Technical Contents

Engineering Guide: Space Machining

Engineering Insight: Precision in Space Machining

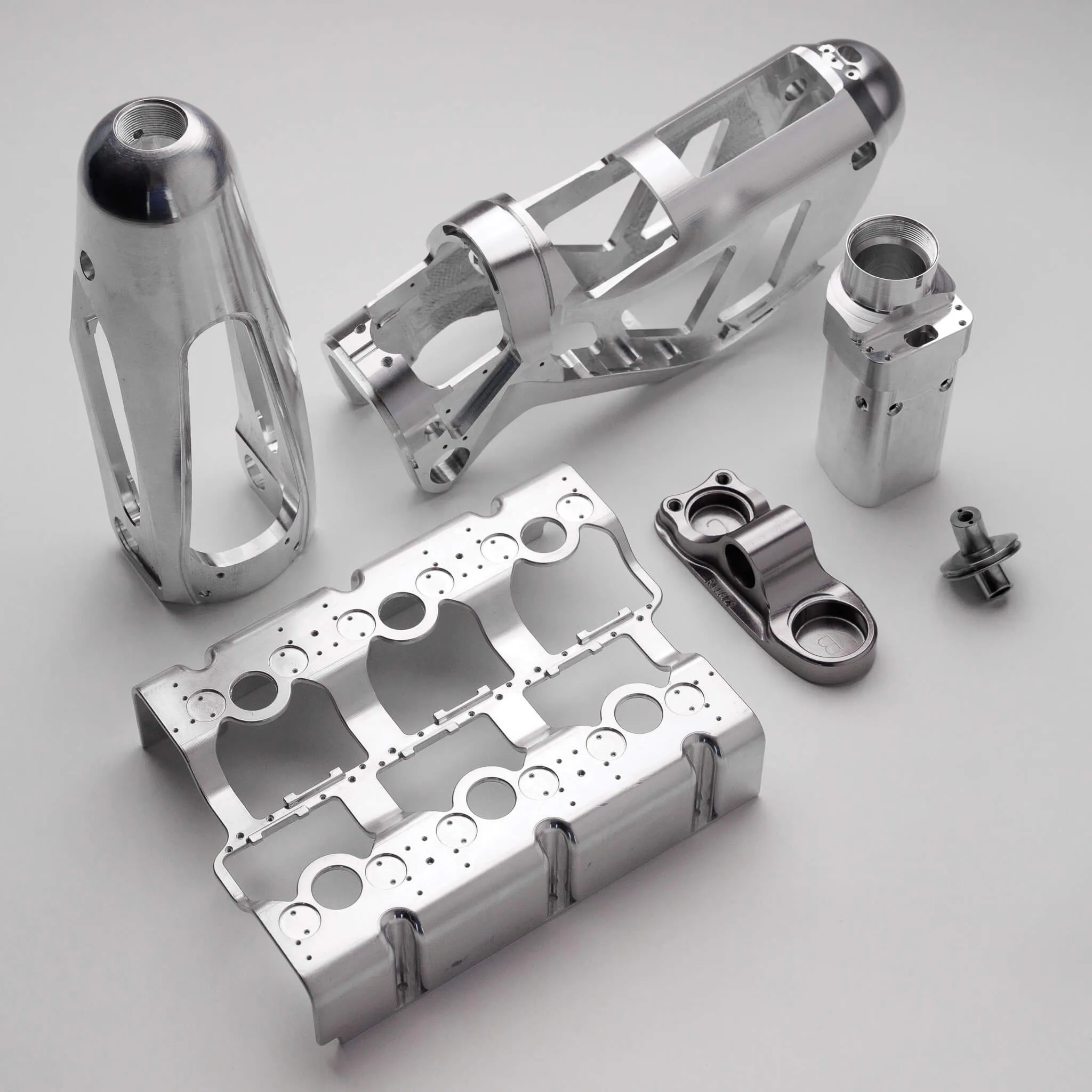

In the realm of advanced manufacturing, space machining represents the pinnacle of precision engineering. Components destined for aerospace and satellite systems operate in extreme environments—vacuum, radiation, thermal cycling, and high mechanical stress—where even micron-level deviations can lead to catastrophic failure. At Wuxi Lead Precision Machinery, we understand that success in space begins with uncompromising accuracy, repeatability, and material integrity. Our decades-long commitment to high-precision CNC machining has positioned us as a trusted partner in custom metal manufacturing for mission-critical applications.

