Technical Contents

Engineering Guide: 3D Printing Service Nyc

Engineering Insight Precision Imperatives in NYC Metal 3D Printing Services

New York City’s advanced manufacturing sector demands components that perform flawlessly under exacting conditions. When sourcing metal additive manufacturing services locally, the distinction between adequate and exceptional output hinges entirely on engineered precision. Many NYC-based 3D printing providers focus solely on geometry replication, overlooking the critical metrology and material science rigor required for functional end-use parts in aerospace, medical, or high-performance industrial applications. True precision encompasses dimensional accuracy, consistent mechanical properties, surface integrity, and repeatability across builds – factors directly impacting part lifespan, assembly fit, and regulatory compliance. Selecting a service partner without demonstrable metrology capabilities and material expertise risks costly iterations, production delays, and field failures, negating the speed advantages of additive manufacturing.

Precision in metal 3D printing is not inherent to the machine; it is engineered through controlled processes, rigorous validation, and deep materials knowledge. It requires closed-loop monitoring of melt pools, precise inert gas management, calibrated post-processing, and traceable quality documentation meeting AS9100 or ISO 13485 standards. At Wuxi Lead Precision Machinery, we treat every build as a precision engineering project, not just a print job. Our process integrates decades of CNC machining discipline with additive expertise, ensuring parts meet tight tolerances and performance specs on the first attempt. This methodology is validated by our work supplying mission-critical components for Olympic infrastructure projects demanding zero-failure reliability and for military aerospace systems where dimensional stability under extreme stress is non-negotiable. We understand that NYC manufacturers need partners who guarantee parts function as engineered, not merely resemble CAD models.

The following specifications represent our baseline capabilities for critical metal 3D printing projects, reflecting the precision standards required by high-stakes industries:

| Parameter | Capability | Industry Standard Context |

|---|---|---|

| Material Options | Ti-6Al-4V, Inconel 718, 17-4PH SS, AlSi10Mg | Aerospace & medical grade certified |

| Layer Thickness | 20–50 μm | Enables complex geometries with fine features |

| Dimensional Tolerance | ±0.02 mm per 100 mm | Critical for mating surfaces and assemblies |

| Surface Roughness (As-Built) | Ra 8–12 μm | Optimized for functional performance pre-finishing |

| Build Volume | Ø250 x 325 mm | Suitable for high-value NYC prototyping & low-volume production |

| Post-Processing | Precision machining, HIP, stress relief, surface finishing | Ensures final dimensional accuracy and material properties |

NYC engineering teams cannot afford to compromise on precision when additive manufacturing enables design freedom. Partnering with a provider whose core competency is metrology-driven manufacturing – proven in Olympic-scale validation and military-grade reliability – transforms 3D printing from a prototyping tool into a trusted production solution. Wuxi Lead Precision Machinery delivers the certified accuracy and material integrity NYC innovators require to deploy metal AM with confidence. Demand precision engineered, not just printed.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for high-precision industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining, enabling us to produce complex geometries with exceptional accuracy and surface finish. Designed for industries demanding tight tolerances and repeatable performance—such as aerospace, medical, robotics, and high-end automotive—our machining centers operate with continuous multi-axis synchronization, allowing for intricate part features that cannot be achieved with conventional 3-axis systems.

Our 5-axis CNC platforms integrate high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent material removal rates and dimensional stability. This level of control is critical when working with challenging alloys such as titanium, Inconel, tool steels, and high-strength aluminum. By minimizing setup changes and enabling tool approach from multiple angles, we reduce cycle times and eliminate cumulative fixture errors, resulting in parts that meet the most stringent functional and regulatory requirements.

Quality assurance is embedded throughout our manufacturing process. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM) to verify geometric accuracy, surface profiles, and critical dimensional features. Our CMM systems operate with sub-micron resolution, providing full traceability and detailed inspection reports aligned with ISO 10360 standards. This metrology-backed validation ensures compliance with AS9100, ISO 13485, and other industry-specific quality frameworks.

