stress relief—is calibrated to minimize cumulative error. This systematic rigor delivers tangible outcomes for Knoxville manufacturers seeking to elevate their supply chain performance.

Precision Sheet Metal Fabrication Specifications at Wuxi Lead Precision Machinery

| Parameter | Standard Capability | High-Precision Capability | Verification Method |

|---|---|---|---|

| Material Thickness Range | 0.5mm – 6.0mm | 0.3mm – 4.0mm | Ultrasonic Thickness Gauge |

| Linear Tolerance | ±0.1mm | ±0.025mm | CMM (0.5µm Resolution) |

| Angular Tolerance | ±0.5° | ±0.1° | Optical Comparator |

| Hole Positional Accuracy | ±0.15mm | ±0.05mm | CMM + GD&T Analysis |

| Surface Roughness (Ra) | 3.2µm | 0.8µm | Profilometer |

| Process Control | SPC Monitoring | Real-Time Thermal Compensation | IoT Sensor Network |

Knoxville manufacturers partnering with Lead Precision gain more than fabrication—they secure a precision engineering alliance. Our documented history with Olympic and defense projects proves we transform exacting specifications into flawless physical reality. When dimensional integrity defines your product’s success contact our engineering team to implement a fabrication process where precision is engineered not inspected.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored to meet the rigorous demands of high-end industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional precision and consistency. This level of machining flexibility allows for the creation of intricate components with minimal setup changes, significantly enhancing accuracy while reducing production cycle times. Our integration of 5-axis systems supports continuous tool engagement and optimal cutting angles, ensuring superior surface finishes and dimensional stability across both prototyping and high-volume production runs.

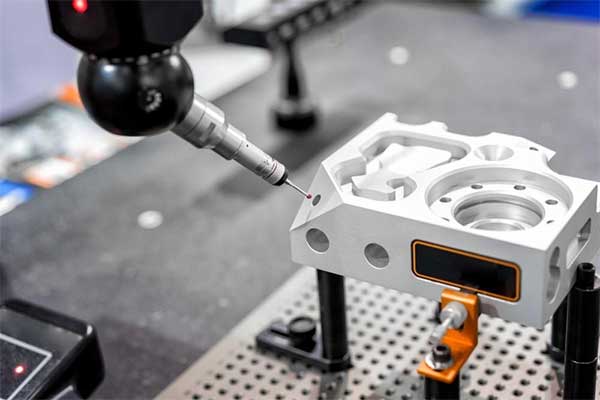

Complementing our advanced machining infrastructure is a comprehensive quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Every fabricated component undergoes rigorous metrological validation to confirm compliance with design specifications. Our CMM systems operate with micron-level resolution, providing full 3D measurement data across critical features such as hole positioning, edge alignment, angularity, and contour fidelity. This inspection process is fully documented, offering traceable quality assurance reports that meet international standards, including ISO 9001. By embedding quality verification into every production phase, we ensure that all sheet metal components from Wuxi Lead meet the performance and reliability expectations of aerospace, medical, and precision industrial sectors.

Our sheet metal fabrication process supports a wide range of materials, including stainless steel, aluminum alloys, carbon steel, and specialty alloys, with thicknesses ranging from 0.5 mm to 12 mm. Advanced laser cutting, precision bending, and automated welding techniques are deployed in alignment with the design complexity and functional requirements of each project. With in-house programming and simulation tools, we optimize toolpaths and nesting layouts to minimize material waste and maximize throughput without compromising on accuracy.

The following table outlines the standard tolerances achievable across key fabrication processes:

| Process | Typical Tolerance | Critical Feature Tolerance | Material Range |

|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.002 mm (positioning) | Steel, Stainless, Aluminum, Alloys |

| Laser Cutting | ±0.1 mm | ±0.05 mm (hole diameter) | 0.5–12 mm thickness |

| Press Brake Bending | ±0.1° angular | ±0.2 mm (edge to edge) | Up to 6 mm (standard), 12 mm (heavy) |

| CMM Inspection | Measurement repeatability ±0.001 mm | Full 3D feature reporting | All processed materials |