Space machining demands more than just tight tolerances; it requires a holistic understanding of material behavior, geometric complexity, and long-term reliability. Aerospace alloys such as Inconel 718, titanium Ti-6Al-4V, and aluminum 7075-T7351 are commonly used due to their strength-to-weight ratios and resistance to thermal deformation. However, these materials are notoriously difficult to machine, requiring optimized toolpaths, specialized tooling, and real-time process monitoring to maintain dimensional stability. At Lead Precision, our engineering team employs 5-axis simultaneous machining, high-speed milling, and in-process probing to ensure every component meets the exacting standards of space qualification.

Our expertise is not theoretical. We have delivered precision-machined components for projects with Olympic-level timing systems and military-grade navigation units—applications where failure is not an option. These experiences have honed our ability to manage tight deadlines, stringent documentation requirements, and full traceability from raw material to final inspection. Our quality management system is aligned with ISO 9001 and AS9100 standards, ensuring compliance with aerospace-specific regulatory frameworks.

Every part produced for space applications undergoes rigorous metrology. We utilize coordinate measuring machines (CMM), optical comparators, and laser scanning to verify conformity to design specifications. Surface finishes are controlled to minimize particulate shedding in vacuum environments, and residual stresses are relieved through precision heat treatment and stress-relief cycles.

The following table outlines typical specifications achievable at Wuxi Lead Precision Machinery for space-grade components:

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish (Ra) | 0.4 μm to 1.6 μm (custom down to 0.1 μm) |

| Materials | Aluminum 7075, Titanium Ti-6Al-4V, Inconel 718, Stainless Steel 17-4 PH |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm (5-axis) |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanner, Roughness Tester |

| Certifications | ISO 9001, AS9100 (in progress), RoHS compliant |

At Wuxi Lead Precision Machinery, we do not merely manufacture parts—we engineer reliability. Our experience in high-stakes industries underscores our capability to meet the unique challenges of space machining. When precision defines performance, Lead Precision delivers with confidence.

Precision Specs & Tolerances

Technical Capabilities for Aerospace Precision Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components for the global aerospace sector, where dimensional accuracy directly impacts flight safety and system performance. Our technical foundation centers on advanced 5-axis CNC machining capabilities, enabling complex geometries unattainable with 3-axis systems. Utilizing state-of-the-art DMG MORI and Haas UMC platforms, we achieve simultaneous multi-axis contouring for turbine blades, structural brackets, and fuel system housings. This technology eliminates manual repositioning errors, reduces lead times by up to 40%, and ensures surface integrity for high-stress applications. All machining occurs within climate-controlled environments to mitigate thermal drift, with real-time tool wear compensation maintaining tolerances across extended production runs.

Rigorous quality control is non-negotiable in aerospace manufacturing. Every component undergoes comprehensive inspection via Zeiss CONTURA CMM systems, providing sub-micron measurement repeatability. Our inspection protocol includes first-article validation per AS9102 standards, in-process checks at critical operations, and full FAI reports with GD&T analysis. Material traceability is maintained from raw bar stock through final shipment, with full certification to AMS, ASTM, and customer-specific material specifications. This end-to-end control extends to surface finish verification using profilometers and non-destructive testing coordination for critical parts.

Our process control framework integrates statistical process control (SPC) methodologies, with capability studies (Cp/Cpk) conducted on all high-volume features. This proactive approach identifies process drift before non-conformances occur, ensuring consistent output even for low-volume, high-complexity programs.

