Technical Contents

Engineering Guide: Plastic Laser Cutting Services

Engineering Insight: Precision in Plastic Laser Cutting Services

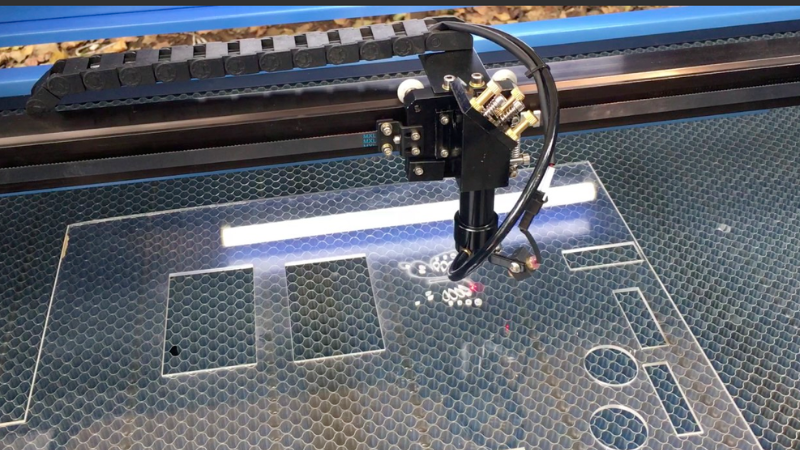

In the realm of advanced sheet metal and polymer fabrication, plastic laser cutting services represent a critical intersection of material science, thermal dynamics, and micron-level accuracy. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is the foundation of functional reliability, especially in high-stakes industries such as aerospace, defense, and medical device manufacturing. The thermal sensitivity of plastics demands a laser cutting process that balances power, speed, and beam control to prevent melting, warping, or microfractures along cut edges.

Plastic materials such as polycarbonate, acrylic (PMMA), PEEK, and ABS exhibit varying absorption rates to laser wavelengths, particularly in CO₂ laser systems operating at 10.6 μm. Without precise calibration, even minor deviations in focus or feed rate can lead to degraded edge quality or dimensional inaccuracy. This is where engineered control systems and decades of process refinement become indispensable. At Lead Precision, our laser platforms integrate real-time beam modulation, high-resolution motion control, and closed-loop environmental monitoring to maintain ±0.05 mm dimensional tolerance across complex geometries.

Our expertise is not theoretical. Wuxi Lead Precision Machinery has delivered mission-critical components for Olympic-standard timing systems and precision enclosures for military communication units—applications where failure is not an option. These projects demanded not only exacting cuts in flame-retardant polycarbonates and ESD-safe plastics but also full traceability, cleanroom-compatible processing, and zero-defect output. The success in these programs underscores our capability to manage the full spectrum of technical challenges in plastic laser cutting, from material selection to post-process inspection.

Beyond hardware, our engineering team applies deep process knowledge to optimize kerf width, minimize heat-affected zones (HAZ), and ensure edge clarity—critical for optical-grade acrylics used in instrumentation. Each job undergoes rigorous pre-production simulation, ensuring that thermal expansion and clamping dynamics are accounted for before the first cut is made.

The following table outlines key performance specifications for our plastic laser cutting services:

| Parameter | Specification |

|---|---|

| Laser Type | CO₂, 10.6 μm wavelength |

| Maximum Cutting Area | 1500 mm × 3000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Minimum Feature Size | 0.2 mm (micro-cutting capable) |

| Edge Roughness (Ra) | ≤ 1.6 μm (optical-grade finish) |

| Material Thickness Range | 0.5 mm – 20 mm (material-dependent) |

| Supported Plastics | Acrylic, Polycarbonate, PEEK, ABS, PET, PVC |

| Lead Time (Standard) | 3–7 working days |

| Quality Certification | ISO 9001:2015, Full CMM Inspection Reports |

Precision in plastic laser cutting is not achieved through automation alone—it requires engineering insight, proven experience, and a commitment to excellence. At Wuxi Lead Precision Machinery, we bring all three to every project.

