Technical Contents

Engineering Guide: Mold Parts

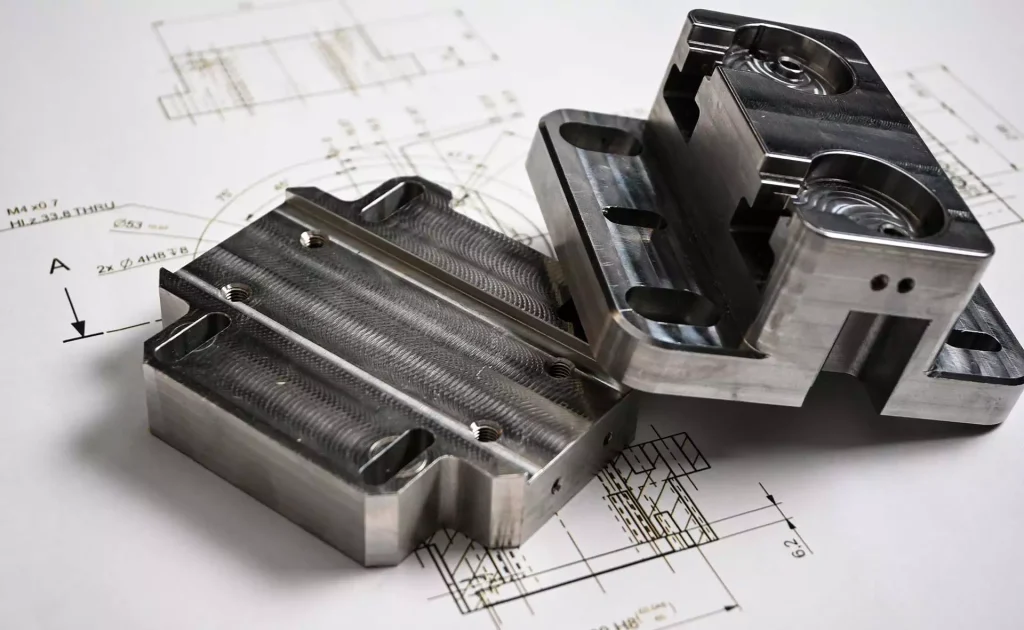

Engineering Insight: The Critical Role of Precision in Mold Parts Manufacturing

In the world of custom metal manufacturing, mold parts represent one of the most technically demanding and precision-sensitive components. These parts serve as the foundational elements in injection molding, die casting, and stamping processes, directly influencing the quality, consistency, and performance of end products across industries such as automotive, aerospace, medical devices, and consumer electronics. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations in mold geometry can result in part defects, reduced tool life, and costly production delays. This is why precision is not merely a target—it is a non-negotiable standard.

Mold parts must endure extreme pressures, thermal cycling, and mechanical stress during operation. Their dimensional accuracy, surface finish, and material integrity directly affect mold alignment, part ejection, cooling efficiency, and overall cycle time. A tolerance deviation of ±0.005 mm may seem negligible, but in high-cavity molds or multi-component assemblies, such discrepancies compound rapidly, leading to flash, warping, or incomplete fills. Moreover, precision in mold construction ensures repeatability across thousands—or even millions—of production cycles, a critical requirement for clients in regulated sectors.

At Wuxi Lead Precision Machinery, our engineering approach integrates advanced CNC machining, coordinate measuring machine (CMM) validation, and finite element analysis (FEA) to optimize mold performance from design through delivery. With over 15 years of specialized experience in high-tolerance metal fabrication, we have supplied mission-critical mold components for projects requiring the highest levels of reliability. Notably, our work has supported precision tooling systems used in Olympic-grade sports equipment manufacturing and defense-grade component production, where failure is not an option.

Our facility in Wuxi operates under strict ISO 9001-certified protocols, utilizing 5-axis machining centers and electrode discharge machining (EDM) to achieve complex geometries with tight tolerances. We specialize in mold bases, cores, cavities, lifters, and inserts made from hardened steels, aluminum alloys, and specialty tooling materials, all machined to meet or exceed international standards.

