Technical Contents

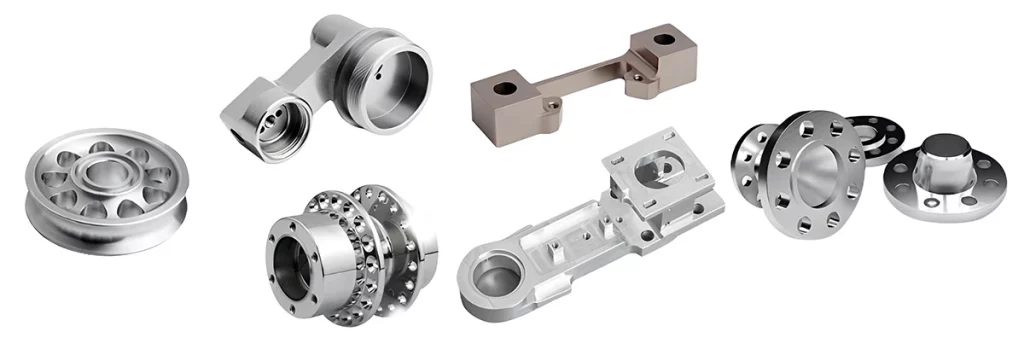

Engineering Guide: Machining Quotes

Engineering Insight: Precision in Machining Quotes – Why Tolerances Matter Beyond the Numbers

In high-stakes manufacturing, machining quotes are not merely cost estimates—they are a reflection of your product’s reliability, safety, and performance. At Wuxi Lead Precision Machinery, we treat every quote as a collaborative engineering commitment. While industry standards like ±0.005″ (0.13mm) for metal or ±0.010″ (0.25mm) for plastics serve as baseline references, true precision demands more than tolerances on paper. Misapplied tolerances—whether overly loose for critical applications or unnecessarily tight for non-critical features—can lead to costly failures, rework, or even catastrophic system breakdowns. Our ISO 9001-certified process ensures every dimension is engineered for function, not just compliance.

The Real Cost of Misapplied Tolerances

Tolerances are not a one-size-fits-all metric. Over-specifying tight tolerances inflates costs without adding value, while under-specifying risks part failure. Below is how we align tolerances with real-world application needs:

| Tolerance Range | Typical Applications | Standard Supplier Capability | Lead Precision Capability |

|---|---|---|---|

| ±0.005″ (0.13mm) | General industrial parts, automotive | Standard | ISO 9001-controlled baseline with 100% inspection |

| ±0.002″ (0.05mm) | Aerospace components, medical devices | Optional premium | Standard with enhanced process control |

| ±0.0005″ (0.013mm) | Defense systems, satellite optics | Rare (specialized setup) | Routine for critical projects |

| ±0.00025″ (0.006mm) | High-precision instrumentation | Only for niche suppliers | Zero-defect protocol for mission-critical use |

Note: Human hair thickness is ~0.002″ (0.05mm). Our ±0.00025″ capability is 20x tighter than a hair’s width—achievable only through rigorous environmental controls, calibrated tooling, and real-time process monitoring.

Material Certification & Traceability – The Foundation of Zero Defects

Precision machining begins with material integrity. Our ISO 9001-certified supply chain ensures every batch of metal or engineering plastic is traceable from origin to finished part. No material enters production without verified certifications, and every component carries a unique identifier for full lifecycle tracking.

| Material Type | Common Standards | Lead Precision Traceability Process |

|---|---|---|

| Aluminum 6061-T6 | ASTM B221, AMS 4027 | QR-coded batch tracking + certified mill reports |

| Titanium Grade 5 | ASTM F136, AMS 4928 | Laser-etched serial numbers + third-party NDT verification |

| Stainless 316L | ASTM A276, ISO 9712 | Melt batch records + chemical composition analysis |

| PEEK (Engineering Plastic) | ASTM D6109, ISO 10993 | Biocompatibility certificates + 100% lot-specific testing |

Every material certificate is digitally archived and accessible to clients via our secure portal. This ensures compliance with FDA, AS9100, and MIL-STD requirements—without delays.

Olympic & Military-Grade Precision: Our Commitment to Excellence

At Wuxi Lead Precision Machinery, “Zero Defects” is not a slogan—it’s a non-negotiable standard. We’ve delivered 100% defect-free components for:

Olympic-grade timing systems where microsecond accuracy determines medal outcomes.

