Technical Contents

Engineering Guide: Commercial 3D Printing Service

Engineering Insight: The Critical Role of Precision in Commercial 3D Printing Services

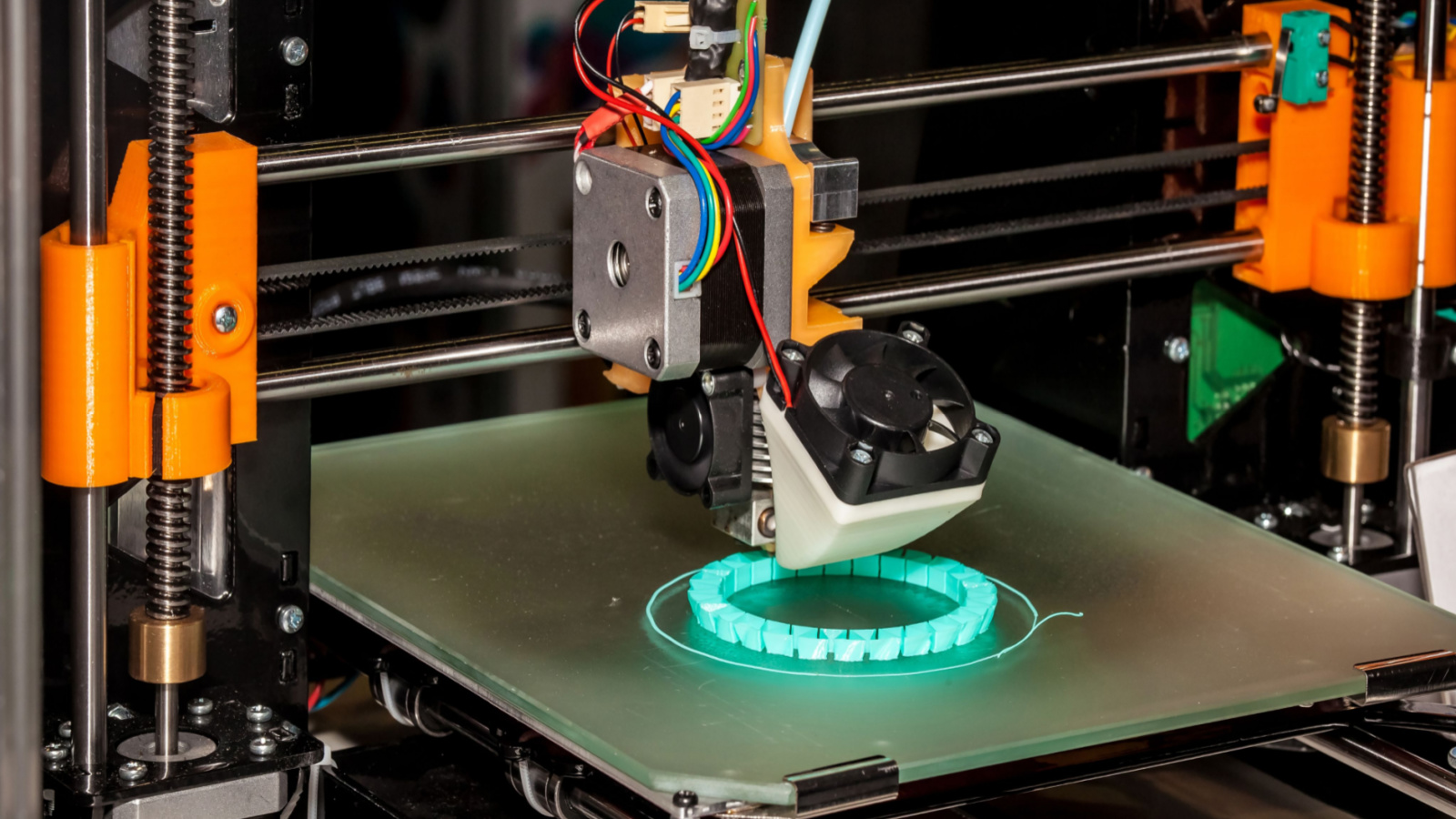

In the realm of custom metal manufacturing, commercial 3D printing services have transitioned from prototyping tools to essential production solutions. However, the true value of additive manufacturing lies not merely in its ability to produce complex geometries, but in its capacity to deliver repeatable, high-precision components that meet exacting engineering standards. At Wuxi Lead Precision Machinery, we understand that precision is the cornerstone of performance, reliability, and safety—especially in mission-critical applications across aerospace, defense, and high-performance industrial sectors.

