Technical Contents

Engineering Guide: Clear Molding

Engineering Insight: Clear Molding in High-Precision Metal Manufacturing

In the realm of advanced metal manufacturing, the term clear molding refers not to transparency in material, but to the absolute fidelity and dimensional accuracy achieved in the replication of complex geometries through precision molding processes. This concept is critical in sectors where even microns of deviation can compromise performance, safety, or compliance—such as aerospace, defense, and high-end medical device production. At Wuxi Lead Precision Machinery, clear molding is not merely a production goal; it is a standard enforced through rigorous engineering discipline, advanced CNC tooling, and decades of accumulated expertise.

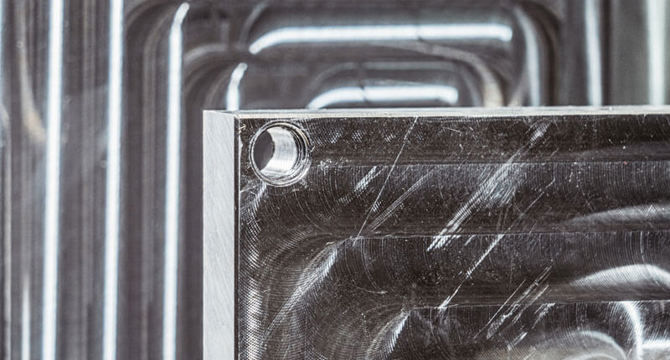

Clear molding demands more than just high-resolution equipment—it requires a holistic understanding of material behavior, thermal dynamics, and tool-path optimization. The process begins with precision die and mold fabrication, where tolerances are maintained within ±0.002 mm. This level of accuracy ensures that every cavity, contour, and surface finish is reproduced identically across production runs, eliminating variability and ensuring seamless integration with downstream components. In mission-critical applications such as military-grade connectors or structural elements used in Olympic-standard sporting equipment, this consistency is non-negotiable.

Wuxi Lead Precision Machinery has been at the forefront of clear molding technology for over 15 years, serving clients in defense logistics, national infrastructure, and international sports engineering. Our involvement in supplying components for Olympic training apparatus underscores our capability in delivering parts that meet global performance benchmarks. Similarly, our work with certified military suppliers has required adherence to MIL-STD and ISO 13485 standards, where traceability, material certification, and repeatable precision are rigorously audited.

Our manufacturing ecosystem integrates multi-axis CNC machining, real-time in-process metrology, and closed-loop feedback systems to maintain molding clarity across extended production cycles. Each mold is subjected to thermal stability testing and surface integrity analysis to ensure long-term performance under operational stress. This engineering-first approach enables us to achieve not only geometric accuracy but also optimal grain structure and mechanical properties in the final metal form.

The following table outlines key performance specifications achieved in our clear molding processes:

| Specification | Value | Testing Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768 |

| Surface Roughness (Ra) | 0.1 – 0.4 µm | ISO 4287 |

| Material Utilization Efficiency | >92% | Internal QA Protocol |

| Tool Life (Average) | 50,000+ cycles | ASTM E292 |

| Production Repeatability (CpK) | ≥1.67 | SPC Control Charts |

At Wuxi Lead Precision Machinery, clear molding is the convergence of precision engineering, advanced technology, and proven application experience. Our track record with high-stakes industries reflects our commitment to delivering metal components where clarity of form translates directly into reliability of function. For OEMs demanding zero-defect performance, we provide not just parts—but engineered certainty.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

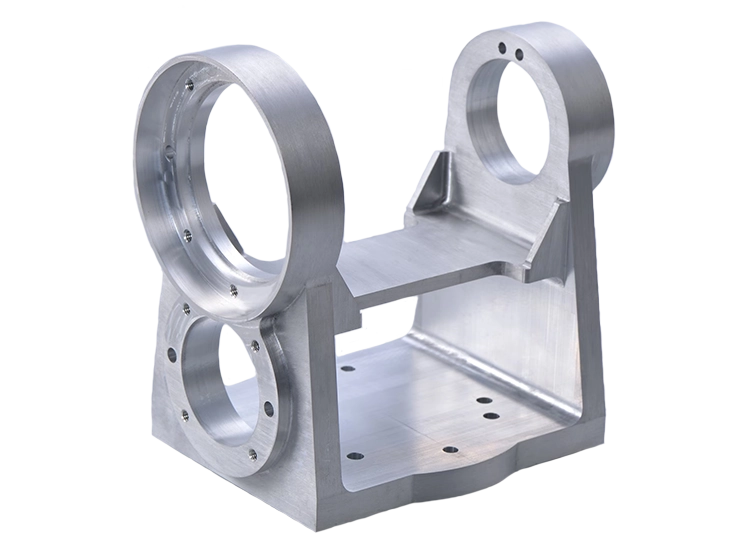

Wuxi Lead Precision Machinery addresses the critical need for ultra-precise metal components, particularly where optical clarity and dimensional perfection are paramount, such as in specialized optical housings, sensor mounts, and fluidic systems requiring transparent sections. While ‘clear molding’ terminology often references polymers, our core expertise lies in delivering the foundational metal structures and precision interfaces that enable high-performance clear component assemblies. We achieve this through advanced metal manufacturing processes, ensuring the rigid, stable, and dimensionally stable platforms required for optical integrity.

