Technical Contents

Engineering Guide: Machine Shop Boston

Engineering Insight: The Role of Precision in Modern Machine Shop Operations – A Boston Market Perspective

In the highly competitive landscape of precision manufacturing, particularly within industrial hubs such as Boston, the margin for error is measured in microns. Machine shop operations in this region serve a diverse clientele ranging from medical device developers to aerospace innovators and defense contractors—sectors where component reliability and dimensional accuracy are non-negotiable. As automation, advanced materials, and smart manufacturing continue to redefine expectations, the demand for ultra-precision machining has never been more critical.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a specification—it is a foundational engineering principle. With over 15 years of experience in custom metal manufacturing, our facility in Wuxi, China, has delivered mission-critical components for high-stakes applications, including systems used in Olympic athletic equipment and defense-grade hardware for military subcontractors. These projects required not only tight tolerances but also rigorous process validation, material traceability, and full compliance with international quality standards—capabilities that mirror the expectations of Boston-area manufacturers.

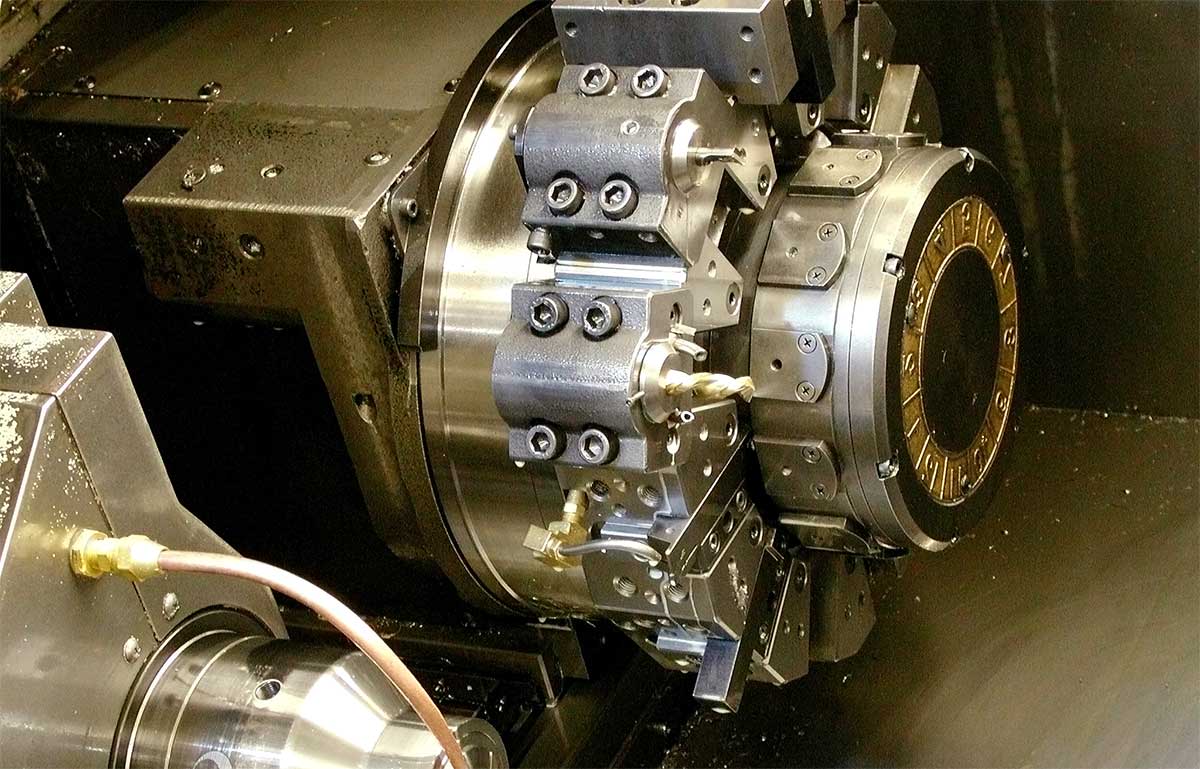

The Boston market, known for its concentration of R&D centers and advanced engineering firms, often requires prototypes and low-volume production runs that push the limits of conventional machining. Components used in life sciences, for example, may involve complex geometries in titanium or stainless steel, machined to tolerances of ±0.0002 inches. In such cases, the integration of high-speed CNC milling, multi-axis turning, and in-process metrology becomes essential. At Lead Precision, our investment in Swiss-type lathes, 5-axis CNC centers, and laser scanning inspection systems ensures that we meet and exceed these technical demands consistently.