Our experience in delivering precision-engineered components for Olympic-grade equipment and military-grade systems has reinforced a fundamental truth: tolerances matter. In additive manufacturing, even micron-level deviations can compromise structural integrity, thermal performance, or dynamic balance. This is why our commercial 3D printing service integrates precision at every stage—from material selection and build orientation to post-processing and metrology. We utilize state-of-the-art metal additive systems with in-situ monitoring and closed-loop feedback control to ensure dimensional accuracy and material consistency across every build.

Unlike conventional manufacturing methods, 3D printing allows for design freedom and part consolidation, but this advantage must be balanced with rigorous process control. At Lead Precision, we apply decades of CNC machining expertise to our additive workflows, ensuring that as-built parts meet or exceed industry standards such as AS9100 and ISO 13485. Our engineers conduct thorough design for additive manufacturing (DfAM) reviews, optimizing support structures, minimizing residual stress, and planning precision machining steps where tight tolerances are required.

We specialize in processing high-performance alloys—including Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel, and AlSi10Mg—each selected for thermal stability, corrosion resistance, and mechanical strength. Our post-processing capabilities, such as hot isostatic pressing (HIP), stress relieving, and precision CNC finishing, further enhance part reliability and surface integrity.

The following table outlines key specifications of our commercial 3D printing service:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.05 mm over 100 mm |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processing Options | HIP, CNC Machining, Polishing, CMM Inspection |

| Materials Available | Ti-6Al-4V, Inconel 718, 17-4 PH, AlSi10Mg, CoCr |

| Quality Standards | ISO 9001, AS9100, MIL-STD-810 compliant |

Precision in commercial 3D printing is not an optional upgrade—it is a requirement for functional, reliable, and certifiable components. At Wuxi Lead Precision Machinery, our legacy in high-stakes manufacturing drives our commitment to excellence in every printed part. Whether supporting defense logistics or enabling next-generation industrial innovation, we deliver additive solutions where precision is non-negotiable.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

