Technical Contents

Engineering Guide: Laser Cut Steel Plate

Engineering Insight: Laser Cut Steel Plate – The Foundation of Precision Fabrication

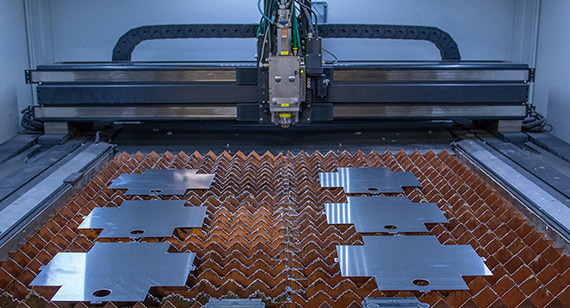

In high-end sheet metal fabrication, the quality of a laser cut steel plate is not merely a matter of dimensional accuracy—it is a fundamental determinant of structural integrity, assembly compatibility, and long-term performance. At Wuxi Lead Precision Machinery, we understand that precision in laser cutting transcends tight tolerances; it encompasses material consistency, edge quality, thermal management, and repeatability across production runs. These factors collectively define the reliability of downstream processes such as bending, welding, and surface finishing.

Laser cutting steel plates demands a balance between power control and motion dynamics. High-powered fiber lasers, when paired with advanced CNC motion systems, enable clean, narrow kerf widths and minimal heat-affected zones (HAZ). This precision is critical in applications where components must interface seamlessly within complex assemblies—particularly in aerospace, defense, and high-load structural systems. At Lead Precision, our investment in state-of-the-art laser platforms ensures micron-level accuracy, even on plates up to 25 mm thick, allowing us to serve clients with mission-critical requirements.

Our engineering team applies rigorous process validation protocols, including real-time beam monitoring, adaptive focus control, and inert gas assist for oxidation-free edges. These measures ensure that every cut meets exact geometric specifications while preserving the metallurgical properties of the base material. Whether working with mild steel, high-strength low-alloy (HSLA) grades, or abrasion-resistant steel, our processes are calibrated to maintain edge squareness, minimize dross, and deliver consistent part-to-part repeatability.

The importance of precision is magnified in large-scale industrial applications. For example, components used in Olympic-grade sporting infrastructure and military-grade mobile platforms require not only exacting dimensional control but also long-term durability under dynamic loads. Wuxi Lead Precision Machinery has been entrusted with such projects, where our laser-cut steel plates formed the backbone of structural frameworks subject to extreme environmental and mechanical stress. These engagements underscore our capability to meet and exceed the most stringent fabrication standards.

We integrate material traceability, in-process inspection, and full documentation into every production batch. This systems-level approach ensures that our clients receive not just parts, but engineered solutions backed by verifiable quality data.

Below are key performance specifications for our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 4000 mm × 15000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Laser Source | Fiber Laser, up to 12 kW |

| Cut Edge Roughness (Ra) | ≤ 6.3 µm (typical) |

| Kerf Width Tolerance | ±0.1 mm |

| Supported Materials | Mild Steel, HSLA, AR400/500, Stainless Steel |

| Gas Assist Options | N₂, O₂, Air (application-specific selection) |

| Lead Time (Standard Batch) | 7–12 working days (varies by complexity) |

Precision in laser cutting is not an isolated operation—it is the starting point of excellence in fabrication. At Wuxi Lead Precision Machinery, we engineer every cut with the final application in mind, delivering steel components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting for Steel Plate Fabrication