Tier-1 defense contractors requiring parts that function flawlessly under extreme stress (e.g., missile guidance systems, UAV components).

Medical implants certified to ISO 13485, where failure is not an option.

Our 24/7 Customer Service ensures seamless collaboration:

Dedicated engineering teams available around the clock for urgent design reviews or production adjustments.

Real-time progress tracking via our cloud-based platform, with daily quality reports.

Proactive communication on potential risks—never surprises, only solutions.

“We don’t just manufacture parts—we engineer your success. From initial design consultation to final delivery, we act as your precision partner, not just a supplier.”

When your application demands perfection, partner with Wuxi Lead Precision Machinery. Our ISO 9001-certified processes, combined with zero-defect engineering, ensure your components meet the highest standards—every time. [Contact us today to discuss your project’s precision requirements.]

Precision Specs & Tolerances

Technical Capabilities & Tolerances

As your trusted manufacturing partner, Wuxi Lead Precision Machinery delivers engineering-grade precision with unwavering commitment to quality. Our capabilities are designed to meet the most demanding specifications while optimizing cost, lead time, and performance. Below, we detail our technical standards and quality protocols to empower your design decisions.

Precision Tolerance Specifications

Tolerance selection directly impacts part functionality, cost, and manufacturability. Our engineers collaborate with you to define the optimal tolerance for your application—balancing precision with economic feasibility.

| Tolerance Grade | Metal (±) | Plastic (±) | Typical Applications | Notes |

|---|---|---|---|---|

| Standard | 0.005″ (0.127mm) | 0.010″ (0.254mm) | General industrial components, non-critical assemblies | Industry baseline; ideal for cost-effective production |

| Precision | 0.002″ (0.051mm) | 0.005″ (0.127mm) | Medical implants, aerospace components, high-performance machinery | Requires advanced CNC calibration and process control |

| Ultra-Precision | 0.0005″ (0.013mm) | 0.001″ (0.025mm) | Semiconductor equipment, optical instruments, defense systems | Custom-engineered solutions; subject to design feasibility assessment |

Note: Tighter tolerances may impact lead time and cost. Our engineering team provides real-time DFM (Design for Manufacturability) feedback to ensure your specifications align with production realities.

Quality Assurance Protocols

We engineer quality into every process—no compromises. Our ISO 9001:2015-certified systems ensure traceability, consistency, and defect-free outcomes.

Zero Defects Commitment: Rigorous 100% inspection of critical dimensions across all production batches, backed by AI-powered statistical process control (SPC) and automated defect detection.

Olympic Quality Standards: Precision engineered to the highest global benchmarks for mission-critical applications, validated through rigorous testing protocols (e.g., tensile strength, hardness, thermal stability).

Comprehensive Inspection Protocols:

First-article inspection (FAI) for all new programs

Coordinate Measuring Machine (CMM) verification with sub-micron accuracy

Automated reporting with full digital traceability

Material Certification: Full traceability of raw materials, including mill certificates, chemical analysis reports, and mechanical property data for all metals and engineering plastics (e.g., ABS, PEEK, Nylon).