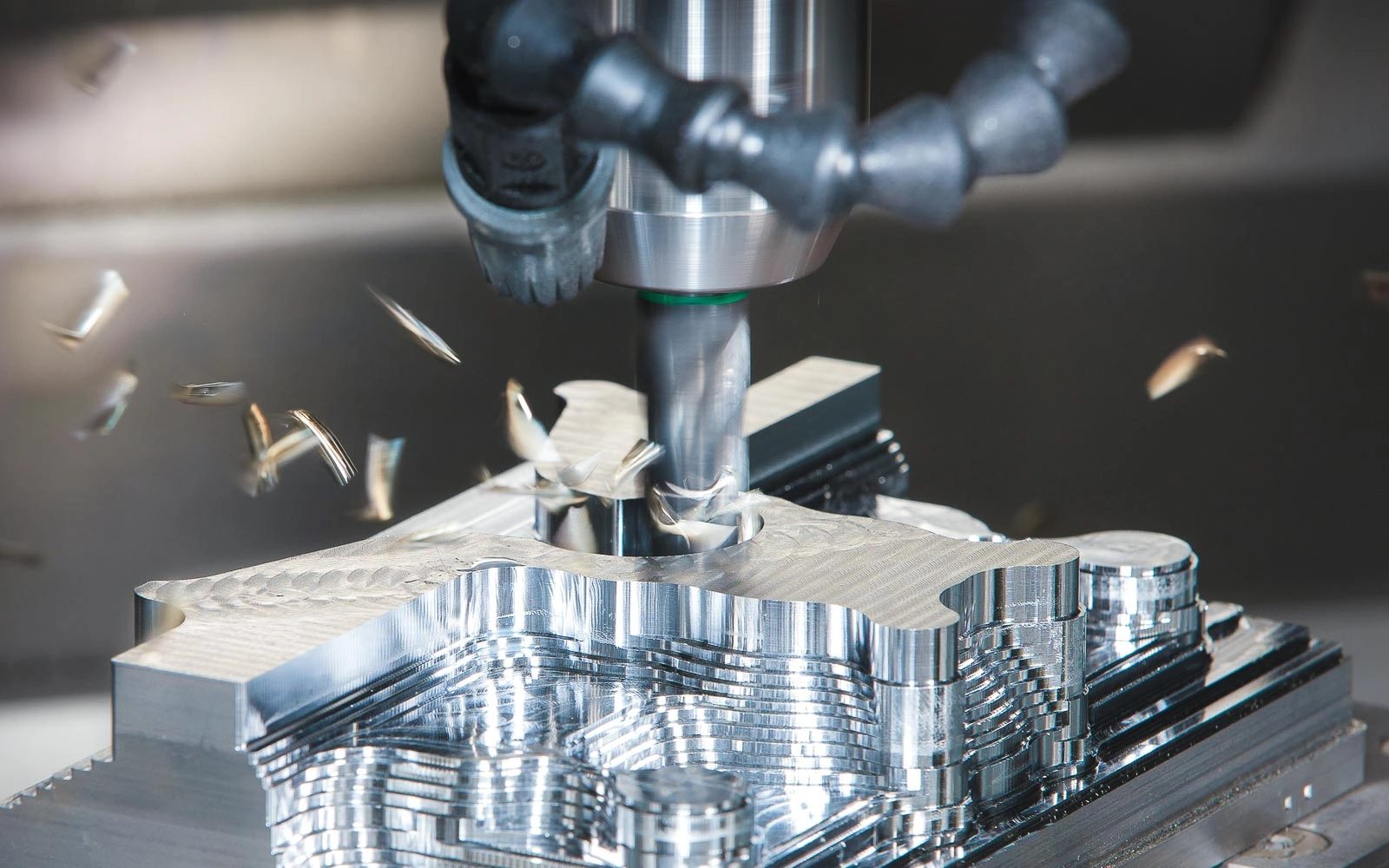

Wuxi Lead Precision Machinery integrates advanced 5-axis CNC machining with additive manufacturing workflows to deliver end-use metal components meeting the most stringent aerospace, medical, and energy sector requirements. Our facility bridges the gap between rapid prototyping via commercial 3D printing services and volume production, ensuring geometric complexity from additive processes is refined to exacting dimensional and surface integrity standards. The HAAS UMC-750 and DMG MORI CMX 600 V ecoline 5-axis centers form the core of our metal finishing capability, enabling single-setup machining of impellers, turbine blades, and orthopedic implants with sub-5μm positional repeatability. This eliminates cumulative error from multiple fixturing stages, critical for parts with intersecting compound angles or internal cooling channels common in printed near-net-shapes.

Material versatility spans Inconel 718, Ti-6Al-4V, 17-4PH stainless steel, and maraging steels, processed under strict environmental controls to prevent thermal distortion during high-precision milling. All operations adhere to AS9100 and ISO 13485 protocols, with real-time tool wear compensation and in-process probing validating critical features before final inspection. Our closed-loop quality system begins with first-article inspection using Renishaw RMP60 probes during machining and culminates in full CMM validation.

Dimensional Accuracy and Surface Finish Specifications

The table below defines achievable tolerances for machined surfaces following additive manufacturing, validated per ASME Y14.5-2018 standards using Zeiss CONTURA CMM systems with 0.9μm volumetric accuracy:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Typical Application Example |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Hydraulic valve spools |

| Angular Features | ±0.05° | ±0.01° | Turbine vane mounting faces |

| Hole Position | ±0.020 mm | ±0.008 mm | Bolt patterns for assemblies |

| Surface Roughness (Ra) | 0.8 μm | 0.2 μm | Sealing surfaces, implants |

| True Position | 0.030 mm | 0.010 mm | Bearing bores, couplings |

This precision is non-negotiable for components transitioning from printed prototypes to certified production. For instance, aerospace brackets printed additively require reamed holes within ±0.008 mm to interface with hydraulic systems—tolerances unattainable through printing alone. Our CMM reports provide full GD&T analysis, including profile deviation heatmaps and surface finish histograms, ensuring compliance with NADCAP audit requirements. Statistical process control data from 50+ concurrent production runs confirms 99.2% first-pass yield for features held to ±0.010 mm.