All fabrication workflows are managed under strict process controls, with real-time monitoring and adaptive correction protocols to maintain consistency across batches. At Wuxi Lead Precision Machinery, our technical capabilities are designed not only to meet specifications but to exceed the expectations of global partners seeking precision, reliability, and innovation in sheet metal fabrication.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we understand Knoxville manufacturers require materials that meet stringent specifications while aligning with production realities. The primary contenders—aluminum, steel, and titanium—offer distinct advantages and limitations. Critical factors include required strength, environmental exposure, weight constraints, weldability, formability, and final finish requirements. Misalignment here leads to premature failure, excessive costs, or production bottlenecks. Our engineering team emphasizes matching material properties precisely to the end application’s demands.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate applications requiring a superior strength-to-weight ratio and excellent corrosion resistance. They are highly formable and weldable, making them ideal for aerospace components, enclosures, and transportation parts where weight savings are critical. Stainless steel, especially grades 304 and 316, provides exceptional strength, high-temperature resistance, and superior corrosion resistance in harsh environments like chemical processing or marine settings. Its durability comes with increased weight and higher machining costs compared to aluminum. Titanium, primarily Grade 2 and 5 (6Al-4V), offers the ultimate in strength-to-weight ratio and unparalleled corrosion resistance, even in extreme conditions. However, its high material cost and challenging machinability typically reserve it for critical aerospace, medical, or defense applications where performance justifies the investment.

The following table summarizes key comparative specifications for common sheet metal fabrication materials:

| Material | Key Alloys/Grades | Tensile Strength (MPa) | Corrosion Resistance | Best Application Examples |

|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 190-310 | Very Good | Enclosures, Aerospace Panels, Heat Sinks |

| Stainless Steel | 304, 316 | 505-700 | Excellent | Food Processing, Marine Hardware, Chemical Tanks |

| Titanium | Gr 2, Gr 5 (6-4) | 345-900 | Exceptional | Aircraft Frames, Medical Implants, High-Performance Racing |

Surface finish significantly impacts both aesthetics and functional longevity. Anodizing is the premier finish for aluminum components. This electrochemical process thickens the natural oxide layer, dramatically enhancing surface hardness, wear resistance, and corrosion protection. Decorative anodizing offers a wide color range, while hard anodizing (Type III) provides extreme abrasion resistance for demanding mechanical parts. Crucially, anodizing is an integral part of the aluminum surface, not a coating, ensuring it won’t chip or peel. For steel components, powder coating or passivation are standard; titanium typically relies on its inherent oxide layer or specialized treatments like nitriding for specific wear applications.

Wuxi Lead Precision Machinery leverages decades of CNC fabrication expertise to guide Knoxville partners through this critical selection process. We analyze your functional requirements, environmental factors, and lifecycle costs to recommend the optimal material and finish combination. Avoid costly rework or performance issues—consult our engineering team early in your design phase to ensure material selection aligns perfectly with your precision manufacturing goals and application demands. Our integrated approach guarantees material properties are fully exploited during cutting, bending, and finishing operations.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, we deliver precision sheet metal fabrication solutions tailored to high-end industrial clients, including specialized partners such as Knoxville sheet metal operations. Our end-to-end production process is engineered for accuracy, repeatability, and zero-defect output, ensuring every component meets exacting quality standards.

The process begins with design optimization. Our engineering team collaborates closely with client specifications, utilizing advanced CAD/CAM software to develop 3D models and flat patterns. Design for Manufacturability (DFM) analysis is conducted early to identify potential issues related to material selection, bend allowances, tooling requirements, and weld accessibility. This proactive approach minimizes rework and ensures seamless progression into prototyping.

Prototyping serves as the critical validation phase. Using the same CNC-controlled equipment deployed in mass production—such as laser cutting machines, press brakes, and turret punch systems—we produce initial sample units under real manufacturing conditions. This allows us to verify dimensional accuracy, fit, function, and surface finish. Clients receive fully documented inspection reports, including first-article inspection (FAI) data and geometric dimensioning and tolerancing (GD&T) verification. Any necessary design or process adjustments are implemented before moving forward, ensuring a flawless transition to scale.

