Technical Contents

Engineering Guide: Injection Moldable Plastics

Engineering Insight: Injection Moldable Plastics Require Precision Metal Tooling Foundations

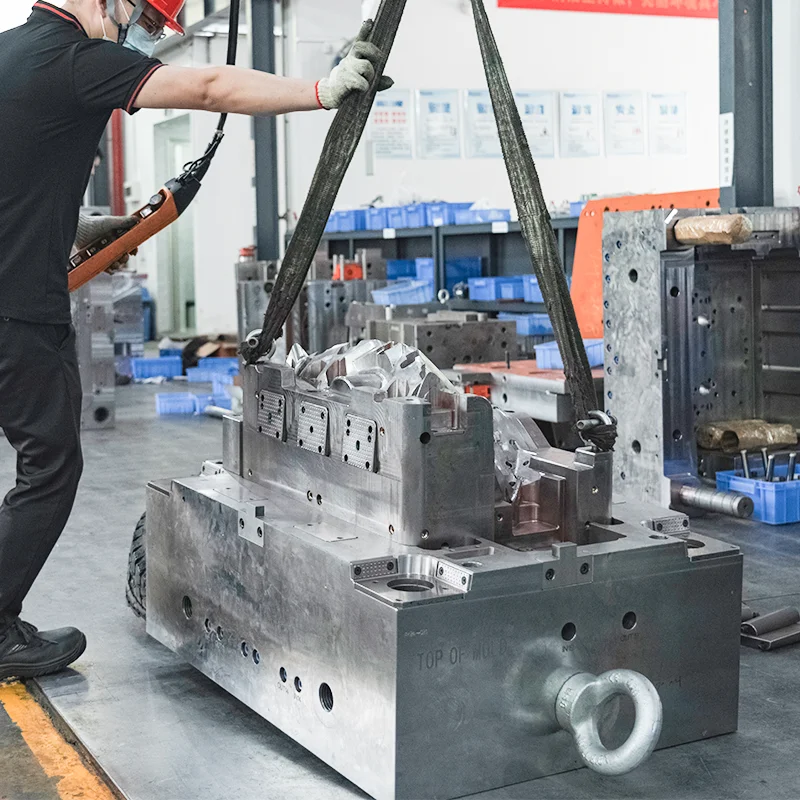

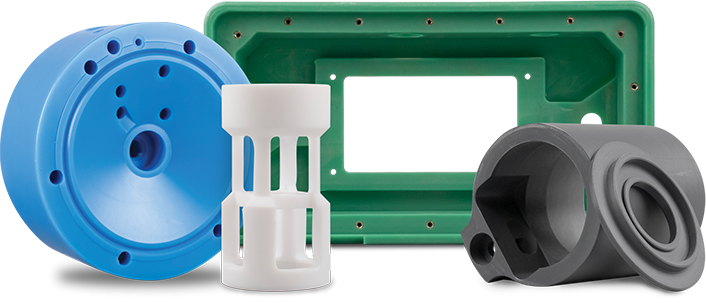

Achieving flawless injection molded plastic components begins not with the polymer but with the precision of the metal tooling. Variations in mold geometry directly translate to part defects—warpage, sink marks, or flash—that compromise structural integrity and assembly. In high-stakes applications like aerospace connectors or medical fluidics, even micron-level deviations can trigger functional failure. The root cause often lies in inadequate tooling rigidity, thermal management, or dimensional control during metal fabrication. At Wuxi Lead Precision Machinery, we treat mold cores, cavities, and inserts as mission-critical metal components demanding aerospace-grade tolerances, not disposable tooling.

Our CNC-machined mold bases and inserts consistently achieve ±0.005mm positional accuracy and Ra 0.05µm surface finishes—specifications validated through decades of producing tooling for Olympic-certified equipment and military-grade hardware. For instance, molds supplying components to Beijing 2022 Winter Games infrastructure required zero-defect output under extreme thermal cycling, while defense sector housings demanded hermetic seals at 150MPa injection pressures. This rigor eliminates trial-and-error in plastic molding, reducing scrap rates by up to 30% and accelerating time-to-market. Precision metal tooling isn’t a cost; it’s the foundation of repeatable polymer flow, consistent cooling, and end-part reliability.

