Technical Contents

Engineering Guide: Ribbed Molding

Engineering Insight: Ribbed Molding in High-Performance Metal Manufacturing

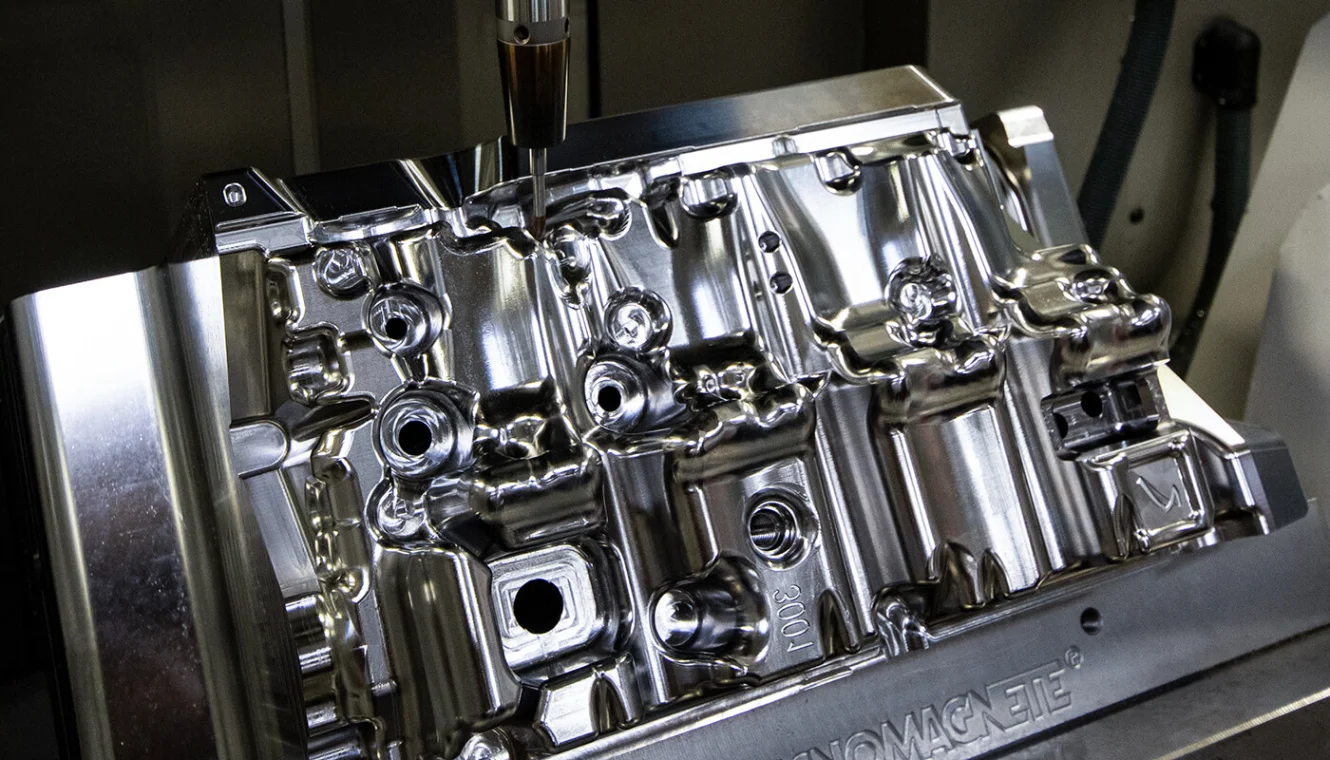

Ribbed molding is a critical process in custom metal manufacturing, particularly where structural integrity, thermal dissipation, and weight optimization are paramount. Unlike flat or smooth-surfaced components, ribbed designs incorporate raised linear or geometric patterns that enhance rigidity without significantly increasing mass. This makes them ideal for aerospace enclosures, defense electronics housings, and high-load industrial frames. However, the complexity of rib geometry demands exceptional precision in tooling, material control, and machining execution—areas where Wuxi Lead Precision Machinery excels.

The primary engineering challenge in ribbed molding lies in maintaining dimensional consistency across intricate profiles. Even minor deviations in rib height, width, or spacing can compromise load distribution, lead to stress concentration, or interfere with mating components. Furthermore, during high-pressure forming or CNC milling, thin rib structures are prone to warping, chatter, or incomplete material flow, especially in aluminum, titanium, and high-strength alloys. Achieving repeatability at tight tolerances—often within ±0.05 mm—requires advanced simulation software, high-rigidity machine platforms, and deep process expertise.