The following table outlines typical specifications we achieve for custom mold parts:

| Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Maximum Part Weight | 5,000 kg | 2,000 kg |

| Materials Supported | P20, H13, S136, 718H, Aluminum 7075 | Maraging Steel, Titanium Alloys |

| Machining Processes | CNC Milling, Turning, Grinding, EDM | 5-Axis Simultaneous, Micro-EDM |

Precision in mold parts is not just about accuracy—it is about enabling our clients to achieve superior product quality, reduced downtime, and enhanced production efficiency. At Wuxi Lead Precision Machinery, we combine technical excellence with proven experience in high-stakes manufacturing environments to deliver mold solutions that perform under pressure—every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mold Excellence

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the uncompromising demands of high-performance mold manufacturing. We specialize in transforming complex designs into mission-critical mold components with micron-level accuracy, leveraging advanced 5-axis CNC machining centers and rigorous quality control protocols. Our integrated workflow ensures dimensional stability, surface integrity, and repeatability essential for injection, die-casting, and compression molds operating under extreme conditions.

Our core strength lies in the strategic deployment of Makino a500Z 5-axis vertical machining centers, featuring sub-micron repeatability and integrated thermal compensation systems. This technology enables single-setup machining of intricate geometries—such as conformal cooling channels, core pins, and cavity inserts—eliminating cumulative errors from multiple fixturing stages. High-speed spindles (30,000 RPM) and dynamic tool path optimization deliver superior surface finishes while maintaining tight tolerances across diverse materials, including P20, H13, S136, aluminum alloys, and hardened tool steels up to 60 HRC.

Quality assurance is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. Our metrology lab validates critical features—flatness, concentricity, positional accuracy—and generates full-first-article reports with GD&T analysis. Real-time process monitoring via Renishaw probes ensures in-cycle correction, while material traceability and environmental controls (20±0.5°C) guarantee thermal stability during production. This closed-loop system achieves consistent part conformity, reducing scrap rates and accelerating time-to-market for our clients.

The following table details our standard tolerance capabilities, reflecting achievable performance under controlled production conditions:

| Feature Type | Standard Tolerance | Precision Tolerance | Material Applicability | Surface Finish Ra (µm) |

|---|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm | All steels, aluminum, brass | 0.8 (standard) |

| Hole Diameter | ±0.008 mm | ±0.0015 mm | Hardened steels (≤58 HRC) | 0.4 (precision bore) |

| Positional Accuracy | ±0.005 mm | ±0.001 mm | Multi-cavity molds | 0.2 (mirror finish) |

| Flatness | 0.008 mm/m | 0.002 mm/m | Plate components ≥100 mm | 0.1 (optical grade) |

| Angular Features | ±0.005° | ±0.001° | 5-axis contoured surfaces | 0.4 (as-machined) |

We exceed industry benchmarks by integrating design-for-manufacturability (DFM) analysis early in the process. Our engineering team collaborates directly with clients to optimize part geometry, minimize stress concentrations, and validate cooling channel efficiency—ensuring molds achieve maximum cycle life and part consistency. With 15+ years of specialization in automotive, medical, and consumer electronics tooling, Wuxi Lead delivers not just components, but performance-engineered solutions that reduce total cost of ownership. Partner with us for mold parts where precision defines performance.

Material & Finish Options

Material selection is a critical phase in the development of high-performance mold components, directly influencing durability, thermal management, surface finish, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-manufactured custom mold parts tailored to meet the rigorous demands of industries such as automotive, aerospace, medical, and consumer electronics. Our expertise spans the strategic application of aluminum, steel, and titanium—each offering distinct mechanical and thermal properties suited to specific molding environments.

Aluminum alloys, particularly 6061 and 7075, are widely used for prototype molds and low-to-medium volume production due to their excellent machinability and superior thermal conductivity. These properties enable faster cooling cycles, reducing overall cycle time and increasing productivity. While aluminum lacks the wear resistance of steel, its lightweight nature and cost-efficiency make it ideal for applications where rapid turnaround and thermal performance are prioritized.

Steel remains the standard for high-volume production molds. Tool steels such as P20, H13, and S136 offer exceptional hardness, wear resistance, and dimensional stability under prolonged thermal cycling. These characteristics ensure long service life and consistent part quality, especially in injection molding of abrasive or high-temperature materials. Hardened steel molds are essential when tight tolerances and surface integrity must be maintained across tens of thousands of cycles.

