Technical Contents

Engineering Guide: Injection Molding Careers

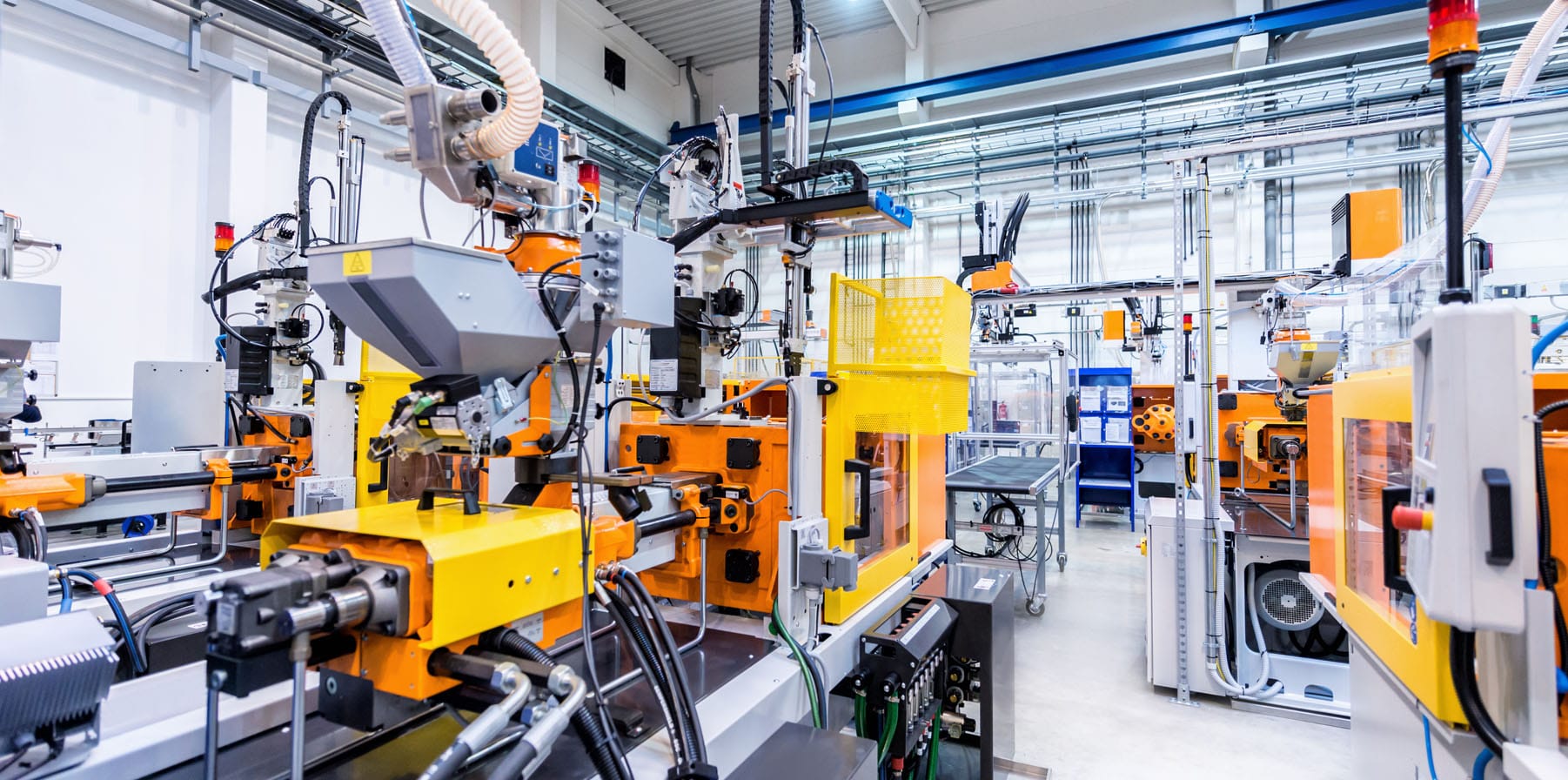

In the world of custom metal manufacturing, precision is not merely a goal—it is the foundation upon which reliability, performance, and innovation are built. Nowhere is this more evident than in injection molding, where the integrity of every component hinges on micron-level accuracy and repeatable consistency. Careers in injection molding demand a deep understanding of material science, tooling design, and process control, but at the core of every successful operation lies an unwavering commitment to precision engineering.

