Technical Contents

Engineering Guide: Injection Molding In Canada

Engineering Insight: The Role of Precision in Injection Molding in Canada

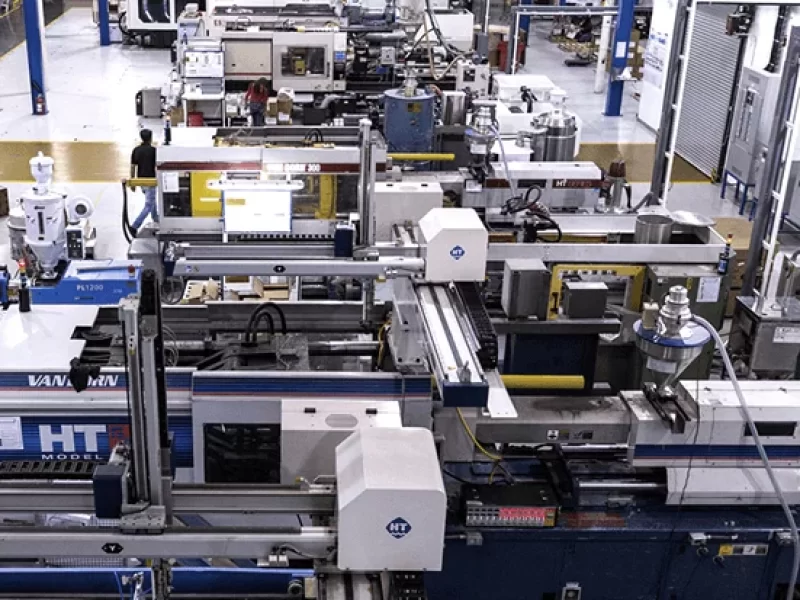

In the evolving landscape of advanced manufacturing, injection molding in Canada continues to serve as a cornerstone for industries demanding high repeatability, structural integrity, and material efficiency. While traditionally associated with plastics, the integration of precision metal components—particularly in aerospace, defense, and medical sectors—has elevated the need for tighter tolerances and superior process control. This shift underscores a critical truth: the success of injection molding applications, especially in mission-critical environments, hinges on precision engineering at every stage.

Canadian manufacturers are increasingly adopting metal injection molding (MIM) and precision insert molding techniques to meet the demands of lightweight, complex components. These processes require not only advanced tooling but also an in-depth understanding of material behavior, thermal dynamics, and geometric accuracy. A deviation of even a few microns can compromise part functionality, especially in applications such as aerospace actuators or medical implant carriers. This is where the expertise of specialized metal manufacturing partners becomes indispensable.

Wuxi Lead Precision Machinery brings over 15 years of experience in delivering custom metal solutions that meet the most stringent global standards. Our engineering team has supported projects for Olympic-grade equipment and military-grade defense systems, where failure is not an option. These high-stakes applications demand more than just advanced machinery—they require a culture of precision, rigorous quality control, and deep metallurgical insight. This same discipline is applied to every component we produce for the Canadian injection molding sector.

Our collaboration with North American partners focuses on the production of precision molds, inserts, and structural components that directly influence the performance and longevity of injection molding systems. From hardened tool steels to corrosion-resistant alloys, our manufacturing processes—including CNC milling, wire EDM, and surface grinding—are calibrated to achieve tolerances within ±0.002 mm. This level of accuracy ensures seamless integration with molding equipment, reduces cycle times, and minimizes wear—critical factors in high-volume production environments.

The following table outlines key specifications that define our precision manufacturing capabilities for injection molding applications:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 – 0.8 µm |

| Materials | 420SS, 17-4PH, H13, Tool Steel, Titanium Alloys |

| Maximum Part Weight | 50 kg |

| Machining Processes | 5-axis CNC, Wire EDM, Surface Grinding, CMM Inspection |

| Quality Standards | ISO 9001:2015, MIL-STD-810G (for defense projects) |

In Canada’s competitive manufacturing ecosystem, partnering with a supplier that combines technical excellence with proven field performance is essential. Wuxi Lead Precision Machinery stands at the intersection of innovation and reliability, providing Canadian injection molders with the precision metal components necessary to maintain global competitiveness. Whether supporting next-generation medical devices or ruggedized defense systems, our engineering insight ensures that precision is not just a specification—it’s a guarantee.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Injection Mold Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components for the Canadian injection molding industry through integrated high-precision manufacturing systems. Our facility specializes in complex mold bases, cavities, cores, and inserts requiring micron-level accuracy and superior surface integrity. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, featuring Siemens or Heidenhain controls with nanometer-resolution feedback systems. These machines enable single-setup machining of intricate geometries—including undercuts, conformal cooling channels, and organic parting lines—eliminating cumulative errors from multiple fixturing operations. Material utilization efficiency exceeds 95% for premium mold steels such as NAK80, S136, and H13, while high-speed machining protocols minimize thermal distortion during production. All processes adhere to ISO 9001:2015 and IATF 16949 standards, with digital work instructions traceable to individual machine tool calibration records.