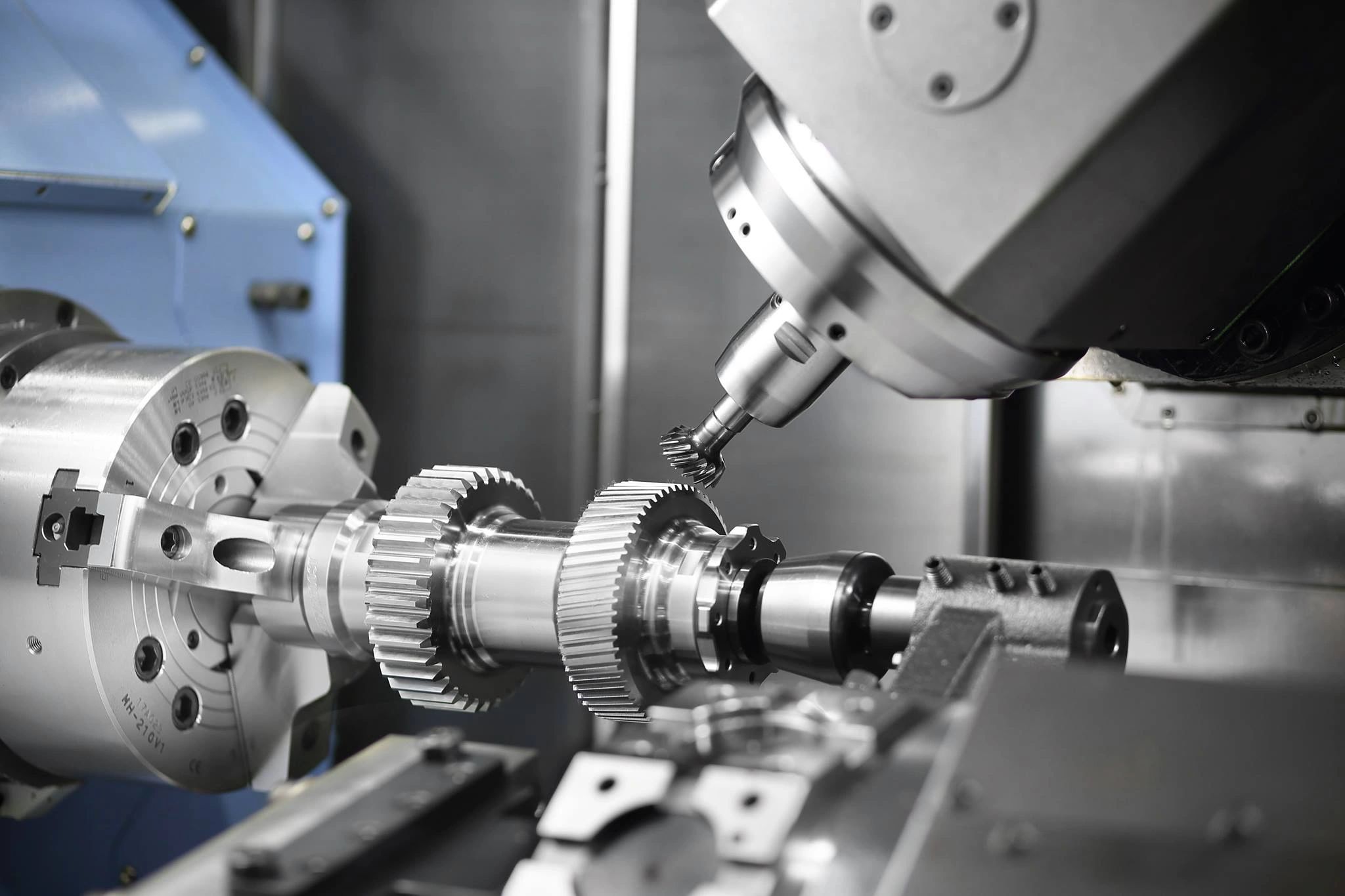

Advanced Equipment Capabilities

Our state-of-the-art manufacturing infrastructure ensures consistent precision across complex geometries.

3/4/5 Axis CNC Machining Centers:

Haas VF-2SS, DMG MORI CTX beta, and Makino T5 for high-speed, high-accuracy machining

In-process probing and automated tool changers for unattended operation

Capability to handle tight tolerances (down to ±0.0005″ / 0.013mm) with minimal thermal distortion

Specialized Processes:

Micro-machining for features as small as 0.1mm

Multi-axis simultaneous machining for complex aerospace components

Surface finishing options (e.g., anodizing, passivation, polishing) to meet exacting aesthetic and functional requirements

Partner-Centric Support Ecosystem

We don’t just manufacture—we collaborate. Your success is our priority, 24/7.

24/7 Customer Service:

Dedicated account managers available around the clock for urgent inquiries

Real-time quote tracking and design optimization feedback within 24 hours

Emergency production support with expedited lead times for critical orders

End-to-End Transparency:

Secure portal for live production updates, inspection reports, and material certifications

Collaborative design reviews to eliminate potential issues before tooling begins

Sustainable Partnership:

Long-term cost optimization through design-for-manufacturability (DFM) expertise

Scalable solutions from prototyping to high-volume production (1–100,000+ units)

Wuxi Lead Precision Machinery: Where engineering excellence meets unwavering commitment.

We don’t just meet your specifications—we exceed your expectations.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

At Wuxi Lead Precision Machinery, we don’t just supply parts—we engineer solutions. As your strategic manufacturing partner, we combine ISO 9001-certified processes, Zero Defects commitment, and 24/7 engineering support to ensure every component meets your exact performance, cost, and timeline requirements. From material certification to finish selection, we optimize for reliability without compromise.