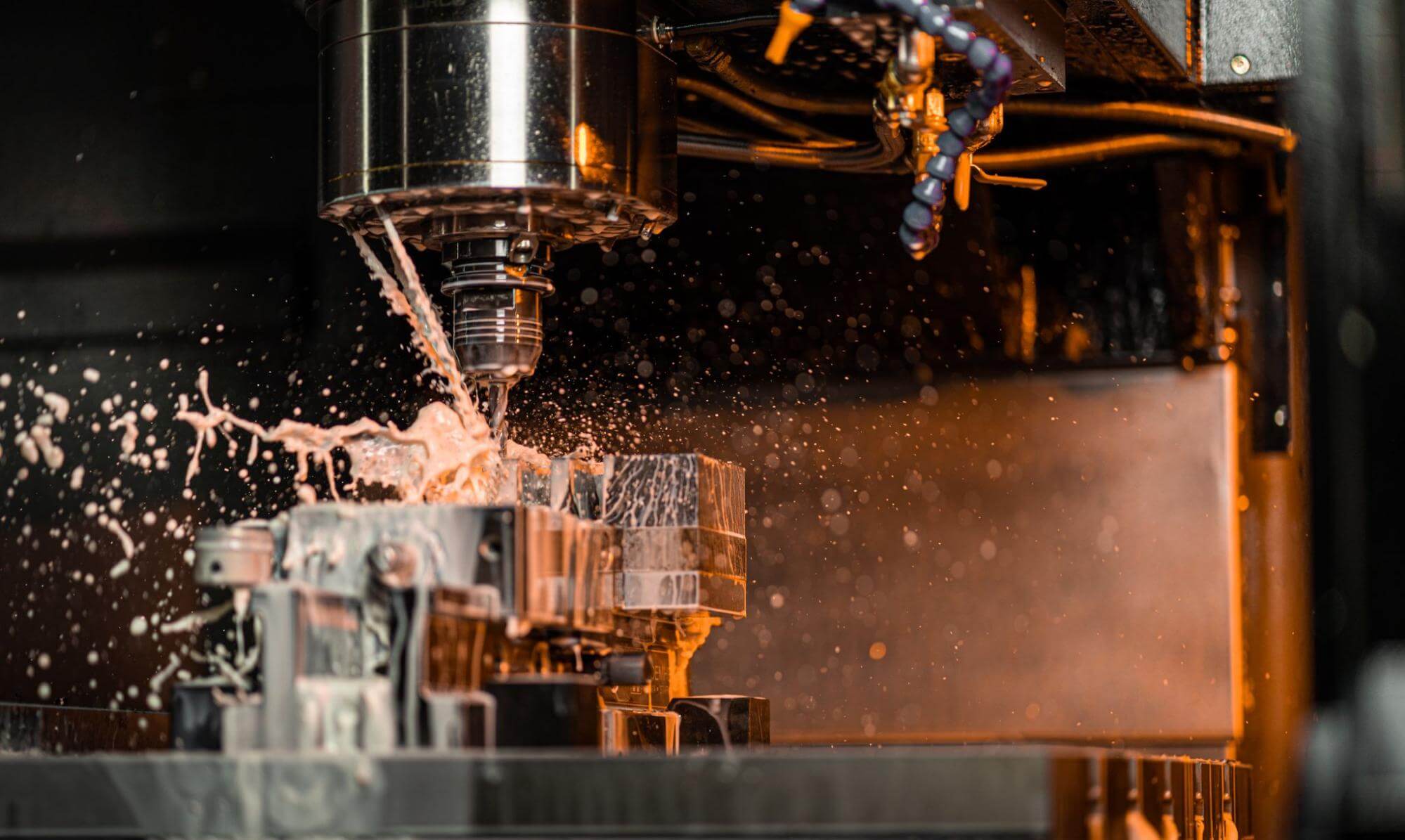

Our primary manufacturing asset is a comprehensive fleet of state-of-the-art 5-axis CNC machining centers. These systems provide simultaneous multi-axis motion, enabling the production of complex geometries, intricate contours, and tight internal features impossible with 3-axis technology. High-torque spindles operating at speeds up to 24,000 RPM ensure exceptional surface finishes and material removal rates across a wide range of metals, including aerospace-grade aluminum alloys, titanium, stainless steels, and engineered copper alloys. Integrated probing systems allow for in-process verification, minimizing setup errors and ensuring consistent part accuracy from the first piece through high-volume production runs. This capability is essential for creating the precisely aligned bores, sealing surfaces, and mounting interfaces critical for optical assemblies.