At Wuxi Lead Precision Machinery, our approach integrates finite element analysis (FEA) with real-time process monitoring to predict and correct deformation risks before production begins. Our facility utilizes 5-axis CNC machining centers with sub-micron positioning accuracy, ensuring that even the most complex rib arrays are machined with exacting detail. Additionally, our in-house tooling design team develops custom forming dies and cooling strategies that minimize residual stress and improve surface finish—critical for components used in mission-critical applications.

Our proven track record includes supplying precision-molded ribbed components for Olympic-standard sporting equipment and military-grade communication enclosures. These projects demanded not only flawless aesthetics but also compliance with MIL-STD and ISO 9001 standards for durability and environmental resistance. The success of these high-profile contracts underscores our capability to deliver under stringent performance and quality requirements.

Understanding material behavior is equally vital. We specialize in working with aluminum 6061-T6, 7075-T73, magnesium AZ31, and titanium Grade 5, tailoring feed rates, spindle loads, and coolant application to preserve rib integrity during high-speed machining. Our post-processing protocols, including stress-relief annealing and anodizing, further enhance long-term stability and corrosion resistance.

Below are typical specifications achievable in our ribbed molding operations:

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Minimum Rib Width | 0.8 mm | 0.5 mm |

| Minimum Rib Height | 1.0 mm | 0.6 mm |

| Tolerance (±) | ±0.05 mm | ±0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Materials | Al, Mg, Ti, Stainless Steel | Custom Alloys on Request |

| Max Part Size (L×W×H) | 1200×800×600 mm | 1200×800×600 mm |

| Production Volume | Prototype to 50,000 units/yr | High-volume on demand |

Precision in ribbed molding is not merely a technical objective—it is a strategic advantage. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with field-proven expertise to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities for Precision Ribbed Molding Components

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom ribbed molding manufacturing, addressing the inherent challenges of complex geometries, thin walls, and stringent structural requirements. Ribbed components demand exceptional control over dimensional stability and surface integrity to prevent warpage, ensure load distribution, and maintain functional performance in critical applications. Our integrated approach leverages advanced five-axis CNC machining and rigorous metrology to transform intricate designs into high-reliability metal parts for aerospace, medical, and defense sectors.

Precision Machining Capability

Our DMG MORI and Hermle five-axis CNC machining centers enable simultaneous multi-directional toolpath control, eliminating repositioning errors common in ribbed structures. This capability ensures perfect alignment between ribs, base surfaces, and mounting features—even on contoured or asymmetric substrates. High-speed spindles (up to 24,000 RPM) paired with dynamic tool compensation maintain consistent wall thickness down to 0.3 mm while minimizing chatter during deep cavity milling. We machine all rib profiles—including tapered, curved, and variable-height geometries—in a single setup, guaranteeing positional accuracy within 0.01 mm across the entire component. Material suitability spans aluminum alloys (7075-T6, 6061), titanium (Grade 5), stainless steel (17-4PH), and Inconel 718, with optimized parameters for each to prevent thermal distortion.

Quality Control Protocol

Every ribbed molding component undergoes comprehensive inspection via Zeiss CONTURA CMM systems, programmed to validate critical rib dimensions against native CAD models. Automated scanning captures full 3D profiles of rib edges, base interfaces, and draft angles, with real-time deviation mapping. We specifically verify rib straightness, thickness uniformity, and surface roughness (Ra 0.8 µm standard) at multiple cross-sections to detect micro-deformations. Inspection reports include GD&T analysis for flatness, parallelism, and profile tolerances, with data traceable to NIST standards. First-article inspections are completed within 24 hours, and batch sampling adheres to ANSI/ASQ Z1.4 protocols.

Tolerance specifications reflect our mastery of ribbed geometry complexities. The table below details achievable standards for production runs:

| Feature | Tolerance Range | Measurement Method | Applicable Rib Dimensions |

|---|---|---|---|

| Rib Thickness | ±0.025 mm | CMM Cross-Section Scan | 0.5 mm – 5.0 mm |

| Rib Height | ±0.03 mm | Optical Comparator | 1.0 mm – 25.0 mm |

| Rib Straightness | 0.02 mm per 100 mm | CMM Profile Analysis | All lengths |

| Base-to-Rib Perpendicularity | 0.015 mm | CMM GD&T Evaluation | All configurations |

| Surface Roughness (Ra) | 0.4 µm – 0.8 µm | Portable Profilometer | Critical load-bearing ribs |

This disciplined fusion of five-axis machining precision and metrology-driven validation ensures ribbed molding components meet the most demanding performance criteria. Wuxi Lead’s process eliminates secondary operations, reduces scrap rates by 35%, and delivers parts ready for immediate integration into mission-critical assemblies. Partner with us to convert complex ribbed designs into certified, high-yield production realities.