By combining 5-axis CNC’s deterministic accuracy with additive manufacturing’s design freedom, Wuxi Lead transforms printed metal parts into flight-worthy or implant-certified components. Every process parameter—from toolpath optimization for residual stress relief to vibration-dampened finishing cuts—is engineered to preserve the integrity of the base material while achieving micron-level conformity to CAD models. This integrated approach ensures your printed metal components meet not just dimensional targets, but the functional reliability demanded by Tier 1 supply chains.

Material & Finish Options

Material Selection for High-Performance Commercial 3D Printing Services

In commercial 3D printing for custom metal manufacturing, material selection directly influences part performance, durability, and application suitability. At Wuxi Lead Precision Machinery, we specialize in advanced metal additive manufacturing using premium-grade aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties, making them ideal for specific industrial environments including aerospace, automotive, medical, and energy sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for their excellent strength-to-weight ratio and thermal conductivity. This material is ideal for lightweight structural components, heat exchangers, and complex geometries where weight reduction is critical. Its low density and good fatigue resistance make it a preferred choice in aerospace and automotive applications requiring high-performance without added mass.

Stainless steel, especially 316L and 17-4 PH, delivers superior corrosion resistance, high tensile strength, and excellent performance in extreme environments. 316L is optimal for marine, chemical, and medical applications due to its non-reactive nature and biocompatibility. 17-4 PH stainless steel, a precipitation-hardening alloy, provides exceptional hardness and wear resistance, making it suitable for tooling, valves, and high-stress mechanical components.

Titanium alloys, primarily Ti6Al4V (Grade 5), are renowned for their exceptional strength-to-density ratio and resistance to high temperatures and corrosion. This makes titanium the material of choice for critical aerospace components, medical implants, and high-performance racing parts. Its biocompatibility and fatigue resistance further enhance its value in medical device manufacturing.

Post-processing surface finishes significantly impact both aesthetics and functionality. Anodizing, particularly for aluminum components, enhances surface hardness, improves wear resistance, and allows for color coding for part identification. While anodizing is not applicable to steel or titanium in the same manner, titanium can undergo acid passivation or oxide layer enhancement, and steel parts benefit from electropolishing, passivation, or coating processes tailored to environmental exposure.

Understanding material and finish compatibility ensures optimal performance and longevity of 3D printed components. Below is a comparative overview of key materials offered in our commercial 3D printing service.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 2.67 | Aerospace, automotive, heat sinks | Anodizing, sandblasting |

| 316L Stainless Steel | 550–600 | 350–400 | 8.0 | Medical, marine, chemical processing | Electropolishing, passivation |

| 17-4 PH Steel | 950–1050 | 750–850 | 7.8 | Tooling, valves, high-stress parts | HVOF coating, polishing |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | Aerospace, medical implants, racing | Acid passivation, micro bead blast |

Selecting the right material and finish requires a comprehensive understanding of operational demands. Wuxi Lead Precision Machinery supports clients in this decision with engineering consultation and material testing to ensure every printed component meets exacting industrial standards.

Manufacturing Process & QC

Precision Metal Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our commercial metal 3D printing service transcends rapid prototyping to deliver certified, zero-defect production components. We implement a rigorously controlled process spanning design validation through high-volume manufacturing, ensuring every part meets aerospace, medical, and industrial precision standards. This integrated workflow eliminates defects at source, not through final inspection.