Precision Specs & Tolerances

Technical Capabilities: Precision Plastic Laser Cutting

Wuxi Lead Precision Machinery delivers advanced plastic laser cutting services engineered for demanding industrial applications. Our core strength lies in leveraging state-of-the-art CO2 laser systems specifically optimized for non-metallic materials, ensuring clean, burr-free cuts across a diverse range of engineering plastics. Unlike standard metal-cutting platforms, our dedicated plastic processing cells utilize precisely controlled lower-power densities and specialized assist gases, primarily nitrogen, to minimize thermal distortion, eliminate charring, and produce optically clear or consistently smooth edges essential for medical, electronics, and optical components. This material-specific approach is fundamental to achieving the dimensional integrity and surface finish required in high-value assemblies.

Central to our capability is the integration of 5-axis CNC laser technology. This advanced configuration allows for the precise cutting of complex three-dimensional contours and intricate internal features directly from solid plastic stock or sheet, significantly reducing the need for secondary operations and fixture changes. The simultaneous motion control across five axes ensures consistent beam focus and angle relative to the workpiece surface, even on compound curves, resulting in uniform edge quality and tolerance adherence throughout the entire part geometry. This capability is particularly critical for prototyping and low-volume production of housings, fluidic manifolds, and custom optical mounts where traditional 2D cutting would be insufficient or cost-prohibitive.

Rigorous quality control is embedded within our manufacturing process. Every critical plastic laser cutting project undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection protocols, aligned with ISO 13485-grade documentation standards, validate dimensional conformity against the original CAD model across all critical features, including hole sizes, slot widths, profile tolerances, and complex 3D contours. This metrology-driven approach provides objective evidence of part accuracy and process stability, ensuring first-article conformity and sustained production quality. In-process checks further guarantee consistency during extended production runs.

The achievable precision for plastic laser cutting is inherently influenced by material type, thickness, and geometry. The following table details our standard tolerance capabilities under controlled production conditions:

| Material Thickness Range | Dimensional Tolerance | Edge Quality Standard |

|---|---|---|

| 0.5 mm – 3.0 mm | ± 0.10 mm | Smooth, no visible charring, minimal recast layer |

| 3.1 mm – 6.0 mm | ± 0.15 mm | Smooth, slight matte finish acceptable, no significant burr |

| 6.1 mm – 12.0 mm | ± 0.25 mm | Clean cut, minor striations possible, no thermal damage beyond 0.2mm |

| 12.1 mm – 25.0 mm | ± 0.30 mm | Functional edge, thermal effects managed, no delamination |

These tolerances represent our standard production capability for common engineering plastics like acrylic (PMMA), polycarbonate (PC), ABS, and POM under optimal process parameters. For mission-critical applications requiring tighter control, Wuxi Lead implements enhanced process validation and dedicated machine calibration protocols. Our technical team collaborates closely with clients during the design phase to optimize part geometry for laser manufacturability, ensuring the final component meets stringent functional and aesthetic requirements while maximizing yield and cost efficiency. This commitment to precision engineering and verifiable quality defines our service in the global plastic fabrication market.

Material & Finish Options

Material Selection for High-Precision Plastic Laser Cutting Applications

When integrating plastic laser cutting services into advanced manufacturing workflows, the selection of compatible materials and post-processing finishes plays a critical role in achieving optimal performance, durability, and aesthetic quality. At Wuxi Lead Precision Machinery, we specialize in precision sheet metal fabrication, and our expertise extends to supporting hybrid systems where laser-cut plastics interface with high-performance metals such as aluminum, stainless steel, and titanium. Understanding the thermal, mechanical, and chemical behavior of these materials ensures seamless integration and long-term reliability in demanding industrial environments.

Aluminum is a preferred choice for structural and enclosure components due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. When paired with laser-cut plastic elements—such as insulating panels or protective housings—aluminum provides robust support while minimizing overall system weight. It responds exceptionally well to fiber laser cutting, producing clean, burr-free edges ideal for downstream finishing processes. Similarly, stainless steel offers superior corrosion resistance and mechanical strength, making it suitable for applications in medical, aerospace, and food processing industries where hygiene and durability are paramount. Its higher reflectivity and thermal resistance require precise laser parameter control, which our advanced CNC systems deliver with repeatability.