Precision also extends beyond the machine tool. It encompasses process control, environmental stability, and skilled engineering oversight. Our quality management system is ISO 9001:2015 certified, and we employ real-time SPC (Statistical Process Control) monitoring across all production lines. Every component undergoes first-article inspection and batch traceability, ensuring full alignment with customer engineering requirements—whether those come from a biotech startup in Cambridge or a defense integrator in the greater Boston area.

The following table outlines key capabilities that support precision manufacturing at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Maximum Machining Tolerance | ±0.0001″ (2.5 μm) |

| CNC Milling Axes | Up to 5-axis simultaneous |

| CNC Turning | 2-axis to 6-axis Swiss-type |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Maximum Part Size (Milling) | 800 mm × 600 mm × 500 mm |

| Maximum Part Size (Turning) | Ø2 mm to Ø65 mm diameter, up to 300 mm length |

| Surface Finish | As low as Ra 0.4 μm (16 μin) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, AS9100 compliance available |

For Boston-based engineering teams seeking a reliable offshore partner, Wuxi Lead Precision Machinery offers the technical rigor, quality assurance, and project execution discipline required for today’s most demanding applications. Precision is not just what we deliver—it is how we engineer every solution.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing, specifically engineered to meet the stringent requirements of advanced industries served by leading Boston-area machine shops. Our core strength lies in integrating cutting-edge multi-axis technology with rigorous quality control protocols, ensuring components meet exacting specifications on time and within budget. We understand the critical nature of precision in aerospace, medical device, and defense applications prevalent in the New England manufacturing ecosystem, where dimensional accuracy directly impacts performance and safety.

Advanced 5-Axis Machining Capabilities

Our facility is anchored by a comprehensive fleet of state-of-the-art 5-axis CNC machining centers from industry leaders. This technology enables the simultaneous machining of complex geometries from multiple angles in a single setup. The elimination of multiple fixturing stages significantly reduces cumulative error, enhances part accuracy, improves surface finish consistency, and dramatically shortens lead times compared to traditional 3-axis methods. We excel at producing intricate components such as turbine blades, surgical instrument housings, hydraulic manifolds, and complex structural brackets from a wide range of materials including titanium alloys, Inconel, stainless steels, aluminum alloys, and engineered plastics. Our programming and setup engineers possess deep expertise in optimizing toolpaths for maximum efficiency and precision on these sophisticated platforms.

Rigorous Quality Assurance: Beyond Standard Inspection

Precision manufacturing demands verification at the highest level. Every critical component undergoes comprehensive dimensional validation using calibrated Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMM systems provide micron-level accuracy for verifying complex contours, positional tolerances, and geometric features that cannot be reliably checked with manual methods. This CMM inspection is not a final step but is integrated throughout the production process, enabling real-time process control and immediate corrective action. Our quality management system is ISO 9001:2015 certified, with documentation fully compliant with AS9100 and ITAR requirements, providing Boston partners with the audit trail and traceability essential for regulated sectors.

