Technical Contents

Engineering Guide: Polycarbonate Injection Moulding

Engineering Insight: Precision Imperatives in Polycarbonate Injection Moulding

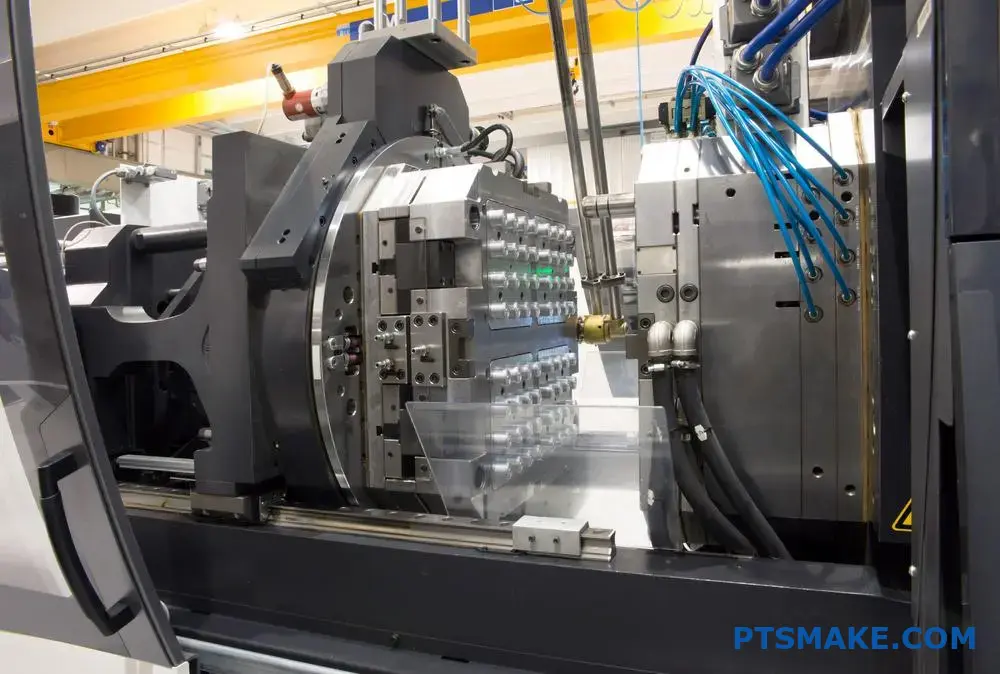

Polycarbonate (PC) injection moulding presents unique engineering challenges distinct from standard thermoplastics, demanding exceptional precision at every process stage. Its high melt viscosity, sensitivity to shear heating, and stringent thermal stability requirements necessitate far more than standard machine capability. Inadequate control over melt temperature, injection speed, pressure profiles, or cooling rates directly translates to critical defects: internal stresses causing premature fracture, optical haze compromising clarity, dimensional instability, or weld line weakness. For mission-critical applications in aerospace, medical devices, or advanced optics – where PC is often specified for its unmatched impact resistance and transparency – these defects are unacceptable. True precision moulding of polycarbonate hinges on the machine’s ability to maintain micron-level tolerances in clamp force, injection repeatability, and temperature uniformity across the entire cycle, not just during initial fill.

The core challenge lies in managing PC’s narrow processing window. Excessive shear rates during injection generate localized overheating, degrading the polymer chain and sacrificing mechanical properties. Conversely, insufficient pressure or suboptimal melt temperature leads to incomplete cavity filling or high residual stress. Precise control over the velocity-to-pressure switchover point is paramount to avoid flash or short shots while minimizing molecular orientation. This requires servo-hydraulic or all-electric drive systems with sub-millisecond response times and closed-loop feedback on critical parameters. Thermal management is equally vital; consistent barrel and nozzle temperatures within ±1°C, coupled with highly uniform mould cooling circuits, are non-negotiable for preventing warpage and ensuring part dimensional fidelity. Material drying must also achieve and maintain dew points below -40°C, as moisture causes hydrolysis and catastrophic loss of impact strength.