We maintain full in-house control over material sourcing, machining, heat treatment, surface finishing, and inspection, enabling rapid prototyping and scalable production runs with consistent quality. Our engineering team collaborates directly with clients to optimize part design for manufacturability, reducing cost and lead time without compromising performance.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm (±0.0002 in) |

| Linear Dimensional Tolerance | ±0.010 mm (±0.0004 in) |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Angular Tolerance | ±0.05° |

| Maximum Work Envelope | 1200 x 800 x 650 mm (47.2 x 31.5 x 25.6 in) |

| Minimum Feature Size | 0.5 mm (0.020 in) |

| Repeatability | ±0.003 mm (±0.0001 in) |

| Materials Supported | Titanium, Inconel, Stainless Steel, Aluminum, Tool Steel, Brass, Bronze |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for clients seeking precision metal components where failure is not an option. Whether supporting rapid iteration in R&D or full-scale production, our facility delivers the accuracy, consistency, and technical expertise required for mission-critical applications.

Material & Finish Options

Critical Material Selection for High-Performance Metal 3D Printing

Material choice fundamentally dictates the functional capability, longevity, and cost-effectiveness of your 3D printed metal components. At Wuxi Lead Precision Machinery, we prioritize engineering-grade metals proven in demanding aerospace, medical, and industrial applications. Selecting the optimal alloy requires aligning material properties with your specific operational environment and performance requirements. Understanding the core characteristics of Aluminum, Steel, and Titanium is essential for achieving design intent.

Aluminum alloys, particularly 6061 and 7075, offer an exceptional strength-to-weight ratio critical for weight-sensitive applications like drone components, automotive brackets, and heat sinks. Their inherent thermal conductivity and machinability make them versatile. However, pure aluminum lacks sufficient strength for structural roles; heat-treated 7075-T6 provides higher strength but reduced corrosion resistance compared to 6061, necessitating protective finishes like anodizing for harsh environments. Aluminum excels where minimizing mass without sacrificing moderate strength is paramount.

Stainless steel variants, especially 316L and 17-4 PH, deliver superior strength, durability, and excellent corrosion resistance across diverse conditions. 316L is the standard for marine, chemical, and medical implant applications due to its molybdenum-enhanced resistance to pitting and crevice corrosion. 17-4 PH provides exceptional strength through precipitation hardening, ideal for high-stress aerospace fittings, valves, and tooling. Steel offers the robustness required for load-bearing parts exposed to wear, high pressure, or aggressive chemicals, often requiring post-process machining for critical tolerances.

Titanium Grade 5 (Ti-6Al-4V) is the benchmark for extreme environments demanding the highest strength-to-weight ratio combined with outstanding corrosion resistance and biocompatibility. It withstands high temperatures, severe chemical exposure, and is non-magnetic, making it indispensable for critical aerospace components (brackets, landing gear parts), medical implants, and deep-sea equipment. While more expensive and challenging to process than aluminum or steel, titanium’s performance in life-critical applications justifies its use where failure is not an option.

Anodizing is the premier surface finish for aluminum parts, significantly enhancing surface hardness, wear resistance, and corrosion protection. Type II (Sulfuric Acid) anodizing provides good durability and dyeing capability for cosmetic or moderate-use parts. For maximum performance in demanding industrial or aerospace settings, specify Type III (Hardcoat) anodizing, which creates a much thicker, denser, and harder ceramic-like layer, dramatically improving abrasion resistance and longevity. Proper masking ensures critical functional surfaces maintain precise dimensional tolerances.

The following table summarizes key properties for informed selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Key Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 2.81 | 503-572 | Moderate (Requires Anodize) | Aerospace structures, high-stress fittings |

| Stainless 316L | 8.00 | 505-710 | Excellent (General/Chem) | Medical implants, marine hardware, valves |

| Titanium Ti-6Al-4V | 4.43 | 900-1100 | Exceptional (All Env.) | Aerospace critical parts, medical implants |

Precise material and finish specification, validated through rigorous process control, ensures your NYC-sourced 3D printed metal components meet the highest standards of performance and reliability. Wuxi Lead leverages advanced metal AM systems and stringent QA protocols to deliver parts where material integrity is non-negotiable. Consult our engineering team early to optimize your selection for manufacturability and end-use success.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, ensuring every component meets the exact functional, dimensional, and material requirements of our clients. Our engineering team collaborates directly with client CAD models, conducting comprehensive Design for Manufacturability (DFM) analysis to identify potential challenges before any material is cut. This stage integrates advanced simulation tools to evaluate thermal behavior, stress distribution, and structural integrity—particularly critical for metal 3D printed components used in aerospace, medical, and high-performance industrial applications. We support a wide range of file formats including STEP, IGES, and native SolidWorks, ensuring seamless integration with your design workflow. All designs undergo a formal approval gate, with detailed feedback and optimization recommendations provided to ensure manufacturability and cost-efficiency.