Strategic Material Selection for Optimal Performance

Material choice directly impacts part functionality, manufacturability, and lifecycle cost. Our experts guide you through trade-offs between strength, corrosion resistance, thermal properties, and machining complexity—ensuring optimal performance for your application.

| Material | Key Properties | Typical Applications | Cost Factors | Recommended Finishes | Machinability Notes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | High strength-to-weight ratio, excellent corrosion resistance, good thermal conductivity | Aerospace brackets, automotive frames, consumer electronics | Low raw material cost; fast machining reduces labor costs | Anodizing (Type II/III), Powder Coating, Brushed Finish | Ideal for tight tolerances (±0.005”); stable under thermal cycling |

| Stainless Steel 304 | Non-magnetic, good corrosion resistance, moderate strength | Food processing equipment, medical instruments, marine components | Moderate raw material cost; higher tool wear increases machining time | Passivation, Electropolishing | Requires coolant control to prevent work hardening; standard tolerance ±0.005” achievable |

| Titanium Ti-6Al-4V | Exceptional strength-to-weight, biocompatible, extreme corrosion resistance | Aerospace engine parts, medical implants, high-performance automotive | Very high raw material cost; slow machining speeds and specialized tools increase costs | Plasma Spraying, Anodizing (limited) | Demands precision cooling and tool path optimization; ±0.002” tolerances feasible with dedicated processes |

| PEEK (Polyetheretherketone) | High-temp resistance (250°C+), chemical inertness, low friction | Semiconductor wafer handlers, medical implants, oil/gas seals | High raw material cost; precise temperature control required during machining | None (surface polishing only) | Maintains dimensional stability at ±0.001” with cryogenic machining; ideal for high-precision plastic parts |

| POM (Acetal/Delrin) | Low friction, high stiffness, excellent fatigue resistance | Gears, bearings, automotive trim | Low cost; easy to machine with minimal tool wear | None (natural finish) or UV-stable coatings | Standard tolerance ±0.010” achievable; minimal warpage during machining |

Key Insight: Material selection is the foundation of Zero Defects manufacturing. All materials at Wuxi Lead come with full traceability—certified mill reports, chemical composition analysis, and heat-treatment validations—ensuring compliance with ISO 9001 and AS9100 standards.

Finish Options & Performance Impact

Finishes enhance functionality, aesthetics, and longevity. We tailor surface treatments to your application’s environmental and regulatory needs—never compromising on quality or lead time.

| Finish | Description | Key Benefits | Typical Applications | Cost Impact | Notes |

|---|---|---|---|---|---|

| Anodizing (Type II) | Electrochemical oxide layer for aluminum | Corrosion resistance, color options, wear resistance | Consumer electronics, architectural components | Low to moderate | Standard for ±0.005” tolerances; 1–2 days lead time |

| Anodizing (Type III/Hard Coat) | Thick, dense oxide layer for aluminum | Extreme wear resistance, thermal insulation | Aerospace hydraulic components, military equipment | High | Requires 3–5 days lead time; maintains ±0.002” tolerances |

| Electropolishing | Electrochemical surface smoothing | Microscopic smoothness (Ra < 0.2μm), enhanced corrosion resistance | Medical implants, pharmaceutical equipment | High | Critical for FDA/ISO 13485 compliance; 100% inspection with optical profilometry |

| Passivation | Nitric/citric acid treatment for stainless steel | Removes free iron, prevents rust initiation | Medical devices, food processing machinery | Low | Mandatory for 316L stainless steel in wet environments; verified per ASTM A967 |

| Powder Coating | Electrostatically applied thermoset polymer | UV resistance, impact protection, color consistency | Industrial machinery, outdoor equipment | Moderate | 24/7 color-matching support; ±0.003” tolerance retention post-cure |

| Plasma Spraying | Thermal coating for extreme wear | Hardness up to 70 HRC, thermal barrier properties | Jet engine components, heavy machinery | Very high | Customizable thickness (0.001”–0.020”); ISO 9001-compliant process control |

Zero Defects Guarantee: Every finish undergoes 100% inspection using CMM and surface profilometers. For medical or aerospace applications, we provide full documentation per ASTM/ISO standards—no exceptions.

Cost Optimization Strategies

Balancing performance and cost requires strategic decisions. Our engineering team identifies opportunities to reduce expenses without sacrificing quality:

Material Substitution: For non-critical aerospace brackets, Aluminum 6061-T6 with Type II anodizing delivers 40% lower cost than titanium while maintaining structural integrity.

