Technical Contents

Engineering Guide: Laser Metal Cutting Services

Engineering Insight Precision as the Non-Negotiable Foundation in Laser Metal Cutting

In high-stakes sheet metal fabrication, precision in laser cutting transcends mere dimensional accuracy; it is the absolute cornerstone of functional integrity, assembly success, and ultimate product performance. Tolerances measured in tenths of a millimeter directly impact structural fit, aerodynamic profiles, fluid dynamics in manifolds, and the reliability of critical interfaces. A deviation of 0.1mm might seem insignificant on paper, but in aerospace components, medical device housings, or high-precision machinery, it can trigger catastrophic assembly failures, accelerated wear, or compromised safety margins. The laser cutting process itself introduces complex variables – thermal distortion, material grain variation, assist gas dynamics, and beam focus stability – demanding rigorous engineering control far beyond basic machine operation. True precision requires deep material science understanding, adaptive process calibration, and unwavering commitment to metrology throughout the production cycle. It is not an optional add-on but the fundamental requirement separating viable manufacturing from costly scrap and rework.

Wuxi Lead Precision Machinery has honed this precision discipline over 15+ years, directly supporting applications where failure is not an option. Our engineering team applies extensive experience gained through certified production for Olympic Games infrastructure projects demanding micron-level consistency under intense scrutiny and stringent military specifications requiring absolute reliability in extreme environments. This heritage instills a culture where every cut is treated as mission-critical. We implement closed-loop process monitoring, advanced thermal compensation algorithms, and multi-stage inspection protocols validated against NIST-traceable standards. Our approach integrates material certification, predictive kerf compensation, and real-time beam parameter optimization, ensuring the as-cut part meets the engineered intent, not just the nominal drawing.

The technical capability underpinning this precision is reflected in our core operational specifications for laser cutting services:

| Parameter | Capability | Engineering Significance |

|---|---|---|

| Material Thickness Range | Carbon Steel: 0.5mm – 25mm Stainless Steel: 0.5mm – 20mm Aluminum: 0.5mm – 15mm |

Enables versatile processing of thin gauges for electronics enclosures to thick plates for heavy machinery, maintaining precision across the spectrum. |

| Positional Accuracy | ±0.05mm | Ensures critical hole patterns, mounting features, and contour alignments meet tight assembly tolerances without shimming or rework. |

| Repeatability | ±0.01mm | Guarantees identical part geometry across multi-thousand unit production runs, essential for interchangeability and automated assembly lines. |

| Edge Quality (Ra) | < 3.2 µm (Burr-Free Typical) | Eliminates secondary deburring operations for many applications, reducing cost and preserving material integrity near the cut edge. |

| Kerf Width Control | ±0.02mm | Critical for intricate geometries, nested parts, and ensuring consistent feature sizes, especially in fine features or tight gaps. |

This commitment to engineered precision delivers tangible value: reduced total cost of ownership through minimized scrap and rework, accelerated time-to-market via first-time-right fabrication, and the confidence that every component will perform as designed within the final assembly. For industries where performance and reliability are paramount, partnering with a laser cutting provider whose precision is validated by Olympic and military-grade execution is not just advantageous – it is essential for de-risking your supply chain and ensuring product success. Wuxi Lead Precision Machinery provides that certified foundation.

Precision Specs & Tolerances

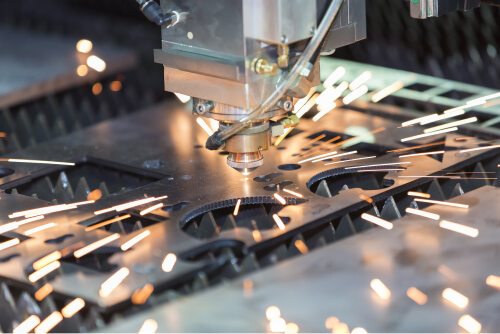

Wuxi Lead Precision Machinery delivers advanced laser metal cutting services as part of our comprehensive sheet metal fabrication solutions. Our technical capabilities are built around high-precision 5-axis CNC laser systems, enabling us to process complex geometries with exceptional accuracy and repeatability. These state-of-the-art machines support a broad range of conductive and non-conductive metals, including stainless steel, carbon steel, aluminum, brass, and copper, with thicknesses ranging from 0.5 mm to 25 mm depending on material type and application requirements.

The integration of 5-axis technology allows for dynamic cutting angles and multi-directional beam control, significantly enhancing our ability to produce intricate contours, beveled edges, and three-dimensional features in a single setup. This reduces cumulative tolerances from multiple operations and improves overall part consistency. Our laser systems utilize high-power fiber laser sources, ensuring faster processing speeds, reduced heat-affected zones, and superior edge quality—critical for high-end industrial applications in aerospace, medical devices, and precision automation.