Wuxi Lead Precision Machinery engineers these exacting demands into our custom moulding platforms. Our systems integrate high-resolution pressure transducers, advanced thermal control algorithms, and rigid machine frames engineered to minimize deflection under extreme clamp forces. This capability is proven in production environments where failure is not an option. We have supplied and supported precision moulding cells producing Olympic-certified safety components requiring flawless optical clarity and defense-grade structural elements demanding absolute dimensional stability under extreme environmental stress. The table below outlines critical precision parameters essential for successful polycarbonate processing.

| Parameter | Critical Range for Polycarbonate | Precision Requirement | Impact of Deviation |

|---|---|---|---|

| Melt Temperature | 280°C – 320°C | ±1°C Stability | Degradation (high) / Poor Flow (low) |

| Mould Temperature | 80°C – 110°C | ±2°C Uniformity | Warpage, Stress Cracking, Haze |

| Injection Pressure | 800 – 1500 bar | ±5 bar Repeatability | Flash, Short Shots, Weld Line Weakness |

| Clamp Force Accuracy | Machine Dependent | ±0.5% Linearity | Flash, Cavity Deflection, Parting Line |

| Drying Dew Point | < -40°C | Continuous Monitoring | Hydrolysis, Loss of Impact Strength |

Achieving consistent, high-integrity polycarbonate parts is fundamentally a precision engineering discipline. It demands machinery designed and built to exacting standards that surpass typical industrial tolerances. At Wuxi Lead Precision Machinery, our focus on micron-level repeatability, thermal stability, and robust construction, forged through demanding applications like Olympic and military projects, provides the foundational reliability required for your most critical polycarbonate components. Precision isn’t just a specification; it’s the core of defect-free, high-performance manufacturing.

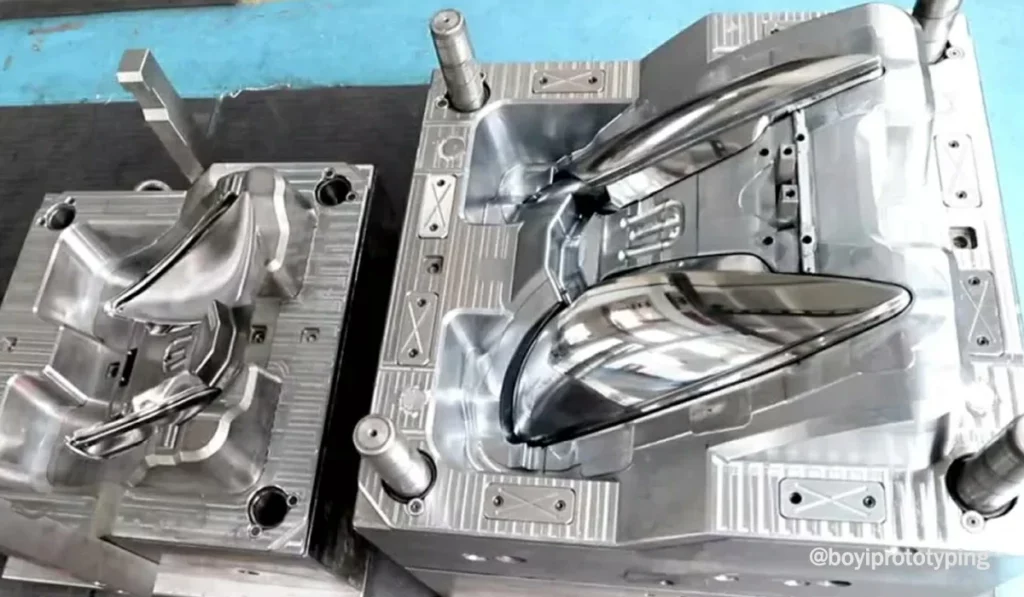

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-performance applications such as polycarbonate injection moulding. Our expertise lies in producing precision-critical mould components that ensure consistent part quality, extended tool life, and optimal cycle efficiency. Utilizing state-of-the-art 5-axis CNC machining centers, we achieve complex geometries and superior surface finishes unattainable with conventional 3-axis systems. This level of precision is essential for manufacturing mould cores, cavities, sliders, and other intricate features required in polycarbonate tooling, where dimensional stability and thermal management are critical.

Our 5-axis CNC technology enables simultaneous multi-directional cutting, reducing setup times and minimizing cumulative tolerances associated with multiple fixturing stages. This results in higher accuracy, improved part repeatability, and faster lead times. All machining operations are performed under strict environmental controls to mitigate thermal deformation, ensuring micron-level consistency across production batches. Materials commonly processed include P20, H13, S136, and other tool steels optimized for high-gloss finishes and resistance to the elevated temperatures associated with polycarbonate processing.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing full 3D verification of geometric dimensions and tolerances. Our CMM protocols are aligned with ISO 10360 standards, ensuring traceable, repeatable measurement results. In addition to dimensional accuracy, surface roughness is monitored using profilometers to guarantee optical-grade finishes required for transparent polycarbonate parts.

