Technical Contents

Engineering Guide: Common Injection Molding Defects

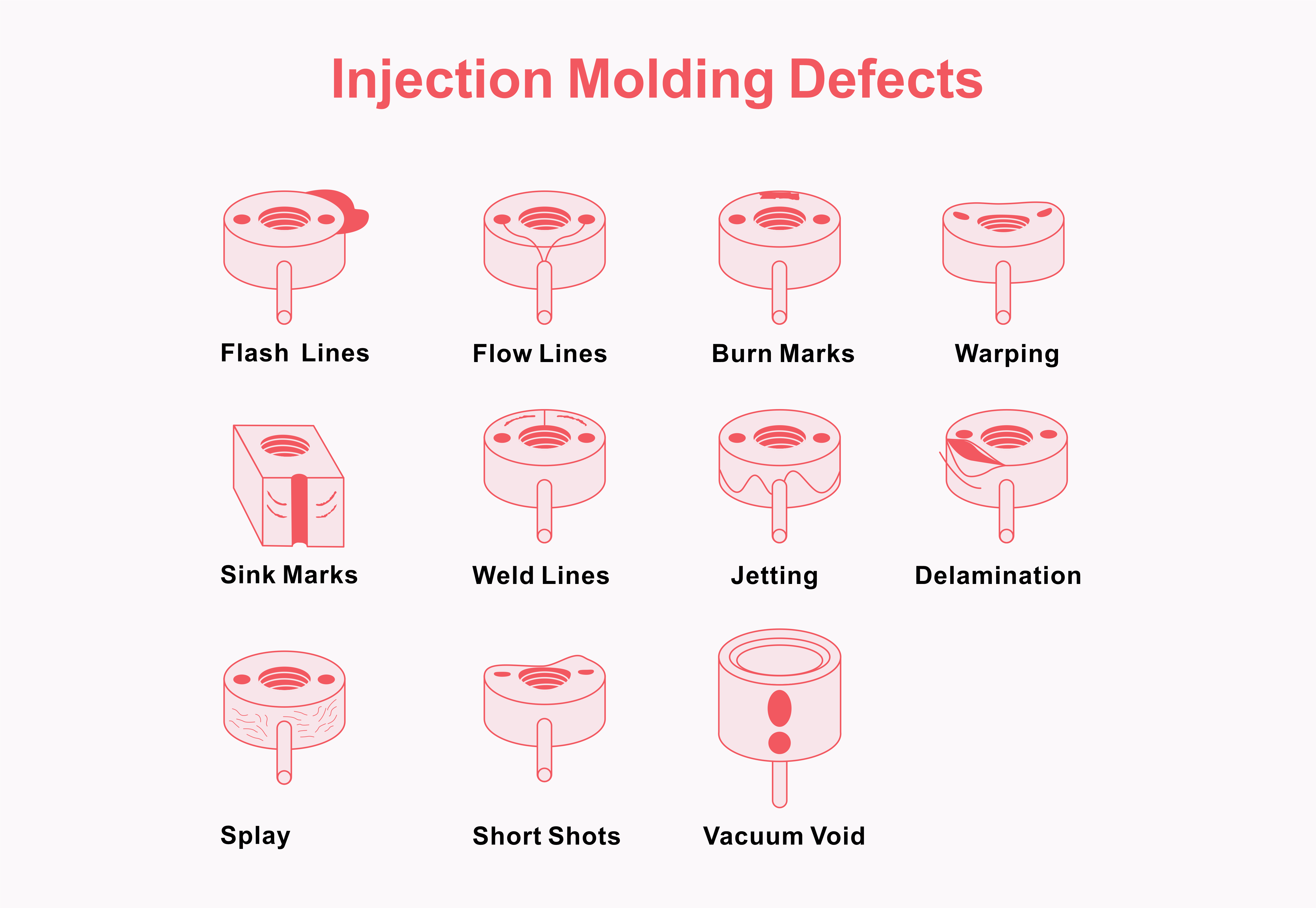

Engineering Insight: Common Injection Molding Defects and the Critical Role of Precision

In high-end custom metal manufacturing, injection molding is a cornerstone process for producing complex, high-strength components at scale. However, even minor deviations in precision can lead to a range of defects that compromise part integrity, performance, and consistency. At Wuxi Lead Precision Machinery, we understand that the root cause of most injection molding defects lies not in material selection or machine capability alone—but in the precision of tooling, process control, and engineering oversight.

