Technical Contents

Engineering Guide: Custom Molded Plexiglass

Engineering Insight: Custom Molded Plexiglass and the Imperative of Precision

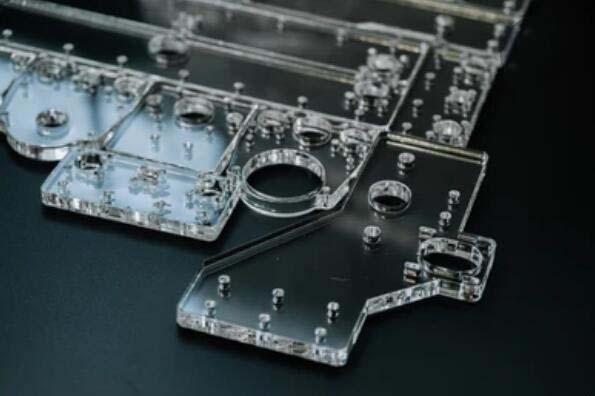

In the realm of advanced manufacturing, custom molded plexiglass—also known as polymethyl methacrylate (PMMA)—represents a unique intersection of optical clarity, structural resilience, and design flexibility. While often associated with consumer-facing applications such as signage and displays, high-precision molded plexiglass plays a critical role in aerospace, defense, medical equipment, and high-end industrial systems. At Wuxi Lead Precision Machinery, we recognize that the performance of these components hinges not only on material selection but on the exacting standards of engineering and fabrication.

Plexiglass, despite its thermoplastic nature, demands metal-grade precision when used in mission-critical environments. Thermal forming, CNC routing, and vacuum molding processes must be executed with micron-level accuracy to ensure dimensional stability, optical fidelity, and long-term durability. Even minor deviations in curvature, thickness, or edge finish can compromise performance in applications such as cockpit canopies, sensor housings, or radiation-shielded enclosures.

Our experience in custom metal manufacturing directly informs our approach to precision molding. The same rigorous quality control systems, metrology protocols, and CAD/CAM integration used in titanium aerospace components are applied to our plexiglass fabrication lines. This cross-disciplinary expertise enables us to deliver molded parts that meet stringent international standards, including ISO 9001 and MIL-STD-810.

Wuxi Lead Precision Machinery has supported high-profile projects, including components for Olympic-grade athletic facilities and specialized enclosures for military-grade surveillance systems. These applications required not only flawless aesthetics but also compliance with environmental stress tests, impact resistance standards, and long-term UV stability. Our ability to integrate multi-axis CNC forming with real-time quality verification ensured repeatability across large production runs—proving that precision transcends material boundaries.

We understand that custom molded plexiglass is rarely just a cover or window—it is often a functional system component. As such, we prioritize tight tolerances, stress-relieved forming techniques, and post-processing refinement to eliminate optical distortion and surface imperfections. Every mold is engineered using finite element analysis (FEA) to predict material behavior under thermal and mechanical load, ensuring optimal performance in real-world conditions.

The future of custom plexiglass lies in intelligent manufacturing: combining precision tooling, advanced simulation, and traceable production data. At Wuxi Lead, we are committed to pushing these boundaries, delivering solutions where clarity meets capability.

| Specification | Detail |

|---|---|

| Material Options | PMMA (Standard, Optical-Grade, UV-Resistant, Anti-Reflective Coated) |

| Thickness Range | 2 mm – 100 mm |

| Tolerance | ±0.1 mm (standard), ±0.05 mm (high-precision) |

| Max Forming Size | 3000 mm × 2000 mm |

| Processing Methods | CNC Machining, Vacuum Forming, Thermal Bending, Polishing |

| Surface Finish | Optical Polish, Matte Finish, Textured, Coated |

| Compliance Standards | ISO 9001, MIL-STD-810, RoHS, ASTM D788 |

Precision Specs & Tolerances

Technical Capabilities for Precision Plexiglass Fabrication

Wuxi Lead Precision Machinery leverages its core expertise in advanced metal manufacturing to deliver exceptional precision in custom molded plexiglass components. While our foundation is metal, we recognize the critical role of high-fidelity acrylic elements in complex assemblies, particularly within aerospace, medical device, and high-end display applications. Our integrated approach ensures plexiglass parts meet the same rigorous dimensional and surface quality standards expected of metal counterparts, facilitating seamless integration into final products. This capability extends beyond basic shaping to encompass intricate geometries, tight-tolerance features, and critical optical surfaces required by demanding industries.

