Technical Contents

Engineering Guide: Aluminum Cutting Service

Engineering Insight Precision in Aluminum Cutting Services

Aluminum’s dominance in aerospace defense and high-performance industrial applications stems from its strength-to-weight ratio and thermal conductivity. However these same properties demand exceptional precision during machining. Thermal expansion coefficients require micron-level compensation strategies while soft alloys risk burring and dimensional drift without optimized toolpaths and rigid fixturing. At Wuxi Lead Precision Machinery we treat tolerance stability not as a target but as a non-negotiable engineering outcome. Our CNC protocols integrate real-time thermal monitoring adaptive feed rate control and multi-axis vibration damping specifically calibrated for aluminum’s material behavior. This eliminates post-process rectification saving clients critical time and cost in mission-critical production cycles.

Over 15 years of aerospace and defense contract manufacturing has ingrained a zero-defect culture at our Wuxi facility. We executed precision aluminum components for Beijing Olympic infrastructure where thermal cycling resistance was paramount and supplied mil-spec housings for satellite communication systems requiring RF shielding integrity down to 0.005mm tolerances. Each project reinforced that precision begins with material science understanding not just machine capability. Our engineers analyze alloy temper grain structure and residual stress profiles before selecting cutting parameters ensuring microstructural integrity remains uncompromised. This approach prevents warpage in thin-walled enclosures and maintains thread accuracy in hydraulic manifolds under extreme pressure cycles.

The following table outlines our core aluminum machining capabilities reflecting the standards demanded by Tier 1 defense and Olympic-scale projects

| Parameter | Capability | Application Impact |

|---|---|---|

| Positional Tolerance | ±0.003mm | Ensures seamless assembly in multi-part systems |

| Surface Finish | Ra 0.4µm (as-machined) | Eliminates secondary polishing for optical/aesthetic parts |

| Max Work Envelope | 2000 x 1200 x 800mm | Supports monolithic structural components |

| Tool Life Control | ±2% dimensional drift per 50 parts | Guarantees batch consistency for long runs |

| Material Utilization | 92% average | Reduces waste in high-cost aerospace alloys |

Precision aluminum machining transcends technical specifications—it is a commitment to operational reliability. When Wuxi Lead Precision Machinery handles your aluminum cutting service we apply lessons from validating components under military environmental testing protocols and Olympic venue load simulations. This rigor ensures every part meets not only your print but the unspoken demands of real-world performance. Contact our engineering team to discuss how our process control systems can secure your next critical aluminum fabrication.

Precision Specs & Tolerances

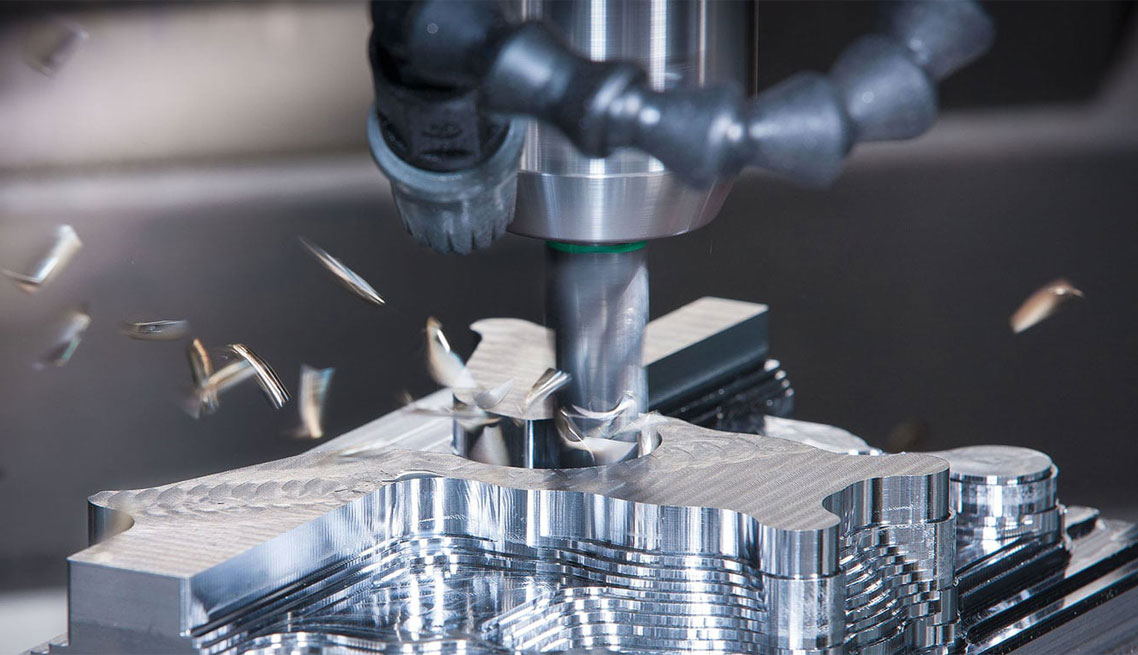

Wuxi Lead Precision Machinery delivers advanced aluminum cutting services tailored for high-performance industries such as aerospace, automotive, medical, and industrial automation. Our technical capabilities are built around precision engineering, state-of-the-art equipment, and rigorous quality assurance protocols. At the core of our machining operations is a fleet of 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, minimizing setup changes and ensuring tight alignment across intricate features. This capability is particularly critical in aluminum components where dimensional stability, heat dissipation, and structural integrity are paramount.

