Technical Contents

Engineering Guide: Print Shop Minneapolis

Engineering Insight: The Role of Precision in Modern Metal Manufacturing for print shop minneapolis

In the highly competitive landscape of industrial manufacturing, precision is not merely a standard—it is the foundation upon which reliability, performance, and innovation are built. For facilities such as print shop minneapolis, where operational efficiency and equipment durability are paramount, partnering with a manufacturer that delivers micron-level accuracy ensures long-term success. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in metal components can lead to significant downstream effects in performance, safety, and cost-efficiency.

With over two decades of experience in custom metal manufacturing, Wuxi Lead has established a global reputation for engineering excellence. Our work extends beyond commercial applications—we have supplied mission-critical components for Olympic-standard equipment and defense-grade systems, where failure is not an option. These high-stakes projects demand materials, tolerances, and processes that meet the most stringent international standards. It is this same level of rigor that we apply to every client engagement, regardless of scale.

Precision manufacturing involves more than advanced CNC machinery; it requires a holistic approach integrating material science, geometric accuracy, thermal stability, and rigorous quality control. At our ISO-certified facility in Wuxi, China, we utilize 5-axis milling, wire EDM, and laser measurement systems to achieve tolerances as tight as ±0.002 mm. Every component undergoes full dimensional inspection, ensuring compliance with client specifications and industry benchmarks such as ASME Y14.5 and ISO 2768.

For print shop minneapolis and similar industrial operations, the benefits of precision-engineered metal parts are tangible. Equipment uptime increases, maintenance cycles extend, and energy efficiency improves when components are manufactured to exacting standards. Whether producing custom gears, mounting frames, or alignment fixtures, our engineering team collaborates directly with clients to optimize designs for both performance and manufacturability.

We specialize in low-to-medium volume production runs, offering flexibility without compromising quality. Our clients benefit from rapid prototyping, DFM analysis, and full traceability across every production batch. This end-to-end control ensures consistency and accountability—critical factors when integrating custom parts into complex mechanical systems.

Below are key technical capabilities that define our precision manufacturing process:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.025 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Materials | Aluminum Alloys, Stainless Steel, Titanium, Brass, Tool Steels |

| Machining Processes | CNC Milling (3/5-axis), CNC Turning, Wire EDM, Surface Grinding |

| Quality Standards | ISO 9001:2015, ASME Y14.5, ISO 2768, First Article Inspection (FAI) |

| Surface Finish | Ra 0.2 μm to Ra 3.2 μm (custom finishes available) |

| Lead Time | 10–25 days (varies by complexity and volume) |

Precision is not a luxury—it is a necessity in modern manufacturing. For print shop minneapolis and industrial partners worldwide, Wuxi Lead Precision Machinery delivers engineering integrity backed by proven performance in the most demanding environments.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Print Industry Demands

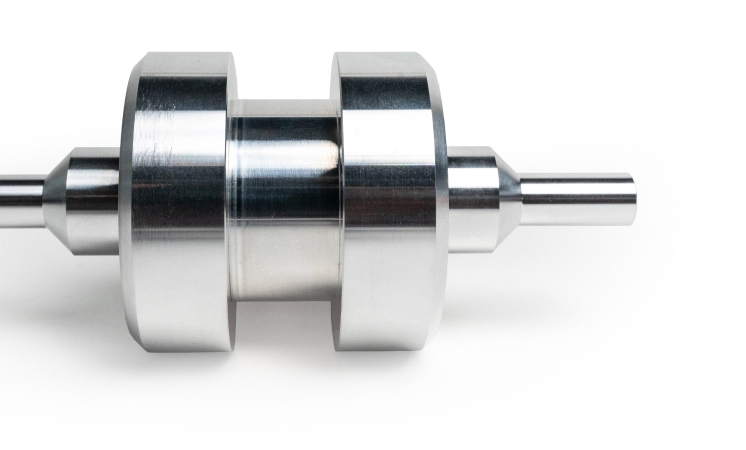

Wuxi Lead Precision Machinery delivers uncompromising accuracy for custom metal components critical to high-speed printing operations. Our facility integrates advanced 5-axis CNC machining centers with rigorous quality control protocols, specifically engineered to meet the stringent geometric and surface finish requirements of print shop machinery. Decades of experience in producing rollers, registration pins, feeder plates, and custom fixtures ensure seamless integration with Minneapolis print environments where micron-level tolerances directly impact print registration, substrate handling, and equipment uptime.