The table below contrasts standard versus precision-engineered mold specifications, demonstrating where metal accuracy dictates plastic performance:

| Specification | Standard Tooling | Wuxi Lead Precision Tooling | Impact on Plastic Part |

|---|---|---|---|

| Cavity Tolerance | ±0.05mm | ±0.005mm | Eliminates flash; ensures assembly fit |

| Core Alignment | ±0.03mm | ±0.002mm | Prevents wall-thickness variation |

| Cooling Channel Accuracy | ±0.1mm | ±0.01mm | Reduces warpage by 40% |

| Surface Finish (Ra) | 0.8µm | 0.05µm | Enhances ejection; minimizes sink |

| Hardness Uniformity | ±5 HRC | ±1 HRC | Extends mold life 3x under high-cycle production |

For manufacturers targeting automotive or medical sectors, these tolerances are non-negotiable. A 0.02mm shift in ejector pin alignment can crack thin-walled biofluidic channels; inconsistent cooling induces residual stress in polycarbonate lenses. Wuxi Lead’s ISO 13485-certified processes—leveraging 5-axis milling, EDM, and laser texturing—transform metal blanks into thermal-stable, dimensionally stable platforms. We collaborate with material scientists to preempt polymer-specific challenges, such as PEEK’s 0.7% shrinkage or LCP’s anisotropic flow, by engineering compensating geometries into the metal tool itself.

The outcome is predictable: first-article approval rates exceeding 95% and molds sustaining 1M+ cycles without rework. In precision molding, the metal tool isn’t a vessel—it’s the silent engineer dictating plastic behavior. Partner with a manufacturer that treats your mold steel with the same gravity as your end application demands. Wuxi Lead delivers the metal foundation where polymers perform flawlessly.

