Technical Contents

Engineering Guide: Metal Fabrication Companies In Usa

Engineering Insight: The Critical Role of Precision in U.S. Metal Fabrication

In the competitive landscape of American manufacturing, metal fabrication companies in the USA are under increasing pressure to deliver components that meet exacting standards across aerospace, defense, medical, and high-performance industrial sectors. At the core of this demand lies one non-negotiable requirement: precision. Dimensional accuracy, repeatability, and material integrity are no longer optional—they define the threshold for market entry and long-term success.

Precision in sheet metal fabrication directly impacts product performance, assembly efficiency, and lifecycle durability. Even a deviation of ±0.005 inches can result in misaligned assemblies, compromised structural integrity, or costly field failures. For industries such as military systems or aerospace, where components operate under extreme conditions, such variances are unacceptable. This is where advanced engineering practices, coupled with state-of-the-art machinery and rigorous quality control, become decisive differentiators.

Wuxi Lead Precision Machinery brings over 15 years of high-precision manufacturing expertise to global partners, including collaborations on projects aligned with Olympic-standard equipment and military-grade systems. These engagements demanded zero-defect production, full traceability, and compliance with international standards such as ISO 9001 and AS9100. Our experience underscores a fundamental truth: precision is not achieved through equipment alone—it is engineered into every stage of the fabrication process, from design validation to final inspection.

Our approach integrates laser cutting, CNC punching, precision bending, and automated welding, all governed by tight process controls and real-time monitoring. Each component undergoes comprehensive metrology checks using coordinate measuring machines (CMM) and 3D scanning technologies to ensure compliance with design specifications. This level of control enables us to support U.S. fabricators who require offshore manufacturing partners capable of matching or exceeding domestic quality benchmarks.

The following table outlines key precision capabilities that define high-end sheet metal fabrication:

| Specification | Capability | Tolerance Range |

|---|---|---|

| Laser Cutting | Fiber laser, up to 20 mm thickness | ±0.05 mm |

| CNC Punching | High-speed turret punching, complex geometries | ±0.08 mm |

| Press Brake Bending | CNC-controlled, up to 1000 mm length | ±0.1° angular, ±0.1 mm linear |

| Welding | TIG, MIG, spot welding with distortion control | Full weld certification available |

| Surface Finish | Deburring, grinding, polishing, coating | Ra ≤ 0.8 μm (machined), custom textures |

| Quality Assurance | CMM, 3D scanning, first article inspection | Full GD&T reporting |

For U.S. metal fabrication companies navigating supply chain complexity and rising customer expectations, partnering with a precision-focused manufacturer like Wuxi Lead ensures not only cost efficiency but also technical reliability. In an era where performance hinges on microns, precision is not just an advantage—it is the foundation of trust.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered to meet the exacting standards of North American manufacturers. Our integrated technical infrastructure centers on 5-axis CNC machining systems, enabling the production of complex, high-tolerance components with minimal secondary operations. This capability is critical for US fabricators seeking to reduce lead times and part consolidation costs while maintaining geometric integrity across multi-faceted designs. Our DMG MORI and MAZAK 5-axis platforms handle materials from aluminum alloys to stainless steel and titanium, supporting thicknesses ranging from 0.5 mm to 6.0 mm. Advanced workholding and adaptive toolpath strategies ensure consistent surface finishes below Ra 0.8 µm, even on contoured geometries where traditional 3-axis systems face limitations.

Quality assurance is non-negotiable in our process. Every critical dimension undergoes verification via Zeiss CONTURA Coordinate Measuring Machines (CMM), operating under ISO 17025-accredited protocols. This metrology backbone provides full traceability, with inspection reports detailing GD&T compliance, surface profile deviations, and positional accuracy. Our CMM workflow integrates directly with client CAD models, enabling real-time deviation mapping and rapid corrective action during production runs. This eliminates costly rework cycles and ensures first-article approval aligns with ASME Y14.5 standards—essential for aerospace, medical, and defense contractors in the USA.

The following table details achievable tolerances under controlled production conditions. These specifications reflect our standard process capability (CpK ≥ 1.33) for components up to 500 x 400 x 200 mm, validated through statistical process control:

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm | CMM / Optical Comparator |

| Hole Position | ±0.05 mm | ±0.03 mm | CMM |

| Flatness | 0.1 mm / 100 mm | 0.05 mm / 100 mm | CMM / Surface Plate |

| Angular Deviation | ±0.1° | ±0.05° | CMM / Precision Angle Gauge |

| Hole Diameter (Reamed) | +0.025 / -0.000 mm | +0.010 / -0.000 mm | Air Gage / CMM |

These capabilities translate directly to reduced assembly friction for US clients. By achieving tighter tolerances in primary machining operations, we minimize fit-up issues in welded or fastened subassemblies—addressing a persistent pain point in domestic fabrication workflows. Our engineering team collaborates proactively with US customers during DFMA reviews to optimize part geometry for manufacturability, ensuring tolerances are held without unnecessary cost escalation. All processes adhere to ISO 9001:2015 frameworks, with dedicated project managers providing real-time production updates and inspection documentation via secure client portals. For US metal fabricators balancing cost pressures with uncompromised quality, Wuxi Lead offers a verifiable precision alternative without sacrificing supply chain reliability.