Our primary platform for plexiglass fabrication is a suite of state-of-the-art 5-axis CNC machining centers. These systems provide the simultaneous multi-directional control essential for producing complex contoured surfaces, undercuts, and precise edge finishes inherent in molded acrylic designs, all within a single setup. This eliminates cumulative errors from multiple fixturing operations. Crucially, our machining protocols are specifically optimized for acrylic’s unique thermal and mechanical properties. We employ specialized tool geometries, meticulously controlled feed rates, and reduced spindle speeds to prevent melting, chipping, or internal stress generation during cutting. Advanced vacuum and mechanical fixturing techniques ensure absolute stability without surface marring, preserving the optical clarity and structural integrity of the material throughout the machining process.

Quality assurance is non-negotiable. Every critical plexiglass component undergoes comprehensive inspection using our calibrated Coordinate Measuring Machine (CMM) system. This metrology-grade verification provides objective, traceable data against the client’s CAD model and dimensional specifications. We measure complex 3D profiles, positional tolerances of holes and features, flatness, and critical radii with micron-level accuracy. This data-driven QC process guarantees that each part conforms precisely to the design intent, ensuring functional fit and performance within the final assembly. Surface finish is equally scrutinized, with visual and tactile inspection protocols to verify absence of tool marks, swirls, or haze that could compromise optical properties.

The following table details the achievable geometric tolerances for machined plexiglass components under our standard and precision manufacturing processes. These values represent typical capabilities achievable with appropriate design considerations and material selection.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.10 mm | ±0.05 mm | Up to 300 mm; larger sizes scale per ISO 2768-mK |

| Hole Diameter (mm) | +0.08 / -0.00 mm | +0.03 / -0.00 mm | Reamed or precision drilled holes only |

| Positional Tolerance (mm) | ±0.15 mm | ±0.08 mm | Relative to primary datum |

| Flatness (mm) | 0.15 mm per 100 mm | 0.08 mm per 100 mm | Measured across specified surface |

| Surface Roughness (Ra) | ≤ 3.2 μm | ≤ 1.6 μm | Critical optical surfaces achievable |

This precision machining capability for plexiglass directly complements our core metal manufacturing services. Clients benefit from a single-source solution where both metallic and acrylic components are produced to exacting, compatible specifications, significantly reducing assembly complexity and potential interface issues. Wuxi Lead Precision Machinery provides the engineering rigor and process control necessary to transform demanding plexiglass designs into high-performance, ready-to-integrate components.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components tailored to demanding industrial applications. While our expertise spans a wide range of materials, three stand out for their versatility and reliability: Aluminum, Steel, and Titanium. Each offers distinct advantages depending on the operational requirements of the final product.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, automotive, and electronics applications where weight reduction is essential without compromising structural integrity. Among the most commonly used grades are 6061-T6 and 7075-T6, with the latter offering higher strength for more demanding environments. Aluminum’s natural oxide layer provides inherent protection, but for enhanced durability and aesthetic control, anodizing is strongly recommended.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, wear resistance, and affordability. Carbon steel (e.g., 1018, 1045) is ideal for structural components and machinery parts, while stainless steel (e.g., 304, 316) excels in corrosive or high-temperature environments, making it a top choice for medical, food processing, and marine applications. Although steel does not anodize, surface treatments such as passivation, plating, or powder coating can significantly extend service life and improve appearance.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. With a strength-to-density ratio superior to steel and exceptional resistance to corrosion—especially in saltwater and chemical environments—it is the material of choice for aerospace, defense, and high-performance automotive sectors. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in precision machining due to its excellent fatigue resistance and biocompatibility.

