Technical Contents

Engineering Guide: Plastic Injection Mold Tooling

Engineering Insight: The Critical Role of Precision in Plastic Injection Mold Tooling

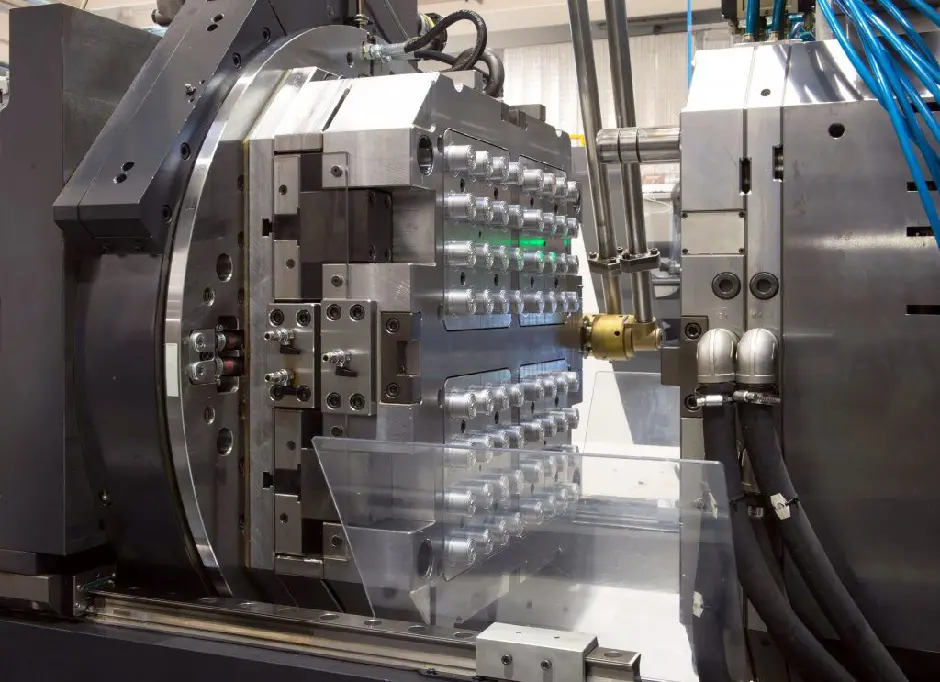

In the realm of custom metal manufacturing, plastic injection mold tooling stands as one of the most technically demanding disciplines. The performance, longevity, and consistency of a mold directly impact the quality of every plastic component produced. At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is the foundation. Our engineering approach integrates micron-level tolerances, advanced material science, and rigorous quality control to deliver molds that perform under the most demanding production environments.

Precision in mold tooling begins with design integrity. Even minor deviations in cavity dimensions, cooling channel placement, or ejection mechanisms can lead to part warpage, sink marks, or inconsistent cycle times. These defects compound rapidly in high-volume manufacturing, resulting in costly downtime and rejected batches. Our in-house engineering team employs 3D simulation software and finite element analysis (FEA) to anticipate thermal expansion, stress distribution, and flow dynamics before any metal is cut. This predictive capability ensures that each mold is optimized for both performance and durability.

Material selection is equally critical. We utilize high-grade tool steels such as P20, 718H, and H13, often enhanced with surface treatments like nitriding or chrome plating to resist wear and corrosion. For specialized applications—particularly those serving medical, aerospace, or defense sectors—we implement hardened steels and stainless alloys to meet stringent regulatory and performance standards.

Our commitment to precision is validated through real-world performance. Wuxi Lead has successfully delivered mold tooling solutions for projects associated with Olympic-grade equipment and military-spec components, where failure is not an option. These engagements demanded not only exacting dimensional accuracy but also full traceability, robust documentation, and compliance with international quality benchmarks. Our molds have operated continuously in 24/7 production lines with minimal maintenance, a testament to their engineering integrity.

