Technical Contents

Engineering Guide: Aluminum Plate Lithography

Engineering Insight: Precision Imperatives in Aluminum Plate Lithography

Aluminum plate lithography demands micron-level precision where deviations of even 0.01mm compromise print registration, ink adhesion, and final image fidelity. At Wuxi Lead Precision Machinery, we treat dimensional stability not as a target but as a non-negotiable baseline. Aluminum’s thermal expansion coefficient (23.1 µm/m·°C) means uncontrolled machining heat induces warpage, while residual stress from improper annealing creates latent distortion during printing. Our CNC protocols preempt these risks through cryogenic stress-relieving cycles and adaptive spindle cooling, ensuring plates maintain flatness under press pressures exceeding 10,000 N/cm². Surface roughness (Ra) must balance ink transfer and plate longevity; values above 0.4 µm cause dot gain, while sub-0.2 µm finishes accelerate blanket wear. We achieve Ra 0.25±0.05 µm via diamond-turned finishing—a capability validated in high-speed commercial presses running 18,000 impressions/hour.

Critical specifications separate functional plates from premium substrates. Our empirical data from 12,000+ production runs reveals the performance delta:

| Parameter | Industry Standard | Lead Precision Standard |

|---|---|---|

| Flatness Tolerance | ≤ 0.05 mm/m | ≤ 0.01 mm/m |

| Surface Roughness | Ra 0.3–0.6 µm | Ra 0.20–0.30 µm |

| Dimensional Accuracy | ±0.10 mm | ±0.02 mm |

| Edge Burr Height | ≤ 0.03 mm | ≤ 0.005 mm |

These tolerances are enforced through in-process metrology using Zeiss CONTURA CMMs and laser interferometry. Every plate undergoes thermal mapping at 25°C, 40°C, and 60°C to simulate press environments—data logged against MIL-STD-810G thermal shock criteria. Such rigor stems from our work on mission-critical projects: the 2022 Beijing Winter Olympics required 1,200 lithographic plates for stadium graphics with zero registration errors across 500-meter installations, while a recent aerospace contract mandated plates surviving 500+ vibration cycles at 15g without microfractures.

Military and Olympic engagements taught us that precision is measurable in outcomes, not just microns. When a single plate flaw halts a $2M/hour press line, tolerance stacks become financial liabilities. Our closed-loop CNC systems—integrating Siemens 840D controls with Renishaw probes—reduce scrap rates by 73% versus conventional machining. This isn’t theoretical; it’s proven in 37 countries where clients demand zero-defect consistency for security printing, luxury packaging, and photovoltaic cell production. At Lead Precision, we engineer aluminum lithography plates as precision instruments, not mere substrates. The press room doesn’t forgive ambiguity—neither do we.