Finish Simplification: Standard electropolishing on 316L stainless steel meets FDA requirements for medical devices—eliminating costly custom surface treatments.

Plastic Optimization: POM (Acetal) with natural finish provides superior wear resistance for gears at 60% lower cost than PEEK, with identical dimensional stability.

Why Partner with Wuxi Lead?

– Zero Defects Commitment: Every part undergoes 100% inspection with CMM, optical metrology, and material certification—guaranteed.

– Olympic Quality Standards: We exceed ISO 9001 with proprietary QC protocols, including real-time process monitoring and failure-mode analysis.

– 24/7 Customer Service: Dedicated engineering support from design review to delivery—available via phone, email, or chat.

– Material Certification: Full traceability for all raw materials, with test reports provided for every batch.

Ready to optimize your next project?

Contact our engineering team for a tailored quote—where precision meets partnership.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer your success. Our ISO 9001-certified process ensures seamless transition from concept to delivery, with Zero Defects as our non-negotiable standard. Every step is optimized for precision, transparency, and speed, backed by Olympic-grade quality and 24/7 dedicated engineering support.

Design Analysis: Engineering Excellence Starts Here

Our design validation phase eliminates costly errors before production begins. Our ISO 9001-certified engineers conduct rigorous DFM (Design for Manufacturing) reviews, analyzing CAD models for tolerances, material compatibility, and manufacturability. We verify critical features against your specifications and industry standards, ensuring optimal performance without compromise.

| Tolerance Level | Metal (Typical) | Plastic (Typical) | Cost Impact | Wuxi Lead’s Approach |

|---|---|---|---|---|

| Standard | ±0.005″ (0.13mm) | ±0.010″ (0.25mm) | Base | ISO 9001-compliant, standard process |

| Precision | ±0.002″ (0.05mm) | ±0.005″ (0.13mm) | +15-25% | Enhanced metrology, dedicated setups |

| Ultra-Precision | < ±0.0005″ (0.013mm) | < ±0.002″ (0.05mm) | +40-60% | Cleanroom machining, 5-axis precision |

💡 Key Insight: While industry standards often cite ±0.005″ for metal and ±0.010″ for plastic as “typical,” we tailor tolerances to your application. Tighter tolerances require specialized setups—but we never sacrifice ISO 9001 quality for speed.

Transparent Pricing: No Surprises, Just Precision

We provide itemized quotes with zero hidden fees. Our pricing model reflects your specific requirements—no guesswork, no surprises.

| Pricing Factor | Impact | How We Optimize |

|---|---|---|

| Tolerance Tightness | Higher for tighter tolerances | Process optimization without quality trade-offs |

| Material Type | Varies by grade (e.g., titanium vs. aluminum) | Strategic sourcing of certified materials at competitive rates |

| Production Volume | Lower per-unit cost at scale | Economies of scale with consistent QC protocols |

| Surface Finish | Additional cost for specialized finishes | Streamlined processes to minimize extra steps |

✅ Our Commitment: All quotes include full material certification documentation—no hidden fees, no compromises.

Rapid Prototyping: From Concept to Validated Design

Get functional prototypes in 3–5 days using the same CNC machines, tooling, and quality protocols as our production line. Every prototype undergoes 100% first-article inspection (FAI) per AS9102 standards, ensuring dimensional accuracy and material compliance before you commit to mass production.

Zero Defects Guarantee: 100% inspection of critical features at prototyping stage

Real-Time Feedback: Engineering team provides design tweaks within 24 hours

Material Traceability: Full certification for every batch (e.g., ASTM, ISO, RoHS)

⚙️ Why It Matters: Prototypes aren’t just “test parts”—they’re your production blueprint. We validate tolerances, material behavior, and assembly fit before scaling.

Mass Production: Scalable Excellence with Zero Defects Guarantee

From 10 to 100,000+ units, our ISO 9001-certified production process delivers consistent quality at scale. Our Zero Defects commitment is enforced through:

In-process SPC (Statistical Process Control): Real-time monitoring of critical dimensions

Automated Vision Inspection: 100% part verification for geometric tolerances

Final QA Checks: Triple-verified against your exact specifications

Full Material Traceability: Batch-level certification for aerospace, medical, and defense applications

| Metric | Wuxi Lead Standard | Industry Benchmark |

|---|---|---|

| Defect Rate | < 0.01% | 0.1–0.5% |

| On-Time Delivery | 98.5% | 85–90% |

| First Pass Yield | 99.2% | 90–95% |

| Lead Time (Prototyping) | 3–5 days | 7–10 days |

| Material Certification | Full traceability | Often partial |

🌐 24/7 Dedicated Support: Your project manager is available around the clock for real-time updates, troubleshooting, and priority issue resolution—ensuring seamless communication from prototype to delivery.