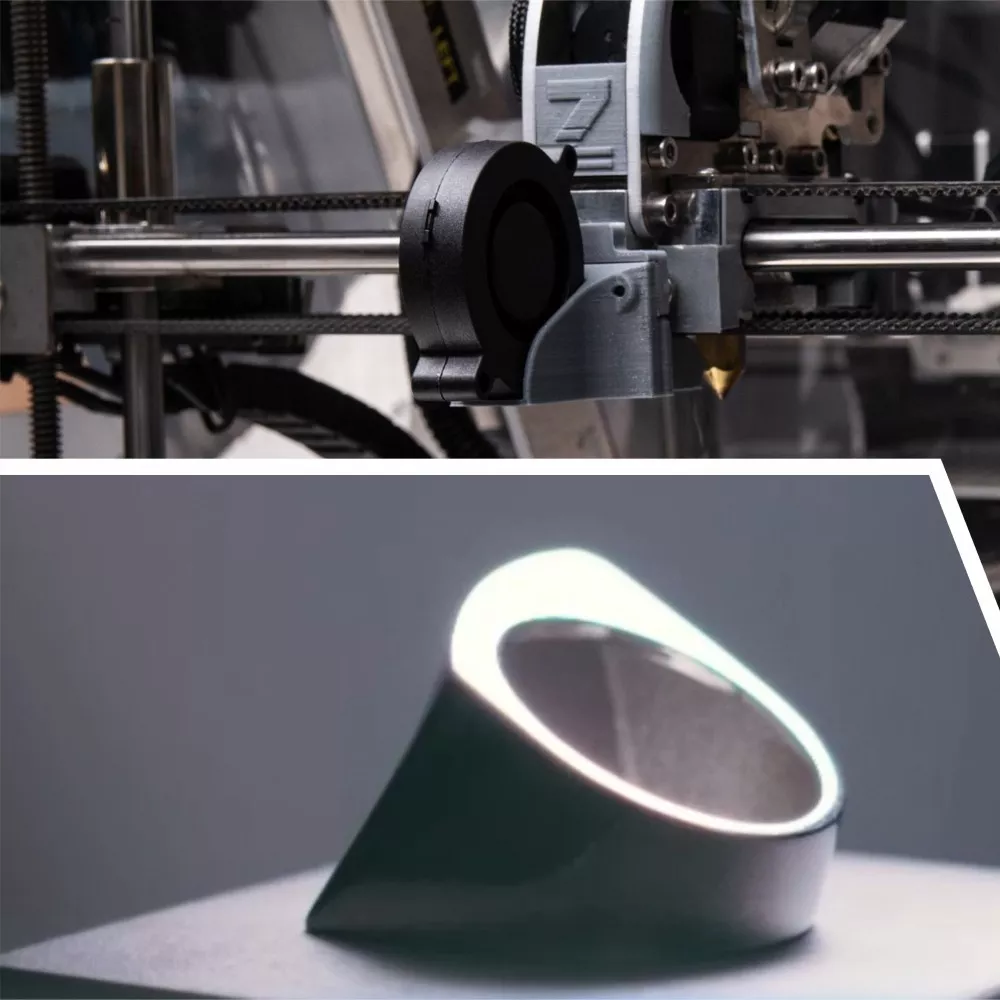

The foundation is Engineering-Driven Design for Additive Manufacturing (DfAM). Our application engineers collaborate closely with clients during the initial design phase, leveraging topology optimization and thermal simulation software. We analyze part geometry, material selection (Inconel 718, Ti-6Al-4V, 316L, AlSi10Mg), and support structure requirements to prevent warpage, porosity, and residual stress before the build begins. Critical features undergo Design Failure Mode and Effects Analysis (DFMEA), ensuring manufacturability and eliminating inherent design flaws that cause downstream defects. This proactive engineering phase is non-negotiable for achieving zero defects in serial production.

Validated Prototyping Precedes Mass Production. Initial builds utilize the exact production-grade metal powder, machine parameters, and post-processing sequence planned for volume runs. Each prototype undergoes comprehensive metrology: 100% dimensional inspection via Coordinate Measuring Machine (CMM), non-destructive testing (NDT) including Micro-CT scanning for internal integrity, and mechanical property verification per ASTM/ISO standards. We validate surface finish, density (>99.95%), and microstructure against client specifications. Only when prototype data consistently meets all critical-to-quality (CTQ) parameters do we authorize mass production. This step confirms process capability and identifies any need for micro-adjustments to the build strategy.