Beyond technical excellence, we emphasize collaboration. Each custom mold is developed in close consultation with the client, ensuring that design for manufacturability (DFM) principles are applied from the outset. This proactive engagement reduces time-to-market and eliminates costly revisions.

The table below outlines key specifications that define our precision mold tooling capabilities.

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Maximum Mold Size | 1200 x 800 x 700 mm |

| Tool Steel Options | P20, 718H, H13, S136, 420SS |

| Surface Finishes | SPI #A1, #B2, #C3; VDI 3400 up to 20 |

| Lead Time (Average) | 4–8 weeks, depending on complexity |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) |

| Applications | Automotive, Medical, Defense, Consumer Electronics |

At Wuxi Lead Precision Machinery, we do not merely build molds—we engineer solutions that drive manufacturing excellence. Precision is not an aspiration; it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Tooling Execution

Wuxi Lead Precision Machinery delivers uncompromising precision for complex plastic injection mold tooling through integrated advanced manufacturing and rigorous quality assurance. Our core strength lies in mastering the intricate geometries demanded by high-cavitation molds, micro-features, and conformal cooling channels, ensuring optimal part quality, cycle time, and tool longevity for demanding applications in medical, automotive, and consumer electronics.

Precision Machining Capabilities

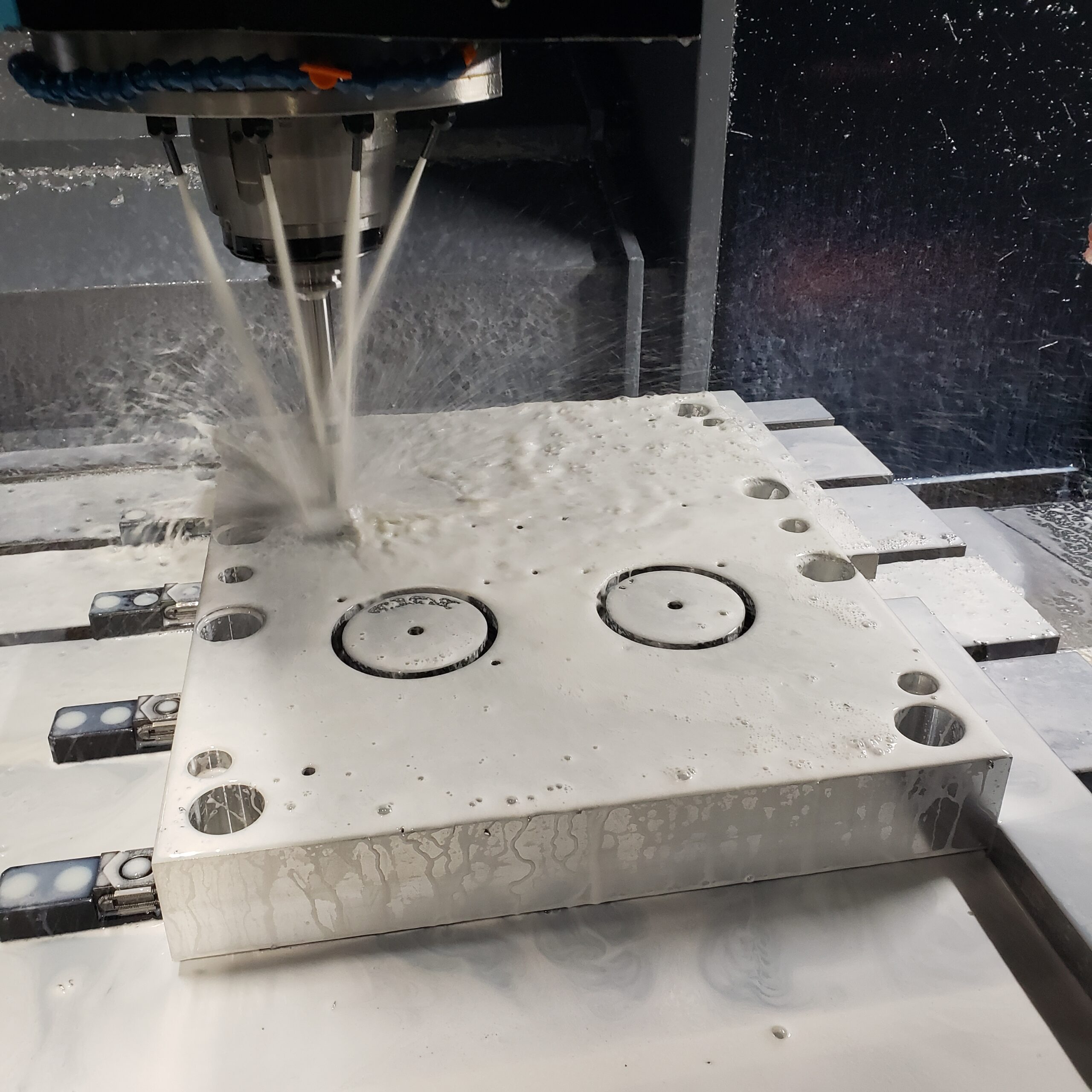

