Technical Contents

Engineering Guide: 3D Plastic Printing Services

Engineering Insight: The Role of Precision in 3D Plastic Printing Services

In the realm of advanced manufacturing, 3D plastic printing services have evolved from rapid prototyping tools into critical components of end-part production, especially within high-performance industries such as aerospace, defense, and precision instrumentation. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not just in geometric freedom or reduced lead times, but in the consistency and accuracy of output. Precision is not an added benefit—it is the foundation upon which reliable, repeatable, and mission-critical parts are built.

While 3D plastic printing enables complex geometries unachievable through traditional methods, the dimensional stability, layer adhesion, and surface fidelity must meet stringent engineering tolerances. In military and Olympic-grade applications—where our expertise has been rigorously tested—deviations measured in microns can determine functional success or failure. Our engineering team applies decades of metrology-driven manufacturing insight to ensure that every printed component conforms to ISO and MIL-STD specifications, even under thermal cycling, mechanical stress, and prolonged operational exposure.

Wuxi Lead Precision Machinery brings a unique advantage to 3D plastic printing: a heritage rooted in custom metal manufacturing for defense systems and high-precision sporting equipment used at the Olympic level. This background instills a culture of zero-defect tolerance and process validation. We apply the same disciplined approach to polymer additive processes, integrating laser calibration, environmental chamber controls, and post-processing techniques such as annealing and CNC trimming to achieve final part accuracy.

Our facility utilizes industrial-grade FDM, SLS, and MJF platforms, all maintained under controlled conditions to eliminate variability. Each build undergoes in-process inspection and full first-article inspection (FAI) when required. Material traceability, humidity management, and thermal post-treatment are standard—not exceptions—ensuring that mechanical properties match datasheet values across every batch.

Below are key performance specifications for our primary 3D plastic printing processes:

| Process | Material Options | Layer Resolution | Typical Tolerance | Build Volume (mm) | Common Applications |

|---|---|---|---|---|---|

| FDM (Fused Deposition Modeling) | ABS, PC, ULTEM 9085, Nylon 12 | 0.1 – 0.3 mm | ±0.1 mm (X,Y), ±0.2 mm (Z) | 400 x 350 x 400 | Functional prototypes, jigs, end-use parts |

| SLS (Selective Laser Sintering) | Nylon 11, Nylon 12, Glass-filled PA | 0.08 – 0.12 mm | ±0.2 mm | 300 x 300 x 300 | Complex enclosures, ducting, lightweight structures |

| MJF (Multi Jet Fusion) | Nylon 12, TPU | 0.08 mm | ±0.2 mm | 380 x 280 x 380 | High-detail prototypes, low-volume production |

Our commitment to precision extends beyond equipment and into engineering collaboration. We work closely with design teams to optimize part orientation, support structures, and material selection—ensuring that the final product performs as intended in its operational environment.

For industries where performance is non-negotiable, Wuxi Lead Precision Machinery delivers 3D plastic printing services engineered with the rigor of military-grade manufacturing and refined through Olympic-level precision.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Solutions for Advanced Applications