Material & Finish Options

Material Selection in Sheet Metal Fabrication: Aluminum, Steel, and Titanium

Selecting the appropriate material is a foundational decision in sheet metal fabrication, directly influencing product performance, longevity, and cost-efficiency. For high-precision applications across aerospace, automotive, medical, and industrial equipment sectors, three primary metals dominate: aluminum, steel, and titanium. Each offers distinct mechanical properties, workability, and environmental resistance, making them suitable for specific use cases. Understanding their characteristics ensures optimal design and manufacturing outcomes.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is particularly effective in applications where weight reduction is critical, such as transportation and portable electronics. Grade 6061-T6 is one of the most commonly used alloys, offering good weldability and machinability. However, aluminum’s lower hardness compared to steel requires careful handling during forming and cutting operations to prevent deformation.

Steel, particularly cold-rolled steel (CRS) and stainless steel (e.g., 304 and 316), remains a staple in industrial fabrication due to its high tensile strength, durability, and cost-effectiveness. Stainless variants provide superior resistance to oxidation and chemical exposure, making them ideal for food processing, medical devices, and outdoor enclosures. While heavier than aluminum, steel’s robustness supports structural applications requiring load-bearing capacity and impact resistance.

Titanium, though more expensive and challenging to process, delivers exceptional performance in extreme environments. With a strength-to-density ratio surpassing both aluminum and steel, and outstanding resistance to corrosion—even in saline or acidic conditions—titanium is the material of choice for critical aerospace, defense, and medical implant applications. Its biocompatibility and non-magnetic properties further expand its utility in sensitive technical fields.

Surface finishing plays a crucial role in enhancing both functionality and aesthetics. Anodizing, primarily applied to aluminum, is an electrochemical process that increases surface hardness and corrosion resistance while allowing for color customization. Type II (sulfuric acid) anodizing is commonly used for decorative and moderate protective needs, whereas Type III (hardcoat anodizing) provides a thicker, wear-resistant layer suitable for industrial components subject to friction or harsh environments. Anodized layers are integral to the base metal, ensuring they do not chip or peel under stress.

Below is a comparative overview of key properties for common sheet metal materials used in precision fabrication.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | High | 6061-T6, 5052-H32 | Aerospace, electronics, transport |

| Stainless Steel | 8.0 | 505–860 | Very High | 304, 316 | Medical, food processing, enclosures |

| Carbon Steel | 7.8 | 370–550 | Low (without coating) | 1018, A36 | Industrial frames, machinery |

| Titanium | 4.5 | 900–1,170 | Exceptional | Grade 2, Grade 5 | Aerospace, defense, medical implants |

At Wuxi Lead Precision Machinery, we support advanced material processing across these metals, ensuring dimensional accuracy and surface integrity. Our expertise in CNC punching, laser cutting, and finishing—including precision anodizing coordination—enables seamless production of high-performance sheet metal components tailored to your engineering requirements.

Manufacturing Process & QC

Sheet Metal Fabrication: Precision Process from Concept to Zero Defects Production

Precision begins long before metal meets tool. At Wuxi Lead Precision Machinery, our integrated process for US metal fabrication partners ensures dimensional integrity and functional reliability from initial concept through high-volume delivery. We eliminate costly rework and delays by embedding quality at every stage, adhering strictly to the Zero Defects philosophy demanded by aerospace, medical, and advanced industrial sectors.

Design Phase: Engineering Flawless Foundations

Our process initiates with rigorous Design for Manufacturability (DFM) analysis. US client CAD models undergo comprehensive review by our engineering team, focusing on material selection, bend allowances, grain direction, and tooling feasibility. We identify potential stress points, weld accessibility issues, and tolerance stack-ups early, providing actionable feedback to optimize the design for both performance and efficient fabrication. This collaborative stage leverages advanced simulation software to predict springback and deformation, ensuring the virtual model translates perfectly to physical reality. Clear geometric dimensioning and tolerancing (GD&T) specifications, aligned with ASME Y14.5 standards, are established as the non-negotiable blueprint for all subsequent stages.

Prototyping Phase: Validating Performance Before Scale

Prototyping is not merely a sample; it is critical validation. We produce functional prototypes using the exact materials and intended production tooling paths. Each prototype undergoes stringent first-article inspection (FAI) against the approved design, verifying critical dimensions, surface finishes, and assembly fit. Material certifications and process documentation are fully traceable. This phase confirms the DFM adjustments, validates the manufacturing sequence, and provides the US client with tangible proof of concept and performance under real-world conditions. Only when the prototype meets all specifications without deviation do we proceed to mass production.

