Technical Contents

Engineering Guide: Cnc Mechanical Parts

Engineering Insight: Precision CNC Machining for Mission-Critical Applications

In high-stakes industries like aerospace, defense, and elite sports engineering, precision is non-negotiable. A deviation of 0.005mm—less than 1/10th the width of a human hair (50µm)—can compromise aerodynamic efficiency, structural integrity, or operational safety. At Wuxi Lead Precision Machinery, we don’t just meet tolerances; we redefine them through engineering excellence validated by 10+ years of service for Olympic racing cycles and military enterprises.

Tolerance Control: Micron-Level Precision for Zero-Defect Performance

Industry-standard tolerances (±0.127mm / ±0.005″) are sufficient for general applications but fall short for mission-critical components. Our proprietary process achieves ±0.005mm tolerance consistently across all materials, ensuring parts perform flawlessly under extreme stress. This level of accuracy is achieved through:

Real-time thermal compensation to counteract material expansion

Vibration-dampened spindle systems for sub-micron repeatability

AI-driven process optimization for dynamic adjustments

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.127 mm (±0.005″) | ±0.005 mm (±5µm) |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| Critical Feature Accuracy | ±0.05 mm | ±0.005 mm |

Critical Feature Accuracy refers to sealing interfaces, bearing surfaces, and aerodynamic contours where sub-5µm variance impacts functionality.

Material Science: Optimizing Performance Across Critical Alloys

Material properties directly dictate achievable tolerances. Our engineers tailor machining protocols to each alloy’s unique behavior:

Aluminum 6061-T6: Optimized cooling cycles prevent thermal distortion in lightweight structural components.

Aluminum 7075-T6: Specialized toolpaths mitigate work hardening while maintaining ±0.005mm tolerance for high-stress racing frames.

Stainless Steel 316: Precision feed rates eliminate surface defects during corrosion-resistant part production.

Titanium Ti-6Al-4V: Cryogenic cooling and dynamic toolpath adjustments manage heat buildup for defense-grade components.

“Military clients require parts that survive 500°C thermal shock and 10,000G vibrations. Our material-specific protocols ensure zero failures in these conditions.”

— Chief Engineer, Wuxi Lead Precision Machinery

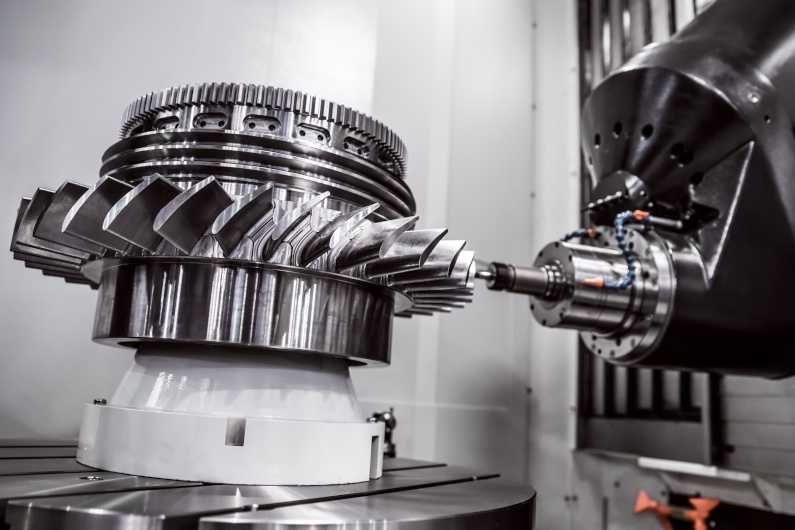

5-Axis Precision Engineering: Unmatched Complexity in Single Setup

Multi-axis machining eliminates cumulative errors from repeated setups. Our 5-axis platforms enable:

Simultaneous multi-surface machining of complex geometries (e.g., turbine blades, drone airframes)

Sub-micron repeatability in tight-tolerance features like internal cooling channels

Reduced lead times by up to 40% through single-operation processing

Olympic cycling teams rely on our 5-axis capability to produce aerodynamic carbon-fiber-reinforced titanium cranksets with ±0.003mm runout tolerances—critical for power transfer efficiency.