We maintain full in-house control from design validation to final inspection, allowing rapid iteration and real-time process adjustments. Our engineering team collaborates directly with clients to review DFM reports, optimize cooling channel layouts, and select appropriate surface treatments such as nitriding or chrome plating to enhance wear resistance and corrosion protection.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Flatness, Roundness) | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.05 µm |

| CMM Measurement Uncertainty | ±0.0025 mm (at 95% confidence) |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Material Compatibility | Tool steels, stainless steels, aluminum, brass, and engineered alloys |

Wuxi Lead Precision Machinery is committed to delivering mould components that meet the stringent demands of polycarbonate injection moulding, combining advanced technology, rigorous quality control, and engineering excellence to ensure optimal performance in high-volume, high-precision production environments.

Material & Finish Options

Material Selection for Polycarbonate Injection Moulding

Polycarbonate injection moulding demands precise material selection for moulds due to the polymer’s high processing temperatures (280–320°C) and inherent abrasiveness. Suboptimal mould materials accelerate wear, cause thermal fatigue, and compromise part clarity or dimensional stability. At Wuxi Lead Precision Machinery, we prioritize metals that balance thermal management, durability, and cost efficiency for your production volume and part complexity.

Aluminum alloys (e.g., 7075-T6) excel in rapid prototyping and low-volume runs. Their superior thermal conductivity (130–180 W/m·K) enables faster cycle times and uniform cooling, critical for minimizing PC’s internal stresses. However, aluminum’s lower hardness (150 HB) limits use beyond 50,000 cycles, especially with glass-filled polycarbonate. Steel variants—such as H13 tool steel (hardened to 48–52 HRC)—are essential for high-volume production. H13 withstands thermal cycling and abrasive fills, offering 500,000+ cycles with proper maintenance. For extreme wear resistance in optical-grade PC, consider maraging steel (50–54 HRC), though at higher cost and machining complexity. Titanium alloys (e.g., Ti-6Al-4V) provide exceptional corrosion resistance and strength-to-weight ratios but are rarely cost-justified for PC moulds due to poor thermal conductivity (7 W/m·K) and exorbitant machining costs.

Surface finishes further dictate part quality and release efficiency. Anodizing is exclusively applicable to aluminum moulds, enhancing surface hardness (up to 600 HV) and corrosion resistance. Type III (hard) anodizing at 50–75 µm thickness is standard for PC, reducing galling and improving release without silicone sprays. Note that steel moulds require alternative treatments: nitriding for wear resistance or electroless nickel plating for corrosion protection. Avoid PTFE coatings for PC—they degrade under high temperatures, contaminating parts.

Our CNC expertise ensures optimal material pairing with your polycarbonate grade. For instance, unfilled PC suits aluminum for <20,000 cycles, while 30% glass-filled PC mandates H13 steel. Below is a comparative overview:

| Material | Thermal Conductivity (W/m·K) | Hardness (HRC/HB) | Typical Use Case | Cost Factor |

|---|---|---|---|---|

| Aluminum 7075 | 130–180 | 150 HB | Prototyping, low-volume unfilled PC | Low |

| H13 Tool Steel | 25–30 | 48–52 | High-volume filled/unfilled PC | Medium |

| Maraging Steel | 20–25 | 50–54 | Optical-grade high-precision PC | High |

| Titanium Ti-64 | 6–7 | 36 HRC | Not recommended for standard PC | Very High |

Selecting the right mould material prevents costly downtime and part rejections. Partner with Wuxi Lead to analyze your polycarbonate formulation, volume, and tolerances—we engineer solutions where material science meets precision manufacturing.

Manufacturing Process & QC

Design Phase: Precision Engineering for Polycarbonate Injection Moulding

The foundation of flawless polycarbonate injection moulding begins with advanced design engineering. At Wuxi Lead Precision Machinery, we integrate CAD/CAM/CAE technologies to develop mould designs that meet exact client specifications while optimizing for material flow, cooling efficiency, and ejection dynamics. Polycarbonate, known for its high impact resistance and optical clarity, demands precise thermal and pressure control during injection. Our design team conducts detailed moldflow analysis to predict potential defects such as warpage, sink marks, or air traps, adjusting gate locations, runner systems, and cooling channels accordingly. This virtual validation ensures that the final mould geometry supports consistent part quality and structural integrity. All designs are reviewed for manufacturability, ensuring compatibility with high-speed production cycles and long-term durability under repeated thermal cycling.