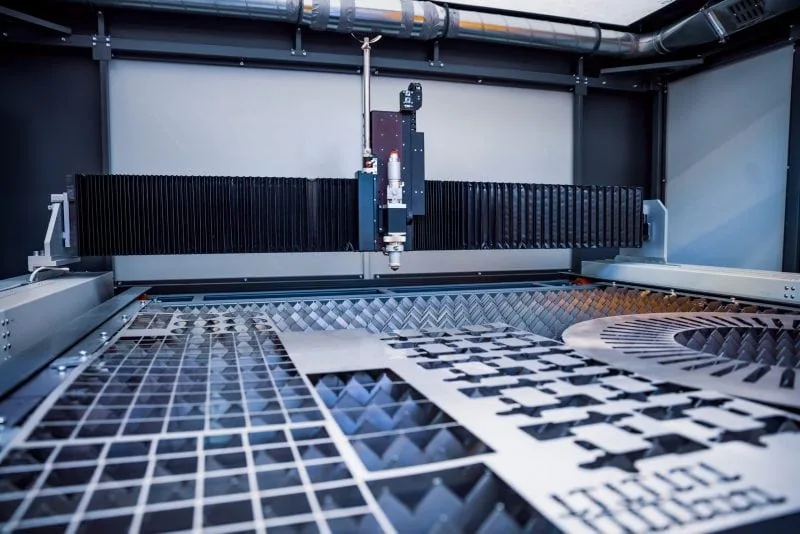

Wuxi Lead Precision Machinery delivers industry-leading precision in laser-cut steel plate fabrication through advanced 5-axis CNC technology and rigorous quality control. Our fiber laser systems, including the Bystronic BySprint Pro and TRUMPF TruLaser 5030, process carbon steel, stainless steel, and aluminum plates up to 25mm thickness with exceptional edge quality and minimal thermal distortion. The 5-axis capability enables complex contour cutting, beveling, and piercing in a single setup, eliminating secondary operations and ensuring geometric accuracy for critical structural and enclosure components. High-pressure nitrogen and oxygen assist gases are precisely regulated to optimize cut quality across varying material grades and thicknesses, achieving surface roughness values consistently below Ra 6.3 µm.

Material handling is integrated via automated pallet systems, supporting continuous 24/7 production for high-volume orders while maintaining tight schedule adherence. All programming leverages Siemens 840D SL and FANUC 31i-B5 controls, with nesting software optimizing material utilization to 95%+ and reducing waste. Crucially, every cut undergoes validation through our coordinate measuring machine (CMM) inspection process. A Zeiss CONTURA G2 CMM with VAST XT gold sensor verifies dimensional conformity against CAD models per ISO 10360-2 standards, measuring critical features such as hole positions, slot widths, and profile deviations. This closed-loop verification ensures first-article approval and batch consistency, with full inspection reports provided for traceability.

Our tolerance performance reflects the synergy of cutting-edge hardware and metrology. The following table details achievable standard tolerances for laser-cut steel plates under controlled production conditions:

| Feature Type | Material Thickness | Tolerance (± mm) | Standard Reference |

|---|---|---|---|

| Linear Dimensions | ≤ 3 mm | 0.05 | ISO 2768-mK |

| Linear Dimensions | 3.1–10 mm | 0.10 | ISO 2768-mK |

| Linear Dimensions | 10.1–25 mm | 0.15 | ISO 2768-mK |

| Hole Diameter | ≤ 10 mm | 0.05 | ISO 2768-fH |

| Hole Diameter | 10.1–30 mm | 0.10 | ISO 2768-fH |

| Angular Features | All Thicknesses | ±0.25° | ISO 2768-c |

| Profile Accuracy | All Thicknesses | 0.10 | ISO 13920-B |

These capabilities are reinforced by a climate-controlled production environment (20±2°C) and operator certification per ISO 9001:2015 protocols. We prioritize dimensional stability in post-cut handling, utilizing non-marring fixtures and stress-relief protocols to prevent warpage. For mission-critical applications, we implement real-time process monitoring with laser power and beam quality sensors, adjusting parameters dynamically to maintain tolerance bands. Partner with Wuxi Lead to transform steel plate specifications into certified, assembly-ready components with uncompromised repeatability.

Material & Finish Options

Material Selection for High-Precision Laser Cut Steel Plate Applications

Selecting the appropriate material for laser cut steel plate components is critical in achieving optimal performance, durability, and cost-efficiency in industrial applications. While the term “laser cut steel plate” often refers broadly to carbon or stainless steel, advanced fabrication projects may also involve aluminum and titanium, depending on mechanical requirements, environmental exposure, and design constraints. At Wuxi Lead Precision Machinery, we support clients in evaluating these materials based on strength, weight, corrosion resistance, and compatibility with finishing processes such as anodizing—particularly relevant when working with non-ferrous metals.