Precision Specs & Tolerances

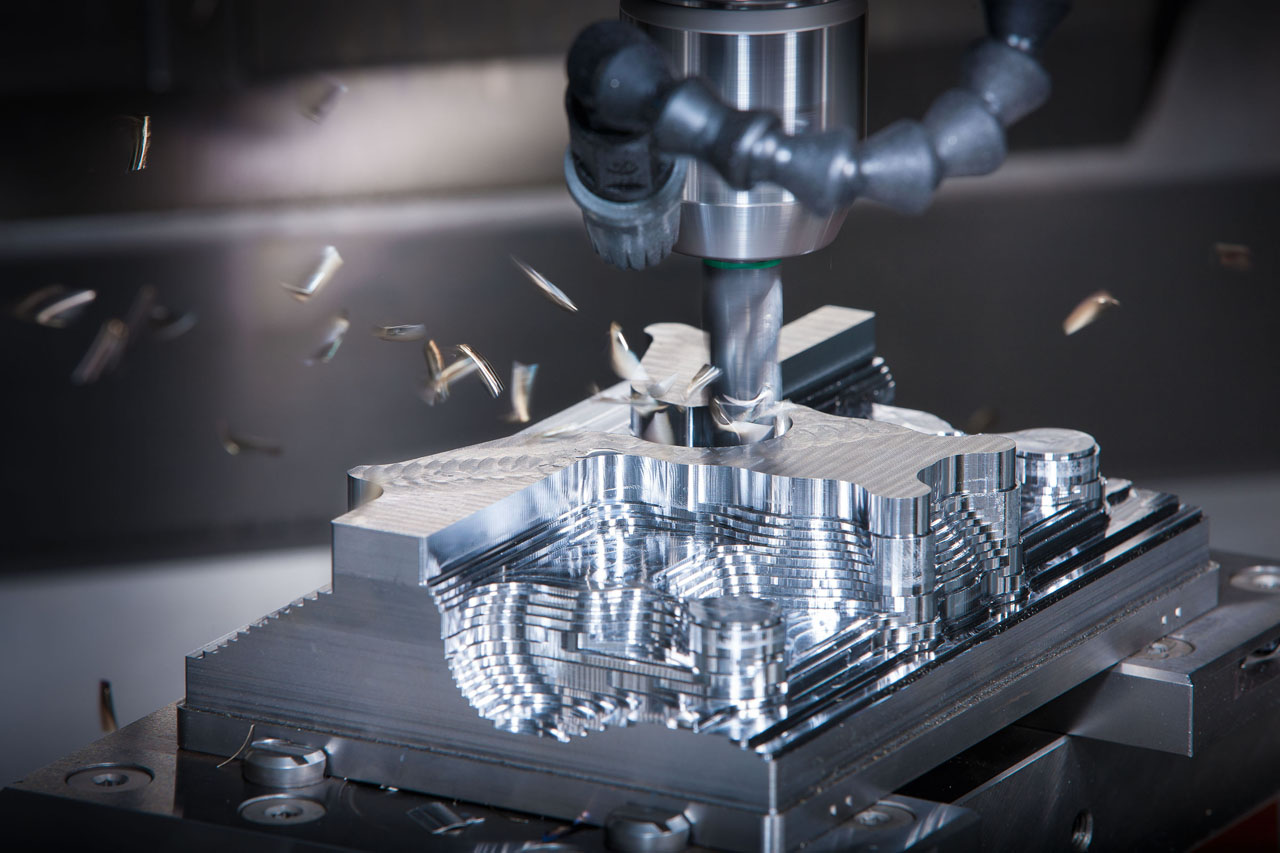

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the stringent demands of high-performance industries, including aerospace, medical, automotive, and industrial equipment. At the core of our technical capabilities is our precision 5-axis CNC machining platform, which enables the production of complex, net-shape components with exceptional accuracy and surface finish. This technology allows for simultaneous multi-axis movement, reducing setup times and part handling while maintaining geometric integrity across intricate contours and deep cavities.

Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time tool compensation, ensuring consistent material removal rates and dimensional stability across a wide range of metals—from hardened steels and titanium alloys to aluminum and specialty stainless grades. This flexibility supports the fabrication of molds, inserts, and structural components designed for injection molding applications, where thermal conductivity, wear resistance, and long service life are critical. Each machine is operated by certified machinists with extensive experience in tight-tolerance work, ensuring adherence to engineering specifications from prototype to full-scale production.

Quality is integrated into every phase of our manufacturing process. All critical components undergo comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM) with tactile and optical probing systems. This allows for full 3D geometric dimensioning and tolerance (GD&T) verification, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Our CMM inspection routines are programmed to match customer CAD models, enabling first-article inspection reports (FAIR), production part approval process (PPAP) documentation, and batch traceability. In addition to CMM analysis, we utilize surface roughness testers, hardness testers, and optical comparators to validate material and finish characteristics.

The following table outlines the standard precision tolerances we consistently achieve through our integrated machining and inspection workflow:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Roundness | 0.008 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities are supported by a robust quality management system compliant with ISO 9001:2015 standards. At Wuxi Lead Precision Machinery, we combine cutting-edge 5-axis CNC technology with rigorous metrology to deliver injection mold components that meet the highest standards of precision, repeatability, and durability. Our engineering team collaborates closely with clients to optimize designs for manufacturability, ensuring rapid turnaround without compromising quality.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal base material for injection molds is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we engineer custom metal molds where material properties must withstand significant thermal cycling, mechanical stress, and corrosive environments inherent in high-volume plastic molding. Aluminum, steel, and titanium each offer distinct advantages and limitations; the choice hinges on production volume, part complexity, resin characteristics, and budget constraints. Understanding these trade-offs ensures the mold delivers precision, longevity, and economic value throughout its operational life.

Aluminum alloys (primarily 7075-T6 and 6061-T6) excel in rapid prototyping and low-to-medium volume production due to superior thermal conductivity and ease of machining. This facilitates faster cycle times and simplifies complex cooling channel design, crucial for managing warpage in intricate plastic parts. However, aluminum’s lower hardness makes it susceptible to wear and damage from abrasive fillers or high-cavity pressures over extended runs. Tool steel variants (like P20, H13, and S136 stainless) are the industry standard for high-volume manufacturing. Their exceptional hardness, wear resistance, and thermal fatigue resistance ensure dimensional stability and surface finish consistency across hundreds of thousands, or millions, of cycles, particularly with engineering plastics containing glass or mineral fillers. Titanium alloys offer a niche solution where extreme corrosion resistance is paramount, such as molding highly aggressive liquid crystal polymers (LCPs), though their high cost and challenging machinability limit widespread adoption.