At Wuxi Lead Precision Machinery, we have spent over 15 years refining our capabilities to meet the most stringent requirements in the industry. Our experience extends to high-stakes applications, including components used in Olympic-grade equipment and mission-critical military systems. These projects demand zero margin for error, where even a deviation of a few microns can compromise structural integrity or operational performance. It is this level of accountability that defines the modern injection molding professional—engineers and technicians who blend technical mastery with meticulous attention to detail.

Precision in injection molding begins with tooling. The mold itself must be manufactured to exacting tolerances, often using hardened steels or advanced alloys, and machined with CNC equipment capable of sub-micron repeatability. At Lead Precision, our in-house tooling division leverages state-of-the-art 5-axis machining centers and laser measurement systems to ensure every cavity and core aligns perfectly. This precision translates directly into part consistency, reduced cycle times, and minimized post-processing—key factors in high-volume production environments.

Beyond tooling, process optimization plays a vital role. Injection parameters such as pressure, temperature, and cooling rates must be precisely controlled to prevent warping, sink marks, or internal stresses. Our engineering teams employ real-time monitoring systems and statistical process control (SPC) to maintain stability across production runs. This data-driven approach is now a standard expectation in advanced manufacturing careers, where operators and engineers are required to interpret complex datasets and make rapid, informed decisions.

For professionals entering or advancing in injection molding careers, the bar is higher than ever. Employers seek individuals who understand the interplay between design, materials, and machinery—and who can uphold the precision standards demanded by aerospace, defense, and high-performance sports industries.

The following table outlines key precision specifications routinely achieved at Wuxi Lead Precision Machinery:

| Specification | Typical Value | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | CMM (Coordinate Measuring Machine) |

| Surface Finish | Ra 0.1 – 0.4 µm | Surface Profilometer |

| Mold Alignment | < 0.005 mm runout | Laser Alignment System |

| Part Repeatability (Cp/Cpk) | ≥ 1.67 / 1.33 | Statistical Process Control |

| Tool Life | > 1,000,000 cycles | In-Process Monitoring |

Precision is not an accident—it is engineered. At Wuxi Lead Precision Machinery, we continue to set benchmarks in custom metal manufacturing by combining advanced technology with disciplined engineering practices. For those pursuing careers in injection molding, mastering this discipline is the key to unlocking opportunities in the most demanding sectors of global industry.

Precision Specs & Tolerances

Precision Metal Components for Advanced Injection Molding Systems

Wuxi Lead Precision Machinery delivers the exacting metal components essential for high-performance injection molding applications. Our core competency lies in transforming complex engineering designs into mission-critical mold bases, inserts, cores, and precision tooling hardware. This capability is fundamentally enabled by our advanced manufacturing infrastructure, specifically engineered to meet the stringent demands of modern molding processes where dimensional stability, surface integrity, and thermal management are non-negotiable.

Central to our technical offering is a dedicated fleet of state-of-the-art 5-axis CNC machining centers, primarily DMG MORI and Makino platforms. These systems provide the simultaneous multi-directional movement required to machine intricate contours, deep cavities, and undercuts in a single setup. This eliminates cumulative error from multiple fixturing operations, ensuring superior geometric accuracy and part consistency vital for molds producing tight-tolerance plastic components. We routinely machine challenging materials including P20, H13, S136 stainless steel, aluminum alloys, and specialized tool steels to the exact specifications demanded by the molding cycle and end-part requirements.

Rigorous quality control is integrated at every stage, forming the bedrock of our reliability. Comprehensive Coordinate Measuring Machine (CMM) inspection is mandatory for all critical features. Our Zeiss and Hexagon CMMs perform 100% first-article inspection against CAD models and conduct statistical process control (SPC) on high-volume runs. This data-driven approach guarantees that every component adheres to the specified dimensional and geometric tolerances before shipment. Surface finish verification via profilometry and hardness testing further validate material properties and process control.