Titanium, though more challenging to process due to its low thermal conductivity and high reactivity at elevated temperatures, is indispensable in aerospace and defense applications. When used alongside laser-cut polymer components for insulation or vibration damping, titanium’s high strength and temperature resistance enhance system performance under extreme conditions. Our laser cutting protocols are calibrated to minimize heat-affected zones and prevent oxidation, ensuring structural integrity.

A critical post-processing step for aluminum components is anodizing, which enhances surface hardness, corrosion resistance, and electrical insulation. Anodized finishes also provide an aesthetically consistent base for color dyeing, beneficial in consumer-facing industrial equipment. For parts that interface with laser-cut plastics, anodizing prevents galvanic corrosion and improves wear resistance. We offer Type II (sulfuric acid) and Type III (hard coat) anodizing, tailored to application demands.

The following table outlines key material properties and processing parameters relevant to our plastic-metal hybrid fabrication services:

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Compatible Finishes | Laser Type |

|---|---|---|---|---|---|

| Aluminum 6061 | 0.5 – 12.0 | 310 | 167 | Anodizing, Powder Coating | Fiber Laser |

| Stainless Steel 304 | 0.8 – 15.0 | 505 | 16.2 | Passivation, Electropolish | Fiber Laser |

| Titanium Grade 5 | 0.8 – 10.0 | 880 | 6.7 | Anodizing, Shot Peening | Pulsed Fiber Laser |

Material compatibility, precision cutting, and proper finishing are interdependent. At Wuxi Lead Precision Machinery, we ensure each stage—from laser cutting to anodizing—is optimized for performance in integrated systems involving plastic and metal components.

Manufacturing Process & QC

Precision Plastic Laser Cutting: From Concept to Flawless Production

Wuxi Lead Precision Machinery executes plastic laser cutting with uncompromising engineering discipline, transforming client specifications into dimensionally perfect components through a rigorously controlled three-phase workflow. This methodology, honed within our ISO 9001-certified facility, ensures zero defects are achievable from initial design through high-volume manufacturing, specifically tailored for demanding industrial applications where plastic component integrity is non-negotiable.

Design Phase: Engineering Validation Before Cutting

The process begins with meticulous CAD model analysis and CAM programming optimization. Our engineering team scrutinizes part geometry, material properties, and thermal dynamics inherent to plastics like acrylic, polycarbonate, ABS, and PETG. We validate kerf width, heat-affected zone predictions, and potential warpage risks using advanced simulation software, ensuring the digital blueprint is inherently manufacturable. Critical tolerances, surface finish requirements, and nesting efficiency are finalized collaboratively with the client, eliminating ambiguities that could compromise quality later. Material certification and traceability documentation are established at this stage, forming the foundation for consistent output.

Prototyping: Metrology-Driven Iteration

Physical validation occurs through low-volume prototyping using production-intent laser parameters on the exact material grade specified. Each prototype undergoes comprehensive metrological inspection against the validated CAD model using CMMs and optical comparators, measuring critical dimensions, edge quality, and dimensional stability post-processing. Any deviation triggers immediate root cause analysis—adjusting laser power, pulse frequency, assist gas, or focal point—and iterative re-cutting. This phase is not merely sample creation; it is a closed-loop engineering verification proving the process capability meets the stringent ±0.05mm tolerance standard required for final production. Client sign-off on prototype metrology reports is mandatory before scaling.

Mass Production: Zero Defects Execution

Transitioning to volume production, Wuxi Lead implements its Zero Defects protocol. Laser systems operate under SPC (Statistical Process Control) with real-time monitoring of beam power, gas pressure, and positional accuracy. Every component undergoes 100% automated optical inspection for edge defects, dimensional conformity, and surface blemishes, integrated directly into the production line. In-process audits verify material lot consistency and machine calibration hourly. Our closed-loop feedback system instantly adjusts parameters if trends approach tolerance limits, preventing non-conforming output. Full traceability—from raw material batch to final inspection data—ensures accountability and rapid corrective action if required, guaranteeing every shipped part meets the prototype’s certified quality standard.