Prototyping: Validating Performance Before Scale

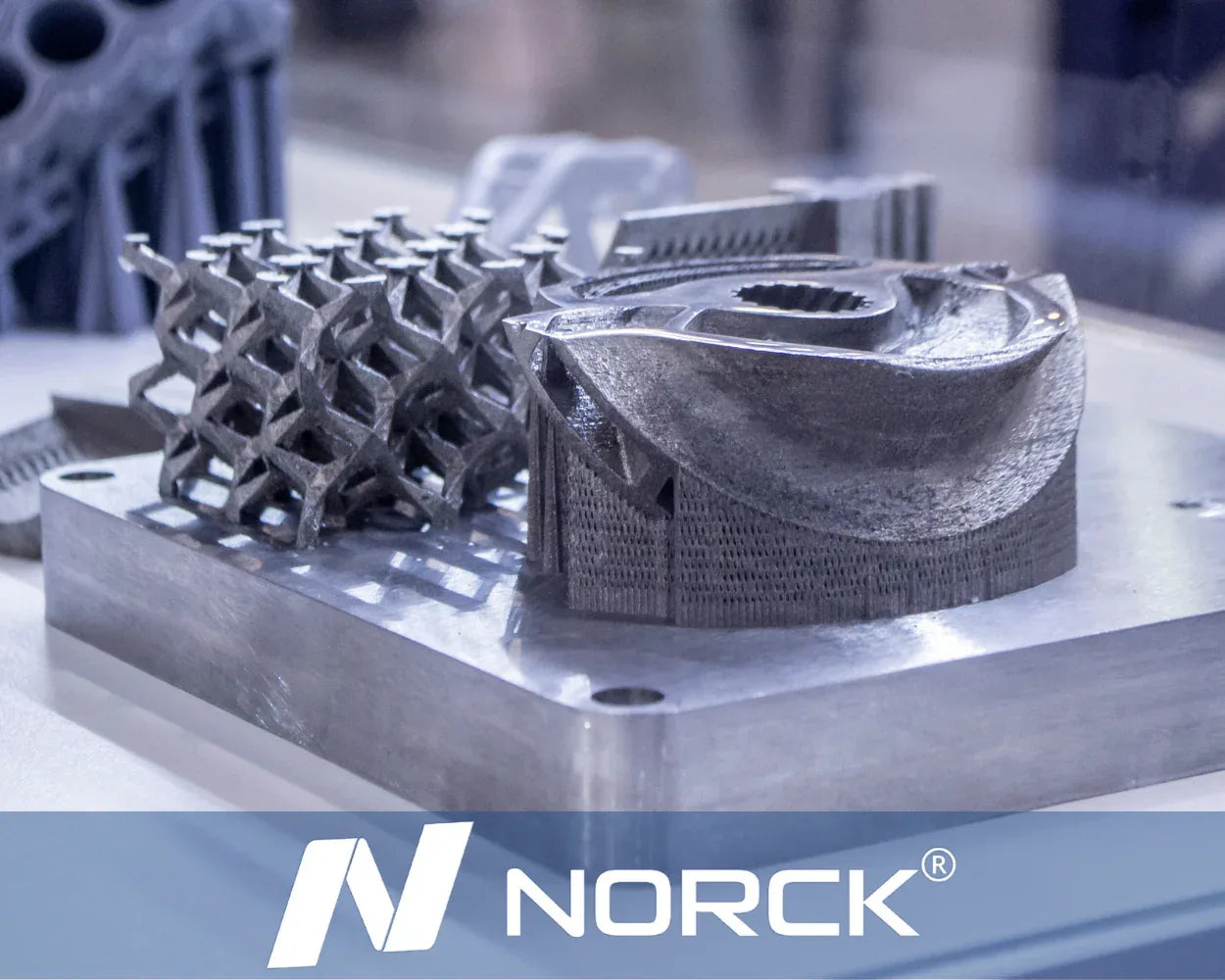

Once the design is finalized, we proceed to the prototyping phase using state-of-the-art metal additive manufacturing technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS). These processes enable the fabrication of complex geometries unachievable through traditional machining, such as internal cooling channels and lattice structures. Prototypes are produced in the same high-grade materials intended for final production—ensuring accurate representation of mechanical properties and performance. Each prototype undergoes rigorous metrology testing using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.02 mm. Functional testing, including pressure, fatigue, and fit-check evaluations, ensures the prototype performs as expected in real-world conditions. This phase is critical for minimizing risk and validating design integrity prior to mass production.