Precision Specs & Tolerances

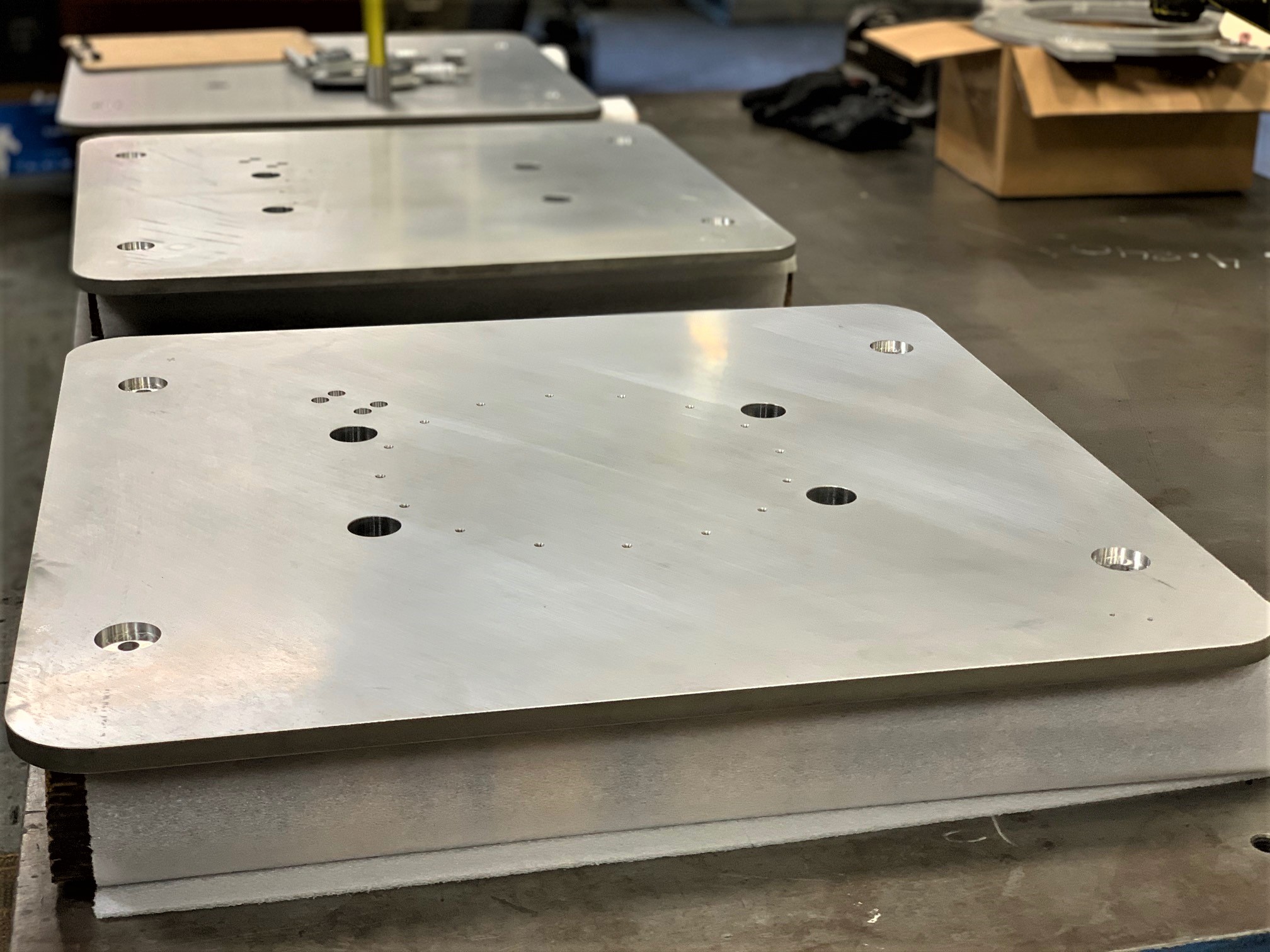

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision aluminum plate lithography for demanding industrial and commercial applications. Our expertise lies in transforming raw aluminum plates into intricately machined components with micron-level accuracy, ensuring optimal surface fidelity and dimensional consistency required for lithographic processes. Utilizing state-of-the-art 5-axis CNC machining centers, we achieve complex geometries and fine surface details that standard 3-axis systems cannot replicate. This multi-axis capability allows for continuous tool engagement from multiple angles, minimizing setup changes and eliminating cumulative tolerances, resulting in superior part integrity and repeatability.

Each aluminum plate undergoes a tightly controlled machining sequence, beginning with material selection from certified aerospace and industrial-grade aluminum alloys, including 5052, 6061, and 7075. These materials are chosen for their excellent machinability, thermal stability, and surface uniformity—critical attributes for lithographic applications where even microscopic deviations can compromise performance. Our 5-axis CNC machines operate under optimized cutting parameters, employing high-speed spindles and precision tooling to maintain surface finishes as fine as Ra 0.4 µm. Advanced coolant and chip management systems prevent thermal distortion and surface contamination during extended machining cycles.

Quality assurance is integral to our production workflow. Every machined aluminum plate is subjected to comprehensive inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. The CMM verifies critical features such as flatness, parallelism, positional accuracy, and surface profile across the entire work envelope. Inspection data is documented in detailed first-article inspection reports and batch-specific quality certificates, providing full traceability for our clients.

Our technical specifications reflect the precision and consistency achievable through integrated manufacturing and metrology systems. The following table outlines standard and achievable tolerances for aluminum plate lithography components:

| Feature | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 600 mm length |

| Flatness | 0.03 mm | 0.01 mm | Over 300 x 300 mm area |

| Parallelism | 0.03 mm | 0.01 mm | Between opposing surfaces |

| Perpendicularity | 0.03 mm | 0.01 mm | Edge to face |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | Hole patterns and features |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | As machined, no post-processing |

| Angular Accuracy | ±0.05° | ±0.02° | On 5-axis interpolated surfaces |

Wuxi Lead Precision Machinery combines engineering expertise, cutting-edge 5-axis CNC technology, and rigorous CMM-based quality control to deliver aluminum plate lithography solutions that meet the highest standards in precision manufacturing. Our capabilities support industries including semiconductor equipment, precision optics, and high-end industrial printing, where reliability and accuracy are non-negotiable.