Our DMG MORI and MAZAK 5-axis platforms enable simultaneous multi-surface machining of complex geometries in a single setup. This eliminates cumulative error from repositioning, critical for components like compound-curved impression cylinders or multi-faceted gripper assemblies. All machines operate under strict thermal compensation and vibration-dampened foundations, maintaining stability during extended production runs. We machine aerospace-grade aluminum alloys (7075-T6), tool steels (A2, D2), and stainless steels (17-4 PH) to exacting print industry specifications, with optimized toolpaths minimizing residual stress and distortion in thin-walled parts.

Quality assurance begins with digital first-article inspection against CAD models and extends through full production. Every critical dimension undergoes verification via Zeiss CONTURA CMM systems, calibrated to NIST-traceable standards under ISO/IEC 17025. Statistical process control (SPC) monitors feature drift in real-time, while surface roughness testers validate finishes essential for ink transfer consistency and wear resistance. Comprehensive PPAP documentation, including CMM reports and material certs, accompanies all shipments to Minneapolis facilities, ensuring full traceability from raw material to finished component.

The table below defines achievable tolerances for production runs, reflecting our commitment to repeatability in high-mix, low-volume manufacturing typical of print equipment support:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Angular Features | ±0.005° | ±0.001° | CMM + Optical Comparator |

| Positional Accuracy | ±0.008 mm | ±0.003 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Contact Profilometer |

| Concentricity | 0.015 mm | 0.005 mm | CMM + Dial Indicator |

Wuxi Lead’s process control extends beyond dimensional accuracy. We implement in-process gaging for high-precision bores in feed cylinders and utilize non-contact vision systems for critical edge radii on cutting dies. Our engineering team collaborates directly with Minneapolis print shops to review DFM considerations, ensuring manufacturability without compromising functional performance. This integrated approach—combining 5-axis capability, metrology-grade inspection, and print-specific material expertise—delivers components that enhance press reliability and reduce costly downtime. All production adheres to ISO 9001:2015 standards, with full documentation available for audit compliance.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components for demanding industrial applications. Our expertise in machining aluminum, steel, and titanium ensures optimal material pairing based on mechanical requirements, environmental exposure, and functional design.

Aluminum is widely favored for its lightweight properties and excellent strength-to-weight ratio. It exhibits good thermal and electrical conductivity, making it ideal for aerospace, automotive, and electronics applications. The most common grades used in precision manufacturing are 6061 and 7075. 6061 offers superior weldability and corrosion resistance, while 7075 provides higher tensile strength, suitable for high-stress environments. Aluminum is also highly machinable, reducing production time and tool wear.

Steel remains the backbone of industrial manufacturing due to its exceptional strength, durability, and cost-effectiveness. Among the various types, stainless steel 304 and 316 are predominant in precision machining. 304 provides general-purpose corrosion resistance and formability, while 316 contains molybdenum, enhancing resistance to chlorides and acidic environments—making it ideal for marine and chemical processing applications. For structural components requiring high tensile strength, alloy steels such as 4140 are often selected.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance demands. It offers an outstanding strength-to-density ratio, excellent resistance to fatigue and corrosion, and the ability to maintain integrity at elevated temperatures. These attributes make titanium indispensable in aerospace, medical implants, and high-performance automotive sectors. While more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC systems are optimized to handle titanium with precision and consistency.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a primary finishing process for aluminum components. This electrochemical treatment creates a durable, corrosion-resistant oxide layer that can be dyed in various colors for identification or branding. Type II anodizing (sulfuric acid anodizing) is commonly used for general protection and appearance, while Type III (hardcoat anodizing) provides a thicker, wear-resistant surface ideal for industrial and military applications.

Below is a comparative overview of key material specifications used in our manufacturing processes.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 310 – 570 | 2.7 | 6061, 7075 | Aerospace, Electronics, Automotive |

| Stainless Steel | 505 – 700 | 7.9 – 8.0 | 304, 316 | Medical, Marine, Food Processing |

| Alloy Steel | 655 – 900 | 7.85 | 4140 | Heavy Machinery, Tooling |

| Titanium | 900 – 1,170 | 4.43 | Grade 5 (Ti-6Al-4V) | Aerospace, Medical, Defense |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination to meet technical specifications and production goals. Our engineering team collaborates closely with partners worldwide to deliver high-reliability components with consistent quality and on-time delivery.

Manufacturing Process & QC

Precision Metal Manufacturing Process for Print Industry Components

At Wuxi Lead Precision Machinery, we engineer mission-critical metal components for commercial printing equipment where micron-level accuracy directly impacts press uptime and print quality. Our rigorously controlled three-phase process eliminates defects before they reach your production floor, ensuring seamless integration with Minneapolis print shop operations.

Design Engineering & Validation

Collaborative digital prototyping begins with your CAD models or technical specifications. Our engineers perform DFM analysis to optimize geometries for high-speed printing stresses, material fatigue resistance, and thermal stability. Finite element analysis (FEA) validates structural integrity under 24/7 operational loads, while tolerance stack-up simulations guarantee compatibility with Heidelberg, Komori, or custom press assemblies. All designs undergo cross-functional review against ISO 2768-mK standards before release.