Titanium, though less common, is selected for specialized applications requiring high strength-to-density ratio, corrosion resistance, and performance at elevated temperatures. While its use in mold construction is typically limited to inserts or cores due to cost and machining complexity, titanium excels in environments where weight reduction and resistance to chemical degradation are paramount.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional properties of mold components. Anodizing aluminum increases surface hardness, improves wear resistance, and provides electrical insulation. Type II (sulfuric acid) anodizing offers a decorative and protective layer, while Type III (hardcoat anodizing) delivers a thicker, more durable ceramic-like surface capable of withstanding significant mechanical stress. This process also allows for color coding of mold components for easy identification during assembly and maintenance.

Below is a comparative overview of key material properties relevant to mold part performance.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 (HB) | 130 | Prototype molds, low-volume runs |

| P20 Steel | 900–1100 | 28–32 | 30 | High-volume injection molds |

| H13 Steel | 1300–1600 | 45–52 | 35 | Hot work, high-temperature molding |

| Titanium Ti-6Al-4V | 900–950 | 35–40 (HRC) | 7 | Corrosion-resistant inserts, cores |

Selecting the optimal material and finish requires a comprehensive understanding of operational demands, production volume, and environmental conditions. Wuxi Lead Precision Machinery provides engineering consultation to ensure every mold component is manufactured to exacting standards, maximizing performance and lifecycle.

Manufacturing Process & QC

Precision Mold Parts Manufacturing: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our mold parts production process is engineered for absolute reliability, eliminating defects before they impact your production line. We integrate advanced design validation, iterative prototyping, and rigorously controlled mass production to deliver components that meet the most demanding automotive, aerospace, and medical industry standards. Every phase is governed by our Zero Defects philosophy, ensuring your molds perform flawlessly from day one.

The process begins with collaborative design engineering. Our team utilizes 3D CAD/CAM software to simulate mold flow, stress points, and thermal dynamics, identifying potential weaknesses before metal is cut. We enforce ISO 2768-mK geometric tolerances and surface finishes down to Ra 0.05 µm during this stage, aligning precisely with your application’s thermal cycling and wear requirements. Material selection—whether H13 tool steel, S136 stainless, or custom alloys—is validated through finite element analysis to prevent deformation under pressure. This preemptive scrutiny reduces downstream rework by up to 70%.

Prototyping transforms digital models into physical validation. Using 5-axis CNC milling and wire EDM, we produce functional prototypes within 10–15 days. Each prototype undergoes rigorous metrology: CMM inspections cross-verify critical dimensions against CAD data, while pressure testing confirms seal integrity and ejection performance. This phase is non-negotiable; we identify and resolve micro-defects—such as minute sink marks or gate imbalances—that could cause part rejection in mass production. Clients receive detailed deviation reports, enabling joint refinement before tooling commitment.

Mass production leverages our automated, climate-controlled facility to sustain zero-defect output. All components progress through sequential quality gates: in-process laser scanning after roughing, final CMM certification for every batch, and 100% visual inspection under magnification. Statistical process control (SPC) monitors tool wear in real time, triggering automatic tool replacement before tolerances drift. Our closed-loop system ensures batch-to-batch consistency, with traceable material certificates and inspection data archived for your audit compliance.

The table below summarizes our core production capabilities for critical mold components:

| Parameter | Capability | Industry Standard Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ±0.01 mm |

| Surface Roughness (Ra) | 0.05–0.4 µm | 0.8–1.6 µm |

| Material Range | H13, S136, 420SS, Maraging Steel | Standard Tool Steels Only |

| Lead Time (Prototype) | 10–15 days | 20–30 days |

| Max Component Size | 800 x 600 x 500 mm | 600 x 400 x 300 mm |

Zero Defects is not a slogan but a measurable outcome of our integrated workflow. By embedding quality at every stage—from simulation to final packaging—we prevent the catastrophic ripple effects of mold failures: production halts, scrap surges, and delayed time-to-market. Partner with Wuxi Lead to transform your mold specifications into perpetually reliable manufacturing assets. Your success hinges on precision we deliver without compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Mold Parts Manufacturing