Aluminum, known for its favorable strength-to-weight ratio and machinability, requires precise control over cutting parameters to avoid deformation and achieve optimal surface quality. Our engineers leverage extensive material-specific expertise to fine-tune spindle speeds, feed rates, and toolpath strategies. We support a wide range of aluminum alloys, including 6061, 7075, 2024, and 5052, processing them with carbide and diamond-coated tooling to extend tool life and maintain consistency across production runs. Our machines are equipped with high-speed spindles and automated tool changers, ensuring efficient operations for both prototyping and high-volume production.

Quality is embedded at every stage of our aluminum cutting process. Each component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM systems provide micron-level verification of critical dimensions, hole locations, flatness, and contour accuracy. All inspection data is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality plans. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate dimensional and surface characteristics.

Our facility maintains strict environmental controls to minimize thermal variation, which is essential when holding tight tolerances in aluminum. All machines are regularly maintained and calibrated to ensure repeatability and long-term performance. With integrated CAD/CAM programming and real-time process monitoring, we ensure every aluminum part meets the highest standards of precision and reliability.

The following table outlines the standard technical specifications and achievable tolerances for our aluminum cutting services:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.01 mm |

| Linear Dimension Tolerance | ±0.05 mm | ±0.02 mm |

| Hole Diameter Tolerance | ±0.025 mm | ±0.01 mm |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm (polished finish) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Flatness | 0.05 mm over 100 mm | 0.02 mm over 100 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom upon request |

| Minimum Feature Size | 0.5 mm (drilled hole) | 0.3 mm (with micro-tooling) |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with disciplined quality control to deliver aluminum components that meet the most demanding engineering requirements.

Material & Finish Options

Strategic Material Selection for Precision Aluminum Cutting Services

Material selection directly impacts manufacturability, performance, and total cost in high-precision CNC machining. At Wuxi Lead Precision Machinery, we guide clients through optimal choices for aluminum, steel, and titanium based on application demands and process efficiency. Aluminum remains the dominant choice for lightweight, high-conductivity applications requiring excellent machinability. Its superior thermal conductivity dictates specific CNC parameters to prevent work hardening and ensure dimensional stability during high-speed cutting. Steel offers unmatched strength for structural components but demands robust tooling and slower feeds due to higher hardness. Titanium provides exceptional strength-to-weight ratios and corrosion resistance for aerospace or medical use, yet its low thermal conductivity necessitates specialized cutting strategies to manage heat generation and avoid galling.

Understanding core mechanical properties is critical for process optimization. The following table outlines key specifications influencing CNC machining decisions:

| Material | Key Alloys | Tensile Strength (MPa) | Machinability Rating | Best Suited For |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 (6061), 572 (7075) | Excellent | Enclosures, heat sinks, drone frames |

| Stainless Steel | 304, 316, 17-4PH | 505 (304), 1000 (17-4PH) | Moderate | Hydraulic fittings, food processing |

| Titanium | Ti-6Al-4V (Grade 5) | 900 | Poor | Aircraft components, medical implants |

Aluminum 6061-T6 delivers the optimal balance for most precision cutting services, combining weldability, corrosion resistance, and cost efficiency. For extreme strength requirements, 7075-T6 is viable but requires tighter process control due to lower fracture toughness. Steel selection hinges on required hardness and environmental exposure; 316 stainless is essential for marine applications despite its challenging machinability. Titanium machining demands rigid setups, sharp carbide tools, and consistent coolant flow to prevent built-up edge and maintain surface integrity.

Surface finish selection significantly enhances part functionality and longevity. Anodizing is the industry-standard post-process for aluminum components, providing critical wear and corrosion resistance. Type II (sulfuric acid) anodizing offers economical general protection with dyeing capability for identification. For demanding industrial or military applications, Type III (hard coat) anodizing creates a thicker, denser ceramic layer exceeding 50 µm, dramatically improving abrasion resistance while maintaining precise dimensional control. Our integrated anodizing line ensures consistent coating thickness and adherence to MIL-A-8625 specifications, eliminating supply chain delays. We rigorously control pre-treatment and sealing processes to guarantee pore closure and maximum corrosion resistance in harsh environments.

Material and finish decisions must align with your functional requirements and production volume. Wuxi Lead Precision Machinery leverages decades of CNC expertise to recommend the optimal alloy, machining strategy, and surface treatment—ensuring your aluminum cutting service delivers precision, durability, and value. Contact our engineering team for application-specific material validation.

Manufacturing Process & QC

The production process for our aluminum cutting service at Wuxi Lead Precision Machinery follows a disciplined, three-phase methodology: Design, Prototyping, and Mass Production. This structured approach ensures precision, repeatability, and zero-defect outcomes tailored to high-end industrial applications.

