Technical Contents

Engineering Guide: Assembly 3D Modelling Services

Engineering Insight Precision in Assembly 3D Modeling Services

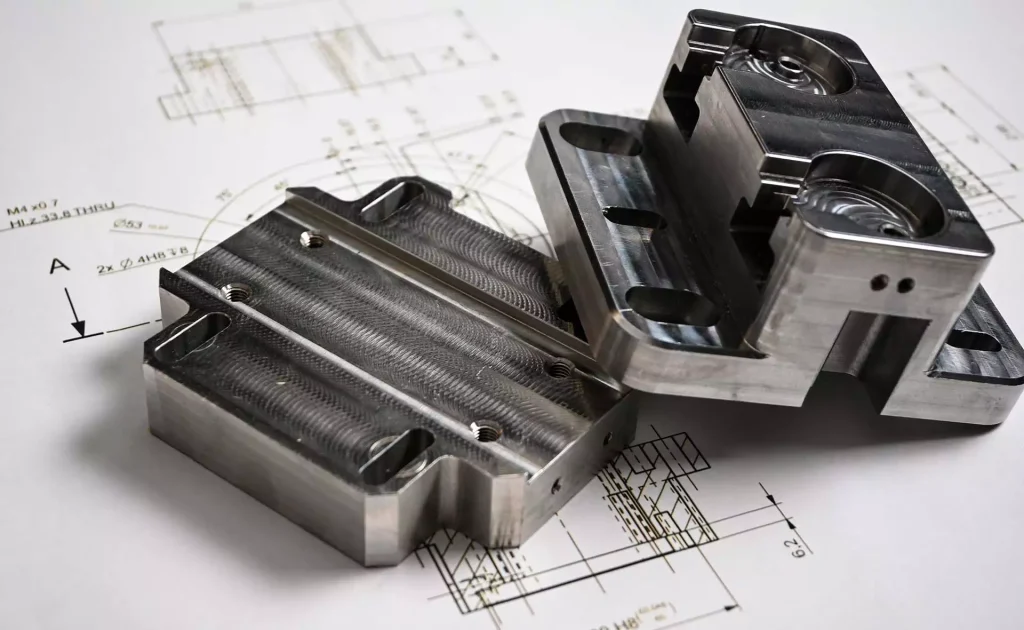

Achieving flawless physical assembly begins long before the first component is machined. It originates in the virtual environment of the 3D assembly model. For high-integrity custom metal manufacturing, especially in aerospace, defense, and advanced industrial equipment, the precision of this digital twin is non-negotiable. Inaccurate models lead to catastrophic downstream consequences: parts that refuse to mate, critical alignment failures, costly rework, and project delays that erode profitability and trust. The assembly model must not only represent individual geometries accurately but must also rigorously validate fit, function, and tolerance stack-up across the entire system under simulated operational conditions. This demands more than basic CAD proficiency; it requires deep engineering insight into manufacturing realities, material behavior, and the cumulative impact of microscopic deviations.

At Wuxi Lead Precision Machinery, we treat assembly 3D modeling as a critical engineering validation step, not merely a drafting exercise. Our process integrates decades of hands-on precision machining expertise directly into the modeling phase. We go beyond nominal dimensions, embedding realistic tolerance zones, anticipated thermal effects, and potential deformation under load into the virtual assembly. This proactive approach identifies interference, clearance issues, and assembly sequence challenges before a single chip is produced, saving significant time and resources. Our engineers leverage advanced simulation tools within the model to predict performance, ensuring the digital assembly accurately forecasts the behavior of the physical product.

Our commitment to precision modeling is proven in the most demanding environments. We have successfully delivered components and sub-assemblies for Olympic-level sporting equipment where marginal gains are measured in milliseconds, and for critical military applications where failure is not an option. These projects demanded assembly models capable of resolving tolerances down to microns and validating complex interactions under extreme stress – a level of rigor we apply to every client project.

The technical foundation of our assembly modeling service is reflected in our core capabilities:

| Parameter | Capability | Application Impact |

|---|---|---|

| Geometric Tolerance | ±0.005mm standard; ±0.001mm achievable | Ensures critical fits in high-precision mechanisms |

| Model Complexity | 50,000+ part assemblies | Handles intricate industrial & aerospace systems |

| Tolerance Stack Analysis | Full GD&T compliant simulation | Predicts cumulative error; prevents assembly failure |

| File Format Support | STEP AP242, Parasolid, JT, native CAD | Ensures seamless integration with client workflows |

| Validation Depth | Kinematic, thermal, FEA pre-check integration | Verifies functional performance pre-manufacture |

This disciplined approach transforms the 3D assembly model from a simple visualization tool into a predictive engineering asset. It is the cornerstone of reliable, efficient, and cost-effective manufacturing for complex metal assemblies. Partnering with a manufacturer whose modeling rigor is forged in mission-critical applications like the Olympics and defense sectors provides the assurance that your assembly will perform exactly as designed, every time. Precision in the model guarantees precision in reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced assembly 3D modeling services tailored for high-precision custom metal manufacturing. Our engineering-driven approach integrates design validation, geometric optimization, and manufacturability analysis to ensure assemblies meet exact functional and dimensional requirements. By leveraging industry-leading CAD and simulation software, we generate fully associative 3D models that support downstream processes including CNC machining, tooling development, and quality assurance. Each assembly model is constructed with precise component relationships, tolerance stack-up analysis, and interface coordination to eliminate fit issues during production and final integration.