Rigorous quality control is non-negotiable in precision metal manufacturing. Every critical dimension undergoes verification using certified Coordinate Measuring Machines (CMMs) equipped with advanced tactile and optical sensors. Our inspection protocols adhere strictly to ISO 9001 standards, with full traceability from raw material certification through final inspection reports. CMM data provides comprehensive geometric dimensioning and tolerancing (GD&T) analysis, surface profile validation, and positional accuracy confirmation, ensuring components meet the exacting demands of optical integration and system performance. This systematic approach guarantees first-time-right yield and long-term reliability.

The achievable precision of our metal components is fundamental to system success. The following table outlines typical tolerance capabilities for machined features, reflecting our standard high-precision production level. Achieving the tightest tolerances consistently requires optimized fixturing, process control, and material stability, which are core strengths of our engineering team.

| Feature Category | Standard Production Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.003 mm (±0.0001″) |

| Geometric Tolerances | ±0.015 mm (±0.0006″) | ±0.005 mm (±0.0002″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) |

| Hole Position | ±0.012 mm (±0.0005″) | ±0.005 mm (±0.0002″) |

| Flatness | 0.015 mm (0.0006″) / 100 mm | 0.005 mm (0.0002″) / 100 mm |

Note: Specific tolerances are material, geometry, and feature-size dependent. Tight tolerance capabilities require detailed engineering review and may impact lead time/cost. All measurements traceable to national standards.

Wuxi Lead Precision Machinery delivers the metal foundation for high-performance systems. Our integrated 5-axis CNC manufacturing and metrology-driven quality assurance provide the dimensional certainty and surface integrity necessary for successful integration with clear optical or fluidic elements, ensuring your final assembly meets the highest standards of function and reliability.

Material & Finish Options

Material Selection for Clear Molding Applications in Precision Metal Manufacturing

In high-precision metal manufacturing, particularly for clear molding applications, material selection plays a pivotal role in determining both the performance and aesthetic quality of the final product. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components where clarity, durability, and surface finish are critical. The most commonly used materials in these applications are aluminum, steel, and titanium—each offering distinct mechanical properties and compatibility with finishing processes such as anodizing.

Aluminum is often the preferred choice for clear molding due to its excellent machinability, lightweight nature, and high reflectivity. When paired with clear anodizing, aluminum surfaces achieve a transparent, protective oxide layer that enhances corrosion resistance while preserving the metallic appearance. This makes it ideal for consumer electronics, architectural components, and optical housings where visual precision is as important as structural integrity.

Steel, particularly stainless steel grades such as 304 and 316, provides superior strength and wear resistance. While it cannot be anodized in the traditional sense, steel can undergo electropolishing or passivation to achieve a smooth, cleanable surface suitable for clear coating applications. These treatments improve corrosion resistance and are frequently used in medical devices, food processing equipment, and high-stress industrial molds where hygiene and longevity are paramount.

Titanium stands out for its exceptional strength-to-density ratio and outstanding resistance to extreme environments. Though more challenging to machine, titanium offers excellent performance in aerospace and high-performance automotive applications. When clear anodized, titanium develops a thin, stable oxide layer that not only protects against oxidation but also allows for subtle color interference effects—useful for identification or aesthetic differentiation without compromising transparency.

The decision between these materials must consider not only mechanical and environmental demands but also the intended finish. Clear anodizing, for instance, is most effective on aluminum and titanium, enhancing surface hardness and wear resistance while maintaining visual clarity. For steel, alternative surface treatments are required to achieve similar levels of protection and smoothness.

Below is a comparative overview of key material properties relevant to clear molding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Anodizing Compatibility | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.70 | 310 | Moderate to High | Excellent | Consumer electronics, molds, lighting |

| Stainless Steel 304 | 8.00 | 505 | High | Not applicable (requires passivation) | Medical devices, food equipment |

| Titanium Grade 5 | 4.43 | 895 | Very High | Excellent | Aerospace, performance automotive |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on functional requirements, environmental exposure, and aesthetic goals. Our engineering team ensures that every component meets stringent quality standards, delivering precision and reliability in every clear molding application.

Manufacturing Process & QC

Precision Metal Manufacturing: The Clear Molding Production Process

At Wuxi Lead Precision Machinery, we define “clear molding” not as optical transparency, but as an unambiguous, defect-free manufacturing pathway for complex metal components. This process eliminates ambiguity in production, ensuring absolute dimensional fidelity and surface integrity from initial concept to final shipment. Our rigorous three-phase methodology—Design, Prototyping, Mass Production—is engineered for Zero Defects, critical for aerospace, medical, and semiconductor applications where failure is not an option.