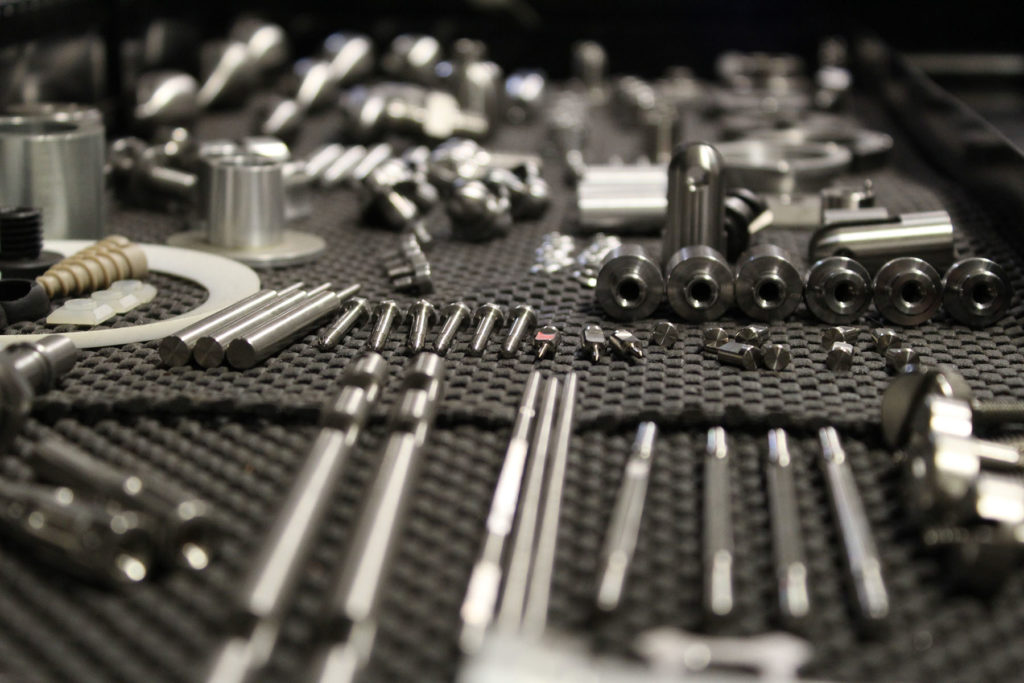

When it comes to high-performance mold components, precision, reliability, and consistency are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions tailored specifically for the mold industry. With over 15 years of experience serving global OEMs, automotive suppliers, and industrial molders, we have built a reputation for engineering excellence, tight-tolerance machining, and on-time delivery — every time.

Our advanced CNC machining centers, combined with rigorous quality control protocols, enable us to produce mold plates, cavities, cores, lifters, ejector systems, and other critical mold components to the most exacting standards. Whether your application demands hardened tool steels, aluminum prototypes, or corrosion-resistant stainless alloys, our team applies material science expertise and precision engineering to ensure optimal performance under real-world production conditions.

We understand that mold performance directly impacts your production efficiency, part quality, and tooling lifespan. That’s why we go beyond standard fabrication — we partner with your engineering team to optimize designs for manufacturability, reduce cycle times, and enhance mold longevity. From initial concept review to final inspection, our collaborative approach ensures seamless integration into your supply chain.

Our facility in Wuxi, China, is ISO 9001:2015 certified and equipped with state-of-the-art 3-, 4-, and 5-axis CNC machines, wire EDM, surface grinding, and CMM inspection systems. This allows us to maintain tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.1 µm, meeting the highest demands of the injection molding, die-casting, and compression molding industries.

Below are key capabilities that define our mold parts manufacturing service

| Specification | Detail |

|---|---|

| Materials | P20, 718H, S136, NAK80, H13, 420SS, Aluminum 6061/7075, Brass, Titanium |

| Tolerances | ±0.002 mm |

| Surface Finish | Ra 0.1 – 3.2 µm (custom finishes available) |

| Max Workpiece Size | 1200 × 800 × 600 mm |

| Machining Centers | 3-axis, 4-axis, 5-axis CNC, Wire EDM, CNC Turning |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, Full CMM Reporting |

| Lead Times | 7–25 days (depending on complexity and volume) |

We are not just a supplier — we are an extension of your engineering and production team. Our technical sales engineers provide responsive communication, detailed progress updates, and full documentation to ensure transparency and traceability across every order.

If you’re seeking a reliable, high-precision partner for custom mold components, look no further than Wuxi Lead Precision Machinery. Contact us today at [email protected] to discuss your next project. Let us help you achieve superior mold performance, reduced downtime, and faster time-to-market.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.