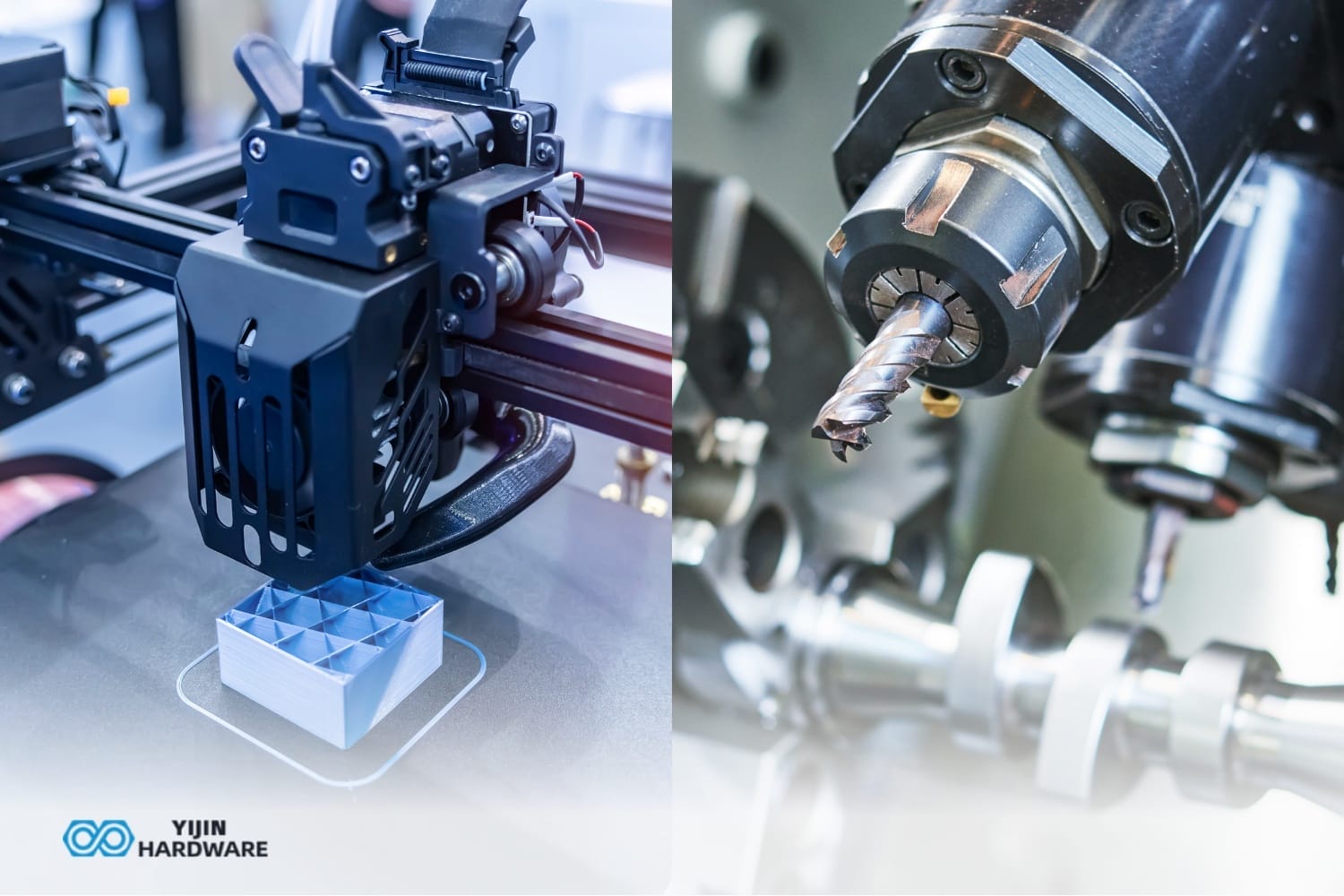

Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with superior surface integrity and tight positional accuracy. These multi-axis platforms allow for single-setup machining of intricate parts, minimizing human intervention and reducing cumulative errors typically associated with multi-stage processes. The integration of 3D assembly modeling with 5-axis programming ensures toolpaths are optimized for both efficiency and precision, particularly for aerospace, medical, and automation components where conformity to design intent is critical.