Precision Validation Through Metrology

Every component undergoes rigorous dimensional verification via Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM). Our metrology lab operates under ISO/IEC 17025 accreditation, with temperature-controlled environments maintained at 20°C ±0.5°C. CMM inspection routines validate geometric dimensioning and tolerancing (GD&T) per ASME Y14.5, including complex profile tolerances and position callouts critical for mold alignment. Statistical process control (SPC) data is generated for high-volume runs, with real-time capability indices (Cp/Cpk) reported to clients. Surface roughness is quantified using Mitutoyo SJ-410 profilometers, ensuring cavity finishes meet SPI-A1 to A3 standards or client-specified Ra values. Full inspection reports, including 3D deviation color maps, are provided with each shipment.

Achievable Tolerance Specifications

| Parameter | Standard Capability | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / Air Gage |

| Geometric Tolerances | ±0.015 mm | ±0.005 mm | CMM / Optical Comparator |

| Hole Position | ±0.012 mm | ±0.004 mm | CMM / Ball Bar |

| Surface Roughness | Ra 0.8 μm | Ra 0.2 μm | Profilometer |

| Flatness | 0.015 mm | 0.005 mm | CMM / Optical Flat |

These specifications are validated across production runs of 1–500+ units, with first-article inspection (FAI) reports compliant with AS9102B. Our technical team collaborates directly with Canadian mold designers during DFM analysis to optimize manufacturability—recommending tolerance adjustments that maintain functionality while reducing lead times by 15–25%. This engineering partnership ensures seamless integration of our components into mold assemblies, directly enhancing cycle time stability and part consistency for end-product manufacturers. Wuxi Lead Precision Machinery provides the dimensional certainty required for high-cavitation molds operating in demanding Canadian production environments, from automotive to medical device sectors.

Material & Finish Options

Material Selection for Injection Molding Tooling in Canada: Aluminum, Steel, and Titanium

Selecting the appropriate material for injection molding tooling is critical to achieving optimal performance, longevity, and cost-efficiency in high-volume or precision manufacturing environments. In Canada’s competitive industrial landscape, where environmental conditions and production demands vary significantly, choosing between aluminum, steel, and titanium requires a thorough understanding of mechanical properties, thermal behavior, and compatibility with finishing processes such as anodizing. Wuxi Lead Precision Machinery provides expert guidance on material selection tailored to North American manufacturing standards and production requirements.

Aluminum is widely used for prototype molds and low-to-medium volume production due to its excellent machinability and thermal conductivity. It enables faster cycle times by dissipating heat efficiently, making it ideal for rapid development cycles common in the automotive and consumer electronics sectors. However, aluminum’s lower hardness limits its use in high-wear applications. When paired with hard anodizing, aluminum tools gain improved surface hardness and wear resistance, extending service life while maintaining thermal advantages.

Steel, particularly tool steels such as P20, H13, and S136, remains the standard for high-volume injection molding. Its superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling make it suitable for complex molds producing millions of cycles. Stainless steel variants also offer corrosion resistance, essential for molding abrasive or chemically aggressive resins. While steel molds require longer machining times and higher initial costs, their durability provides a lower total cost of ownership in large-scale operations across Canadian manufacturing facilities.

Titanium is less common but offers exceptional strength-to-density ratio and corrosion resistance. Though rarely used for full mold bodies due to cost and machinability challenges, titanium alloys are increasingly considered for critical mold components such as inserts and ejector pins where weight reduction and resistance to galling are paramount. Its biocompatibility also makes it suitable for medical-grade molding applications, a growing sector in Canada’s advanced manufacturing industry.

Anodizing is a key surface treatment, particularly for aluminum molds. The process creates a durable, non-conductive oxide layer that enhances wear and corrosion resistance. Hard anodizing, performed under controlled low temperatures with sulfuric acid electrolytes, can produce coatings with hardness exceeding 60 HRC, significantly improving tool life in abrasive molding environments.

The following table summarizes key mechanical and thermal properties of these materials relevant to injection molding tooling:

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Common Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 540–570 | 150 | 130 | Moderate (improved with anodizing) | Prototyping, low-volume production |

| Tool Steel H13 | 1,300–1,600 | 230 | 35 | Good | High-volume, high-temperature molds |

| Stainless Steel S136 | 900–1,100 | 280 | 25 | Excellent | Corrosion-resistant precision molds |

| Titanium Grade 5 | 900–1,000 | 360 | 7 | Exceptional | High-stress inserts, medical molds |

Material selection must align with production volume, part complexity, resin type, and total cost targets. Wuxi Lead Precision Machinery supports Canadian manufacturers with custom tooling solutions engineered for performance, supported by advanced finishing techniques like hard anodizing to maximize service life and consistency.