The following table details our standard aerospace machining tolerances, achievable across aluminum alloys (e.g., 7075-T7351), titanium (Ti-6Al-4V), and Inconel 718:

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM / Optical Comparator |

| Geometric Tolerancing | ±0.05 mm | ±0.01 mm | CMM (GD&T Analysis) |

| Hole Position | ±0.02 mm | ±0.008 mm | CMM |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm | Profilometer |

| Flatness | 0.05 mm/m | 0.01 mm/m | CMM / Granite Surface |

These capabilities are certified under AS9100D and ISO 9001:2015 quality management systems, with dedicated aerospace work cells isolated from non-aerospace production. Our engineering team collaborates directly with clients during DFM stages to optimize part geometry for manufacturability without compromising performance. By combining 5-axis precision, metrology-grade validation, and aerospace-specific process controls, Wuxi Lead ensures components meet the extreme reliability demands of modern aviation and space systems. This technical rigor minimizes scrap, accelerates time-to-market, and provides documented evidence of conformance for stringent regulatory audits.

Material & Finish Options

Material Selection for High-Precision Space Machining Applications

In the field of space machining, material selection is a critical engineering decision that directly impacts performance, reliability, and mission success. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for aerospace and satellite systems, where dimensional stability, strength-to-weight ratio, and resistance to extreme environments are non-negotiable. Among the most widely used materials in space applications are aluminum, steel, and titanium—each offering unique advantages depending on the functional requirements of the component.

Aluminum alloys, particularly 6061 and 7075, are favored in space systems for their excellent strength-to-density ratio and machinability. These alloys are commonly used in satellite housings, optical benches, and structural brackets where weight reduction is paramount. While aluminum lacks the ultimate strength of steel or titanium, its performance can be enhanced through heat treatment and precision CNC machining to tight tolerances. Additionally, aluminum is highly responsive to surface finishing processes such as anodizing, which improves wear and corrosion resistance—essential for components exposed to launch environments and orbital thermal cycling.

Steel, especially aerospace-grade stainless variants like 17-4 PH and 304/316, provides superior strength, hardness, and dimensional stability under mechanical load. These properties make steel ideal for load-bearing components, fasteners, and mechanisms requiring long-term durability in vacuum and radiation-heavy conditions. While steel is denser than aluminum or titanium, its use is justified in applications where structural integrity cannot be compromised. Our machining processes ensure minimal residual stress and optimal surface finish, critical for fatigue resistance in cyclic loading environments.

Titanium alloys, such as Ti-6Al-4V, offer an exceptional balance of high tensile strength, low density, and outstanding corrosion resistance. These characteristics make titanium a preferred choice for high-stress, weight-sensitive applications such as propulsion mounts, landing gear components, and structural fittings in launch vehicles. Titanium’s biocompatibility and performance at elevated temperatures further expand its utility in space-rated systems. However, its low thermal conductivity and high chemical reactivity require specialized tooling and machining parameters—expertise we have refined over years of aerospace production.

Surface treatment is equally vital in space machining. Anodizing, particularly Type II and Type III (hardcoat) anodizing on aluminum, enhances surface hardness, electrical insulation, and resistance to galvanic corrosion—especially important in mixed-material assemblies. All finishes are applied under controlled conditions to meet MIL-A-8625 and ASTM B580 standards.

Below is a comparative overview of key material properties relevant to space applications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Uses in Space Systems | Typical Finish |

|---|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 570 | 505 | Satellite frames, brackets | Hardcoat Anodizing |

| Stainless Steel 17-4 PH | 7.75 | 1310 | 1180 | Fasteners, actuators | Passivation |

| Titanium Ti-6Al-4V | 4.43 | 950 | 880 | Structural fittings, engine parts | As-machined, Alodine |

At Wuxi Lead Precision Machinery, we support material certification, traceability, and full compliance with aerospace quality standards, ensuring every component meets the rigorous demands of spaceflight.

Manufacturing Process & QC

Precision Manufacturing Process for Space Applications

At Wuxi Lead Precision Machinery, space-grade component production demands absolute adherence to zero-defect protocols. Our integrated workflow—Design, Prototyping, Mass Production—ensures orbital reliability through rigorously controlled stages. Every phase incorporates aerospace-specific standards (AS9100, ISO 27001) and real-time data analytics to eliminate tolerances beyond microns.

Design begins with collaborative CAD/CAM optimization using Siemens NX and ANSYS simulation. We analyze thermal expansion, micro-vibration, and material stress under vacuum conditions, selecting alloys like Titanium Grade 5 or Inconel 718 for extreme environments. Finite element analysis validates structural integrity against launch loads, while geometric dimensioning and tolerancing (GD&T) are locked at ±0.001mm. Client design files undergo cross-functional review with our materials science team to preempt micro-fracture risks.