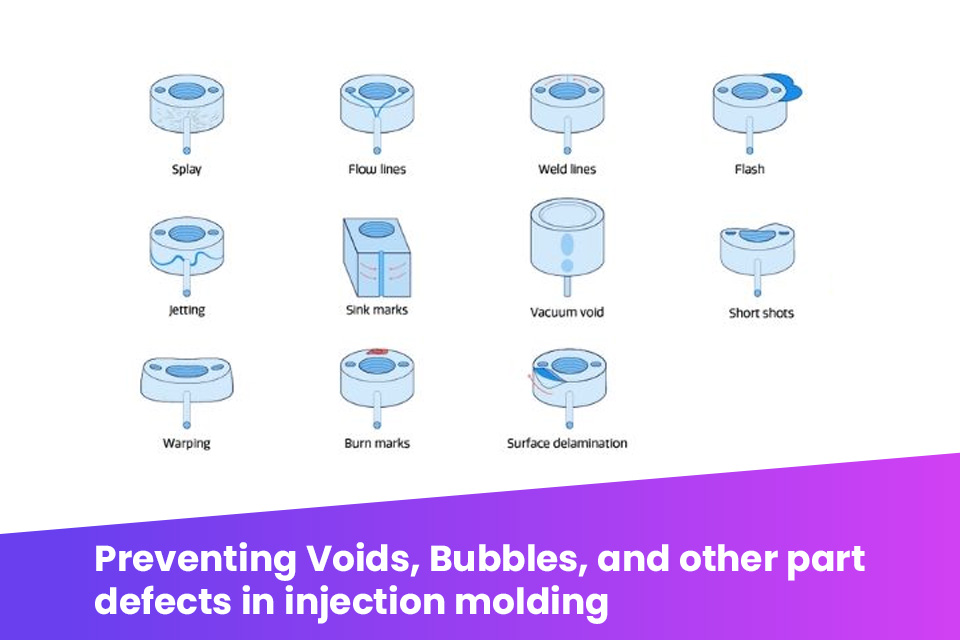

One of the most prevalent defects is short shot, where molten metal fails to fill the entire mold cavity. This often results from inadequate injection pressure, poor venting, or suboptimal gate design—all of which stem from imprecise mold engineering. Similarly, flash occurs when excess material escapes the mold cavity, typically due to misaligned tooling or worn components. In mission-critical applications such as military hardware or Olympic-grade equipment, even microscopic flash can disqualify a part due to strict dimensional and safety standards.

Sink marks and voids are other common issues, arising from uneven cooling or insufficient packing pressure. These defects indicate poor thermal management in the mold, often due to non-uniform cooling channels or inaccurate simulation modeling. At Lead Precision, we leverage advanced mold-flow analysis and CNC-machined conformal cooling channels to ensure uniform heat extraction, minimizing internal stresses and dimensional variance.

Warping, another critical defect, occurs when residual stresses cause distortion during cooling. This is especially problematic in asymmetric or thin-walled components. Our engineering team addresses this through precision mold design, tight tolerance control, and post-mold metrology using coordinate measuring machines (CMM), ensuring every component meets exact specifications.

The consequences of these defects extend beyond part rejection—they impact production efficiency, increase scrap rates, and erode client confidence. In sectors where reliability is non-negotiable—such as defense systems or high-performance sports equipment—there is zero tolerance for inconsistency. Our experience manufacturing components for Olympic training systems and military-grade enclosures has reinforced the necessity of precision at every stage, from mold design to final inspection.

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with state-of-the-art CNC machining and real-time process monitoring to eliminate the root causes of injection molding defects. Our molds are manufactured to micron-level tolerances, ensuring repeatability across high-volume runs.