Achievable Tolerance Standards

The table below outlines the typical tolerance capabilities achievable across common feature types using our integrated 5-axis machining and CMM verification processes. Specific capabilities may vary based on part geometry, material, and size.

| Feature Type | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Positional Tolerance | ±0.025 mm (±0.001″) | ±0.010 mm (±0.0004″) |

| Geometric Tolerances (Flatness, Roundness) | 0.025 mm (0.001″) | 0.010 mm (0.0004″) |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) |

Partnering with Wuxi Lead provides Boston machine shops access to scalable, high-integrity manufacturing capacity without compromising on the precision or quality standards demanded by their end clients. Our commitment to technical excellence, transparent communication, and adherence to US-specific documentation and reporting protocols ensures a seamless extension of your production capabilities. We focus on mitigating your supply chain risk through proven process reliability and unwavering commitment to the specifications critical to your success. Contact our engineering team to discuss how our capabilities solve your most challenging precision machining requirements.

Material & Finish Options

Material selection is a critical step in precision manufacturing, directly influencing the performance, durability, and cost-efficiency of custom metal components. At Wuxi Lead Precision Machinery, we specialize in delivering high-tolerance parts tailored to the demanding requirements of industries such as aerospace, medical devices, and advanced automation. Understanding the mechanical properties and finishing compatibility of key materials—aluminum, steel, and titanium—enables engineers and procurement teams to make informed decisions that align with functional and environmental demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications requiring lightweight structures without sacrificing structural integrity. The most commonly used grades in precision machining are 6061-T6 and 7075-T6. While 6061 offers good weldability and moderate strength, 7075 delivers higher tensile strength, making it ideal for high-stress environments. Aluminum is also highly compatible with anodizing, a finishing process that enhances surface hardness and wear resistance while providing aesthetic control.

Steel remains the material of choice for components subjected to high mechanical loads and wear. Among the various types, stainless steel 304 and 316 are preferred for their corrosion resistance and biocompatibility, making them ideal for medical and food processing applications. For structural and industrial parts, alloy steels such as 4140 and 4340 offer superior toughness and hardenability. While steel does not anodize, it can be treated with passivation, plating, or coating to improve surface performance and longevity.

Titanium, particularly Grade 5 (Ti-6Al-4V), is used in mission-critical applications where extreme strength, low density, and exceptional resistance to corrosion and high temperatures are required. Common in aerospace and implantable medical devices, titanium presents machining challenges due to its low thermal conductivity and tendency to gall. However, with optimized toolpaths and cutting parameters, high-precision results can be consistently achieved. Titanium does not anodize in the conventional sense but can undergo specialized surface treatments such as thermal oxidation or nitriding to enhance surface properties.

The following table summarizes key mechanical and finishing characteristics of commonly used materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Good | Yes | Enclosures, brackets, heat sinks |

| Aluminum 7075-T6 | 570 | 2.8 | Moderate | Yes | Aerospace components, fittings |

| Stainless 304 | 505 | 8.0 | Excellent | No | Medical devices, food processing |

| Stainless 316 | 570 | 8.0 | Excellent | No | Marine, chemical processing |

| Steel 4140 | 655 | 7.85 | Moderate | No | Shafts, tooling, industrial parts |

| Titanium Ti-6Al-4V | 950 | 4.43 | Excellent | Specialized only | Aerospace, medical implants |

Selecting the right material involves balancing performance requirements, environmental exposure, and post-processing needs. At Wuxi Lead, we support clients through material consultation, prototyping, and finishing integration to ensure optimal outcomes for every custom manufacturing project.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production workflow designed for Boston’s high-stakes manufacturing sector. Our process eliminates variability through integrated quality gates, ensuring every component meets aerospace, medical, and defense specifications without compromise. This methodology transforms client designs into flawless serial production, mitigating cost-intensive rework common in offshore partnerships.

The journey begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team reviews CAD models alongside Boston-based clients to optimize geometry, material selection, and toolpaths. We validate material certifications against AMS, ASTM, or client-specific standards upfront, preventing downstream non-conformances. Critical tolerances are cross-referenced with GD&T callouts, and thermal stability simulations ensure performance under operational loads. This phase concludes with a signed-off DFM report, establishing unambiguous production criteria.