The Design phase begins with deep collaboration. Our engineering team translates your functional requirements into a manufacturable reality using advanced CAD/CAM and simulation tools. Finite Element Analysis (FEA) predicts material behavior under load and thermal cycles, while Mold Flow Analysis optimizes gating and cooling for investment or die casting processes. Critical tolerances, surface roughness parameters (Ra), and material grain structure are defined with micron-level precision. This phase establishes the immutable blueprint; any ambiguity here propagates defects downstream. We validate all digital models against client specifications and material science principles before physical work commences.

Prototyping transforms the digital design into tangible validation. Utilizing our high-precision CNC machining centers and rapid casting capabilities, we produce functional prototypes matching the intended production method. These prototypes undergo exhaustive metrology: Coordinate Measuring Machines (CMM) verify geometric dimensioning and tolerancing (GD&T) to ±0.005mm, surface profilometers confirm Ra values, and non-destructive testing (NDT) like X-ray or fluorescent penetrant inspection checks for internal voids or micro-cracks. Client feedback is integrated immediately. This stage is not merely a sample check; it is the critical stress test of the entire process design, where potential failure modes are identified and eradicated. Only when the prototype meets all specifications with zero deviations do we authorize mass production.

Mass Production executes the perfected process at scale, governed by our Zero Defects Quality Management System. Every stage—from raw material certification and precision casting/machining to heat treatment and final finishing—is monitored in real-time. Statistical Process Control (SPC) tracks key parameters, triggering automatic process adjustments before deviations occur. 100% in-process inspection at critical control points and final batch validation against the approved prototype ensure unwavering consistency. Traceability is absolute, with laser-etched part IDs linking to full production data. This closed-loop system guarantees that every component leaving our Wuxi facility meets the exact specifications validated in prototyping, batch after batch.

Critical Process Specifications at Wuxi Lead

| Parameter | Industry Standard | Wuxi Lead Standard | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.025mm | ±0.005mm | CMM (Calibrated to ISO 10360) |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Profilometer |

| Material Purity | ASTM B247 | Enhanced Vacuum Melt | Spectrographic Analysis |

| Internal Defect Level | Accept Minor Voids | Zero Voids/Cracks | X-ray NDT, MPI |

| Batch Traceability | Lot Level | Per-Part ID | Laser Marking + Digital Log |

This disciplined progression—rigorous design validation, failure-proof prototyping, and intelligently controlled mass production—forms the core of Wuxi Lead’s Clear Molding process. We deliver not just parts, but guaranteed performance, eliminating the cost and risk of defects in your most demanding applications. Partner with us for manufacturing clarity you can measure.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Clear Molding and Custom Metal Manufacturing

When precision, clarity, and performance converge, the results redefine industry standards. At Wuxi Lead Precision Machinery, we specialize in advanced custom metal manufacturing solutions engineered to support high-performance clear molding applications. Our integrated approach combines state-of-the-art CNC machining, tight-tolerance fabrication, and material science expertise to deliver components that ensure optical clarity, structural integrity, and long-term reliability in demanding environments.

Clear molding—often used in medical devices, optical sensors, consumer electronics, and high-end packaging—requires more than just transparent materials. It demands precision tooling, flawless surface finishes, and zero-defect manufacturing processes. Any imperfection in the metal components used in molds or supporting structures can compromise the clarity and functionality of the final product. That’s where Lead Precision excels. We design and manufacture custom metal parts with micron-level accuracy, ensuring compatibility with clear resins, UV stability, and thermal consistency during injection cycles.

Our engineering team works closely with clients from concept to production, offering DFM (Design for Manufacturability) analysis, rapid prototyping, and scalable production runs. Whether you require mold bases, cooling inserts, ejector systems, or custom housings for optical assemblies, we apply advanced materials such as stainless steel, aluminum alloys, and hardened tool steels—each treated and finished to prevent contamination and ensure repeatable performance.

We understand that clear molding applications often operate under strict regulatory and quality requirements. Our facility is ISO 9001 certified, and we maintain full traceability, in-process inspections, and comprehensive quality reporting. Every component is validated using coordinate measuring machines (CMM), surface profilometers, and optical comparators to guarantee compliance with your technical specifications.

Below are key specifications reflecting our manufacturing capabilities for clear molding support components:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.05 µm |

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 650 mm |

| Materials Processed | Stainless Steel (304, 316), Aluminum (6061, 7075), Tool Steel (H13, S136), Titanium |

| Secondary Processes | Passivation, Anodizing, Polishing, PVD Coating |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports, PPAP Level 3 Available |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, precision, and on-time delivery. We don’t just produce parts—we engineer solutions that enhance the performance and manufacturability of your clear molding systems.

For technical consultations or to request a quote, contact us at [email protected]. Let’s build the future of clarity, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.