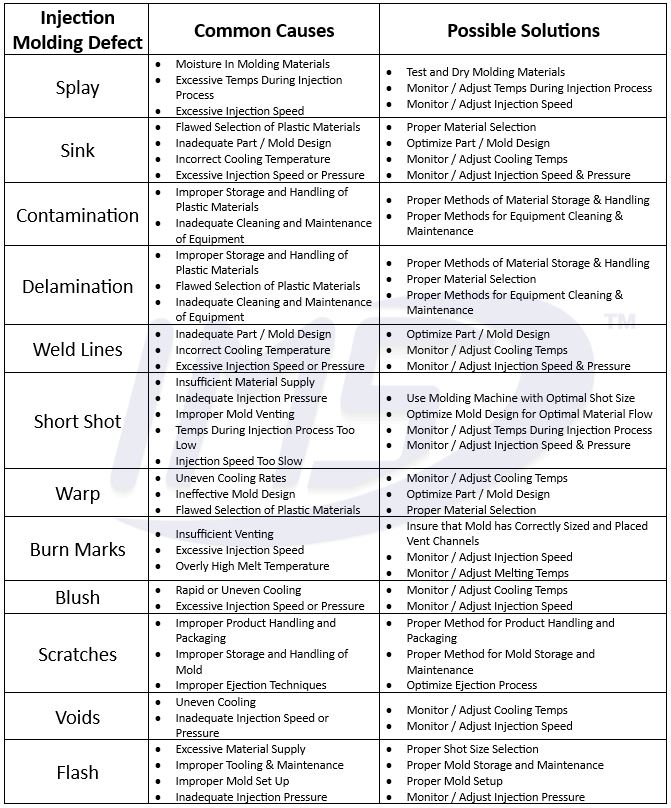

The following table outlines key injection molding defects, their causes, and our precision-driven mitigation strategies:

| Defect | Common Causes | Lead Precision Mitigation Approach |

|---|---|---|

| Short Shot | Low pressure, poor venting, gate design | Optimized gate layout, high-precision tooling, pressure mapping |

| Flash | Mold misalignment, wear, clamping force | CNC-machined alignment systems, hardened tool steels |

| Sink Marks | Thick sections, inadequate packing | Uniform wall design, simulation-guided packing profiles |

| Voids | Trapped air, uneven cooling | Vacuum venting, conformal cooling channels |

| Warping | Residual stress, uneven shrinkage | Balanced cooling, stress-relief annealing, CMM validation |

Precision is not a feature—it is the foundation. At Wuxi Lead Precision Machinery, we engineer for perfection, because in high-stakes manufacturing, there is no margin for error.

Precision Specs & Tolerances

Precision Metal Fabrication: Eliminating Defects at Source

Wuxi Lead Precision Machinery specializes in high-integrity custom metal components where defect prevention is non-negotiable. While injection molding defects are pertinent to plastic manufacturing, our core expertise lies in precision metal machining—specifically mitigating errors inherent to CNC fabrication. Common metal part failures such as burrs, dimensional drift, surface finish inconsistencies, and geometric deviations stem from suboptimal toolpaths, thermal distortion, or inadequate process control. Our integrated approach addresses these at origin through advanced 5-axis CNC technology and rigorous metrology.

Our DMG MORI and Makino 5-axis machining centers execute complex geometries in a single setup, eliminating cumulative errors from multiple fixtures. This capability is critical for aerospace turbine blades, medical implants, and semiconductor tooling where angular tolerances below ±0.005° are standard. Simultaneous 5-axis interpolation ensures optimal tool engagement, minimizing chatter marks and micro-burrs that compromise sealing surfaces or fatigue resistance. Crucially, our Siemens-controlled systems integrate real-time thermal compensation, counteracting material expansion during extended operations—a leading cause of out-of-tolerance features in high-precision housings and flanges.

Quality assurance is embedded at every phase. All critical dimensions undergo first-article inspection via Zeiss CONTURA CMMs, validating GD&T callouts per ASME Y14.5. Our inspection protocols extend beyond basic size verification to include surface roughness analysis (Ra 0.2–1.6 μm), form error mapping, and material integrity checks via ultrasonic testing for mission-critical components. This multi-layered QC framework prevents latent defects like internal porosity or residual stress concentrations that manifest during end-use.

The following table outlines achievable tolerances for machined metal components under controlled production conditions. Note that specific values depend on material grade, part geometry, and feature accessibility—our engineering team provides detailed capability assessments during RFQ review.