Our commitment to precision is quantifiable through the achievable tolerances across key feature types. The following table reflects our standard production capabilities; tighter tolerances are attainable through specialized processes and rigorous process validation for critical applications.

| Feature Type | Standard Tolerance | Precision Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Geometric (Flatness) | 0.010 mm | 0.005 mm |

| Geometric (Roundness) | 0.008 mm | 0.003 mm |

| Hole Diameter | +0.008 / -0.000 mm | +0.003 / -0.000 mm |

| Positional Accuracy | ±0.008 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

This level of dimensional control directly translates to reduced molding downtime, minimized part flash, extended mold life, and consistent plastic part quality for our customers. We understand that the performance of an injection mold is intrinsically linked to the precision of its metal components. Wuxi Lead Precision Machinery provides the technical foundation – through advanced 5-axis machining, uncompromising CMM-based quality assurance, and demonstrable tolerance mastery – necessary for mold makers and brand owners to achieve excellence in high-volume, high-specification plastic part production. Partnering with us ensures your molding systems are built on components engineered for peak performance and longevity.

Material & Finish Options

Material Selection for Injection Molding Components: A Precision Engineering Guide

In high-precision injection molding tooling, material selection directly influences tool life, part quality, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of injection mold fabrication. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal performance, and cost targets. Each material offers distinct mechanical properties and responds uniquely to surface treatments such as anodizing, which enhances durability and wear resistance.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-volume production. Their high thermal conductivity enables rapid cooling, reducing cycle times significantly. Additionally, aluminum is easier to machine, allowing for faster lead times and lower fabrication costs. However, its lower hardness compared to steel limits its use in high-wear applications. Anodizing aluminum is a standard practice in mold manufacturing, creating a protective oxide layer that improves surface hardness, corrosion resistance, and release properties. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with hardcoat anodizing offering superior wear resistance for critical mold surfaces.

Steel remains the dominant material for high-volume injection molding due to its exceptional strength, hardness, and longevity. Tool steels such as P20, H13, and S136 are frequently selected based on required toughness, polishability, and resistance to corrosion. While steel molds require longer machining times and higher initial investment, their extended service life justifies the cost for large production runs. Surface treatments such as nitriding and chrome plating are often used with steel, though anodizing is not applicable due to steel’s composition. Instead, precision polishing and electroplating are preferred for enhancing surface finish and part release.

Titanium, though less common, offers a unique combination of high strength-to-density ratio, excellent corrosion resistance, and thermal stability. It is typically reserved for specialized applications where weight reduction and extreme durability are critical. While challenging to machine and costly, titanium molds can outperform both aluminum and steel in aggressive environments, such as molding highly corrosive resins. Surface treatments like anodizing are effective on titanium, providing not only protection but also aesthetic coloration through controlled oxide layer thickness.

Understanding the trade-offs between these materials ensures optimal mold performance and cost-efficiency. Below is a comparative overview of key properties.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatible |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | Prototypes, low-volume | Yes (Type II, III) |

| P20 Steel | 280–320 | 30 | High-volume production | No |

| H13 Steel | 230–260 | 35 | Hot-runner systems | No |

| Titanium (Grade 5) | 360 | 7.2 | Corrosive environments | Yes (decorative/protective) |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and surface treatment based on application requirements, ensuring molds meet exacting standards for precision, durability, and performance.

Manufacturing Process & QC

Injection Molding Production Process: The Zero Defects Pathway

Mastering the end-to-end injection molding production process is fundamental for career advancement in high-precision custom metal manufacturing. At Wuxi Lead Precision Machinery, we define excellence through a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase demands specialized engineering skills and unwavering commitment to Zero Defects, forming the core competency ladder for operators, technicians, and engineers within our facility and across the industry.

The Design Phase initiates the journey, where cross-functional teams translate client specifications into manufacturable reality. Our engineers utilize advanced CAD/CAM software and mold flow analysis to optimize part geometry, material selection, and gating systems. Critical considerations include thermal management, ejection mechanics, and stress distribution to prevent warpage or sink marks. This stage establishes the foundational tolerances and surface finish requirements that subsequent phases must achieve. Precision here eliminates 80% of potential defects before metal cutting begins, making expertise in simulation and DFM analysis highly valued.

Prototyping follows, serving as the critical validation checkpoint. Using high-speed CNC machining and electrical discharge machining (EDM), we produce single-cavity molds from premium tool steels like H13 or S136. Short-run trials under controlled parameters verify the design’s integrity. Every prototype undergoes comprehensive metrology: CMM inspections, optical comparators, and material testing confirm dimensional accuracy, mechanical properties, and surface quality against the original CAD model. This phase identifies subtle flaws—micro-shrinkage, flow lines, or venting issues—that full-scale production could amplify. Technicians skilled in rapid mold iteration and failure analysis are indispensable here.