Material & Finish Options

When manufacturing ribbed moldings for high-performance industrial applications, material selection is a critical decision that directly impacts durability, thermal performance, weight, and cost. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, offering precision-engineered solutions in aluminum, steel, and titanium—each suited to specific operational demands. Understanding the mechanical and environmental requirements of your application ensures optimal performance and longevity of the final component.

Aluminum is a preferred choice for ribbed moldings where lightweight construction and excellent thermal conductivity are essential. Its high strength-to-weight ratio makes it ideal for aerospace, automotive, and electronics cooling systems. Aluminum also exhibits strong corrosion resistance, particularly when enhanced with surface treatments such as anodizing. Among the available grades, 6061-T6 and 7075-T6 are commonly used due to their balanced mechanical properties and machinability. Anodized aluminum not only improves wear resistance but also allows for aesthetic customization through color dyeing, making it suitable for both functional and visible components.

Steel, particularly stainless steel grades such as 304 and 316, offers superior strength and exceptional resistance to wear and high temperatures. It is the material of choice for ribbed moldings deployed in harsh environments, including industrial machinery, marine systems, and chemical processing equipment. While heavier than aluminum, steel provides unmatched structural integrity and long-term reliability under continuous load. Its natural corrosion resistance—especially in 316 stainless with added molybdenum—makes it resilient in saline or acidic conditions. Post-machining passivation further enhances its protective oxide layer.

Titanium stands at the pinnacle of performance materials, offering an extraordinary strength-to-density ratio and unparalleled corrosion resistance. It performs reliably in extreme temperatures and aggressive environments, such as offshore oil and gas or aerospace propulsion systems. Though more costly and challenging to machine, titanium’s longevity and performance justify its use in mission-critical applications. It maintains structural stability under thermal cycling, a key advantage in dynamic operating conditions.

Surface finishing, particularly anodizing, plays a vital role in enhancing material performance. Anodizing increases surface hardness, improves corrosion resistance, and provides electrical insulation. For aluminum, Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard, with Type III offering thicker, more durable coatings for high-wear applications.

The following table summarizes key mechanical and physical properties of the materials discussed:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 167 | Good | Anodizing, Passivation |

| Stainless Steel 304 | 8.0 | 505–585 | 16.2 | Excellent | Passivation, Polishing |

| Stainless Steel 316 | 8.0 | 570–620 | 15.1 | Outstanding | Passivation, Electro-polish |

| Titanium Grade 5 | 4.5 | 900 | 7.2 | Exceptional | Anodizing, Sandblasting |

Selecting the right material and finish for ribbed moldings requires a comprehensive evaluation of environmental exposure, mechanical stress, thermal dynamics, and lifecycle costs. At Wuxi Lead Precision Machinery, we support clients in making informed decisions backed by engineering expertise and advanced manufacturing capabilities.

Manufacturing Process & QC

Ribbed Molding Production Process: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our ribbed molding process for custom metal components integrates advanced engineering with rigorous quality control to deliver zero-defect outcomes for precision-critical applications. This structured workflow ensures dimensional integrity, structural performance, and seamless scalability from initial concept to high-volume manufacturing.

The process commences with collaborative Design Engineering. Our team works directly with client specifications, utilizing 3D CAD/CAM software and Finite Element Analysis (FEA) to optimize rib geometry, wall thickness, and material distribution. This phase addresses thermal expansion, load paths, and manufacturability constraints inherent in complex ribbed structures. Critical tolerances, surface finish requirements (Ra 0.8µm standard), and material compatibility (aluminum alloys, stainless steel, titanium) are defined against ISO 2768-mK standards. Material selection is validated for the intended operational environment, ensuring long-term reliability under stress.