In the Design phase, our engineering team collaborates closely with the client to translate technical requirements into manufacturable designs. Utilizing advanced CAD/CAM software, we analyze part geometry, material behavior, and tolerances to optimize tool paths and fixture strategies. Every design is reviewed for manufacturability, ensuring minimal waste, maximum structural integrity, and adherence to international quality standards such as ISO 9001. Thermal expansion characteristics of aluminum alloys are factored in to maintain dimensional accuracy across varying production environments.

The Prototyping phase is where theoretical designs meet real-world validation. Using high-speed CNC machining centers with sub-micron positioning accuracy, we produce initial samples under actual production conditions. This allows us to verify form, fit, and function before scaling up. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and optical profilometers to confirm compliance with geometric dimensioning and tolerancing (GD&T) specifications. Any deviations are traced to root causes—whether tool wear, clamping force, or coolant dynamics—and corrected in the digital process model. Client feedback is integrated at this stage, ensuring alignment with end-use performance criteria.

Upon approval, we transition seamlessly into Mass Production. Our facility leverages automated pallet systems, tool presetters, and real-time in-process monitoring to maintain consistency across thousands of parts. Each aluminum component is machined from certified stock, with full material traceability from supplier to final shipment. Our zero-defect philosophy is enforced through Statistical Process Control (SPC), where critical dimensions are continuously sampled and analyzed. Any trend toward out-of-specification conditions triggers immediate corrective action, preventing non-conformance before it occurs.

Throughout all phases, environmental controls—such as stable workshop temperatures and humidity regulation—ensure metrological stability. We specialize in complex aluminum components used in aerospace, medical devices, and high-performance automation, where reliability is non-negotiable.

Below are key technical specifications of our aluminum cutting capabilities.

| Parameter | Specification |

|---|---|

| Material Types | 6061, 7075, 2024, 5052, and custom alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.003 mm |

| Process Control | SPC, CMM inspection, first-article reporting |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 10–15 working days (volume-dependent) |

This end-to-end process ensures that every aluminum component we deliver meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Aluminum Cutting Excellence

Aluminum’s unique properties—lightweight strength, thermal conductivity, and corrosion resistance—make it indispensable across aerospace, automotive, and medical device manufacturing. Yet its machinability presents distinct challenges: thermal expansion during cutting, chip evacuation complexities, and stringent surface finish requirements. Substandard processes lead to dimensional drift, micro-fractures, or scrapped components, directly impacting your production timelines and bottom line. At Wuxi Lead Precision Machinery, we transform these challenges into competitive advantages through engineered precision and material science expertise.

Our dedicated aluminum cutting division operates beyond standard industry tolerances, leveraging 5-axis milling, high-speed routing, and wire EDM tailored to aluminum’s metallurgical behavior. We implement cryogenic cooling and adaptive feed-rate algorithms to eliminate thermal distortion, while proprietary toolpath strategies ensure burr-free edges and Ra 0.4 µm surface finishes—critical for hydraulic components and structural assemblies. Every process is validated against your exact material grade, from 6061-T6 to 7075 aerospace alloys, ensuring repeatability across micro-batch to high-volume runs.

Technical Capabilities for Aluminum Fabrication

| Process Type | Max Dimensions (mm) | Tolerance (mm) | Material Thickness Range (mm) | Machine Technology |

|---|---|---|---|---|

| 5-Axis CNC Milling | 2500 x 1500 x 1000 | ±0.005 | 0.5 – 300 | DMG MORI, Makino |

| High-Speed Routing | 3000 x 1500 x 200 | ±0.01 | 1.0 – 150 | Hermle, Haas |

| Wire EDM | 400 x 400 x 300 | ±0.002 | 0.2 – 250 | Sodick, Mitsubishi |

| Laser Cutting | 4000 x 2000 | ±0.05 | 0.5 – 20 | Trumpf, Bystronic |

Why do global Tier-1 suppliers trust Lead Precision? We integrate material-specific process validation into every workflow. Our AS9100-certified quality system includes in-process CMM verification at critical stages, real-time spindle load monitoring to prevent tool deflection, and post-machining stress-relief protocols that eliminate latent warpage. Unlike commodity shops, our engineers collaborate from design-for-manufacturability (DFM) review through first-article inspection, reducing your time-to-assembly by up to 30%. This proactive partnership approach has delivered zero non-conformances for 27 consecutive months across 12,000+ aluminum components annually.

Your project demands more than cutting—it requires metallurgical insight, predictive process control, and unwavering accountability. Lead Precision delivers certified precision where others deliver parts. Contact our engineering team directly at [email protected] to submit your drawing or schedule a technical consultation. Specify “Aluminum Cutting Assessment” in your subject line to receive a complimentary DFM analysis within 24 hours. Let us prove how precision aluminum machining becomes your operational advantage.

Wuxi Lead Precision Machinery: Where Material Science Meets Manufacturing Mastery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.