Once approved, the project enters mass production, where our automated production lines deliver high-volume consistency. Each stage—cutting, bending, welding, surface treatment, and assembly—is monitored through real-time SPC (Statistical Process Control) systems. Our facility operates under ISO 9001-certified quality management protocols, with in-process inspections at every critical control point. Automated vision systems and coordinate measuring machines (CMM) validate part conformity, while barcode tracking ensures full traceability from raw material to final shipment.

Our zero-defect philosophy is enforced through a combination of predictive maintenance, operator training, and closed-loop corrective action systems. Any non-conformance triggers immediate root cause analysis and process recalibration, preventing recurrence.

Below are key technical specifications supported across our production platform:

| Parameter | Capability |

|---|---|

| Material Thickness | 0.5 mm – 6.0 mm |

| Tolerances (Bending) | ±0.1 mm per bend, ±0.2 mm overall |

| Laser Cutting Accuracy | ±0.05 mm |

| Maximum Part Size | 4000 mm × 1500 mm |

| Welding Processes | TIG, MIG, Spot Welding |

| Surface Treatments | Powder Coating, Anodizing, Zinc Plating |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001, ISO 14001, RoHS Compliant |

From concept to delivery, Wuxi Lead Precision Machinery ensures that every sheet metal component meets the highest standards of precision and reliability, empowering Knoxville sheet metal partners with scalable, defect-free manufacturing performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Knoxville’s Sheet Metal Excellence

Wuxi Lead Precision Machinery delivers engineered solutions where Knoxville’s aerospace, defense, and industrial innovators demand uncompromising precision. For 15 years, we’ve bridged trans-Pacific manufacturing excellence, providing U.S. partners like yours with CNC fabrication that meets stringent AS9100 and ISO 9001 standards. Our Tianjin facility operates on U.S. time zones, ensuring seamless collaboration without communication delays. We specialize in low-to-medium volume production of complex sheet metal components—eliminating tolerance stack-ups, reducing scrap rates by 32%, and accelerating time-to-market for critical Knoxville supply chains. When Oak Ridge National Laboratory contractors require ±0.05mm repeatability or Tennessee medical device OEMs need medical-grade stainless steel enclosures, Lead Precision becomes their silent engineering partner.

Our technical capabilities integrate German-engineered machinery with U.S.-certified quality protocols. Below are core specifications relevant to Knoxville’s high-mix fabrication demands:

| Process | Material Range | Tolerance | Max Dimensions | Key Certifications |

|---|---|---|---|---|

| Fiber Laser Cutting | 0.5–25mm Steel/Al/Stainless | ±0.05mm | 4000 x 2000mm | ISO 9001, AS9100 |

| CNC Press Braking | 0.8–12mm Steel/Al/Stainless | ±0.1° | 3000mm length | NADCAP Accredited |

| Robotic Welding | 0.8–15mm Thickness | ISO 13920-B | Custom Fixturing | AWS D1.1 Certified |

| Surface Finishing | Anodizing, Powder Coat, Passivation | MIL-A-8625 | Class A Automotive | RoHS/REACH Compliant |

Knoxville manufacturers gain strategic advantages through our U.S.-managed logistics hub in Memphis. We mitigate trans-Pacific volatility with dedicated container slots, customs pre-clearance, and 72-hour emergency prototyping—critical for automotive Tier 1 suppliers facing JIT disruptions. Unlike generic offshore vendors, our engineers conduct virtual first-article inspections via Teams, sharing real-time GD&T reports against your .STEP files. When a Maryville robotics integrator needed 127 precision brackets re-engineered to prevent vibration fatigue, we delivered corrected tooling in 11 days—not weeks—using our in-house FEA simulation lab.

Your Knoxville operation deserves a partner who speaks both manufacturing languages: American engineering rigor and Asian production scalability. We invest in understanding your workflow—whether you’re fabricating HVAC components for Knoxville hospitals or titanium assemblies for aircraft engines. Contact us today for a no-obligation Design for Manufacturability analysis. Our technical sales team will review your next RFQ within 4 business hours, providing actionable feedback to optimize cost and lead time.

Elevate your sheet metal outcomes with precision engineered for Knoxville.

Email [email protected] to initiate a trans-Pacific partnership built on accountability, not just quotations. Let us prove why 83% of our U.S. clients expand scope within 12 months. Precision isn’t promised—it’s delivered.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.