Technical Contents

Engineering Guide: Pro Rib Steel

Engineering Insight: The Critical Role of Precision in Pro Rib Steel Fabrication

Pro rib steel components represent the backbone of demanding structural applications where failure is not an option. These precision-engineered stiffening elements, integral to aerospace frames, heavy machinery chassis, and critical infrastructure like stadium roofs, demand dimensional accuracy far beyond standard fabrication. Minute deviations in rib profile, curvature, or mounting interface directly compromise structural integrity, load distribution, and fatigue life. At Wuxi Lead Precision Machinery, we understand that in high-stakes environments, tolerances measured in tenths of a millimeter are not merely specifications – they are non-negotiable requirements for safety and performance. Our decades of experience in mission-critical manufacturing, including components for Olympic venue construction and classified military systems, instill a zero-defect culture where precision is engineered into every process step, from raw material certification through final inspection.

Achieving the requisite precision in pro rib steel necessitates a holistic approach. It begins with advanced CNC multi-axis machining centers capable of maintaining sub-0.05mm tolerances under heavy cutting loads, coupled with rigorous thermal compensation systems. Material selection and traceability are paramount; we utilize only certified high-strength low-alloy steels with documented chemical and mechanical properties. Sophisticated fixturing, designed using FEA to prevent workpiece distortion during machining, ensures geometric fidelity. Real-time in-process metrology, including laser trackers and CMM verification at critical stages, provides immediate feedback for process correction. Surface finish control is equally vital, as micro-irregularities can initiate stress fractures under cyclic loading. This level of control is not accidental; it is the direct result of our institutional knowledge gained from projects where absolute reliability was mandated, such as seismic-resistant structures for major international sporting events and propulsion components for advanced defense platforms.

The performance gap between standard and precision-engineered pro rib steel is quantifiable. Our stringent internal standards consistently exceed typical industry benchmarks, directly translating to enhanced component lifespan and system safety. Below is a comparison of critical specifications achievable through our specialized processes:

| Specification Parameter | Typical Industry Standard | Wuxi Lead Precision Standard | Measurement Method |

|---|---|---|---|

| Profile Tolerance (per meter) | ±0.50 mm | ±0.05 mm | CMM / Laser Scanner |

| Angular Accuracy | ±0.5° | ±0.1° | Precision Angle Gauge |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Surface Profilometer |

| Flatness (Critical Faces) | 0.20 mm | 0.03 mm | Optical Flat / CMM |

| Material Traceability | Mill Cert Only | Full Heat Lot + In-House Verification | Certified Lab Reports |

Partnering with a manufacturer possessing demonstrable experience in the most exacting applications provides assurance that your pro rib steel components will perform flawlessly under extreme conditions. Wuxi Lead Precision Machinery leverages its Olympic and military-grade engineering discipline to deliver pro rib steel solutions where precision isn’t just a metric – it’s the foundation of structural trust. This commitment ensures your critical assemblies achieve maximum operational longevity and safety, meeting the uncompromising demands of modern high-performance engineering.

Precision Specs & Tolerances

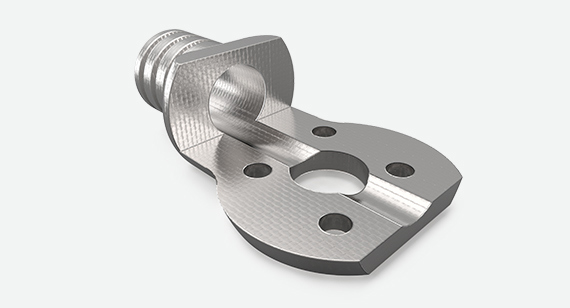

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components from a single setup. This advanced machining method allows for superior geometric accuracy, reduced lead times, and minimized human error by eliminating the need for multiple fixturing stages. Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time monitoring software, ensuring consistent material removal rates and surface integrity across a wide range of alloys, including titanium, Inconel, stainless steel, and hardened tool steels.

Complementing our machining capacity is a rigorous quality control infrastructure anchored by a state-of-the-art Coordinate Measuring Machine (CMM) inspection system. Every critical component undergoes full dimensional validation using a Zeiss CONTURA G2 CMM, which provides micron-level measurement accuracy across three-dimensional geometries. The CMM system is integrated with PC-DMIS software, enabling automated inspection routines, statistical process control (SPC) reporting, and full traceability for every production batch. This ensures that all parts meet or exceed customer-specified GD&T requirements and international standards such as ISO 2768 and ASME Y14.5.

Our manufacturing environment is climate-controlled and ISO 9001:2015 certified, supporting stable thermal conditions essential for maintaining micron-level tolerances. In-house material testing, first-article inspection, and continuous process validation are standard procedures across all production runs. We specialize in low-to-medium volume production with rapid prototyping capabilities, supporting clients from design validation through full-scale manufacturing.