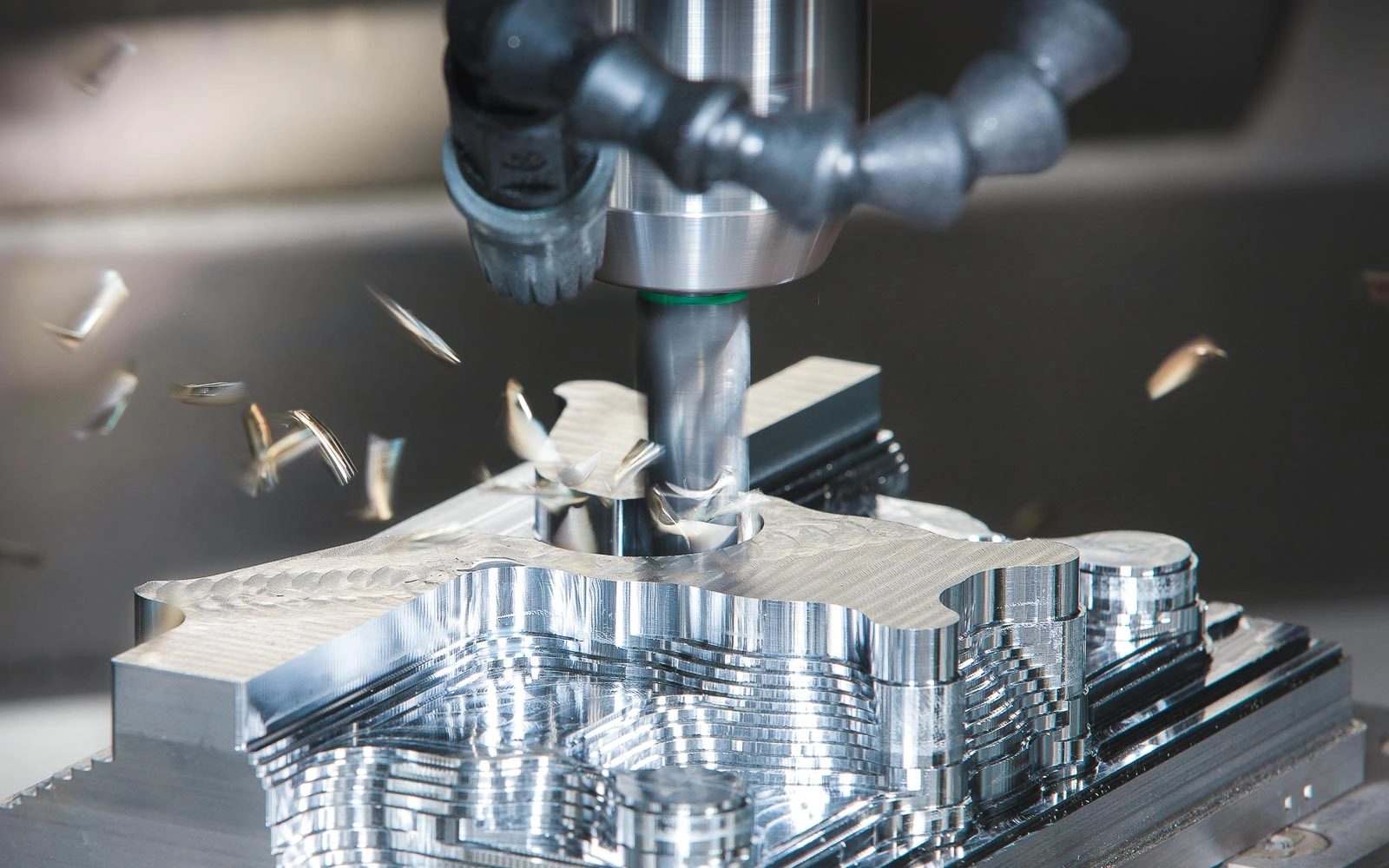

Wuxi Lead Precision Machinery specializes in high-precision custom metal manufacturing, not plastic 3D printing services. While plastic additive manufacturing serves specific prototyping needs, critical end-use components in aerospace, medical, and industrial automation demand the superior strength, thermal stability, and longevity of precision-machined metals. Our expertise lies in transforming complex metal designs into mission-critical parts through advanced subtractive processes, ensuring performance where plastic alternatives fall short.

Our core strength is 5-axis CNC milling and turning, executed on state-of-the-art equipment including DMG MORI and HAAS UMC series machines. This technology enables single-setup machining of intricate geometries—such as impellers, turbine blades, and medical implant fixtures—with exceptional accuracy and surface finish. Multi-axis capability eliminates repositioning errors, reduces lead times by up to 40%, and maintains tight tolerances across compound angles and deep cavities impossible for 3D printing to achieve consistently at scale. All operations are supported by integrated high-pressure coolant systems for optimal chip evacuation and tool life during demanding titanium, Inconel, or hardened steel machining.

Quality assurance is non-negotiable. Every component undergoes rigorous inspection via Zeiss and Hexagon CMM systems, programmed to ISO 10360 standards. Our metrology lab validates dimensional conformity, geometric tolerances, and surface roughness against client CAD models, generating full-first-article inspection (FAI) reports per AS9102 requirements. Real-time SPC data from in-process probes and post-machining CMM scans feed directly into our quality management system, ensuring traceability from raw material to shipment. This closed-loop process guarantees zero-defect delivery for safety-critical applications.