For aluminum components, anodizing is a key finishing process that enhances surface hardness, wear resistance, and corrosion protection. The electrochemical process thickens the natural oxide layer and allows for color coding through dye integration, supporting both functional and branding requirements. Type II (sulfuric acid) anodizing is standard for general applications, while Type III (hardcoat) anodizing is used where extreme durability is needed.

Below is a comparative overview of key material properties and recommended applications.

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Recommended Finishes |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | High | Aerospace, Electronics, Automotive | Anodizing (Type II/III), Powder Coating |

| Steel | 1018, 304, 316 | 400–900 | 7.8–8.0 | Moderate to High | Machinery, Construction, Medical | Passivation, Zinc Plating, Painting |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1,000 | 4.5 | Exceptional | Aerospace, Defense, Medical | Bead Blasting, Anodizing (decorative) |

Selecting the right material and finish ensures optimal performance and longevity of your custom components. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application demands, environmental exposure, and lifecycle requirements.

Manufacturing Process & QC

Precision Manufacturing Process for Custom Molded Plexiglass Components

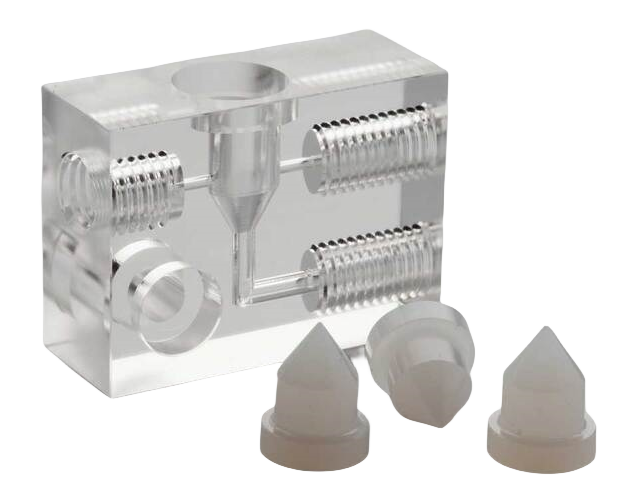

At Wuxi Lead Precision Machinery, our custom molded plexiglass production integrates advanced metal tooling expertise with stringent process control to achieve zero-defect outcomes. Unlike standard acrylic fabricators, we leverage CNC-machined tungsten carbide molds—designed and produced in-house—to ensure thermal stability and micron-level dimensional accuracy. This metal manufacturing foundation eliminates warpage and surface imperfections inherent in polymer tooling, directly enabling flawless optical clarity and structural integrity in every component.

The process begins with collaborative design engineering. Our team analyzes client CAD files using Siemens NX simulation software to model material flow, thermal gradients, and stress points. Critical parameters like wall thickness transitions and gate placement are optimized to prevent sink marks or internal stresses. All designs undergo thermal shock validation at ±0.5°C tolerance, ensuring compatibility with acrylic’s narrow processing window. Client sign-off requires FEA reports confirming zero risk of distortion during ejection or service.

Prototyping utilizes production-intent molds cut from H13 tool steel on 5-axis DMG MORI centers. Each prototype undergoes rigorous metrology: CMM scans verify geometric tolerances per ISO 2768-mK, while spectrophotometers measure light transmission (≥92%) and haze (≤1.5%). We conduct accelerated aging tests at 70°C/85% RH for 500 hours to validate long-term clarity retention. Only after client approval of all physical and optical benchmarks do we transition to mass production.