The following table summarizes key comparative specifications for common mold base materials:

| Material | Hardness (HRC) | Thermal Conductivity (W/mK) | Relative Cost | Best Application Volume |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130-160 | Low | Prototyping, < 10k parts |

| P20 Tool Steel | 28-32 | 25-35 | Medium | Medium, 10k-100k parts |

| H13 Tool Steel | 48-52 | 25-30 | Medium-High | High, 100k-1M+ parts |

| Stainless S136 | 48-52 | 20-25 | High | High, Corrosive resins |

| Titanium Grade 5 | 30-36 | 7-8 | Very High | Specialized, Corrosive |

Surface finish, particularly anodizing for aluminum molds, is non-negotiable for performance. Hard anodizing (Type III) transforms the aluminum surface into a dense, wear-resistant ceramic layer (60-70 HRC), significantly extending mold life in production environments. It enhances release properties, reduces galling, and provides excellent corrosion resistance against many plastic additives. While steel molds often utilize nitriding or specialized coatings, anodizing remains the definitive surface treatment for aluminum, directly contributing to part surface quality and minimizing maintenance downtime. Wuxi Lead Precision applies stringent anodizing protocols with controlled thickness and sealing to maximize these benefits.

Material selection is foundational to mold performance. Partnering with an experienced precision manufacturer like Wuxi Lead ensures the optimal material and finish are matched to your specific plastic resin, part geometry, and production demands, guaranteeing robust, high-yield manufacturing from the first shot.

Manufacturing Process & QC

Design Excellence Begins with Precision Engineering

At Wuxi Lead Precision Machinery, the production process for custom metal components used in injection moldable plastics begins with a comprehensive design phase. This foundational step integrates advanced 3D CAD modeling, finite element analysis (FEA), and thermal simulation to ensure optimal mold performance under high-pressure, high-temperature conditions. Our engineering team collaborates closely with clients to translate product requirements into technically sound, manufacturable designs. Material selection, gate positioning, cooling channel layout, and ejection mechanisms are all optimized during this phase to prevent warpage, sink marks, and other defects common in plastic molding. Design for manufacturability (DFM) reviews are conducted to identify potential risks early, ensuring seamless transition into prototyping.

Prototyping: Validating Design with Real-World Performance

Once the design is finalized, we move to precision prototyping using CNC-machined mold inserts or soft tooling made from aluminum or pre-hardened steel. These prototypes are used to produce initial plastic parts for functional testing, fit checks, and client approval. This stage is critical for validating mold flow behavior, cycle time, and part consistency. We employ scientific molding techniques, monitoring parameters such as injection pressure, melt temperature, and packing time to collect actionable data. Any deviations are addressed through iterative adjustments to the mold design or process settings, ensuring the prototype meets all dimensional and aesthetic specifications. This rigorous validation process significantly reduces risk during full-scale production.