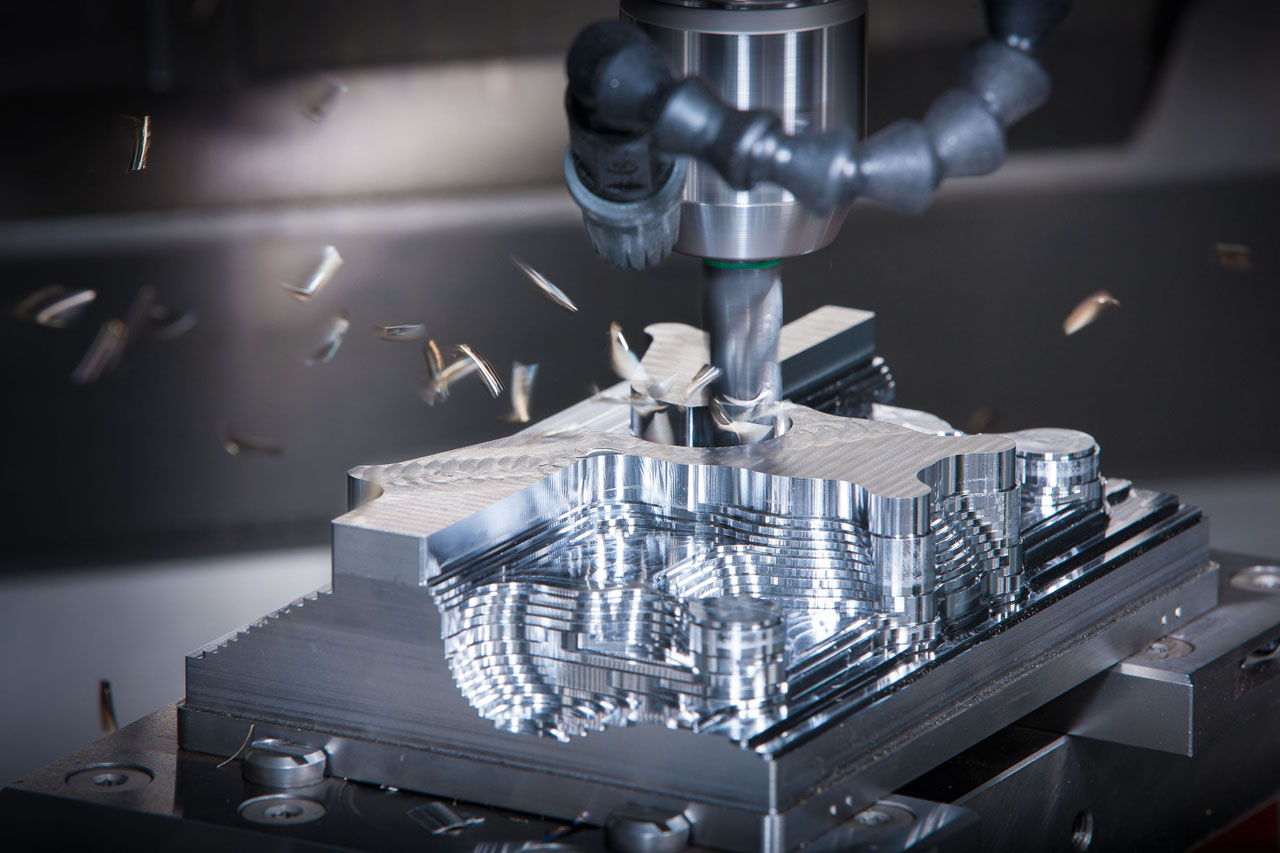

Our foundation is a modern fleet of high-torque, high-accuracy 5-axis CNC machining centers, primarily DMG MORI and Makino platforms. These systems enable single-setup machining of complex mold bases, cavities, cores, and inserts, eliminating cumulative errors from multiple fixturing operations. Utilizing High-Speed Machining (HSM) strategies with specialized toolpath software, we achieve superior surface finishes directly off the machine, significantly reducing hand polishing requirements while maintaining critical dimensional integrity. Expertise spans hardened tool steels (P20, H13, S136, 420SS), aluminum prototypes, and exotic alloys. Our engineers optimize cutting parameters and tooling for each specific material and feature, ensuring thermal stability and micron-level accuracy throughout the machining process.

Quality Control: Metrology-Driven Assurance

Every critical dimension undergoes verification against the original CAD model using state-of-the-art Coordinate Measuring Machines (CMM). Our primary inspection systems are Zeiss CONTURA and GLOBAL platforms, equipped with advanced Renishaw probe heads capable of high-density point cloud scanning and precise tactile measurement. This provides full geometric dimensioning and tolerancing (GD&T) validation, surface contour analysis, and comprehensive first-article inspection reports. All CMM equipment is maintained under strict calibration schedules traceable to national standards, ensuring measurement uncertainty is consistently within ±0.0025mm. Dimensional verification is supplemented by surface roughness testers and hardness verification where required, guaranteeing material properties meet specification.