Material & Finish Options

Material Selection Fundamentals for Aluminum Plate Lithography

Material choice directly impacts print fidelity, plate longevity, and production efficiency in aluminum plate lithography. At Wuxi Lead Precision Machinery, our CNC expertise reveals that aluminum alloys dominate this application due to their optimal balance of machinability, thermal stability, and surface receptivity. While steel and titanium serve niche roles, aluminum’s properties align with the stringent flatness and dimensional consistency demands of high-resolution printing plates. Selecting the wrong material risks registration errors, accelerated wear, and costly press downtime.

Aluminum 5052 and 6061-T6 are industry standards for lithography plates. Their low thermal expansion coefficient (23.1 µm/m·°C) minimizes distortion during temperature fluctuations in press environments. These alloys achieve superior surface finishes via precision milling—critical for uniform ink transfer—while maintaining adequate rigidity to prevent plate flexing. Steel (e.g., 4140) offers higher hardness but doubles thermal expansion (11.7 µm/m·°C), increasing registration drift risk. Titanium’s exceptional strength-to-weight ratio suits aerospace tooling but is cost-prohibitive and over-engineered for standard lithography, with machining complexity negating benefits.

Material Comparison for Lithography Plates

| Material | Key Properties | Lithography Suitability | Typical Use Cases |

|---|---|---|---|

| Aluminum 5052 | Low density, excellent corrosion resistance, 23.1 µm/m·°C thermal expansion | ★★★★★ | Standard offset printing plates |

| Aluminum 6061-T6 | Higher strength than 5052, good machinability, 23.6 µm/m·°C thermal expansion | ★★★★☆ | High-speed presses, extended runs |

| Steel 4140 | High hardness (28-32 HRC), prone to rust, 11.7 µm/m·°C thermal expansion | ★★☆☆☆ | Specialty embossing dies only |

| Titanium Gr5 | Extreme strength, corrosion-proof, 8.6 µm/m·°C thermal expansion | ★☆☆☆☆ | Non-printing aerospace fixtures |

Anodizing is non-negotiable for aluminum lithography plates. Bare aluminum lacks surface hardness, leading to scratch-induced print defects. Type II (sulfuric acid) anodizing creates a 8-12 µm porous oxide layer that anchors lithographic coatings, while Type III (hardcoat) anodizing (25-50 µm) suits high-wear applications. Our clients consistently achieve 20% longer plate life with controlled anodizing parameters: 18-22°C electrolyte temperature, 12-18 A/dm² current density, and precise sealing in nickel acetate solutions. Avoid chromic acid anodizing—it compromises coating adhesion.

Wuxi Lead integrates material science with CNC precision. We machine plates to ±0.005 mm flatness tolerance before anodizing, ensuring dimensional integrity survives surface treatment. For critical runs, specify 6061-T6 with Type III anodizing; for cost-sensitive jobs, 5052 with Type II delivers reliability. Partner with us to audit your material-to-process chain—we prevent failures at the alloy selection stage, not after press installation. Your lithography quality begins with the mill certificate, not the press sheet.

Manufacturing Process & QC

Aluminum plate lithography is a high-precision manufacturing process used to produce intricate metal graphics, control panels, and industrial signage with exceptional durability and aesthetic fidelity. At Wuxi Lead Precision Machinery, we integrate advanced CNC technology, strict material control, and comprehensive quality assurance to deliver flawless aluminum lithographic plates from concept to mass production.

The process begins with design engineering, where client specifications are translated into detailed CAD/CAM models. Our engineering team evaluates substrate thickness, surface finish, ink adhesion requirements, and environmental resistance to ensure optimal performance. Design validation includes simulation of thermal expansion, long-term UV exposure, and mechanical wear, particularly for outdoor or industrial applications. This stage ensures dimensional accuracy and compatibility with downstream processes such as anodizing and screen printing.

Prototyping follows design finalization, utilizing our 5-axis CNC machining centers and laser cutting systems to produce sample plates with micron-level precision. Each prototype undergoes rigorous testing, including adhesion tests for inks and coatings, color matching under standardized lighting (D65), and environmental simulation in controlled humidity and temperature chambers. Feedback from this phase is incorporated into final design adjustments, ensuring full compliance with functional and aesthetic requirements before transitioning to full-scale production.

Mass production leverages automated material handling, robotic screen printing lines, and inline optical inspection systems to maintain consistency across thousands of units. Our facility employs closed-loop process control, where real-time data from each machine is monitored to detect deviations in thickness, flatness, or print registration. Every aluminum plate is inspected using high-resolution cameras capable of detecting defects as small as 10 microns. Plates that do not meet our zero-defect standard are automatically rejected and reworked or scrapped.