The following table outlines the standard technical specifications and achievable tolerances at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (ISO 2768) | m (medium) to f (fine) class |

| Geometric Tolerance (GD&T) | ±0.01 mm for form and position |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finish) |

| Minimum Feature Size | 0.5 mm (internal radii, slots) |

| Max Work Envelope | 1,200 x 800 x 600 mm (X-Y-Z) |

| Materials Supported | Steel, Stainless Steel, Aluminum, Titanium, Inconel, Brass, Plastics (PEEK, Delrin) |

| Inspection Equipment | Zeiss CMM, Optical Comparator, Micrometers, Calipers, Surface Roughness Tester |

| Reporting | Full FAI, SPC, CMM Inspection Reports (PDF/Excel) |

All projects are supported by our engineering team, who collaborate directly with clients to optimize part design for manufacturability, ensuring performance, cost-efficiency, and compliance with industry-specific regulatory requirements.

Material & Finish Options

Material Selection for Precision Ribbed Structural Components

Selecting the optimal material for precision ribbed structural components demands rigorous evaluation of mechanical properties, environmental exposure, and lifecycle costs. At Wuxi Lead Precision Machinery, we prioritize engineering integrity over generic recommendations. “Pro rib steel” denotes a structural application—not a material grade—requiring tailored alloy selection based on load dynamics, weight constraints, and corrosion challenges. Below we compare three core material families for high-stakes industrial use.

Aluminum alloys, particularly 6061-T6 and 7075-T73, deliver exceptional strength-to-weight ratios ideal for aerospace or mobile equipment ribs. Their natural corrosion resistance reduces maintenance in humid or marine settings, though surface hardness remains inferior to steel. Steel variants like 4140 chrome-molybdenum or 304 stainless dominate high-load static structures due to superior tensile strength and fatigue resistance. Carbon steel ribs require protective finishes in corrosive environments, while stainless grades (316L) justify premium costs in chemical processing. Titanium Ti-6Al-4V excels in extreme conditions—think offshore energy or defense—where weight savings, non-magnetic properties, and immunity to saltwater degradation outweigh its machining complexity and cost.

Surface finishing critically extends component service life. Anodizing is exclusive to aluminum, creating a wear-resistant oxide layer that enhances corrosion protection and allows color coding for assembly. Type II (sulfuric acid) anodizing suits general industrial ribs, while Type III (hardcoat) is mandatory for high-abrasion zones. Note that steel ribs require alternative treatments: powder coating for chemical resistance or zinc-nickel plating for salt-spray endurance. Titanium benefits from chemical passivation but rarely needs anodizing in structural roles.

Material specifications must align with your operational thresholds. Refer to the comparative analysis below:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Typical Rib Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Excellent (A) | Drone frames, transport ribs |

| Steel 4140 | 7.85 | 655 | Low (uncoated) | Good (B) | Industrial machinery bases |

| Stainless 316L | 8.0 | 570 | High | Fair (C) | Marine platform supports |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional | Poor (D) | Subsea robotics, jet engine |

Never default to material assumptions. A 15% weight saving with aluminum may compromise rigidity in high-vibration scenarios, while titanium’s cost could be unjustified for indoor applications. Wuxi Lead’s engineering team conducts free feasibility assessments—share your load diagrams and environmental specs. We validate material-performance alignment through FEA simulation before quoting, preventing costly redesigns. Remember: the right material isn’t the strongest or lightest—it’s the one that optimizes total cost of ownership for your specific rib geometry and duty cycle. Partner with us to transform material science into structural certainty.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production journey for pro rib steel components begins with an engineered design phase that integrates client specifications with advanced simulation tools. Our engineering team collaborates directly with clients to interpret structural requirements, load conditions, and dimensional constraints. Utilizing CAD/CAM software such as SolidWorks and AutoCAD, we generate 3D models that precisely define rib geometry, flange dimensions, and mounting features. Finite Element Analysis (FEA) is applied to validate structural integrity under operational stress, ensuring compliance with international standards including ISO 9001 and GB/T 19001. This phase also includes material selection—typically high-strength low-alloy (HSLA) steel or Q355 series—matched to environmental and performance demands. All design outputs are documented and submitted for client approval, establishing a traceable baseline for subsequent stages.