Prototyping leverages 5-axis DMG MORI machining centers for single-setup accuracy. Each prototype undergoes non-destructive testing (NDT): X-ray CT scanning verifies internal porosity, CMM inspection confirms dimensional compliance, and helium leak testing certifies hermetic seals. We iterate until fatigue life exceeds mission requirements by 200%, with full traceability from raw billet to finished part via blockchain-secured logs. Only after client sign-off on all validation reports does mass production commence.

Mass production integrates statistical process control (SPC) with IoT-enabled machine monitoring. Thermal compensation systems counteract ambient fluctuations, while in-process probes auto-correct tool wear deviations. Every 10th part undergoes 100% inspection; outliers trigger immediate line stoppage and root-cause analysis. Our cleanroom assembly stations (ISO Class 7) prevent particulate contamination, and final packaging meets NASA-STD-6001 for outgassing compliance. This closed-loop system achieves 99.998% first-pass yield across 10,000+ part runs.

Space Machining Technical Specifications

| Capability | Specification | Verification Method |

|---|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm | Zeiss CONTURA CMM (0.5µm accuracy) |

| Surface Finish | Ra 0.2 µm to Ra 0.8 µm | Perthometer M2 profilometer |

| Materials | Ti-6Al-4V, Inconel 718, Aluminum 7075 | Spectrochemical analysis |

| Max Part Dimensions | Ø650 mm x 1,200 mm | Laser tracker validation |

| Process Control | Real-time SPC with <0.5 Cpk threshold | Minitab-driven analytics |

Zero defects are non-negotiable in space systems. Wuxi Lead’s process fuses German-engineered machinery with aerospace-grade QA discipline, delivering components that withstand 20,000+ radiation hours and -250°C to +300°C cycling. Partner with us to transform mission-critical designs into flight-proven hardware—on time, to spec, with zero compromises.

Why Choose Wuxi Lead Precision

When it comes to high-precision metal manufacturing for the aerospace and space exploration sectors, partnering with a trusted, technically advanced manufacturer is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical components that meet the extreme demands of space applications. Our engineering expertise, combined with state-of-the-art CNC machining capabilities, ensures that every part we produce adheres to the highest standards of accuracy, durability, and performance.

Space machining requires more than just advanced equipment—it demands a deep understanding of material behavior under extreme conditions, rigorous quality control, and the ability to maintain micron-level tolerances across complex geometries. Our team of senior CNC engineers and manufacturing specialists has years of experience supporting clients in the aerospace, satellite, and propulsion industries. From titanium structural components to high-strength aluminum alloy housings and Inconel-based engine parts, we deliver precision-engineered solutions tailored to your exact specifications.

We understand that reliability in space applications is non-negotiable. That’s why every project at Lead Precision begins with a detailed engineering review, ensuring design for manufacturability, material suitability, and compliance with industry standards such as AS9100 and ISO 9001. Our facility is equipped with 5-axis CNC machining centers, high-speed milling systems, and advanced metrology tools including CMM and laser scanning, enabling us to verify dimensional accuracy down to ±0.002 mm.

Our commitment extends beyond machining. We offer full-service support including rapid prototyping, DFMEA analysis, first-article inspection (FAI) reporting, and scalable production runs—whether you require a single prototype or high-volume batches. With a focus on traceability, documentation, and on-time delivery, we integrate seamlessly into your supply chain as a dependable extension of your engineering team.

Below are key technical capabilities that define our space-grade manufacturing services:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Materials Supported | Aluminum 7075-T6, Titanium Grade 5 (Ti-6Al-4V), Inconel 718 & 625, Stainless Steel 316L, Magnesium Alloys |

| Surface Finishes | Ra 0.4 μm standard, down to Ra 0.1 μm with polishing |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS compliant |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally built for the challenges of space. We don’t just meet specifications—we anticipate the unseen demands of your application and engineer solutions ahead of them.

For engineering inquiries or to submit a request for quotation, contact us today at [email protected]. Let’s build the future of space technology—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.