Manufacturing Process & QC

Precision Injection Molding Process: From Concept to Zero-Defect Production for Canadian Manufacturers

Achieving flawless metal components for demanding Canadian industries—from aerospace in Quebec to medical devices in Ontario—requires an uncompromising, integrated production process. At Wuxi Lead Precision Machinery, we eliminate defects at the source through a rigorously controlled sequence: Design Validation, High-Fidelity Prototyping, and Smart Mass Production. This methodology ensures your parts meet stringent Canadian standards while optimizing cost and lead time.

Design is the critical foundation where 80% of potential defects originate. Our engineering team collaborates directly with your CAD models, performing advanced mold flow analysis and structural simulations specific to Canadian material certifications and environmental conditions. We interrogate draft angles, wall thickness transitions, and gate locations to prevent sink marks, warpage, or voids before metal is cut. This phase includes formal Design for Manufacturability (DFM) sign-off, ensuring geometric complexity aligns with achievable tolerances and your application’s thermal or load requirements. Skipping this step risks costly rework during production.

Prototyping transforms validated designs into physical reality under production-intent conditions. Using our HAAS and DMG MORI 5-axis CNC centers, we machine prototype molds from H13 or S136 tool steel, mirroring mass production metallurgy. Each prototype part undergoes full metrology on Zeiss CMMs against your 3D model, verifying critical dimensions, surface finishes, and assembly interfaces. For Canadian clients, we prioritize validation of corrosion resistance per ASTM B117 and dimensional stability across temperature ranges relevant to Canadian operational environments. Only after prototype approval—confirming zero deviations from spec—do we proceed.

Mass production leverages Industry 4.0 controls to sustain zero defects. Our dedicated molding cells feature real-time pressure, temperature, and velocity monitoring synchronized with robotic part handling. Every cycle is documented via SPC software, with automatic machine lockout if parameters drift beyond ±0.5%. In-process inspections occur hourly using calibrated gages, while final inspection employs 100% critical dimension checks and batch-level material traceability. This closed-loop system intercepts anomalies before they escalate, ensuring consistent output meeting ISO 2768-mK or tighter tolerances demanded by Canadian OEMs.

Our process delivers measurable advantages for Canadian supply chains, as evidenced by key performance metrics:

| Parameter | Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm |

| In-Process Scrap Rate | 3-5% | < 0.25% |

| First Article Approval Time | 10-14 days | ≤ 5 days |

| Traceability Depth | Lot-level | Cavity/Serial-level |

This disciplined approach transforms injection molding from a cost center into a strategic asset for Canadian manufacturers. By embedding quality at every phase—from digital design validation through AI-driven production—we eliminate scrap, reduce time-to-market, and guarantee parts perform reliably in Canada’s toughest applications. Contact Wuxi Lead to implement a zero-defect process tailored to your next metal component program.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Molding Solutions in Canada

When Canadian manufacturers demand precision, durability, and performance in injection molding components, they turn to global leaders with proven engineering excellence. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that meet the rigorous standards of the injection molding industry. Our expertise spans mold bases, precision inserts, ejector systems, and custom tooling engineered to enhance mold longevity and production efficiency. As a trusted partner to forward-thinking manufacturers across North America, we deliver high-performance components that integrate seamlessly into complex molding operations.

Canada’s injection molding sector faces increasing pressure to improve cycle times, reduce downtime, and maintain tight tolerances under high-pressure environments. Off-the-shelf components often fall short. That’s where Wuxi Lead Precision Machinery excels. We design and manufacture fully customized metal solutions using premium-grade materials such as P20, 718H, H13, and S136 stainless steel, all processed through CNC machining, wire EDM, surface grinding, and heat treatment to ensure dimensional stability and wear resistance. Our in-house quality control systems, including CMM inspection and hardness testing, guarantee every part meets or exceeds international standards.

Our engineering team collaborates directly with clients to analyze application requirements, optimize material selection, and deliver solutions tailored to specific molding machines and production environments. Whether you require large-scale mold bases for automotive applications or micro-precision inserts for medical-grade molding, our agile manufacturing processes support rapid prototyping and scalable production runs. With decades of experience serving global markets, we understand the technical demands of high-cavitation molds, hot runner integration, and thermal management systems.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, H13, S136, 420 Stainless Steel, Tool Steel Alloys |

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm (polished to mirror finish if required) |

| Heat Treatment | Vacuum Hardening, Nitriding, Quench & Temper (HRC 28–52 adjustable) |

| Machining Processes | 5-Axis CNC, Wire EDM, Surface & Cylindrical Grinding |

| Quality Assurance | Full CMM Reporting, Hardness Testing, First Article Inspection |

| Lead Time | 15–30 days (varies by complexity and order volume) |

| Certifications | ISO 9001:2015, RoHS Compliant Materials |

We are committed to being more than a supplier—we are a strategic partner in your manufacturing success. By combining Chinese manufacturing efficiency with European-level precision and North American customer support, we offer a unique value proposition for injection molding operations in Canada.

For immediate technical consultation or to request a quote on custom components, contact us at [email protected]. Our engineering team is ready to support your next project with precision, reliability, and speed. Partner with Wuxi Lead Precision Machinery and elevate the performance of your injection molding systems.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.