Why Partner with Wuxi Lead?

“We don’t just meet specifications—we engineer excellence, on time, every time.”

Zero Defects Commitment: Every part is inspected to your exact tolerances—no exceptions.

Olympic-Grade Precision: From standard ±0.005″ to ultra-tight <±0.0005″, we deliver precision that exceeds industry benchmarks.

True Partnership: Your success is our priority. We collaborate from design phase through delivery, with engineering expertise always at your service.

Ready to transform your vision into reality?

[Contact our engineering team] for a no-obligation quote—backed by our 100% satisfaction guarantee.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

Beyond Standard Tolerances: Precision Engineered for Critical Applications

While industry standards define tolerances for basic machining, mission-critical applications demand more than “acceptable” variation. Misapplied tolerances—such as assuming ±0.005″ (0.13mm) is sufficient for aerospace or medical components—can cause catastrophic failures, regulatory non-compliance, and 30%+ rework costs. At Wuxi Lead, we engineer beyond standard limits through ISO 9001-certified processes and real-time adaptive control.

| Aspect | Industry Standard | Wuxi Lead Precision | Benefit |

|---|---|---|---|

| Tolerance Consistency | ±0.005″ (0.13mm) for linear dimensions (metal) | Achieves ±0.0005″ (0.013mm) with ISO 9001-certified processes | Eliminates fit issues in assemblies; reduces machining rework by 40%+ |

| Defect Rate | 1–2% scrap rate in precision machining | <0.01% defect rate with Zero Defects commitment | Zero rework costs; ensures 100% functionality in safety-critical applications |

| Material Certification | Inconsistent traceability; limited test reports | Full traceability with ASTM/ISO-certified test reports per batch | Guarantees material integrity for FDA, AS9100, and ISO 13485 compliance |

| Customer Support | Business-hour-only responses | 24/7 dedicated engineering team for urgent technical queries | Minimizes production delays; 99.9% on-time delivery record |

Our Commitment to Zero Defects: The Olympic Standard in Precision

At Wuxi Lead, “Olympic Quality” isn’t a metaphor—it’s a measurable standard. Just as Olympic athletes push beyond human limits, we engineer tolerances tighter than industry norms while maintaining zero defects through:

ISO 9001-certified quality management: Every process validated through 12+ quality checkpoints.

Real-time process monitoring: AI-driven sensors track dimensional stability during machining, adjusting parameters in microseconds.

Material traceability: Full chemical composition and mechanical property reports for all metals (aluminum, titanium, stainless steel) and engineering plastics (PEEK, Nylon, Delrin).

24/7 customer support: Dedicated engineers available around the clock for urgent design or production issues—no “wait for Monday” delays.

“We don’t just meet tolerances—we guarantee parts that function flawlessly in the most demanding environments. Our Zero Defects commitment means your project isn’t just on time; it’s perfect.”

— Wuxi Lead Engineering Director

Seamless Collaboration from Design to Delivery

We act as your strategic manufacturing partner—not a transactional supplier. From initial concept to final delivery, our team integrates with your engineers to optimize for cost, quality, and speed:

Free DFM Analysis: Submit your CAD files for a no-cost design review. We identify potential manufacturability issues, suggest material/process optimizations, and reduce costs by 15–30% before production begins.

End-to-End Engineering Support: Single-point-of-contact engineers guide you through prototyping, validation, and high-volume production—ensuring consistency across all batches.

Scalable Precision: Whether prototyping a single aerospace component or producing 10,000+ medical implants, our ISO 9001 processes deliver identical tolerances and zero defects at any volume.

Ready to Elevate Your Manufacturing Precision?

Contact our engineering team today for a complimentary Design for Manufacturability (DFM) analysis and competitive quote. We’ll review your design, optimize for cost and quality, and ensure your parts meet the most stringent tolerances—guaranteed.

Contact:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: ISO 9001 Certified • Zero Defects Commitment • 24/7 Engineering Support

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.