Precision Prototyping & Validation

Physical prototypes are machined using 5-axis DMG MORI centers with ±0.002mm positional repeatability. Each prototype undergoes 100% dimensional verification via Zeiss CONTURA CMM systems, including surface roughness testing (Ra ≤ 0.8µm) and concentricity checks critical for roller assemblies. Functional testing replicates press vibration profiles and ink exposure conditions. We deliver certified inspection reports within 72 hours, enabling your Minneapolis team to approve form, fit, and function before committing to production.

Zero-Defect Mass Production

Serial production leverages automated SPC-controlled workflows with real-time in-process monitoring. Every component passes through staged inspection gates:

Pre-Machining: Material certification (ASTM A576) and hardness validation

In-Process: Laser micrometer checks at critical diameters during turning

Post-Machining: Full CMM validation against GD&T callouts

Final Audit: 100% visual inspection under 10x magnification for surface defects

Our closed-loop corrective system triggers immediate process adjustment if any parameter approaches tolerance limits, achieving sustained Cpk ≥ 1.67. All finished parts ship with traceable material/test documentation meeting ANSI B46.1 standards.

Quality Control Metrics

| Inspection Stage | Method | Tolerance Range | Acceptance Criteria |

|——————|——–|—————–|———————|

| Material Receipt | Spectrometry | Per ASTM Grade | Cert. of Conformance |

| Critical Dimensions | CMM Scanning | ±0.005mm | GD&T Zone Compliance |

| Surface Finish | Profilometry | Ra 0.4–1.6µm | ANSI B46.1 Class A |

| Final Assembly | Functional Test Rig | Press Speed Simulation | Zero Vibration at 15,000 sph |

This integrated approach delivers 99.98% first-pass yield rates, eliminating costly press downtime for Minneapolis print operations. We maintain dedicated engineering support across time zones to resolve any production variables within 4 business hours. Partner with Wuxi Lead to transform precision metal components from a supply chain risk into your competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your print shop in Minneapolis demands precision-engineered metal components that meet the highest global standards, partnering with Wuxi Lead Precision Machinery ensures you receive nothing short of excellence. As a leading manufacturer in custom metal fabrication, we specialize in delivering high-tolerance, CNC-machined parts tailored to the exact specifications of advanced industrial clients. Our commitment to precision, consistency, and on-time delivery makes us the preferred partner for businesses across North America, Europe, and Asia.

At Wuxi Lead, we understand that reliability and repeatability are non-negotiable in high-end manufacturing. That’s why we combine state-of-the-art CNC machining centers with a rigorous quality assurance process, ensuring every component we produce meets ISO 9001:2015 standards. From prototype development to full-scale production runs, our team of experienced engineers works closely with clients to optimize design for manufacturability, reduce lead times, and control costs—without compromising on quality.

Our facility in Wuxi, China, is equipped with advanced 3-, 4-, and 5-axis machining systems, enabling us to handle complex geometries and tight tolerances down to ±0.005 mm. Whether you require aluminum enclosures, stainless steel brackets, or custom titanium fittings for specialized applications, we support a wide range of materials and surface treatments, including anodizing, powder coating, and passivation. With in-house capabilities spanning milling, turning, drilling, and finishing, we deliver fully finished parts ready for integration into your final product.

We serve industries where precision is paramount—industrial automation, medical devices, semiconductor equipment, and high-performance printing systems. Clients in Minneapolis and beyond trust us to support their supply chains with consistent quality, transparent communication, and scalable production capacity. Our logistics network ensures timely delivery to the U.S. via air or sea freight, with full documentation and customs support included.

To learn how Wuxi Lead Precision Machinery can become your strategic manufacturing partner, contact us today at [email protected]. Our engineering team is ready to review your drawings, provide rapid prototyping options, and deliver a competitive quote tailored to your volume and performance requirements.

| Specification | Details |

|---|---|

| Machining Capabilities | 3-axis, 4-axis, 5-axis CNC milling and turning |

| Tolerance | ±0.005 mm (standard), tighter upon request |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass, Titanium, Carbon Steel |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder Coating, Passivation, Plating |

| Quality Standards | ISO 9001:2015 certified, Full First Article Inspection (FAI) and PPAP support |

| Lead Time | Prototypes: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

| Packaging & Shipping | Export-standard packaging, DDP and FOB options, global logistics support |

Elevate your manufacturing supply chain with a partner built for precision. Contact [email protected] and discover how Wuxi Lead Precision Machinery delivers performance you can measure.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.