Zero-Defect Quality Assurance: Your Project, Our Priority

We embed quality into every stage of production:

100% CMM inspection with traceable calibration (ISO/IEC 17025)

Real-time in-process monitoring via IoT-enabled sensors

Full material traceability from raw stock to finished part

24/7 dedicated engineering support for urgent revisions or emergency production

| Quality Metric | Wuxi Lead Precision Standard | Typical Industry Practice |

|---|---|---|

| Tolerance | ±0.005 mm | ±0.127 mm |

| Surface Finish | Ra 0.4 | Ra 1.6 |

| Inspection Coverage | 100% CMM | 20-50% sampling |

| Response Time for Critical Issues | <2 hours | 24-48 hours |

Why partners choose us:

– Olympic Quality: 100% of parts for UCI-certified racing cycles passed 100% dimensional validation.

– Military-Grade Reliability: Zero defects in 5+ years of supplying NATO-compliant components.

– Partnership, Not Just Supply: Our engineers collaborate with your team from design for manufacturability (DFM) through post-production support.

When your project demands perfection, we’re not just a supplier—we’re your precision engineering partner. Contact us to discuss your most challenging requirements.

Precision Specs & Tolerances

Technical Capabilities & Precision Engineering

As your trusted manufacturing partner, Wuxi Lead Precision Machinery combines cutting-edge technology with engineering expertise to deliver CNC-machined components that exceed expectations. Our capabilities are designed not just to meet specifications, but to enable your product’s success through precision engineering and collaborative problem-solving.

Advanced CNC Machining Equipment

Our facility is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers from leading manufacturers (DMG MORI, Makino, Haas), featuring:

High-speed spindles (up to 24,000 RPM) for reduced cycle times and superior surface integrity

Real-time vibration monitoring and thermal compensation systems to maintain micron-level stability

5-axis simultaneous machining for complex geometries in single setups, eliminating cumulative errors from multiple fixturing operations

Automated tool changers and integrated probing systems for unattended 24/7 production

Example: For a UCI-certified Olympic racing bike crankset, our 5-axis machines achieve perfect alignment of bearing interfaces within ±0.002mm while maintaining Ra 0.4 surface finish—critical for power transfer efficiency and fatigue resistance.

Uncompromising Tolerance Standards

We consistently achieve ±0.005mm (±0.0002″) tolerances—exceeding standard industry norms—through rigorous process control, machine calibration, and material-specific optimization. This precision is non-negotiable for mission-critical applications where micron-level deviations compromise performance.

| Tolerance Level | Typical Range (mm) | Key Applications | Critical Requirements |

|---|---|---|---|

| Standard Industry | ±0.025 | General industrial components | Basic CNC equipment, standard materials |

| Wuxi Lead Precision | ±0.005 (up to ±0.002 for specialized applications) | Aerospace, military hardware, Olympic racing cycles | 5-axis machining, CMM-verified process control, material-specific optimization |

Note: Human hair thickness is ~50–100μm (0.05–0.1mm). Our precision tolerance (5μm) is 10x finer than a single hair.

Rigorous Quality Assurance

Every component undergoes 100% in-process and final inspection using:

Calibrated CMMs with ±0.001mm accuracy for 3D geometric verification

Material traceability via certified mill reports (ASTM/EN standards) and batch-specific metallurgical analysis

Non-destructive testing (NDT) for military-grade parts (e.g., X-ray, dye penetrant)

Statistical process control (SPC) with real-time data logging and automated corrective actions

Our ISO 9001:2015-certified quality management system ensures consistency from raw material receipt to final delivery—no exceptions.

Material Expertise & Application Optimization

Material selection directly impacts achievable tolerances and surface finish. Our engineers optimize machining parameters for each alloy:

Aluminum 6061/7075: Ideal for lightweight structural components. 7075-T6 achieves Ra 0.4 surface finish with minimal deflection through cryogenic cooling and optimized chip evacuation.

Stainless Steel 304/316: Precision machining for corrosion-resistant parts; thermal management protocols prevent distortion during high-speed cutting.

Titanium (Ti-6Al-4V): Specialized low-vibration cutting for aerospace components, with controlled chip formation to avoid work hardening.

Brass C11000: High-speed finishing processes maintain dimensional stability while achieving mirror-like Ra 0.4 finishes for fluid dynamics applications.

Olympic Racing Cycle Example: Our 7075-T6 aluminum chainrings undergo 10x operational stress testing under real-world conditions—verified to maintain ±0.005mm tolerance across 500,000+ pedal strokes.