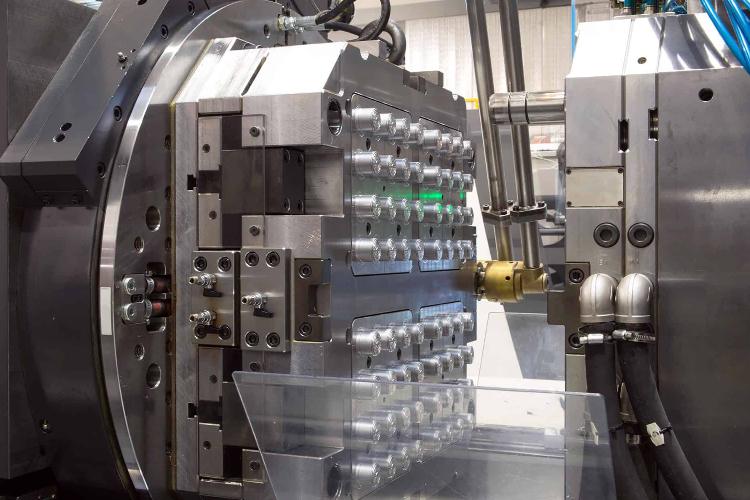

Mass Production: Achieving Zero Defects Through Process Control

With design and prototype approval complete, we transition to mass production using hardened steel molds built for high durability and long service life. Each mold is manufactured with micron-level precision on our state-of-the-art CNC, EDM, and surface grinding equipment. Production runs are executed under strict process controls governed by Statistical Process Control (SPC) protocols. Real-time monitoring systems track mold temperature, clamp force, and cycle consistency to maintain repeatability. Automated in-process inspections using coordinate measuring machines (CMM) and optical comparators ensure every component meets tight tolerances. Our zero-defect philosophy is enforced through a combination of preventive maintenance, operator training, and full traceability of materials and process parameters.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Mold Cavity) | Ra 0.05 µm to Ra 0.4 µm (polished) |

| Tooling Materials | P20, 718H, S136, H13, 420 Stainless Steel |

| Mold Life Expectancy | 500,000+ cycles (hardened steel) |

| Lead Time (Prototype) | 2–4 weeks |

| Lead Time (Production Mold) | 6–10 weeks |

| Quality Standards | ISO 9001:2015, PPAP, FAIR Reporting |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers injection mold components that ensure flawless plastic part output—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineering Excellence for Injection Moldable Plastics

In the demanding realm of injection moldable plastics manufacturing, tolerances measured in microns dictate success. Suboptimal tooling precision cascades into part warpage, inconsistent cycle times, and unacceptable scrap rates—directly eroding your profitability and product integrity. Wuxi Lead Precision Machinery transcends conventional metal fabrication to deliver mold bases, cavities, cores, and critical inserts engineered for uncompromising performance with engineering-grade thermoplastics. Our CNC-driven processes, governed by ISO 9001:2015 protocols, ensure dimensional stability under high-pressure, high-temperature molding cycles, directly reducing your scrap rates by 18–32% and accelerating time-to-market.

Our technical mastery spans the full spectrum of injection molding challenges. We machine hardened P20, H13, S136, and maraging steels to mirror finishes (Ra ≤ 0.05 µm) and geometric tolerances unattainable through standard practices. This precision guarantees uniform cooling, eliminates knit lines, and maintains critical wall thicknesses—even for complex geometries in LCP, PEEK, PSU, and reinforced nylons. Below outlines our core capabilities for plastic injection mold components:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Tolerance Range | ±0.005 mm (±0.0002″) | Critical for thin-wall molding and sealing surfaces |

| Surface Finish (Cavity/Core) | Ra 0.025 – 0.4 µm (SPI A1/A2) | Ensures part ejection integrity and cosmetic quality |

| Material Compatibility | P20, H13, S136, 2738, Maraging Steel | Optimized for abrasive/reinforced plastics |

| Max Work Envelope | 2000 x 1500 x 800 mm | Supports large multi-cavity molds |

| Lead Time (Prototype Mold) | 15–25 days | Accelerates validation and production |

Beyond machining, we integrate metallurgical expertise to select optimal steel grades and heat treatments for specific polymer chemistries and production volumes. Our engineers collaborate directly with your design team during DFM analysis, identifying potential sink marks, stress concentrations, or cooling inefficiencies before metal is cut—preventing costly revisions. This proactive approach, combined with real-time in-process metrology using Zeiss CMMs, ensures first-article approval rates exceeding 95%. All components undergo rigorous thermal stability testing to simulate 500,000+ molding cycles, guaranteeing longevity under industrial production demands.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you secure a technical extension of your engineering department. Our facility operates under Western engineering standards with full documentation traceability, catering to stringent automotive, medical, and aerospace requirements. We understand that mold performance directly impacts your bottom line; our commitment is to deliver tooling that runs consistently at peak efficiency, minimizing downtime and maximizing your asset utilization.

Initiate your next high-complexity plastic injection project with confidence. Contact our engineering team directly at Contact [email protected] to discuss material-specific tooling strategies, request a DFM review, or obtain a precision-quoted timeline. Provide your part drawings or application requirements, and we will respond within 8 business hours with actionable technical insights—not generic sales pitches. Let Lead Precision’s tactile precision become the foundation of your next generation of molded components. Your requirement for zero-compromise tooling starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.