All laser cutting operations are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Each critical dimension is verified against the original CAD model using non-contact and tactile probing methods, ensuring compliance with tight tolerances and geometric specifications. Our quality technicians are certified to ISO 9001 standards and perform first-article inspections, in-process checks, and final audits to guarantee dimensional integrity across production batches.

We maintain full digital traceability of inspection data, allowing clients to access detailed quality reports for every production run. This transparency, combined with our engineering-first approach, ensures that components not only meet but exceed performance expectations in demanding operational environments.

The following table outlines our standard technical specifications and achievable tolerances for laser metal cutting services:

| Parameter | Specification |

|---|---|

| Maximum Working Area | 3000 mm × 1500 mm |

| Material Thickness Range | 0.5 mm – 25 mm (varies by material) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Linear Cutting Tolerance | ±0.05 mm |

| Angular Cutting Tolerance | ±0.1° |

| Bevel Cut Accuracy | ±0.2° (for 30°–45° angles) |

| Hole Diameter Tolerance | +0.05 / –0.02 mm (for diameters ≥ 2 mm) |

| Feature-to-Feature Tolerance | ±0.1 mm (within 100 mm span) |

| Edge Roughness (Ra) | ≤ 3.2 µm (depending on material and thickness) |

| Minimum Internal Radius | 0.8 × material thickness (minimum 0.5 mm) |

These capabilities are continuously validated through preventive maintenance schedules and calibration protocols aligned with international metrology standards. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with disciplined process control to deliver laser-cut components that meet the highest benchmarks in precision manufacturing.

Material & Finish Options

Material Selection for Precision Laser Metal Cutting

Selecting the optimal material is critical for achieving precision, efficiency, and functional performance in laser cutting applications. At Wuxi Lead Precision Machinery, we prioritize material compatibility with our high-power fiber laser systems to ensure clean edges, minimal thermal distortion, and adherence to tight tolerances. Below we detail key considerations for aluminum, steel, and titanium—three materials dominating high-end sheet metal fabrication.

Aluminum alloys, particularly 5052 and 6061, offer excellent strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and electronics enclosures. However, aluminum’s high thermal conductivity and reflectivity demand precise parameter calibration. Our lasers mitigate reflectivity risks through specialized wavelength settings and assist gases, enabling cuts up to 15 mm thick with burr-free edges. Avoid未经表面处理的 aluminum sheets above 8 mm thickness without pre-verification, as reflectivity can compromise cut quality.

Carbon steel and stainless steel remain industry standards for structural components due to their durability and cost efficiency. Mild steel (e.g., Q235) cuts efficiently up to 25 mm using oxygen assist for oxidized edges suitable for welding. For stainless steel (304/316), nitrogen assist preserves corrosion resistance by preventing oxide formation, supporting thicknesses up to 20 mm. Note that high-carbon steels require slower speeds to avoid hardening and micro-cracking.

Titanium alloys, such as Grade 5 (Ti-6Al-4V), are essential for medical implants and aerospace where strength and biocompatibility are non-negotiable. Titanium’s low thermal conductivity necessitates lower power densities and inert gas shielding (argon) to prevent oxygen embrittlement during cutting. We cap titanium cutting at 10 mm thickness to maintain metallurgical integrity and avoid hazardous sparks. Strict environmental controls are enforced to eliminate contamination risks.

Material performance specifications guide feasibility and quality outcomes. Key parameters for our laser systems include:

| Material | Max Thickness (mm) | Reflectivity Risk | Common Applications |

|---|---|---|---|

| Aluminum | 15 | High | Enclosures, Heat Sinks |

| Carbon Steel | 25 | Low | Frames, Chassis |

| Stainless Steel | 20 | Moderate | Medical Devices, Food Equipment |

| Titanium | 10 | Low | Aerospace, Implants |

Anodizing is a post-cutting surface treatment exclusively for aluminum, enhancing wear resistance and enabling color coding. It cannot be applied to steel or titanium without specialized processes. We recommend anodizing after laser cutting to avoid dimensional shifts from the electrolytic bath, but ensure all cut edges are deburred first—imperfections become magnified during anodization. Type II (sulfuric acid) anodizing is standard for functional parts; Type III (hard coat) suits high-abrasion environments.

Material choice directly impacts lead time, cost, and part functionality. Consult our engineering team early in your design phase—we validate material suitability against your GD&T requirements and provide DFM feedback to optimize cut paths and minimize waste. Precision begins with the right substrate.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the laser metal cutting process begins with meticulous design engineering. Our team collaborates closely with clients to review technical drawings, material specifications, and functional requirements. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Autodesk Inventor, we ensure every component is optimized for manufacturability, structural integrity, and dimensional accuracy. Design for Manufacturability (DFM) analysis is conducted in-house to identify potential issues early, including material waste, thermal distortion risks, and feature tolerances. This proactive approach minimizes rework and ensures seamless transition into prototyping. All design data is version-controlled and stored securely, enabling full traceability throughout the production lifecycle.