Tolerance achievement is material and geometry dependent but consistently meets or exceeds industry benchmarks. Key specifications are summarized below:

| Feature Type | Standard Tolerance | Precision Tolerance | Material Applicability |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | Aluminum, Steel, Titanium |

| Geometric (GD&T) | ±0.02 mm | ±0.003 mm | All aerospace alloys |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Critical sealing surfaces |

| Hole Concentricity | ±0.03 mm | ±0.008 mm | Multi-bore hydraulic blocks |

Our process excellence extends beyond machining. We provide comprehensive DFM analysis to optimize part geometry for manufacturability, reducing costs without compromising integrity. Material certifications, heat-treat documentation, and non-destructive testing (NDT) coordination are standard for regulated industries. By focusing on precision metal fabrication—not plastic printing—we deliver components that withstand extreme operational environments, ensuring your assemblies achieve decades of reliable service. Partner with Wuxi Lead for metal parts where failure is not an option.

Material & Finish Options

Material selection is a critical decision in custom metal manufacturing, especially when integrating components designed for compatibility with 3D plastic printing services. At Wuxi Lead Precision Machinery, we understand that the mechanical, thermal, and chemical performance of your end product depends heavily on the base material and surface treatment choices. For high-precision applications involving plastic-to-metal assemblies, Aluminum, Steel, and Titanium stand out as the most reliable options, each offering distinct advantages depending on load requirements, environmental exposure, and production volume.

Aluminum is widely favored for its excellent strength-to-weight ratio and inherent corrosion resistance. It is particularly suitable for enclosures, brackets, and lightweight structural components that interface with 3D printed plastic parts. The material machines efficiently, allowing for tight tolerances and complex geometries. When enhanced with anodizing, aluminum gains a durable oxide layer that improves wear resistance and allows for color coding or branding through dye integration. Our Type II and Type III anodizing processes meet MIL-A-8625 standards, ensuring long-term durability in industrial environments.

Steel, particularly in its stainless (304, 316) and tool steel variants, delivers superior strength and thermal stability. It is the preferred choice for fixtures, molds, and high-stress mechanical interfaces where dimensional integrity under load is non-negotiable. While heavier than aluminum, steel provides exceptional toughness and is ideal for applications exposed to high temperatures or abrasive conditions. Passivation is typically applied to stainless grades to remove free iron and enhance corrosion resistance, while additional coatings can be applied for aesthetic or functional purposes.

Titanium offers the highest performance tier, combining exceptional strength, low density, and outstanding resistance to corrosion—even in marine and chemical environments. Though more challenging to machine, titanium is indispensable in aerospace, medical, and high-performance automotive applications where reliability under extreme conditions is paramount. Its biocompatibility and non-magnetic properties further expand its utility in specialized sectors. Surface finishing for titanium often includes acid etching or anodizing for improved adhesion or aesthetic control.

Below is a comparative overview of key material properties and available finishes:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Standard Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 200–310 | 2.7 | 6061, 7075, 5052 | Anodizing (Type II/III), Powder Coat | Enclosures, brackets, consumer devices |

| Steel | 500–900 | 7.8–8.0 | 304, 316, 4140 | Passivation, Zinc Plating, Painting | Molds, tooling, structural components |

| Titanium | 900–1,100 | 4.5 | Grade 2, Grade 5 | Anodizing, Acid Etch | Aerospace, medical implants, racing |

Selecting the right material and finish ensures seamless integration with 3D printed plastic assemblies, enhances product lifespan, and reduces maintenance costs. At Wuxi Lead Precision Machinery, we support clients in making data-driven decisions backed by decades of precision manufacturing expertise.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled metal manufacturing workflow designed for uncompromising quality and efficiency. Our process transcends basic production, integrating deep engineering collaboration from the earliest concept stage through to high-volume delivery. This systematic approach ensures every component meets exacting aerospace, medical, and industrial specifications while achieving true zero-defect output. We do not provide 3D plastic printing services; our core expertise and facility focus exclusively on precision CNC machining, milling, turning, and grinding of high-performance metals.

The journey begins with intensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates directly with your designers to scrutinize CAD models, identifying potential production challenges, material optimization opportunities, and tolerance stack-up risks long before metal is cut. This proactive phase prevents costly revisions and accelerates time-to-market. We evaluate material suitability—aluminum alloys, stainless steels, titanium, Inconel—against functional requirements, environmental factors, and regulatory standards. Concurrently, our process engineers develop the optimal CNC program sequence, tooling strategy, and fixture design to maximize precision and minimize cycle time. This foundational step is critical for achieving zero defects; eliminating theoretical flaws upfront prevents physical failures downstream.