To maintain the highest standards of quality, every manufactured assembly undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM systems perform non-contact and tactile probing to verify dimensional conformity against the original 3D model, with reports generated in alignment with ISO 10360 standards. This metrology-backed validation process ensures that tolerances are consistently met and provides full traceability for regulated industries. Additionally, our inspection routines include geometric dimensioning and tolerancing (GD&T) verification, surface finish analysis, and first-article inspection (FAI) reporting upon request.

The following table outlines the standard tolerance capabilities achievable through our integrated 3D modeling and machining processes:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on material and geometry |

| Angular Dimensions | ±0.1° | ±0.05° | Verified via CMM and optical alignment |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Includes hole patterns and feature alignment |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Measured with high-precision granite table |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Achieved through fine finishing cycles |

| Thread Accuracy | ISO 2768-mK | ISO 965-2 Class 6H/6g | Internal and external threads |

All tolerances are validated against the final 3D assembly model, ensuring digital continuity from design to delivery. Wuxi Lead Precision Machinery maintains full control over material sourcing, machining parameters, and environmental conditions in our facility to support repeatable, high-integrity production. Our technical team collaborates directly with clients to review assembly models, suggest design improvements, and validate performance criteria before any metal is cut. This proactive engineering support reduces time-to-market and enhances reliability across complex multi-component systems.

Material & Finish Options

Material Selection for Precision Assembly 3D Modeling Services

Material selection is a foundational engineering decision directly impacting the performance, manufacturability, and lifecycle cost of precision-critical assemblies. At Wuxi Lead Precision Machinery, our 3D modeling services integrate deep material science expertise from the earliest design phase. We ensure virtual models accurately reflect real-world material behavior, enabling optimized geometry, tolerance allocation, and process planning. Choosing incorrectly leads to costly redesigns, production delays, or premature field failure. Key considerations include mechanical properties, environmental resistance, weight constraints, thermal characteristics, and secondary processing requirements like finishing.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, robotics, and high-performance automotive applications due to their exceptional strength-to-weight ratio and inherent corrosion resistance. Steel variants, including 304 stainless for chemical resistance and 4140 alloy steel for high strength and wear applications, provide unmatched durability and load-bearing capacity where weight is less critical. Titanium Grade 5 (Ti-6Al-4V) is essential for extreme environments demanding the highest strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility, common in medical implants and critical aerospace components. Each material presents distinct machining characteristics that must be modeled accurately to predict toolpaths, surface finish, and potential distortion.

The following table summarizes critical properties for common engineering alloys used in precision assemblies:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | Very Good | Excellent (A1) |

| Aluminum 7075-T6 | 2.8 | 572 | 503 | Good | Good (A2) |

| Stainless Steel 304 | 8.0 | 515 | 205 | Excellent | Moderate (B) |

| Alloy Steel 4140 | 7.85 | 655 | 414 | Fair | Moderate (B) |

| Titanium Grade 5 | 4.43 | 900 | 830 | Excellent | Poor (C) |

Surface finish selection, particularly anodizing for aluminum, is intrinsically linked to material choice and modeled within our assemblies. Type II (Sulfuric Acid) anodizing provides robust corrosion and wear resistance with dyeing capability for identification, while Type III (Hardcoat) anodizing delivers significantly thicker, harder, and more abrasion-resistant surfaces essential for high-wear components. Our 3D models incorporate precise anodizing thickness allowances (typically 0.0005″ to 0.003″) to maintain critical interference or clearance fits post-finishing. Incorrect modeling of anodizing growth can lead to assembly interference or compromised seal integrity.

Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients during the 3D modeling stage to validate material and finish selections against functional requirements and manufacturing realities. We leverage advanced simulation tools to predict material behavior under load and environmental stress within the digital twin. This proactive approach eliminates downstream surprises, ensuring the final machined assembly meets the highest standards of performance and reliability. Consult our engineering team early in your design process to optimize material selection for your specific application.

Manufacturing Process & QC

From Concept to Precision: The Assembly 3D Modelling Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer manufacturing excellence through a disciplined, three-phase production process: Design, Prototyping, and Mass Production. Each phase is governed by strict quality controls to ensure zero-defect delivery for our global clients in aerospace, medical, automotive, and industrial automation sectors.

The process begins with Design, where our engineering team collaborates closely with client specifications to develop fully parametric 3D assembly models using advanced CAD platforms such as SolidWorks, Siemens NX, and Creo. These models are not just visual representations—they are intelligent, dimensionally accurate digital twins that define tolerances, material properties, and assembly sequences. Our design validation includes interference checking, kinematic simulation, and design-for-manufacturability (DFM) analysis to preempt production issues. Every model is version-controlled and approved through a formal sign-off protocol, ensuring alignment before any physical work begins.