Critical Dimensional Tolerances

The table below reflects our standard achievable tolerances for finished mold components under controlled production conditions. Actual tolerances are always defined collaboratively during the engineering review phase based on part geometry, material, and functional requirements.

| Feature Type | Typical Tolerance Range (Metric) | Typical Tolerance Range (Imperial) | Critical Notes |

|---|---|---|---|

| Cavity/ Core Profile | ±0.010 mm to ±0.025 mm | ±0.0004″ to ±0.0010″ | Complex contours may require specific GD&T |

| Flatness (Cavity) | 0.005 mm / 100 mm | 0.0002″ / 4″ | Critical for part sealing surfaces |

| Core Pin Location | ±0.005 mm | ±0.0002″ | Verified via CMM positional tolerance |

| Slider/ Lifter Motion | ±0.010 mm | ±0.0004″ | Includes wear allowance verification |

| Ejector Pin Holes | H7 / g6 Fit | Class 3 / Class 2 Fit | Matched to pin tolerance per ISO 286 |

| Conformal Cooling | ±0.025 mm (Path) | ±0.0010″ (Path) | Verified via CMM scan of internal path |

This combination of advanced 5-axis machining, deep materials expertise, and CMM-validated metrology forms the bedrock of Wuxi Lead’s capability to produce injection molds meeting the most stringent global industry standards. We deliver not just components, but fully validated, production-ready tooling with complete dimensional traceability and certification.