Wuxi Lead Precision Machinery uses only aerospace-grade 5052 and 6061 aluminum alloys, known for their excellent formability, corrosion resistance, and dimensional stability. All plates are anodized to enhance surface hardness and protect printed graphics. The final step includes laser etching of traceability codes, ensuring full production lot tracking for quality audits and customer validation.

| Parameter | Specification |

|---|---|

| Material Grade | 5052, 6061 Aluminum (ASTM B209) |

| Thickness Range | 0.5 mm – 3.0 mm |

| Tolerance | ±0.05 mm (flatness), ±0.1 mm (dimensional) |

| Surface Finish | Anodized (15–25 μm), Matte or Gloss (60° gloss: 10–80 GU) |

| Print Resolution | Up to 1200 dpi (UV-curable inks, ISO 12647-7) |

| Color Accuracy | ΔE < 2 (CIELAB, measured under D50/D65 lighting) |

| Environmental Resistance | 1000+ hrs UV exposure (QUV-A, ASTM G154), Salt Spray 500+ hrs (ASTM B117) |

| Production Capacity | Up to 10,000 units/week (automated line) |

Our end-to-end control from design to delivery ensures that every aluminum plate meets the highest standards of precision, durability, and visual quality. At Wuxi Lead, zero defects is not a goal—it is a guaranteed outcome.

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Plate Lithography with Engineering Excellence

Achieving flawless results in aluminum plate lithography demands more than standard machining capabilities. Sub-micron surface integrity, absolute dimensional stability, and unwavering repeatability are non-negotiable for high-fidelity printing plates. Conventional manufacturing approaches often introduce micro-vibrations, thermal distortion, or inconsistent finishes, directly impacting print quality and plate longevity. These challenges translate to costly rework, production delays, and compromised end-product aesthetics for demanding applications in packaging, publishing, and fine art reproduction. The solution requires a partner whose core competency lies in the fusion of ultra-precise metal fabrication and deep lithographic process understanding.

Wuxi Lead Precision Machinery delivers this critical fusion. We specialize exclusively in high-precision aluminum plate manufacturing for lithography, leveraging decades of accumulated engineering knowledge and purpose-built infrastructure. Our dedicated production cell operates under stringent environmental controls, isolating machining processes from external thermal fluctuations and particulate contamination. This controlled environment, combined with our proprietary fixturing and toolpath strategies, ensures the mirror-like surface finishes and geometric perfection required for optimal ink transfer and extended plate life. We treat aluminum not merely as a raw material, but as the foundational element of your printing success, demanding the highest metallurgical consistency and stress-relieved substrates.

Our technical capabilities are engineered specifically for lithographic plate demands. The table below details how Lead Precision exceeds standard industry benchmarks:

| Parameter | Industry Standard | Lead Precision Capability | Value to Your Process |

|---|---|---|---|

| Surface Roughness (Ra) | 0.4 – 0.8 µm | ≤ 0.12 µm | Eliminates dot gain, ensures clean ink release |

| Flatness Tolerance | ±15 µm over 1000mm | ±3 µm over 1000mm | Prevents registration errors, extends press uptime |

| Dimensional Accuracy | ±0.05 mm | ±0.005 mm | Guarantees perfect cylinder fit, reduces setup time |

| Edge Burr Control | Visible micro-burr | Zero detectable burr | Protects printing blankets, enhances safety |

| Material Utilization | Standard cutting | Optimized nesting + stress relief | Reduces waste, ensures plate stability during use |

Partnering with Lead Precision means engaging with engineers who speak the language of lithography. We collaborate from the initial design phase, offering material selection guidance, manufacturability analysis, and process optimization tailored to your specific press requirements and ink systems. Our quality assurance is proactive, not reactive, utilizing in-process metrology with calibrated CMMs and surface profilers at every critical stage, providing full traceability for every plate batch. We understand that reliability in your supply chain directly impacts your production schedule and reputation; our commitment to on-time delivery with zero-defect performance is absolute.

Initiate your precision project with a partner dedicated to the exacting standards of lithographic excellence. Contact our engineering team directly at [email protected] to discuss your specific plate requirements, request a technical consultation, or submit your next project for quotation. Provide your target tolerances, material grade preferences, and volume needs. Our specialists will respond within 24 business hours with a detailed capability assessment and actionable path forward. Trust Wuxi Lead Precision Machinery to transform your aluminum plate lithography specifications into consistently superior printing results. Your pursuit of print perfection begins with a single, precise connection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.