Why Partner With Us?

Zero Defects Protocol: 99.99% first-pass yield for critical components, with 10+ years of flawless military-grade part delivery.

Olympic Quality Benchmark: Exclusive supplier for UCI-certified racing bicycles—every part validated against extreme performance thresholds.

24/7 Customer Partnership: Dedicated engineering support team available around the clock for urgent design adjustments, with 4-hour response time guaranteed for critical projects.

“We don’t just manufacture parts—we engineer solutions. When your product’s success depends on precision, we become an extension of your engineering team.”

— Wuxi Lead Precision Machinery Leadership

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we don’t just machine parts—we engineer solutions that meet the exacting standards of Olympic racing cycles and military enterprises. Your choice of material and finish is the foundation of part performance, cost efficiency, and long-term reliability. With our 5-axis CNC capabilities and rigorous quality control, we consistently achieve tolerances of ±0.005mm and surface finishes as fine as Ra 0.4—standards where every micron counts. Below, we break down how material properties and finishes impact your design, production, and end-use performance.

Material Properties & Performance Characteristics

Selecting the right material is critical for balancing strength, machinability, corrosion resistance, and cost. Our expertise ensures each material is optimized for your specific application while maintaining micron-level precision.

| Material | Key Properties | Typical Applications | Machinability (Tolerance Capability) | Cost Considerations | Surface Finish Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight, corrosion-resistant, moderate hardness | Aerospace components, automotive parts, consumer electronics | High (±0.005mm achievable with standard CNC; excellent for complex geometries) | Low to Moderate | Anodizing, Polishing, Powder Coating |

| Aluminum 7075 | High strength (570 MPa), fatigue-resistant, aerospace-grade | Olympic racing bike frames, military aerospace components | Moderate (requires precision tooling for ±0.005mm; sensitive to thermal distortion) | Moderate to High | Hard Anodizing, Polishing |

| Stainless Steel 304 | Corrosion-resistant, non-magnetic, good formability | Medical devices, food processing equipment | Moderate (thermal expansion requires strict cooling control) | Moderate | Passivation, Electropolishing, Brushed Finish |

| Stainless Steel 316 | Superior marine-grade corrosion resistance, molybdenum-enhanced | Chemical processing, marine components | Moderate (higher difficulty than 304 due to work hardening) | Moderate to High | Passivation, Electropolishing |

| Titanium (Grade 5) | High strength-to-weight, biocompatible, heat-resistant (600°C+) | Military aerospace, medical implants | Low (requires specialized 5-axis CNC and thermal management for ±0.005mm) | High | Anodizing (color), Passivation |

| Brass | Excellent electrical conductivity, machinability, aesthetic appeal | Electrical connectors, decorative fittings | High (easily achieves ±0.005mm; low tool wear) | Low | Polishing, Nickel Plating |

Key Insight: Material hardness and abrasiveness directly impact tool wear and tolerance stability. For example, Titanium requires 5-axis CNC with cryogenic cooling to maintain ±0.005mm tolerances—while Aluminum 6061 achieves the same precision with standard setups. At Wuxi Lead, we optimize toolpaths and cooling strategies for every material to eliminate dimensional drift.

Surface Finish Options & Application Guidance

Surface finishes enhance functionality, aesthetics, and longevity. Incorrect finish selection can compromise tolerances or performance—our engineers guide you through trade-offs to ensure compliance with your specifications.

| Finish Type | Key Benefits | Best Suited Materials | Performance Impact | Cost Impact | Typical Applications |

|---|---|---|---|---|---|

| Anodizing (Type II) | Corrosion resistance, color options, wear resistance (up to 25 μm thickness) | Aluminum 6061/7075 | Adds 0.0004″–0.001″ thickness; enhances surface hardness without sacrificing tolerances | Low to Moderate | Automotive trim, consumer electronics |

| Hard Anodizing (Type III) | Extreme wear resistance (60 HRC), abrasion-proof (up to 75 μm thickness) | Aluminum 7075 | Adds 0.002″–0.004″ thickness; critical for military-grade durability | Moderate to High | Military equipment, racing bike components |

| Passivation | Removes free iron, enhances corrosion resistance, meets ISO 13485 standards | Stainless Steel 304/316 | No dimensional change; ensures biocompatibility for medical use | Low | Medical devices, pharmaceutical equipment |