Material & Finish Options

Material selection in plastic injection mold tooling is a critical decision that directly affects mold longevity, production efficiency, surface finish quality, and overall cost. At Wuxi Lead Precision Machinery, we specialize in precision-engineered mold solutions tailored to the specific demands of high-volume and prototype manufacturing. The choice between aluminum, steel, and titanium must be guided by production volume, part complexity, cycle time requirements, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-volume production runs. Their excellent machinability allows for rapid tool fabrication, reducing lead times significantly. Aluminum also offers good thermal conductivity, enabling faster cooling cycles and improved productivity in short runs. However, due to lower hardness and wear resistance, aluminum molds are not suitable for extended production or abrasive resins. These molds are ideal for validating part design and initial testing before committing to hardened steel tools.

For high-volume production, tool steels such as P20, H13, and S136 are the preferred choice. P20 steel offers a balanced combination of toughness and machinability, commonly used in molds requiring moderate durability. H13, known for its thermal stability, is ideal for applications with high thermal cycling, such as hot runner systems. Stainless tool steels like S136 provide superior corrosion resistance, making them essential for molding halogenated or acidic polymers. Hardened steels ensure extended tool life—often exceeding 500,000 cycles—and maintain dimensional stability under continuous operation.

Titanium, while less common in standard mold bases, is increasingly used in specialized components such as ejector pins and wear inserts. Its high strength-to-density ratio, excellent corrosion resistance, and low thermal expansion make it suitable for precision-critical applications. However, titanium’s high cost and challenging machinability limit its use to niche roles where performance justifies investment.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing aluminum molds increases surface hardness, improves wear resistance, and provides a protective oxide layer that resists corrosion. Type II (sulfuric acid) and Type III (hard coat) anodizing are commonly applied, with Type III offering superior durability for molds exposed to repeated ejection cycles. Anodized surfaces also reduce friction, facilitating part ejection and minimizing maintenance.

The following table summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Primary Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | 10,000–20,000 | Prototyping, low-volume production |

| P20 Steel | 28–32 | 30 | 100,000–250,000 | Medium-volume production |

| H13 Steel | 48–52 | 25 | 300,000–500,000 | High-temperature, high-stress molding |

| S136 Steel | 50–54 | 22 | 500,000+ | Corrosion-resistant, high-polish molds |

| Titanium | 35–40 (as used) | 7 | N/A (component-level) | Wear parts, precision inserts |

At Wuxi Lead Precision Machinery, we evaluate each project holistically to recommend the optimal material and finish combination, ensuring performance, cost-efficiency, and reliability across the mold’s lifecycle.

Manufacturing Process & QC

Precision Plastic Injection Mold Tooling: The Zero Defects Production Framework

At Wuxi Lead Precision Machinery, our plastic injection mold tooling process is engineered for uncompromising quality from initial concept to high-volume fulfillment. We implement a rigorously controlled three-stage methodology—Design, Prototyping, Mass Production—integrated with embedded quality checkpoints to achieve true Zero Defects performance. This systematic approach eliminates costly iterations and ensures production readiness.

The Design phase begins with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates directly with client CAD data, utilizing advanced Moldflow simulation to predict flow behavior, cooling efficiency, and potential stress points. Critical factors like gate location, ejector pin placement, and thermal management are optimized iteratively. Material selection is validated against application requirements, including chemical resistance, thermal stability, and mechanical load. All geometric tolerances adhere strictly to ISO 2768-mK standards, with critical features held to ±0.005 mm. This virtual validation prevents 90% of potential tooling failures before metal cutting commences.

Prototyping transitions the validated design into physical reality using our high-speed CNC machining centers and wire EDM. We produce fully functional prototype molds in 15-20 working days, employing the same hardened tool steels (e.g., NAK80, S136H) and surface treatments as production tools. Rigorous first-article inspection (FAI) follows ISO 17025 protocols, measuring all critical dimensions via CMM and optical comparators. Client validation occurs through T1 sample runs under simulated production parameters, with cavity pressure sensors and temperature mapping confirming process stability. Any micro-defects trigger immediate design or process correction—never mass production approval.