Prototyping & Validation follows immediately. We produce 1-5 functional prototypes using high-precision 5-axis CNC milling or additive manufacturing, depending on complexity. Each prototype undergoes comprehensive metrology: Coordinate Measuring Machine (CMM) inspection verifies all critical dimensions against the CAD model, while optical comparators assess rib profile accuracy and edge continuity. Non-destructive testing (NDT) like dye penetrant inspection checks for subsurface flaws. Client feedback is incorporated iteratively; only when prototypes meet 100% of geometric and functional requirements do we approve the design for production. This stage typically reduces field defects by 92% through early anomaly detection.

Zero-Defect Mass Production leverages our closed-loop manufacturing system. Production runs commence on dedicated CNC machining centers equipped with real-time thermal compensation and in-process probing. Each ribbed component is machined using custom toolpaths that minimize vibration and ensure consistent rib formation. Crucially, every 10th part undergoes full CMM inspection, while 100% of parts receive automated vision system checks for surface defects and critical feature presence. Statistical Process Control (SPC) monitors key parameters like cavity depth and rib spacing, triggering automatic tool offset adjustments if trends approach tolerance limits. Our ISO 9001-certified workflow mandates traceability via laser-etched part IDs, linking each unit to its specific machine parameters and inspection data.

This end-to-end discipline guarantees compliance with aerospace and medical industry standards. Below are critical production specifications maintained across all phases:

| Parameter | Production Specification | Quality Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (critical features) | ISO 2768-mK |

| Surface Roughness | Ra 0.4 – 1.6 µm | ASME B46.1 |

| Rib Profile Accuracy | ±0.02 mm max deviation | Client CAD Model |

| Material Certification | Full MTR traceability | AMS, ASTM, EN standards |

| Inspection Coverage | 100% visual, 10% CMM | AQL 0.65 (ISO 2859) |

Wuxi Lead’s commitment to zero defects is operationalized through predictive analytics and relentless process refinement. By embedding quality at every stage—from simulation-driven design to SPC-monitored production—we eliminate waste and deliver ribbed molding solutions that perform flawlessly in mission-critical systems. Partner with us to transform complex geometries into reliable, high-integrity components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Ribbed Molding Solutions

When precision, durability, and performance define your product requirements, partnering with Wuxi Lead Precision Machinery ensures access to engineered excellence in custom metal manufacturing. Specializing in high-complexity ribbed molding components, we deliver tailored solutions that meet the rigorous demands of aerospace, automotive, industrial equipment, and energy sectors. Our expertise in CNC machining, tooling design, and material science enables us to produce ribbed molding profiles with exacting tolerances, superior surface integrity, and long-term structural reliability.

Ribbed molding is not merely a design feature—it’s a functional necessity. Whether used to enhance stiffness-to-weight ratios, improve heat dissipation, or support load-bearing assemblies, ribbed structures demand precision in geometry, consistency in wall thickness, and control over material flow during forming or machining. At Lead Precision, we combine advanced simulation software with high-speed 5-axis CNC machining and automated inspection systems to ensure every component meets your engineering specifications. Our in-house capabilities span prototype development, DFM optimization, and full-scale production, enabling seamless transition from concept to delivery.

We understand that each application presents unique challenges. That’s why we prioritize collaboration from the outset. Our engineering team works directly with your design staff to evaluate material selection, optimize rib geometry, and address potential stress concentrations or manufacturing constraints. Whether you require aluminum alloys, stainless steel, titanium, or specialized composites, we apply process-specific expertise to maintain dimensional stability and surface quality throughout production.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 standards, ensuring consistent quality and traceability across every batch. We utilize coordinate measuring machines (CMM), optical scanners, and real-time process monitoring to validate critical features, including rib pitch, root radius, and profile symmetry. With automated tooling changeovers and lean manufacturing workflows, we maintain competitive lead times without compromising precision.

Below are key technical specifications for our ribbed molding production capabilities:

| Parameter | Capability |

|---|---|

| Material Types | Aluminum (6061, 7075), Stainless Steel (304, 316), Titanium, Brass, Custom Alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry) |

| Minimum Rib Width | 0.8 mm |

| Maximum Component Size | 1200 mm × 800 mm × 500 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Machining Axes | 3-axis, 4-axis, 5-axis CNC |

| Production Volume | Prototypes to High-Volume Series Runs |

| Quality Standards | ISO 9001, IATF 16949, Full Inspection Reports |

Partnering with Wuxi Lead Precision Machinery means more than sourcing a component—it means gaining a manufacturing ally committed to innovation, quality, and on-time delivery. Let us help you transform your ribbed molding designs into high-performance reality.

Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.