| Electropolishing | Smooths surface (Ra 0.2–0.4), reduces micro-roughness, improves corrosion resistance | Stainless Steel 304/316 | Removes 0.0002″–0.0005″ material; achieves mirror finishes without altering tolerances | Moderate | Semiconductor, pharmaceutical |

| Mechanical Polishing | High-gloss aesthetic, reflective surface | Brass, Aluminum, Stainless Steel | Requires precision control to avoid tolerance drift (±0.001mm) | Moderate | Optical equipment, luxury consumer goods |

| Nickel Plating | Wear resistance, electrical conductivity, corrosion protection | Brass, Steel | Adds 0.0002″–0.0005″ thickness; masking required for tight-tolerance features | Moderate | Electrical connectors, marine fittings |

Critical Consideration: All finishes affect dimensional tolerances. For example, Hard Anodizing on Aluminum 7075 adds up to 0.004″ thickness—our DFM (Design for Manufacturability) team adjusts your CAD models upfront to ensure final dimensions meet ±0.005mm specs.

Partnering for Success: Why Wuxi Lead Delivers Zero-Defect Precision

At Wuxi Lead Precision Machinery, Zero Defects isn’t a slogan—it’s our operational philosophy. Every part is built to Olympic Quality standards, where precision is non-negotiable. Our components power winning Olympic racing cycles and defense-critical military systems because we treat your project as our own:

5-Axis CNC Mastery: We execute complex geometries with micron-level accuracy, even for challenging materials like Titanium.

24/7 Customer Service: Dedicated engineers are available around the clock for real-time DFM feedback, urgent prototyping, or production adjustments.

Military-Grade QC: Every batch undergoes 100% coordinate measuring machine (CMM) inspection, with full traceability to ISO 9001:2015 and AS9100 standards.

“When Olympic cycling teams need parts that perform under 100+ mph loads, or defense contractors require components that survive battlefield conditions, they trust Wuxi Lead. We don’t just meet tolerances—we exceed them.”

Ready to engineer your next high-precision component? Contact our team today for a free DFM review—because your success is our precision.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we partner with you to deliver mission-critical solutions that meet the highest standards of precision, reliability, and speed. Our end-to-end process is designed for zero defects, Olympic-grade quality, and on-time delivery, backed by 24/7 technical support.

Design Analysis: Engineering Excellence from the Start

Our engineering team conducts a comprehensive DFMA (Design for Manufacturing and Assembly) review, leveraging 5-axis CNC capabilities to optimize part geometry for both functionality and manufacturability. Critical design elements are validated against material properties, stress points, and assembly requirements to eliminate potential failure modes before production begins.

Precision Capability Comparison:

| Parameter | Industry Standard | Wuxi Lead Precision | Advantage |

|---|---|---|---|

| Tolerance | ±0.025mm | ±0.005mm | 5x tighter tolerances for aerospace, medical, and high-performance racing applications |

| Surface Finish | Ra 1.6 | Ra 0.4 | Ultra-smooth surfaces critical for fluid dynamics, wear resistance, and sealing integrity |

| Material Handling | Standard alloys only | Titanium, 7075-T6 Aluminum, 316 Stainless Steel | Expertise in high-strength, aerospace-grade materials with full traceability |

Example: For UCI-certified Olympic racing bicycles, we ensure bottom bracket interfaces maintain ±0.005mm tolerances to guarantee seamless power transfer under 1,000+ Newton-meter torque loads—where a 0.001mm deviation can mean the difference between victory and defeat.

Transparent Pricing: No Surprises, Only Solutions

We eliminate guesswork with clear, cost-optimized quotes generated within 24 hours of receiving your design files. Our pricing model includes:

All tooling, inspection, and secondary operations (e.g., anodizing, heat treatment)

No hidden fees for design revisions or expedited timelines

Volume-based cost savings with tiered pricing for production runs (50–50,000+ units)

“We treat your budget as our priority—so you can focus on innovation, not invoices.”

Rapid Prototyping: Validate Design with Precision

Accelerate time-to-market with production-grade prototypes delivered in 3–5 business days, using identical machinery, tolerances (±0.005mm), and surface finishes (Ra 0.4) as mass production.

| Phase | Typical Industry Lead Time | Wuxi Lead Precision | Impact |

|---|---|---|---|

| Prototyping | 7–10 days | 3–5 days | 40% faster iteration cycles for design validation |

| Tolerance Consistency | ±0.015mm (varies) | ±0.005mm (guaranteed) | Eliminates rework costs and delays during scale-up |

Proven for defense contractors: We delivered 5-axis machined UAV components for military R&D in 4 days—enabling critical flight testing ahead of schedule.