Mass Production: Consistency, Control, and Zero Defects

Our transition to mass production is governed by a disciplined, data-driven approach designed to achieve zero defects. Production runs are executed on calibrated industrial 3D printers and CNC-supported post-processing stations, with full process traceability from raw material lot to final inspection. We implement real-time process monitoring, including in-situ thermal imaging and layer-wise defect detection, to maintain consistency across every build. All parts undergo 100% first-article inspection and batch-level quality audits in accordance with ISO 9001 and IATF 16949 standards. Non-destructive testing (NDT), including X-ray and ultrasonic inspection, is applied where required to ensure internal integrity.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718, Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.02 mm (standard), ±0.01 mm (precision grade) |

| Surface Roughness (as-built) | Ra 8–12 μm; Ra <1.6 μm achievable with post-processing |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Post-Processing Options | Stress relieving, HIP, CNC machining, polishing, coating |

From concept to volume output, Wuxi Lead ensures every stage of manufacturing is aligned with the highest standards of precision, reliability, and performance—delivering defect-free metal components trusted by global innovators.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Additive Excellence

New York’s advanced manufacturing ecosystem demands precision, speed, and technical agility—especially when prototyping or producing mission-critical metal components. While local 3D printing services offer convenience, they often face constraints in scalability, material diversity, and cost efficiency for complex industrial applications. Wuxi Lead Precision Machinery bridges this gap, delivering enterprise-grade metal additive manufacturing from our ISO 9001-certified facility in China, engineered specifically for discerning North American partners. We eliminate the false choice between offshore cost advantages and uncompromised quality, providing NYC’s aerospace, medical, and industrial innovators with a seamless extension of their supply chain.

Our metal additive capabilities are built on industrial-grade EOS and SLM systems, supported by integrated CNC post-processing and rigorous metrology. Unlike generalist 3D printing bureaus, we specialize exclusively in high-performance metals—including Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel, and aluminum AlSi10Mg—ensuring material properties meet ASTM F75 or AMS 7000 standards. Every build undergoes in-process monitoring and full first-article inspection, with traceable material certificates and NDT reporting. This precision-engineering focus minimizes iteration cycles and accelerates time-to-market for your most demanding projects.

Below are key specifications defining our metal additive production capability

| Parameter | Specification Detail |

|---|---|

| Build Volume | Up to 500 x 500 x 500 mm (EOS M400) |

| Layer Thickness | 20–60 μm (adjustable by material) |

| Dimensional Accuracy | ±0.05 mm for features < 100 mm |

| Surface Roughness (as-built) | Ra 12–25 μm (post-processed to Ra 0.8 μm) |

| Supported Materials | Titanium, Inconel, Cobalt Chrome, Tool Steels, Aluminum Alloys |

Partnering with Lead Precision means direct access to our engineering team for design for additive manufacturing (DFAM) optimization, reducing part weight by up to 40% while maintaining structural integrity. We manage end-to-end production—from powder sourcing to final finishing—ensuring consistent repeatability across batches. Our digital workflow integrates with your PLM system, providing real-time build tracking and secure IP protocols compliant with ITAR and NDA requirements. For NYC-based firms, this translates to 30–50% cost reduction versus domestic metal AM services, without sacrificing the precision your applications demand.

The complexities of advanced manufacturing require a partner who speaks your technical language and anticipates your operational challenges. Wuxi Lead Precision Machinery operates on your timeline, with dedicated project managers fluent in English and structured around Eastern Time Zone handoffs. We handle customs documentation, air freight logistics, and quality validation—delivering certified parts to your NYC facility in 10–15 business days from order confirmation.

Elevate your metal additive strategy beyond local limitations. Contact our engineering team today at [email protected] to discuss your project specifications, request a material sample kit, or schedule a virtual factory audit. Let us prove how precision metal manufacturing, executed with industrial rigor and global agility, becomes your competitive advantage. Your next breakthrough component starts with a conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.