Carbon steel remains the most widely used material in structural and heavy-duty applications due to its high tensile strength and cost-effectiveness. When processed using high-power fiber laser cutting systems, carbon steel plates achieve clean, burr-free edges with tight dimensional tolerances. However, carbon steel is prone to oxidation and typically requires protective coatings such as powder coating or galvanization for outdoor or humid environments.

Stainless steel, particularly grades 304 and 316, offers superior corrosion resistance and aesthetic appeal, making it ideal for food processing, medical, and architectural applications. Its chromium content forms a passive oxide layer that resists rust and staining. Laser cutting stainless steel produces smooth edges suitable for welding and further finishing without extensive post-processing. The material maintains strength at elevated temperatures and performs reliably in aggressive environments.

Aluminum is favored in aerospace, transportation, and electronics industries where lightweight construction and high strength-to-weight ratios are essential. It exhibits excellent thermal and electrical conductivity and responds well to laser cutting, though its high reflectivity requires optimized laser parameters to ensure consistent cut quality. While aluminum cannot be anodized post-laser cutting without masking or secondary treatment, controlled anodizing enhances surface hardness and corrosion resistance—particularly in marine or high-wear settings.

Titanium, though more expensive and challenging to process, delivers exceptional strength, biocompatibility, and resistance to extreme temperatures and corrosive media. It is commonly used in aerospace, defense, and medical implant manufacturing. Laser cutting titanium demands precise control of beam intensity and assist gases to prevent oxidation and maintain material integrity.

Below is a comparative overview of key material properties relevant to laser cutting and finishing:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Anodizing Compatible | Common Grades |

|---|---|---|---|---|---|

| Carbon Steel | 400–550 | 7.85 | Low | No | Q235, Q345 |

| Stainless Steel | 500–700 | 7.90 | High | No | 304, 316 |

| Aluminum | 110–350 | 2.70 | Moderate to High | Yes | 5052, 6061, 7075 |

| Titanium | 900–1,200 | 4.51 | Very High | Yes (special process) | Grade 2, Grade 5 (Ti-6Al-4V) |

Understanding these material characteristics enables informed decisions in sheet metal fabrication. At Wuxi Lead Precision Machinery, we combine advanced laser technology with deep metallurgical expertise to support clients in selecting and processing the optimal material for their application.

Manufacturing Process & QC

Laser Cut Steel Plate Production: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our laser cutting process for steel plates is engineered for uncompromising quality and efficiency, transforming client specifications into flawless components. We adhere to a rigorously controlled three-stage workflow—Design, Prototyping, Mass Production—ensuring zero defects and optimal manufacturability from inception. This systematic approach minimizes waste, accelerates time-to-market, and guarantees consistency for high-volume orders.

The Design phase is foundational. Our engineering team collaborates closely with clients to review CAD files, applying deep expertise in sheet metal fabrication and laser processing physics. We conduct comprehensive Design for Manufacturability (DFM) analysis, focusing on material selection, kerf width compensation, thermal distortion mitigation, and nesting optimization. Critical parameters like lead-ins/outs, pierce points, and part sequencing are meticulously defined to maximize yield and structural integrity. This proactive validation prevents downstream errors, ensuring the digital model is perfectly translated into a physically producible part. Client approval of the finalized cutting program is mandatory before progression.

Prototyping validates the design in reality. Using the exact production-grade laser systems and specified steel grade (e.g., Q235B, Q345B, or stainless variants), we produce a small batch of parts. These undergo stringent dimensional inspection against the CAD model using CMMs and optical comparators, verifying critical tolerances, edge quality (dross levels, squareness), and hole accuracy. Material properties and cut consistency across the plate are assessed. This stage identifies any unforeseen interactions between material behavior and the cutting parameters, allowing immediate program refinement. Only when the prototype meets all specifications and receives client sign-off do we authorize full-scale production.