The following table details key capabilities for common engineering plastics:

| Material | Max Thickness (mm) | Typical Tolerance (±mm) | Edge Quality (Ra µm) | Key Applications |

|---|---|---|---|---|

| Acrylic (PMMA) | 20 | 0.05 | 1.6 – 3.2 | Light guides, enclosures |

| Polycarbonate (PC) | 15 | 0.08 | 3.2 – 6.3 | Safety shields, lenses |

| ABS | 10 | 0.10 | 6.3 – 12.5 | Housings, automotive interiors |

| PETG | 12 | 0.08 | 3.2 – 6.3 | Medical components, displays |

Wuxi Lead’s integrated process transforms plastic laser cutting from a basic fabrication step into a precision engineering solution. By embedding quality at every stage—validated design, metrology-proven prototyping, and statistically controlled mass production—we deliver components where zero defects are not an aspiration, but a measurable outcome. Trust our Chinese engineering excellence for plastics demanding absolute fidelity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Plastic Laser Cutting Expertise

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term manufacturing partnerships. As a leading provider of advanced sheet metal fabrication services in China, we specialize in high-accuracy plastic laser cutting for industries where tolerance, consistency, and material integrity are non-negotiable. From medical device components to aerospace enclosures and custom industrial housings, our capabilities are engineered to meet the most demanding specifications.

Our state-of-the-art fiber and CO₂ laser systems are optimized for processing a wide range of engineering plastics, including polycarbonate, acrylic (PMMA), PEEK, ABS, and polyethylene. Unlike traditional mechanical cutting, our non-contact laser technology eliminates tool wear, minimizes material stress, and delivers clean, burr-free edges with minimal post-processing. This ensures faster turnaround times and superior surface quality—critical advantages for high-volume production and low-volume prototyping alike.

What sets us apart is our integration of precision engineering with rigorous quality control. Every job is supported by in-house CAD/CAM programming, real-time laser monitoring, and full first-article inspection reports. Our ISO 9001-certified manufacturing environment guarantees compliance with international standards, while our experienced engineering team provides Design for Manufacturability (DFM) feedback to optimize your parts for cost and performance.

We understand that global sourcing requires more than just technical capability—it demands transparency, communication, and trust. That’s why we assign a dedicated project manager to every client, ensuring seamless coordination from RFQ to final delivery. Whether you’re based in North America, Europe, or Southeast Asia, our logistics network supports on-time shipments with full traceability and customs documentation.

If you’re seeking a manufacturing partner that combines cutting-edge technology with operational excellence, look no further than Wuxi Lead Precision Machinery. We are committed to becoming an extension of your engineering team, helping you reduce lead times, improve part quality, and scale production efficiently.

Explore how our plastic laser cutting services can elevate your next fabrication project. Contact us today at [email protected] to request a quote, share your design files, or schedule a virtual factory tour.

| Specification | Capability |

|---|---|

| Laser Types | CO₂ and Fiber Laser Systems |

| Material Thickness Range | 0.5 mm – 20 mm (varies by plastic type) |

| Positioning Accuracy | ±0.02 mm |

| Minimum Feature Size | 0.3 mm (typical) |

| Supported Plastics | Polycarbonate, Acrylic (PMMA), PEEK, ABS, Polyethylene, PVC, PET |

| Max Cutting Area | 1500 mm × 3000 mm |

| Tolerance | ±0.1 mm (standard), tighter upon request |

| Finishing Options | As-cut, edge polishing, deburring, masking |

| Quality Standards | ISO 9001:2015 Certified, First Article Inspection, PPAP Support |

| Lead Time | 5–15 days (depending on complexity and volume) |

Reach out now to [email protected] and experience the Lead Precision difference.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.