Prototyping: Validating Precision Before Scale

Once the design is finalized, we proceed to prototyping using our high-precision fiber laser cutting systems. Prototypes are produced under the same conditions as mass production to validate form, fit, and function. This stage allows clients to conduct physical testing, perform assembly trials, and confirm compliance with technical and regulatory standards. Our prototyping cycle typically takes 3–5 working days, depending on complexity. Feedback is incorporated swiftly, and revised iterations are produced if necessary. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy within ±0.05 mm. This validation phase is critical to achieving zero defects in full-scale production.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition to mass production using automated fiber laser cutting platforms integrated with robotic material handling systems. Our facility operates multiple Bystronic and Trumpf laser cutters, ensuring high throughput and consistent quality across batch sizes from 100 to 100,000+ units. The cutting process is monitored in real time via IoT-enabled sensors that track laser power, assist gas pressure, and beam focus, ensuring optimal cut quality on materials ranging from mild steel to stainless steel and aluminum. Every piece is inspected using automated vision systems and spot-checked manually to maintain our zero-defect standard. Statistical Process Control (SPC) data is logged for every production run, enabling continuous improvement and full audit readiness.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm (steel), 0.5 mm – 15 mm (aluminum) |

| Laser Type | Fiber Laser (IPG Photonics, 3 kW – 12 kW) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Cut Tolerance | ±0.05 mm (standard), ±0.02 mm (tight tolerance) |

| Edge Quality | Burr-free, Ra < 3.2 µm (standard) |

| Supported Materials | Mild Steel, Stainless Steel, Aluminum, Brass |

| Max Sheet Size | 4000 mm × 2000 mm |

| Lead Time (Mass Production) | 7–15 working days (depending on volume) |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers laser-cut metal components with uncompromised quality and zero defects.

Why Choose Wuxi Lead Precision

Elevate Your Production with Precision Engineering

Wuxi Lead Precision Machinery stands at the forefront of advanced laser metal cutting solutions, engineered for manufacturers demanding uncompromising precision, efficiency, and reliability. With over 15 years of specialized expertise in sheet metal fabrication, we transform complex design challenges into flawless production outcomes. Our ISO 9001-certified facility in Wuxi integrates cutting-edge fiber laser technology with rigorous quality control protocols, ensuring every component meets the exacting standards of aerospace, medical, and industrial automation sectors. When you partner with Lead Precision, you gain more than a vendor—you secure a strategic ally committed to optimizing your supply chain, reducing material waste by 15–20%, and accelerating time-to-market without sacrificing tolerances.

Our laser cutting systems deliver micron-level accuracy across diverse materials, from stainless steel and aluminum to titanium and specialty alloys. We prioritize thermal distortion elimination and edge quality, critical for secondary processes like welding or coating. Below are core capabilities defining our service excellence:

| Specification | Performance Range | Industry Impact |

|---|---|---|

| Laser Power | 500W – 12kW | Handles thin foils to 40mm structural steel |

| Cutting Tolerance | ±0.03mm | Ensures perfect fit for precision assemblies |

| Max Work Area | 3000mm × 1500mm | Accommodates large-scale industrial panels |

| Material Thickness | 0.5mm – 40mm (steel) | Versatility across prototyping to volume production |

| Positioning Accuracy | ±0.02mm | Eliminates post-processing adjustments |

Unlike conventional service providers, we implement a closed-loop quality management system. Every project undergoes real-time monitoring via integrated sensors, with digital reports tracking kerf width, surface roughness, and dimensional compliance. This transparency allows proactive adjustments, minimizing rework and ensuring first-pass yield rates exceed 99.2%. Our engineering team collaborates directly with your R&D department during the design phase, offering DFM insights to optimize part geometry for laser fabrication—reducing costs before cutting begins.

Global supply chain volatility demands resilient partnerships. Lead Precision mitigates risk through dual-source material procurement, in-house tooling capabilities, and a 72-hour rapid prototyping commitment. We maintain strategic inventory buffers for critical alloys, guaranteeing 95% on-time delivery even during market disruptions. Our clients consistently achieve 30% faster project turnaround compared to industry averages, directly enhancing their competitive agility.

Initiate a precision advantage today. Contact our engineering team at [email protected] to discuss your next project. Include your material specifications, volume requirements, and target tolerances for a tailored capability assessment. We respond within 4 business hours with a technical feasibility analysis and preliminary cost structure—no obligation, pure engineering insight. Partner with Wuxi Lead Precision Machinery to convert precision into productivity.

Reach out now to transform your fabrication challenges into measurable operational gains. Your commitment to excellence deserves a partner engineered to deliver it. Contact us at [email protected] and experience the Lead Precision standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.