Next is Prototyping, a critical validation stage where digital designs are transformed into physical components using precision CNC machining, sheet metal forming, and laser cutting. Prototypes are produced on the same equipment and with the same material grades used in final production, ensuring realistic performance assessment. We conduct comprehensive functional testing, including fit checks, load testing, and environmental exposure where applicable. Any deviations are traced back to the 3D model for immediate correction, and updated iterations are re-prototyped if necessary. This closed-loop approach ensures that design integrity is maintained and manufacturability is proven before scale-up.

The final phase, Mass Production, leverages the validated design and prototype data to launch high-volume manufacturing with zero rework. Our smart factory integrates automated CNC cells, real-time metrology, and in-process inspection using CMM and optical measurement systems. Every component is traceable via batch coding and digital process logs. Statistical process control (SPC) monitors critical dimensions across production runs, enabling predictive adjustments and eliminating drift. Our quality management system is ISO 9001-certified, and we enforce a zero-defect culture through operator training, poka-yoke (error-proofing), and final 100% inspection for mission-critical parts.

This seamless transition from digital design to flawless physical output is what defines Wuxi Lead’s engineering standard. By anchoring every decision in data-rich 3D models and validating rigorously before scale, we deliver precision, consistency, and reliability—on time, every time.

Key Process Specifications

| Parameter | Specification |

|---|---|

| CAD Software | SolidWorks, Siemens NX, Creo, AutoCAD |

| Tolerance Range | ±0.005 mm to ±0.1 mm (depending on feature) |

| Materials Supported | Aluminum, Stainless Steel, Carbon Steel, Brass, Copper, Titanium |

| Prototype Lead Time | 7–14 days (including testing and review) |

| Mass Production Capacity | Up to 50,000 units/month (per project) |

| Quality Standards | ISO 9001, ISO 13485 (medical), PPAP, APQP |

| Inspection Tools | CMM, Optical Comparator, Laser Scanners, Go/No-Go Gauges |

| Traceability | Full batch-level traceability with digital logs |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Through Precision Engineering Partnership

At Wuxi Lead Precision Machinery, we transform complex assembly 3D modeling from a design hurdle into your competitive advantage. Our engineering team operates at the intersection of advanced CAD/CAM systems and real-world CNC manufacturing constraints. We do not merely interpret your models—we rigorously validate them against material behavior, toolpath feasibility, and geometric dimensioning standards. This eliminates costly downstream revisions, accelerates time-to-market, and ensures first-article success. When you partner with us, your digital assembly becomes a production-ready blueprint, engineered for seamless transition from screen to shop floor.

Our proprietary modeling workflow integrates tolerance stack analysis, multi-axis machining simulation, and DFMA (Design for Manufacturing and Assembly) principles at every stage. Unlike generic modeling services, we embed manufacturing intelligence directly into your 3D assemblies. This prevents common pitfalls like interference clashes, inaccessible fastener points, or unachievable tolerances that derail production schedules. We specialize in mission-critical components for aerospace, medical devices, and industrial automation—where precision is non-negotiable and failure is not an option.

Technical Capabilities at a Glance

| Parameter | Specification | Industry Impact |

|---|---|---|

| File Compatibility | STEP, IGES, Parasolid, SolidWorks, CATIA | Seamless integration with all major PLM systems |

| Geometric Tolerance | ±0.005mm (ISO 2768-mK) | Ensures fit/function in high-precision assemblies |

| Model Complexity Limit | 10,000+ components per assembly | Handles ultra-complex systems (e.g., turbine engines) |

| Validation Turnaround | 72 hours for critical path analysis | Reduces design iteration cycles by 40% |

| Material Simulation | Titanium, Inconel, 17-4PH, PEEK | Predicts thermal deformation during machining |

This technical rigor is backed by our 15,000m² ISO 9001:2015 certified facility in Wuxi, housing 86 CNC machining centers including 5-axis mill-turn systems and wire EDM. We maintain traceable calibration to NIST standards, ensuring every model we deliver aligns with physical production realities. Our engineers hold ASME Y14.5 certification and average 12 years’ experience in high-mix, low-volume metal fabrication—meaning we speak the language of both design engineers and shop floor managers.

Partnering with Lead Precision means gaining a manufacturing extension of your engineering team. We provide actionable feedback during model development—not just after prototype failures occur. Our clients report 30% fewer engineering change orders and 22% lower total production costs when leveraging our integrated modeling-to-manufacturing approach. This is not a service transaction; it is a strategic collaboration to de-risk your supply chain and elevate product performance.

Eliminate the guesswork in assembly production. Submit your 3D model requirements to [email protected] today. Our engineering team will respond within 4 business hours with a detailed capability assessment and production feasibility roadmap. Let us prove how precision modeling becomes your foundation for manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.