Prototyping: Validating Performance Before Scale

Once the design is finalized, a functional prototype is manufactured under controlled workshop conditions. This stage employs CNC-controlled laser cutting, precision press braking, and automated welding systems to replicate production-level accuracy. The prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify geometric fidelity within ±0.1 mm tolerance. Mechanical testing, including tensile strength and bend tests, confirms material and weld integrity. Any deviations are analyzed through root cause assessment, and design or process adjustments are implemented before progression. Client feedback is integrated at this stage, ensuring alignment with application-specific expectations. The approved prototype serves as the golden sample for mass production, minimizing downstream variance.

Mass Production: Zero Defects Through Systematic Control

Our mass production process is built on lean manufacturing principles and a zero-defect philosophy. Each pro rib steel unit is fabricated using synchronized CNC workflows that ensure repeatability across batches. Laser cutting systems with automatic material feeding maintain cut accuracy, while robotic welding cells apply consistent weld parameters monitored in real time. Every component passes through an inline quality gate where visual inspection, dimensional checks, and non-destructive testing (NDT) such as ultrasonic and magnetic particle inspection are performed. Process data—including machine settings, material lot numbers, and inspection results—are logged in our Manufacturing Execution System (MES) for full traceability. Final assemblies are subjected to load simulation where applicable, and packaging is executed to prevent deformation during transit.

| Specification | Detail |

|---|---|

| Material Options | Q235, Q355, S355JR, HSLA Steel |

| Thickness Range | 3–16 mm |

| Length Tolerance | ±0.5 mm per meter |

| Angular Accuracy | ±0.3° |

| Surface Finish | Shot-blasted, primed (optional) |

| Weld Standards | ISO 5817, GB/T 12470 |

| Quality Certification | ISO 9001, ISO 14001, CE |

Through integrated design validation, prototype verification, and disciplined mass production, Wuxi Lead ensures every pro rib steel component meets the highest benchmarks in precision, durability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Pro Rib Steel Manufacturing

In the high-stakes arena of structural steel fabrication, pro rib components demand absolute precision in geometry, material integrity, and dimensional stability. Wuxi Lead Precision Machinery stands as your engineered solution for mission-critical pro rib steel production. We merge decades of metallurgical expertise with advanced CNC-driven processes to transform complex specifications into flawless, high-tolerance components. Our ISO 9001-certified facility operates under stringent aerospace and heavy industrial quality protocols, ensuring every rib profile meets or exceeds global structural standards. When tolerances are measured in microns and load-bearing performance is non-negotiable, our integrated engineering-to-manufacturing workflow eliminates guesswork and production bottlenecks.

We specialize in overcoming the unique challenges of pro rib steel: managing thermal distortion during forming, achieving consistent flange rigidity, and maintaining surface integrity for welding or coating adhesion. Our technical team collaborates with your engineers from initial CAD validation through final inspection, leveraging finite element analysis (FEA) to preempt stress points and optimize material utilization. This proactive partnership reduces prototyping cycles by up to 40% while guaranteeing repeatability across volumes—from single prototypes to annual production runs exceeding 50,000 units.

Our technical capabilities are engineered for the demanding requirements of pro rib applications. The table below details our core manufacturing parameters for structural steel components:

| Specification Category | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Grades | Q235B, Q355B, ASTM A36, S355JR, Custom Alloys | EN 10025, GB/T 700, ASTM A6/A6M |

| Dimensional Tolerance | ±0.005mm (CNC Milling), ±0.1° (Bending) | ISO 2768-mK, GD&T ASME Y14.5 |

| Max. Work Envelope | 3,000mm (L) × 1,500mm (W) × 800mm (H) | Custom Fixturing Available |

| Surface Finish | Ra 0.8µm (Machined), Shot-Peened Options | ISO 1302, SSPC-SP6 |

| Certifications | Material Traceability, PMI Testing, 3.1 Mill Certs | EN 10204, API Q1, CE |

This precision is sustained through our investment in 5-axis DMG MORI machining centers, Amada press brakes with laser in-process gauging, and Zeiss CMM validation systems. Every pro rib component undergoes rigorous in-process metrology, including ultrasonic testing for internal discontinuities and coordinate measuring machine (CMM) verification against your 3D model. We do not merely manufacture parts—we deliver certified structural assurance.

Initiate your pro rib steel project with an engineering consultation tailored to your application’s mechanical and environmental demands. Contact our technical sales team directly at [email protected] to submit drawings for rapid feasibility analysis and a bound capacity schedule. Include your target volume, material specifications, and critical tolerance zones for a comprehensive quotation within 72 hours. For urgent requirements, reference “PRO RIB URGENT” in your subject line to activate our priority engineering response protocol.

Wuxi Lead Precision Machinery operates at the intersection of metallurgical science and industrial execution. Partner with us to convert structural steel challenges into competitive advantages—where precision isn’t a claim, but a documented output. Your next-generation pro rib assembly starts with a single email. Reach out today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.