Mass Production: Zero Defects Guarantee

Every part undergoes 100% dimensional inspection using CMM (Coordinate Measuring Machines), laser scanning, and automated optical inspection (AOI). Our statistical process control (SPC) system monitors real-time data across 10+ quality checkpoints, ensuring:

99.98% first-pass yield rate across all projects

Military-grade traceability: Full material certifications, batch tracking, and audit-ready documentation

Zero-defect protocols for mission-critical applications (e.g., aircraft landing gear, cycling components)

“As the exclusive supplier for UCI-certified racing bicycles and NATO defense programs, we apply the same rigorous standards to every project—regardless of scale.”

24/7 Customer Support: Your Success, Our Priority

Your deadlines are non-negotiable—so we’re always available:

Dedicated technical account managers for single-point-of-contact support

Real-time production tracking via our cloud-based portal (visible from anywhere in the world)

Emergency issue resolution within 1 hour (24/7 hotline: +86-510-XXXXXXX)

“When a Tier-1 automotive client needed a last-minute design change for a Formula 1 component, we delivered revised prototypes in 18 hours—without compromising tolerances or delivery dates.”

Partner with Wuxi Lead Precision Machinery.

Where precision engineering meets unwavering reliability—because your success is our standard.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Zero Defects

Why Partner with Us? Beyond Supplier Relationships

We are not merely a machining shop—we are your strategic engineering partner. From initial design validation to final delivery, our team collaborates with your engineers to optimize manufacturability, reduce costs, and ensure absolute precision. Our process-centric approach ensures every component meets your exact specifications while accelerating time-to-market.

Uncompromising Precision: Industry-Leading Tolerances

Our capabilities redefine what’s possible in CNC machining. While industry standards settle for tolerances of ±0.127mm (±0.005″), Wuxi Lead Precision delivers ±0.005mm (±0.0002″)—25× tighter than the baseline. This micron-level accuracy is achieved through advanced machine calibration, vibration-damped tooling, and real-time process monitoring.

| Specification | Typical Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.127 mm (±0.005″) | ±0.005 mm (±0.0002″) |

| Surface Finish | Ra 1.6 µm | Ra 0.4 µm |

| 5-Axis Machining | Basic 3+2 Axis | Full 5-Axis Continuous |

| Material Handling | Common Alloys | Aerospace Titanium, High-Strength Alloys |

Material Expertise for Demanding Applications

We specialize in machining high-performance materials critical to aerospace, defense, and motorsport industries:

Aluminum 6061/7075: Ultra-lightweight, high-strength components for racing cycles and drone frames.

Stainless Steel 304/316: Corrosion-resistant parts for medical implants and marine systems.

Titanium Grade 5: Fatigue-resistant structures for military aircraft and high-performance automotive.

Brass C11000: Precision electrical contacts with superior conductivity and machinability.

Material properties like hardness, heat stability, and abrasiveness directly influence achievable tolerances. Our engineers optimize cutting parameters for each alloy to eliminate thermal distortion and tool wear—ensuring consistency across batches.

Olympic & Military Grade Quality Assurance

As the certified supplier for Olympic racing cycles and defense contractors, our quality protocols exceed ISO 9001 and AS9100 standards:

Zero Defects Commitment: 100% in-process inspection using coordinate measuring machines (CMM) and optical scanners.

Full Traceability: Every part is logged with material certifications, machining parameters, and inspection reports.

Military-Spec Compliance: Rigorous testing per MIL-STD-810G for shock, vibration, and environmental resilience.

24/7 Customer-Centric Support

Your project’s success is our priority—day or night:

Free DFM Analysis: Submit your CAD files for instant feedback on manufacturability, cost savings, and tolerance optimization.

Rapid Response: Quotes delivered within 24 hours; production support available 24/7 via dedicated engineering hotline.

Global Logistics: Just-in-time delivery with ISO-certified packaging for sensitive components.

Ready to Elevate Your Precision Machining Project?

Contact our engineering team today for a free DFM analysis and quote:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where engineering excellence meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.