Mass Production deployment leverages our automated molding cells with real-time SPC monitoring. Each mold undergoes 72-hour continuous validation runs, tracking parameters like clamp force consistency, cycle time variance (<0.5%), and part weight stability (±0.1g). Our closed-loop system automatically adjusts for thermal drift using embedded cavity sensors. Every production batch includes 100% automated vision inspection for surface defects and dimensional conformity against the FAI baseline. Tool maintenance is scheduled proactively based on shot counters and sensor analytics, not reactive breakdowns.

This integrated workflow—where design integrity, prototype validation, and production control operate as a single quality continuum—delivers measurable Zero Defects outcomes. Clients achieve >99.95% first-pass yield rates and eliminate scrap costs inherent in conventional tooling approaches.

Key Process Specifications

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Tolerance Capability | ±0.005 mm (critical) | ±0.01 mm | ±0.01 mm maintained |

| Validation Method | Moldflow Simulation | T1 Samples + CMM FAI | SPC + 100% Vision |

| Lead Time (Typical) | 10-15 working days | 15-20 working days | 30-45 days (tooling) |

| Defect Detection Stage | Virtual (Pre-cut) | Physical (Pre-production) | Real-time (Production) |

| Critical Process Control | DFM Optimization | Parameter Lockdown | Closed-loop Adjustment |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Plastic Injection Mold Tooling

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance manufacturing. As a trusted leader in custom metal manufacturing based in Wuxi, China, we specialize in delivering advanced plastic injection mold tooling solutions engineered to meet the exacting demands of global industries—from automotive and medical devices to consumer electronics and industrial components.

Our engineering team combines decades of hands-on experience with cutting-edge technology to design and produce molds that ensure repeatable accuracy, extended service life, and seamless integration into your production environment. We don’t just manufacture molds—we deliver performance-driven tooling systems optimized for efficiency, cycle time reduction, and long-term cost savings.

When you partner with Lead Precision, you gain access to a vertically integrated manufacturing ecosystem. Our in-house capabilities span precision CNC machining, wire EDM, surface grinding, mold assembly, and comprehensive quality inspection using state-of-the-art CMM and 3D scanning systems. This full control over the production chain enables us to maintain tight tolerances, respond quickly to design changes, and ensure every mold meets international standards such as ISO 9001:2015.

We pride ourselves on transparency, responsiveness, and technical collaboration. From initial concept and mold flow analysis to final validation and after-sales support, our engineers work closely with your team to align every detail with your production goals. Whether you require single-cavity prototypes or high-cavity production molds capable of millions of cycles, we deliver robust solutions tailored to your specific material, part geometry, and volume requirements.

Our clients choose us not only for our technical excellence but also for our commitment to on-time delivery and clear communication. With streamlined processes and a focus on lean manufacturing principles, we consistently deliver high-quality molds within aggressive timelines—without compromising precision.

Below are key specifications that define our plastic injection mold tooling capabilities:

| Specification | Detail |

|---|---|

| Mold Types | Single Cavity, Multi-Cavity, Family Molds, Hot Runner, Cold Runner |

| Maximum Mold Size | 1200 x 1000 x 800 mm |

| Tolerance | ±0.005 mm |

| Steel Types | P20, 718, S136, H13, 420 Stainless, and custom alloys |

| Surface Finishes | Polished (SPI), Textured, EDM, Coatings (TiN, CrN) |

| Lead Time | 4–12 weeks (depending on complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection, FAI Reports |

| Industries Served | Automotive, Medical, Electronics, Packaging, Consumer Goods |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that treats your project as a strategic priority. We are committed to engineering excellence, operational transparency, and long-term collaboration.

Contact us today at [email protected] to discuss your next plastic injection mold tooling project. Let Lead Precision be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.