Mass Production executes the perfected process at scale, where Zero Defects becomes non-negotiable. Multi-cavity molds, often with hot runner systems, run under tightly monitored conditions. Real-time sensors track pressure, temperature, and cycle time, feeding data to our centralized MES. Automated in-line vision systems and robotic part handling ensure 100% inspection against critical dimensions. Statistical process control (SPC) charts continuously validate process stability. Any deviation triggers immediate corrective action, preventing defect propagation. Operators and process engineers must possess deep knowledge of polymer science, machine dynamics, and SPC to maintain this flawless output.

The table below summarizes key specifications governing our Zero Defects mandate across phases:

| Phase | Critical Parameters | Zero Defects Verification Method |

|---|---|---|

| Design | ±0.02mm nominal tolerance; Mold flow balance; Gate location optimization | Simulation validation; DFM sign-off; Material datasheet compliance |

| Prototyping | ±0.005mm critical feature tolerance; Surface roughness Ra ≤ 0.8μm | CMM full-scan; Destructive material testing; Visual inspection per AQL 0.65 |

| Mass Production | ±0.002mm critical feature tolerance; Cycle time stability ±0.5s; Cpk ≥ 1.67 | 100% automated vision; Real-time SPC; Batch certification with traceability |

Achieving Zero Defects requires seamless integration of these phases and deep technical mastery at every role level. Professionals who understand how design choices impact mold longevity, how prototyping data informs production parameters, and how real-time analytics prevent scrap become the strategic assets driving our industry forward. This disciplined process flow isn’t just how we manufacture—it’s the career pathway to engineering leadership in precision manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision to Advance Your Injection Molding Career

At Wuxi Lead Precision Machinery, we don’t just manufacture high-performance metal components—we shape the future of precision engineering. For professionals pursuing a career in injection molding, partnering with Lead Precision means aligning with a global leader in custom metal manufacturing, where innovation, precision, and reliability define every project. Our advanced CNC machining capabilities, deep expertise in mold base production, and commitment to quality make us the preferred partner for Tier 1 manufacturers across automotive, medical, electronics, and industrial sectors.

We understand that a successful injection molding career depends on access to cutting-edge technology, rigorous quality standards, and collaborative engineering support. That’s why we offer more than just parts—we deliver integrated manufacturing solutions that empower design engineers, mold makers, and production teams to achieve superior outcomes. Whether you’re developing complex mold inserts, precision cavities, or high-tolerance ejector systems, our team works closely with clients to ensure optimal material selection, thermal performance, and longevity under high-cycle production environments.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 certifications, ensuring every component meets the strictest international standards. With over 15 years of specialization in custom mold bases and precision-machined metal components, we combine German-inspired engineering principles with state-of-the-art 5-axis CNC centers, wire EDM, and surface grinding technologies. This enables us to deliver tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.05 µm—critical benchmarks for high-cavity and hot-runner mold applications.

For professionals committed to excellence in injection molding, collaboration with Lead Precision opens doors to scalable, repeatable, and technically advanced manufacturing partnerships. We support low-volume prototyping through high-volume production runs, offering rapid turnaround times without compromising on quality. Our engineering team provides DFM analysis, mold flow support, and material optimization guidance—ensuring your designs translate into robust, manufacturable solutions.

Partnering with us means gaining a transparent, responsive, and technically capable ally invested in your long-term success. We communicate in English, offer real-time project tracking, and maintain strict IP confidentiality—essential for global OEMs and contract manufacturers.

To explore how we can support your next injection molding project or advance your professional capabilities through precision manufacturing, contact us today.

Technical Specifications Overview

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.05 µm |

| Max Workpiece Size | 2000 x 1200 x 800 mm |

| Materials Supported | P20, 718, H13, S136, 420SS, Aluminum 7075, etc. |

| CNC Equipment | 5-Axis, 3-Axis, Wire EDM, Surface Grinders |

| Quality Standards | ISO 9001, IATF 16949 |

| Lead Time (Standard) | 15–25 days (varies by complexity) |

| Surface Hardness (HRC) | Up to 52 HRC (post-treatment) |

Contact us at [email protected] to begin a partnership built on precision, performance, and progress.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.