Prototyping is not a separate phase but an integrated validation checkpoint within our production sequence. Utilizing the same multi-axis CNC equipment and quality protocols destined for mass production, we manufacture functional prototypes. These undergo exhaustive metrology: CMM inspection, surface roughness testing, and first-article reports per AS9102 or PPAP standards. Critical dimensions and material properties are verified against the approved DFM output. Only when the prototype consistently meets all specifications—confirmed through documented evidence—is the process locked for scale. This eliminates the common pitfall of prototype-to-production variance, ensuring the first mass-produced part is as perfect as the last.

Mass production leverages our automated, monitored production cells operating under Statistical Process Control (SPC). Every machine feeds real-time data to our central quality management system, tracking critical parameters like tool wear, thermal drift, and dimensional outputs. In-process inspections occur at statistically determined intervals, with automated gaging providing immediate feedback for micro-adjustments. Final inspection employs full-spectrum validation: 100% critical dimension checks, batch material certification, and non-destructive testing as required. Our zero-defect mandate is enforced through this closed-loop system, where deviations trigger immediate containment and root-cause analysis, preventing non-conforming parts from progressing. Continuous improvement is embedded, with process data driving incremental refinements to sustain peak performance.

The following table outlines key specifications achievable within our controlled production environment:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Tolerance | ±0.001mm to ±0.025mm | ISO 2768-mK / Custom GD&T |

| Surface Roughness (Ra) | 0.2µm to 3.2µm | ISO 1302 |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Copper | ASTM/AMS/EN Certified |

| Max Work Envelope | 1200 x 800 x 600mm (5-axis milling) | Per Machine Specification |

This disciplined methodology—DFM rigor, production-intent prototyping, and SPC-driven mass production—forms the backbone of Wuxi Lead’s zero-defect commitment. We transform complex metal component requirements into flawless reality, delivering consistency that protects your brand and reduces total cost of ownership. Partner with us for manufacturing where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing and Advanced 3D Plastic Printing Services

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components integrated with cutting-edge 3D plastic printing services tailored to the exacting demands of modern industrial applications. As a trusted partner in advanced manufacturing, we combine decades of engineering experience with state-of-the-art technology to support global clients in aerospace, medical devices, automation, and high-end equipment manufacturing. Our comprehensive capabilities ensure that your design concepts transition seamlessly from prototype to full-scale production with unmatched consistency and quality.

Our facility in Wuxi, China, is equipped with industrial-grade 3D plastic printing systems capable of processing high-performance polymers such as PEEK, ULTEM, nylon, and other engineering-grade thermoplastics. These materials are ideal for functional prototyping, end-use parts, and complex geometries that traditional manufacturing methods cannot achieve. When combined with our core expertise in CNC machining, sheet metal fabrication, and surface treatment, we offer a fully integrated solution that reduces lead times, minimizes supply chain complexity, and enhances product performance.

We understand that precision, repeatability, and material integrity are non-negotiable in high-end manufacturing. That is why every 3D plastic printing project undergoes rigorous quality control, including dimensional inspection, material certification, and post-processing techniques such as annealing, machining, and surface finishing. Our engineering team works closely with clients throughout the product development cycle, providing DFM analysis, material selection guidance, and iterative prototyping to ensure optimal outcomes.

Whether you require low-volume custom parts or scalable production runs, Wuxi Lead Precision Machinery delivers the technical depth and operational reliability your projects demand. Our ISO 9001-certified processes, in-house tooling capabilities, and agile production planning ensure on-time delivery without compromising quality.

Below are key specifications for our 3D plastic printing services:

| Parameter | Specification |

|---|---|

| Build Volume | Up to 300 x 300 x 400 mm |

| Layer Resolution | 50 – 150 microns |

| Supported Materials | PEEK, ULTEM (PEI), Nylon (PA12), ABS, PC, TPU |

| Tolerance | ±0.1 mm (typical) |

| Post-Processing Options | Annealing, CNC finishing, sanding, painting, coating |

| File Formats Accepted | STEP, IGES, STL, DWG, PDF |

| Lead Time | 3–7 days (prototypes), scalable for production |

| Quality Standards | ISO 9001:2015, Full inspection reports available |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, precision, and long-term collaboration. We are ready to support your next-generation designs with responsive service and engineering excellence.

Contact us today at [email protected] to discuss your project requirements and discover how our integrated 3D plastic printing and custom metal manufacturing services can accelerate your product development and production goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.