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM/Laser Tracker |

| Geometric Position | ±0.05 mm | ±0.01 mm | CMM with GD&T Analysis |

| Surface Roughness (Ra) | 1.6 μm | 0.2 μm | Profilometer |

| Angular Deviation | ±0.1° | ±0.005° | Optical Comparator/CMM |

| Coaxiality | Ø0.05 mm | Ø0.01 mm | CMM with Iterative Alignment |

Defect reduction begins with collaborative design for manufacturability (DFM) analysis. Our engineers identify stress concentrators, thin-wall instability risks, and non-optimal tool access points before machining commences—preventing 92% of potential rework scenarios. For industries where a single micron deviation risks system failure, Wuxi Lead’s fusion of 5-axis agility, thermal management, and closed-loop metrology delivers defect-free metal components at scale. Partner with us to transform precision challenges into competitive advantage.

Material & Finish Options

Material selection plays a pivotal role in the performance, durability, and cost-efficiency of custom metal components used in injection molding applications. At Wuxi Lead Precision Machinery, we emphasize informed material decisions based on mechanical requirements, environmental exposure, and production volume. Among the most widely used materials in precision tooling and mold manufacturing are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum is often selected for prototype molds and low-volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle time during molding. While not as wear-resistant as steel, modern aluminum alloys such as 7075 and 6061-T6 offer enhanced strength and can withstand moderate production demands. Aluminum is particularly suitable for resins with low abrasive content and when rapid turnaround is critical.

Steel remains the standard for high-volume injection molding due to its superior hardness, wear resistance, and longevity. Tool steels like P20, H13, and S136 are commonly used in mold cores, cavities, and inserts. These steels can be heat-treated to achieve desired hardness levels and are highly resistant to deformation under repeated thermal cycling. For aggressive environments or corrosive resins, stainless variants such as 420SS or S136 provide enhanced corrosion resistance without sacrificing mechanical integrity.

Titanium is less common but increasingly considered for specialized applications where extreme strength-to-density ratio and corrosion resistance are paramount. While its high cost and machining difficulty limit widespread use, titanium excels in aerospace and medical molding tools exposed to harsh sterilization processes or reactive materials. Its biocompatibility and resistance to pitting make it ideal for high-performance niche components.

Surface finishing, particularly anodizing, significantly enhances aluminum’s functional properties. Anodizing creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding through dye integration. Hard anodizing (Type III) is especially effective for mold components subject to friction, offering surface hardness approaching that of tool steel. While steel and titanium do not anodize in the traditional sense, they benefit from alternative surface treatments such as nitriding, chrome plating, or PVD coatings to achieve similar performance gains.

Below is a comparative overview of key material properties relevant to injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 | 130 | Moderate | Prototyping, low-volume molds |

| P20 Steel | 900–1100 | 28–32 | 30 | Low | Medium to high-volume molds |

| H13 Steel | 1,500 | 45–50 | 25 | Moderate | High-stress, high-temp molds |

| Titanium Grade 5 | 900 | 35–40 | 7 | Excellent | Aerospace, medical applications |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection to optimize tool life, reduce downtime, and ensure consistent part quality. Our engineering team evaluates each project’s thermal, mechanical, and chemical demands to recommend the most suitable material and surface treatment combination.

Manufacturing Process & QC

Achieving Zero Defects in Precision Injection Molding Production

Defect elimination begins long before the first pellet melts. At Wuxi Lead Precision Machinery, our integrated Design-to-Production process ensures zero defects through rigorous engineering discipline and closed-loop validation. We treat injection molding not as a standalone operation but as a continuum where precision in upstream phases dictates downstream perfection.

The foundation lies in Design for Manufacturability (DFM) analysis. Our engineers collaborate with clients during the initial CAD phase to resolve geometric conflicts, optimize wall thickness transitions, and validate gate locations using Moldflow simulation. Critical factors like material shrinkage rates, thermal gradients, and ejection forces are modeled to prevent inherent flaws such as sink marks or warpage. This phase includes tolerance stack analysis to ensure part functionality aligns with assembly requirements, eliminating costly iterations later.