Mass Production leverages our validated process under a Zero Defects framework. Production runs occur on our high-power fiber or CO2 laser systems, monitored in real-time by integrated sensors tracking power, gas pressure, and nozzle condition. Statistical Process Control (SPC) charts continuously analyze critical dimensions from in-process checks. Every plate undergoes 100% visual inspection for surface defects, while automated edge measurement systems verify dimensional conformity. Material traceability is maintained throughout. Our closed-loop feedback system instantly triggers corrective actions for any parameter drift, preventing non-conforming output. This results in consistent, high-precision parts suitable for demanding applications in aerospace, medical, and automation sectors.

Our core laser cutting capabilities are engineered to support this stringent process:

| Parameter | Specification | Production Capability |

|---|---|---|

| Material Thickness | Carbon Steel | 0.5 mm – 25 mm |

| Stainless Steel | 0.5 mm – 20 mm | |

| Positional Accuracy | ±0.05 mm | |

| Edge Quality | Burr-free, Ra < 6.3 µm (typ.) | |

| Minimum Feature | 0.8 x Material Thickness | |

| Max. Work Envelope | 4000 mm x 2000 mm |

This integrated methodology—where design foresight, physical validation, and defect-proofed volume production converge—delivers exceptional reliability. Wuxi Lead transforms steel plate laser cutting from a simple operation into a strategic asset, ensuring your components arrive perfect, on time, and ready for seamless integration, significantly reducing your total cost of ownership.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Laser Cut Steel Plate Fabrication

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions. As a trusted leader in high-precision sheet metal fabrication, we specialize in delivering laser cut steel plates that meet the most stringent industrial standards. Whether you’re in aerospace, heavy machinery, energy, or advanced automation, your success depends on accuracy, consistency, and speed. That’s where we come in.

Our advanced fiber laser cutting systems, combined with decades of engineering expertise, enable us to process steel plates with exceptional precision—down to ±0.1 mm tolerance. We handle mild steel, stainless steel, and high-strength low-alloy (HSLA) grades, with thicknesses ranging from 0.5 mm to 25 mm. Our automated production lines ensure rapid turnaround without compromising quality, making us the ideal partner for both prototyping and high-volume manufacturing.

What sets Lead Precision apart is our end-to-end control over the fabrication process. From material sourcing and CNC programming to precision cutting and quality assurance, every step is monitored under ISO 9001-certified procedures. Our team of senior CNC engineers and manufacturing specialists collaborates directly with clients to optimize designs for manufacturability, reduce waste, and accelerate time-to-market.

We understand that your projects demand more than just parts—they require reliability, scalability, and technical partnership. That’s why we invest heavily in R&D and maintain one of the most advanced laser cutting fleets in Eastern China. Our Amada and Bystronic laser systems support dynamic piercing, high-speed contouring, and micro-joint cutting for delicate features, ensuring your components perform flawlessly in final assembly.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier. You gain a strategic ally committed to your operational excellence.

Explore how our precision laser cutting capabilities can elevate your manufacturing output. Contact us today at [email protected] to request a quote, share technical drawings, or schedule a virtual factory audit. Our engineering team is ready to support your next project with responsive communication, competitive pricing, and uncompromising quality.

| Specification | Detail |

|---|---|

| Material Types | Mild Steel, Stainless Steel, HSLA Steel |

| Thickness Range | 0.5 mm – 25 mm |

| Laser Cutting Tolerance | ±0.1 mm |

| Max Cutting Area | 4000 mm × 2000 mm |

| Laser Sources | IPG Fiber Lasers (up to 12 kW) |

| Equipment Brands | Amada, Bystronic, Trumpf-compatible systems |

| Quality Standards | ISO 9001:2015 Certified |

| Lead Time (Standard Orders) | 5–12 working days |

| Surface Finish | Burr-minimized, oxide-controlled edges |

| File Formats Accepted | DXF, DWG, STEP, IGES, PDF (with dimensions) |

Reach out now. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.