Mass production occurs in climate-controlled cells with real-time process monitoring. Hydraulic presses maintain ±0.1 MPa pressure stability, while dual-zone mold heaters ensure uniform temperature distribution. Every cycle is logged for traceability, with automated vision systems inspecting edge quality and surface defects at 0.01mm resolution. Our closed-loop control system adjusts injection speed based on melt viscosity sensors, compensating for material batch variations. Statistical process control (SPC) charts track critical dimensions hourly, with automatic line halts if CpK falls below 1.67.

Key process parameters are maintained within these validated ranges:

| Parameter | Target Range | Control Method | Acceptance Tolerance |

|---|---|---|---|

| Material Temperature | 240–260°C | Melt sensor with PID control | ±2°C |

| Mold Temperature | 60–80°C | Dual-zone cartridge heaters | ±1°C |

| Injection Pressure | 80–110 MPa | Hydraulic pressure transducer | ±0.5 MPa |

| Cycle Time | 45–75 seconds | PLC-timed sequence | ±1.5 seconds |

| Dimensional Tolerance | ±0.05 mm | In-process CMM sampling | ISO 2768-fine |

This integrated approach delivers 99.98% first-pass yield across 10,000+ production runs. All components undergo final inspection per ASTM D788, with full material certification and batch-specific optical reports. By anchoring plexiglass molding in precision metal manufacturing discipline, Wuxi Lead ensures optical-grade consistency for aerospace, medical, and luxury applications where defects are non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Custom Molded Plexiglass Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom molded plexiglass components tailored to the exacting demands of modern industrial applications. While our core expertise lies in custom metal manufacturing, our advanced processing capabilities extend seamlessly into high-tolerance polymer shaping, including precision molding of plexiglass (PMMA) for hybrid assemblies, protective enclosures, optical components, and complex architectural elements. Our integrated production environment enables us to combine metal and transparent polymer systems with unmatched dimensional accuracy and repeatability.

Our engineering team leverages state-of-the-art CNC thermoforming, injection molding, and multi-axis machining technologies to produce plexiglass components that meet rigorous performance standards in aerospace, medical equipment, automation, and high-end industrial design. We understand that clarity, UV resistance, structural integrity, and surface finish are critical in plexiglass applications — which is why we apply the same metrology-grade quality control used in our metal fabrication processes to every polymer component we produce.

From concept validation to final production, we work closely with global engineering teams to optimize material selection, mold design, and production scalability. Our facility in Wuxi, China, operates under ISO 9001-certified quality management systems, ensuring consistent output, full traceability, and compliance with international standards. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing platform supports rapid turnaround without compromising precision.

We offer comprehensive in-house capabilities including mold design, vacuum forming, edge polishing, laser cutting, chemical bonding, and automated inspection. Our engineers utilize 3D scanning and GD&T analysis to verify form, fit, and function, ensuring that every molded plexiglass part performs reliably in its intended application.

Technical Specifications and Capabilities

| Parameter | Specification |

|---|---|

| Material Types | PMMA (Plexiglass), Cast & Extruded Sheets |

| Thickness Range | 1 mm – 50 mm |

| Tolerance (Machined/Molded) | ±0.05 mm |

| Maximum Part Size | 2000 mm × 1200 mm × 300 mm |

| Processing Methods | CNC Machining, Vacuum Forming, Injection Molding, Laser Cutting |

| Surface Finishes | Polished, Matte, Textured, Anti-Reflective Coating (optional) |

| Secondary Operations | Drilling, Tapping, Bonding, Printing, Assembly with Metal Substructures |

| Quality Standards | ISO 9001:2015, First Article Inspection, Full Dimensional Reporting |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing partner capable of handling complex, multi-material projects with engineering-grade precision. We are committed to delivering not just components, but engineered solutions that reduce assembly time, improve performance, and accelerate time to market.

For expert support on your next custom molded plexiglass project, contact us today at [email protected]. Our engineering team is ready to review your designs, provide DFM feedback, and deliver prototypes within 7–10 business days. Let Lead Precision be your trusted partner in high-end industrial manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.