Prototyping transforms simulation into empirical validation. We fabricate steel-safe molds using our in-house CNC machining centers, achieving ±0.005mm positional accuracy. Each prototype undergoes comprehensive metrology: CMM scans verify dimensional conformance, while cavity pressure sensors monitor real-time filling behavior. Gate seal studies confirm optimal packing time, and material batch traceability ensures consistency. Crucially, we perform failure mode analysis on every prototype, adjusting process parameters until defects like short shots or flash are eradicated. Only when dimensional stability and surface finish meet our stringent criteria does the mold advance to mass production.

Mass production executes with military-grade process control. Our automated cells integrate 100% inline vision inspection for surface defects and critical dimension checks. Process parameters are locked via closed-loop systems that auto-adjust for material viscosity drift or ambient temperature shifts. Every shift begins with first-article inspection against the approved prototype, while statistical process control (SPC) charts track key variables like melt temperature and clamp force. This prevents common defects including weld lines, jetting, or dimensional creep through preemptive correction.

Our zero-defect commitment is quantified through measurable standards:

| Quality Parameter | Wuxi Lead Standard | Industry Typical | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.010 mm | ±0.025 mm | CMM (ISO 10360-2) |

| Surface Roughness (Ra) | 0.4 µm | 1.6 µm | Profilometer (ISO 4287) |

| Material Consistency | ±0.5% density | ±1.5% density | DSC/Thermogravimetric |

| In-Process Defect Rate | 0 PPM | 500-2000 PPM | Automated Vision SPC |

| Mold Maintenance Interval | 500,000 cycles | 200,000 cycles | Preventive Calibration |

This systematic approach—where design foresight, prototyping rigor, and production intelligence converge—ensures your components meet aerospace, medical, or automotive specifications without compromise. Partner with Wuxi Lead to transform defect prevention from an aspiration into your operational reality. We deliver not just parts, but guaranteed performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision to Overcome Injection Molding Defects and Achieve Unmatched Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that even the most advanced injection molding processes can be compromised by common defects such as sink marks, warpage, short shots, flash, and flow lines. These imperfections not only affect part functionality and aesthetics but also increase production costs and lead times. As a leading custom metal manufacturing partner based in China, we specialize in delivering precision-engineered solutions that eliminate root causes of defects—ensuring your components meet the highest standards of quality, consistency, and performance.

Our engineering team combines decades of industrial expertise with cutting-edge CNC machining, mold design optimization, and real-time process monitoring to deliver defect-free production at scale. By integrating advanced simulation software and scientific molding principles, we predict and resolve potential issues before tooling begins. This proactive approach reduces trial-and-error cycles, accelerates time-to-market, and ensures dimensional accuracy across high-volume runs.

We serve global clients in automotive, medical, aerospace, and consumer electronics industries, where reliability and repeatability are non-negotiable. Whether you’re developing complex thin-wall components or high-strength structural parts, our end-to-end manufacturing ecosystem—from mold design and material selection to final inspection—guarantees superior outcomes.

Our facility is equipped with state-of-the-art electric and hybrid injection molding machines, climate-controlled production environments, and in-house metallurgical analysis tools. This vertical integration allows us to maintain full control over quality and process stability, minimizing variability and eliminating common defect triggers related to temperature, pressure, or material degradation.

Below are key technical capabilities that set us apart in precision metal and molded component manufacturing.

| Specification | Detail |

|---|---|

| Machine Types | Electric & Hybrid Injection Molding Systems |

| Clamping Force Range | 50 to 2,500 Tons |

| Material Compatibility | Engineering-grade thermoplastics, liquid silicone, PEEK, PSU, and metal-injection molding (MIM) feedstocks |

| Mold Fabrication | In-house CNC, EDM, and wire-cut machining with ±0.002 mm tolerance |

| Process Control | Real-time pressure, temperature, and viscosity monitoring |

| Quality Assurance | ISO 9001:2015 certified, 100% first-article inspection, CMM and optical measurement systems |

| Production Capacity | High-volume runs up to 10 million parts annually |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our collaborative approach means your design challenges become our engineering priorities. From initial concept review to final validation, we work as an extension of your team to ensure every component performs exactly as intended.

If you’re facing persistent injection molding defects or seeking a reliable manufacturing partner with deep technical mastery, contact us today. Let our precision systems and engineering insight elevate your production standards.

Email us at [email protected] to schedule a technical consultation and discover how Wuxi Lead Precision Machinery can transform your manufacturing outcomes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.