Zero-Defect Mass Production is Executed via Closed-Loop Process Control. Our certified LPBF (Laser Powder Bed Fusion) production cells operate under strict environmental controls with real-time melt pool monitoring and oxygen level management. Every production build follows a locked-down, client-approved process sheet derived from the validated prototype. In-process inspections occur at defined intervals, while final parts undergo 100% automated optical scanning against the native CAD model and full statistical process control (SPC) charting of key dimensions. Post-processing—including precision machining, heat treatment (HIP, stress relief), and surface finishing—occurs within our integrated facility under the same quality management system (ISO 9001:2015, ISO 13485). Traceability from raw material batch to finished component is absolute.

Critical Process Control Parameters for Zero-Defect Metal AM

| Stage | Critical Parameters Monitored | Verification Method |

|---|---|---|

| Design & Simulation | Thermal stress distribution, Support density, Overhang angles | Finite Element Analysis (FEA) Software |

| Machine Setup | Laser power calibration, Chamber oxygen < 50 ppm, Powder layer thickness | Machine diagnostics, Gas analyzers, Sensors |

| Build Execution | Melt pool stability, Layer-wise thermal history | In-situ cameras, Co-axial sensors, SPC logs |

| Post-Processing | Dimensional accuracy after HIP/machining, Surface roughness Ra | CMM, Optical profilometer, NDT |

| Final Inspection | Conformance to GD&T, Material density, Mechanical properties | CMM, Micro-CT, Tensile/ hardness testing |

This seamless integration of predictive engineering, empirical validation, and closed-loop production control ensures Wuxi Lead delivers metal AM components where defects are engineered out of the process. We guarantee zero escapes, providing clients with the reliability required for mission-critical applications. Your design vision becomes production reality, flawlessly.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