Mass Production: Executing Zero Defects at Scale

Transitioning to volume production, our Zero Defects commitment becomes operational reality. Automated CNC punch presses, laser cutters, press brakes with real-time angle feedback, and robotic welding cells operate under strict process controls. Statistical Process Control (SPC) monitors key parameters like laser power, bend angle, and weld penetration continuously. Inline vision systems and calibrated CMMs perform 100% inspection on critical features and random high-frequency checks on all others. Every component is traceable via serialized barcoding, linking material certs, machine logs, and inspection data. This closed-loop system detects microscopic deviations instantly, triggering immediate process correction to prevent defect escape, ensuring consistent conformance to the tightest tolerances required by US OEMs.

Our disciplined approach transforms design intent into flawless physical products. The table below outlines key process specifications maintained throughout production.

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Standard Tolerance | ±0.1 mm (±0.004″) | ±0.05 mm (±0.002″) |

| Critical Feature Tolerance | ±0.05 mm (±0.002″) | ±0.025 mm (±0.001″) |

| Material Certification | Full Mill Certs + Traceability | Full Mill Certs + Batch Traceability |

| Inspection Frequency | 100% FAI + Functional Test | 100% Critical Features + SPC Sampling |

| Process Control | Manual Verification + SPC Setup | Automated SPC + Real-time Correction |

| Lead Time (Typical) | 5-10 Working Days | 15-25 Working Days (1k pcs) |

Why Choose Wuxi Lead Precision

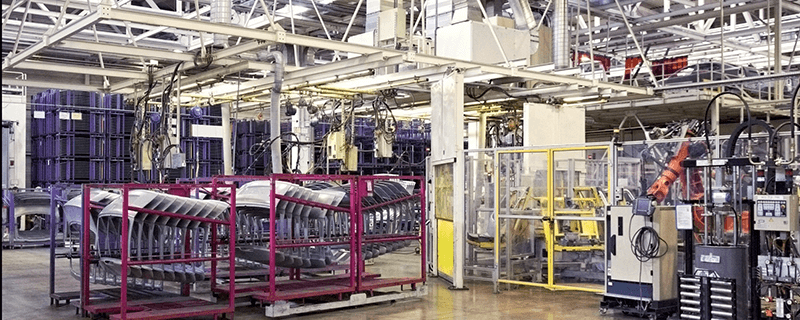

Partner with Wuxi Lead Precision Machinery to elevate your sheet metal fabrication capabilities to the highest industrial standards. As a globally recognized manufacturer based in China, we specialize in precision-engineered CNC machining, laser cutting, bending, and welding solutions tailored for demanding applications in aerospace, automotive, energy, and heavy equipment sectors. Our advanced production floor is equipped with state-of-the-art machinery and operated by a team of certified engineers committed to delivering consistency, accuracy, and on-time performance.

For metal fabrication companies in the USA seeking a reliable offshore partner, Wuxi Lead Precision Machinery offers a strategic advantage. We understand the rigorous quality expectations of North American markets and comply fully with ISO 9001:2015 standards. Every component we produce undergoes stringent in-process and final inspections using coordinate measuring machines (CMM) and 3D scanning technology to ensure full dimensional compliance. Our facility supports low-volume prototypes to high-volume production runs, providing scalability without compromising precision.

Our collaborative approach begins with engineering consultation. Whether you’re refining a design for manufacturability or optimizing a production workflow, our technical team works directly with your engineers to ensure seamless integration. We support a wide range of materials, including carbon steel, stainless steel, aluminum, copper, and specialty alloys, with thicknesses from 0.5 mm to 25 mm. Surface treatments such as powder coating, anodizing, plating, and passivation are available to meet functional and aesthetic requirements.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Laser Cutting | Max Sheet Size: 4000 x 2000 mm, Thickness: Up to 25 mm (steel), Tolerance: ±0.1 mm |

| CNC Bending | Max Bend Length: 3000 mm, Max Capacity: 20 mm steel, Angular Accuracy: ±0.2° |

| CNC Machining | 3/4/5-Axis, Tolerance: ±0.005 mm, Max Work Envelope: 1200 x 800 x 600 mm |

| Welding | MIG, TIG, Spot, Robotic Welding, Certified to AWS D1.1 and ISO 3834 |

| Materials | Carbon Steel, Stainless Steel (304, 316), Aluminum (5052, 6061, 7075), Brass, Copper |

| Finishing | Deburring, Grinding, Polishing, Powder Coating, Anodizing, Zinc Plating |

| Quality Control | ISO 9001:2015 Certified, CMM, 3D Scanning, First Article Inspection, PPAP Support |

We deliver fully documented quality reports, material certifications, and production traceability with every order—ensuring full compliance with your regulatory and audit requirements. Our logistics team coordinates sea and air freight with consolidated shipping options to major US ports, minimizing lead times and customs delays.

For American metal fabricators seeking precision, scalability, and cost efficiency, Wuxi Lead Precision Machinery is your trusted offshore extension. Contact us today at [email protected] to discuss your next project and receive a detailed capability packet and sample quote.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.