Prototyping transitions design into physical validation under real machining conditions. We produce first-article parts using the exact CNC equipment, tooling, and metrology systems designated for mass production. Each prototype undergoes full-spectrum inspection: CMM reports verify dimensional accuracy to ±0.0002″, surface roughness testers confirm Ra values, and cross-sectional analysis checks material integrity. Clients receive comprehensive inspection dossiers including 3D scan overlays against nominal CAD. Only after formal client approval—validating form, fit, and function—does mass production commence.

Mass production integrates Zero Defects protocols at every station. Statistical Process Control (SPC) monitors key parameters in real-time; tool wear sensors auto-compensate for dimensional drift, while in-process gauging rejects deviations before secondary operations. Every lot includes first/last piece inspection with full traceability to raw material heat numbers. Our MES logs 100% of machining data—spindle loads, coolant pressure, vibration metrics—enabling root-cause analysis should anomalies arise. Final inspection employs multi-sensor CMMs and optical comparators, with certificates of conformance detailing actual vs. nominal measurements. This closed-loop system achieves <50 PPM defect rates consistently.

Our capabilities for precision metal components are defined by measurable standards:

| Parameter | Capability | Verification Method |

|---|---|---|

| Tolerance | ±0.0002″ (5μm) | 5-axis CMM with ISO 10360-2 |

| Surface Finish | Ra 0.4 μm (16 μin) | Profilometer per ASME B46.1 |

| Material Certification | Full traceability to MTR | Mill Test Reports + In-house OES |

| Dimensional Inspection | 100% critical features | Automated optical + tactile |

For Boston machine shops demanding uncompromised quality, this process delivers predictable outcomes. We eliminate the risk of offshore production through transparency, technical rigor, and shared accountability—ensuring your components perform flawlessly from the first piece to the last. Partner with us to convert design intent into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your Boston-based machine shop demands precision, scalability, and unwavering reliability in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery sets you apart. As a globally recognized leader in high-tolerance CNC machining, we deliver mission-critical components that meet the exacting standards of aerospace, medical, industrial automation, and advanced robotics sectors. Our facility in Wuxi, China, operates under ISO 9001:2015 certification with full traceability, lean manufacturing protocols, and a zero-defect mindset—ensuring every part shipped to Boston performs exactly as designed.

We understand the challenges faced by high-end machine shops: tight tolerances, complex geometries, demanding materials, and compressed timelines. That’s why we’ve engineered our processes around responsiveness and technical agility. From prototype to full-scale production, Lead Precision integrates 5-axis CNC milling, precision turning, wire EDM, and multi-axis grinding with real-time quality control. Our team of senior CNC engineers collaborates directly with your design and production staff to optimize manufacturability, reduce cycle times, and eliminate costly revisions—delivering parts that are not just dimensionally accurate but functionally superior.

Our clients in North America rely on us not just as a supplier, but as an extension of their engineering capability. With a 98.6% on-time delivery rate and dedicated project management for every order, we ensure seamless integration into your supply chain. Whether you require 50 custom housings for a medical device or 10,000 precision shafts for industrial automation, our scalable infrastructure supports your volume needs without compromising quality.

Below are key technical capabilities that define our manufacturing excellence

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Tolerance Range | ±0.002 mm (±0.00008 in) |

| Surface Finish | As fine as Ra 0.2 µm (8 µin) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Inconel 718, Brass, Tool Steels |

| Secondary Operations | Heat treatment, anodizing, passivation, precision welding, custom packaging |

| Quality Assurance | CMM inspection, optical comparators, full first-article reporting (FAI), PPAP documentation |

Every component we produce is backed by metrology-grade verification and a commitment to continuous improvement. We speak your language—both technically and operationally—ensuring smooth communication, rapid quoting, and agile adjustments to evolving project demands.

For Boston machine shops seeking a strategic manufacturing partner that combines Asian efficiency with Western engineering rigor, the choice is clear. Contact us today to elevate your next project. Email [email protected] and connect with our engineering team for a technical consultation, DFM analysis, or sample evaluation. Let Wuxi Lead Precision Machinery become your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.