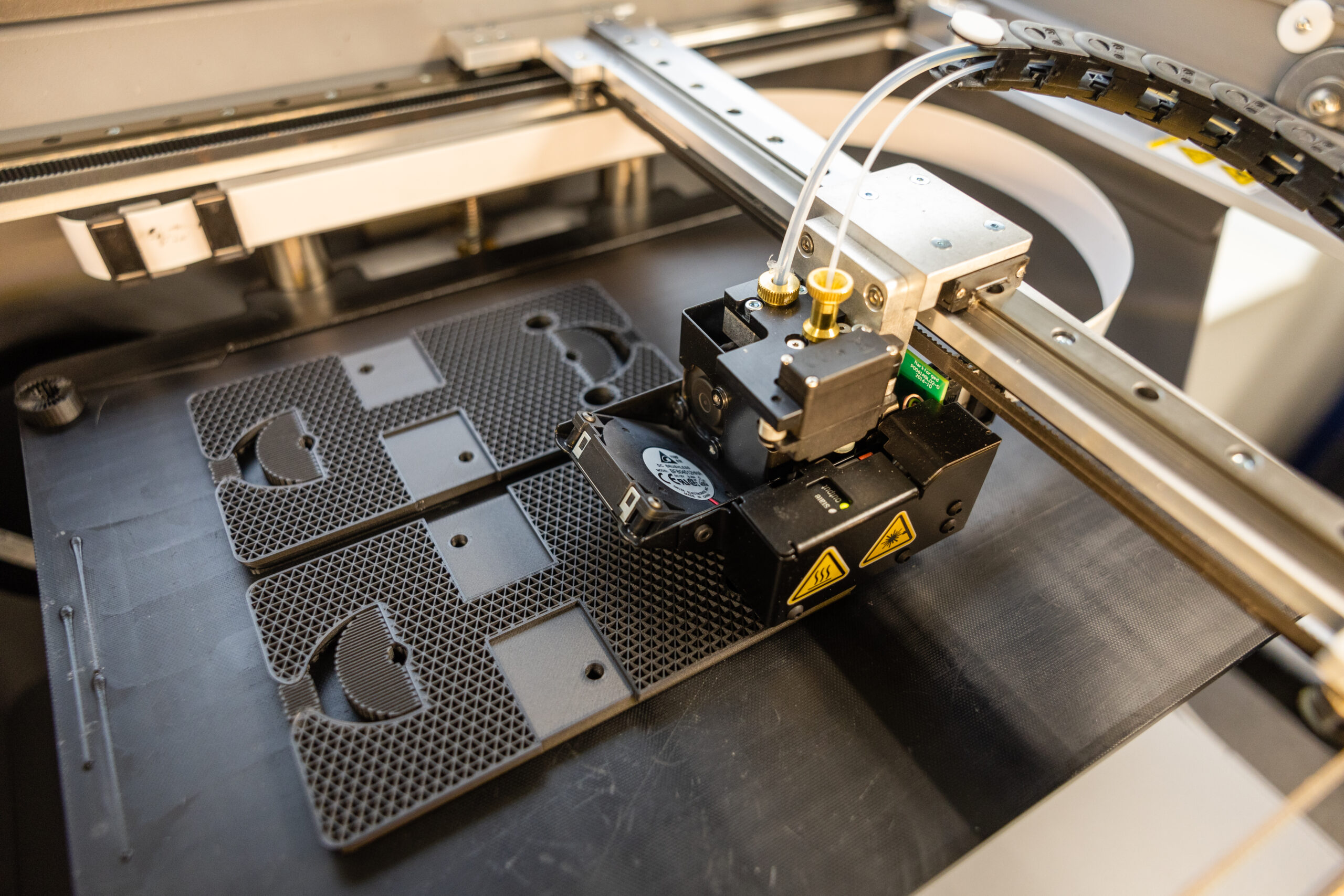

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions tailored to the exact demands of high-performance industries. As a leading provider of advanced commercial 3D printing services in China, we specialize in custom metal manufacturing for aerospace, medical, energy, and industrial automation sectors. Our commitment to excellence, combined with cutting-edge additive technology, ensures your components meet the highest standards of strength, accuracy, and reliability.

When you partner with Lead Precision, you gain access to a team of seasoned CNC engineers and additive manufacturing specialists with over 15 years of experience in precision engineering. We understand that every project comes with unique challenges—whether it’s complex geometry, tight tolerances, or demanding material requirements. That’s why we offer a fully integrated approach, from initial design consultation to final inspection, ensuring seamless execution from concept to completion.

Our state-of-the-art facilities are equipped with metal powder bed fusion systems, high-precision post-processing equipment, and in-house metrology labs. This vertical integration allows us to maintain full control over quality, lead time, and consistency. We work with a wide range of high-performance alloys, including titanium, Inconel, stainless steel, and aluminum, enabling us to meet the thermal, mechanical, and corrosion-resistant needs of your application.

We also provide comprehensive DfAM (Design for Additive Manufacturing) support, helping you optimize part performance while minimizing weight and material waste. Whether you’re prototyping a new design or scaling to low-volume production, our agile manufacturing model ensures rapid turnaround without compromising quality.

Below are the key technical capabilities of our commercial 3D printing service:

| Specification | Detail |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20 – 60 μm |

| Material Options | Titanium (Ti6Al4V), Inconel 718, Stainless Steel 316L, Aluminum AlSi10Mg, Cobalt-Chrome |

| Surface Finish | As-built: Ra ≤ 12 μm; Post-processed: Ra ≤ 1.6 μm |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, anodizing, coating |

| Quality Standards | ISO 9001:2015, full traceability, first article inspection (FAI), CMM reporting |

Your success is our priority. We don’t outsource. We don’t compromise. We engineer with purpose.

Contact us today to discuss your next project. Send your CAD files, specifications, or inquiries to [email protected] and one of our engineering specialists will respond within 24 hours. Let Wuxi Lead Precision Machinery become your trusted partner in precision metal additive manufacturing—where innovation meets industrial reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.