Prototyping: Validating Performance Before Scale

Once the mould design is finalized, a high-precision prototype is manufactured using CNC machining and EDM processes to achieve tolerances within ±0.005 mm. This prototype stage is critical for verifying both the mould functionality and the performance of the polycarbonate material under real processing conditions. We conduct trial runs on our advanced injection moulding machines, adjusting parameters such as melt temperature (typically 280–320°C), injection pressure, and cooling time. Each prototype part undergoes rigorous inspection using CMM (Coordinate Measuring Machines), optical comparators, and mechanical testing to confirm dimensional accuracy, surface finish, and material properties. Any deviations are traced back to the root cause—whether material moisture, venting issues, or thermal imbalance—and corrected before progressing. This closed-loop validation process ensures that the transition to mass production is seamless and defect-free.

Mass Production: Zero-Defect Manufacturing at Scale

With design and prototyping successfully validated, we initiate full-scale production using automated, servo-driven injection moulding systems equipped with real-time monitoring. Every batch is produced under strictly controlled conditions, with raw polycarbonate resin dried to below 0.02% moisture content to prevent hydrolysis and surface defects. Our production lines integrate in-process quality checks, including automated vision inspection and statistical process control (SPC), ensuring 100% compliance with dimensional and aesthetic standards. Preventive maintenance schedules and mould protection systems further minimize downtime and tool wear. Traceability is maintained through batch coding and digital process logs, enabling full auditability.

Key Process Specifications

| Parameter | Specification |

|---|---|

| Material | Polycarbonate (PC), medical/industrial grade |

| Melt Temperature | 280–320°C |

| Injection Pressure | 80–150 MPa |

| Cooling Time | 15–45 seconds (part-dependent) |

| Tolerance | ±0.005 mm to ±0.02 mm |

| Surface Finish | SPI-A1, A2, or custom polish/texture |

| Production Capacity | Up to 500,000 units/month per mould |

| Quality Standard | ISO 9001, IATF 16949, zero-defect target |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers polycarbonate injection moulded components with uncompromised quality, repeatability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Polycarbonate Injection Moulding Excellence

Polycarbonate injection moulding demands extreme precision. Its high melt viscosity, sensitivity to shear, and stringent thermal requirements challenge conventional machinery. Achieving optical clarity, structural integrity, and micron-level tolerances requires more than standard equipment—it demands engineered solutions built for the material’s unique physics. At Wuxi Lead Precision Machinery, we specialize in the custom metal manufacturing that powers these critical processes. Our CNC-machined mould bases, cavities, and precision-engineered components form the foundation for defect-free polycarbonate production.

We understand that polycarbonate failures—stress cracking, flow lines, or dimensional drift—originate in microscopic inconsistencies during moulding. Our approach integrates advanced thermal management, ultra-stable clamping systems, and real-time process validation. Every component we manufacture undergoes rigorous metrology, ensuring ±0.002mm tolerances and surface finishes below Ra 0.1µm. This precision eliminates hot spots, warpage, and knit lines that compromise polycarbonate parts. Partnering with us means your moulds operate at peak efficiency, reducing cycle times by 15–22% while maintaining zero-defect output for aerospace lenses, medical housings, or automotive glazing.

Our capabilities are engineered specifically for high-performance polymers. The table below details our core specifications for polycarbonate-focused mould manufacturing:

| Parameter | Specification | Impact on Polycarbonate Moulding |

|---|---|---|

| Material Grade | H13, S136, or Custom Tool Steel | Thermal stability under 320°C melt temperatures |

| Machining Tolerance | ±0.002 mm | Prevents flash and dimensional drift |

| Surface Finish | Ra 0.05–0.1 µm (Mirror Polish) | Ensures optical clarity and ejection reliability |

| Cooling Channel Precision | ±0.01 mm positional accuracy | Eliminates thermal gradients and sink marks |

| Hardness | 48–52 HRC (Post-Treatment) | Resists wear from abrasive PC grades |

| Lead Time | 25–35 days (Complex Moulds) | Accelerates time-to-market for critical parts |

Beyond component manufacturing, we deliver end-to-end partnership. Our engineers collaborate from DFM analysis through production validation, leveraging in-house CNC milling, wire EDM, and CMM inspection. We prioritize IP security with NDAs and segregated production cells, while our ISO 9001-certified workflows guarantee traceability for regulated industries. Unlike offshore suppliers, we maintain direct engineering oversight—no middlemen, no communication delays. When your polycarbonate application demands zero compromise, our metal manufacturing expertise becomes your competitive advantage.

Do not let substandard tooling undermine your polycarbonate innovation. Schedule a technical consultation with our engineering team to review your project’s thermal, structural, and tolerance requirements. Contact us at Contact [email protected] with your part specifications and volume needs. We will provide a detailed capability assessment within 48 hours, including material selection guidance and a precision manufacturing roadmap. Transform your polycarbonate challenges into market-leading products with Wuxi Lead Precision Machinery—where custom metal manufacturing meets uncompromised polymer science.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.