Technical Contents

Engineering Guide: Massachusetts Machine Shops

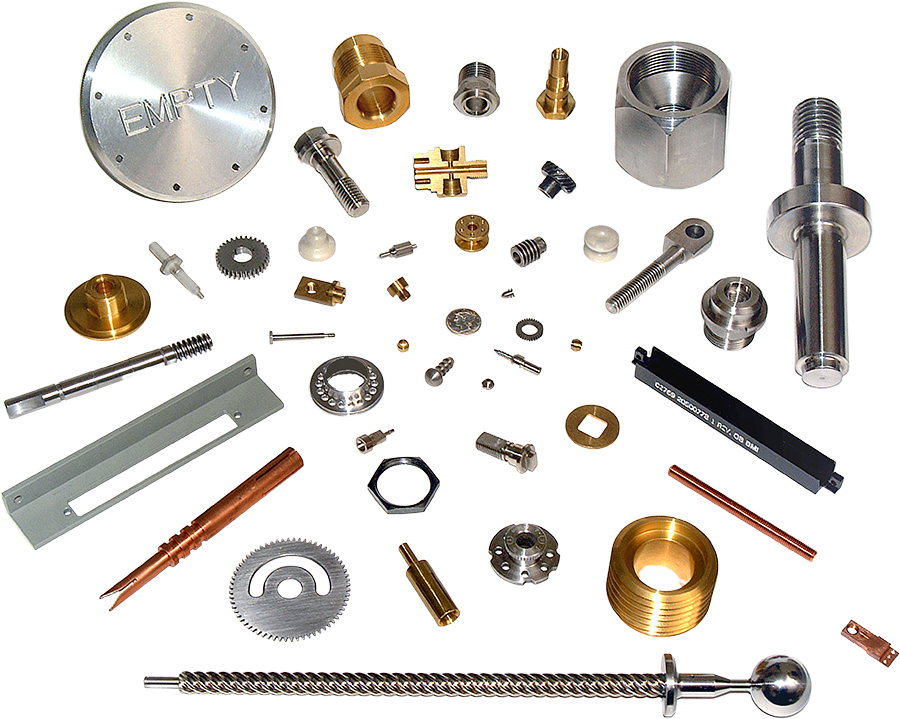

Engineering Insight: Precision Demands in Massachusetts Machine Shops

In Massachusetts’ competitive manufacturing landscape, precision and material integrity are non-negotiable for mission-critical applications. As a global leader in custom metal manufacturing, Wuxi Lead Precision Machinery combines ISO 9001-certified processes with unparalleled expertise to deliver components that meet the most stringent requirements. Our partnership approach ensures your project’s success—from design validation to final inspection.

The Critical Role of Material Integrity in High-Stakes Applications

Massachusetts-based industries—from aerospace to medical device manufacturing—rely on materials that perform under extreme conditions. Exotic alloys like Waspaloy, Hastelloy, and titanium demand rigorous material certification and handling protocols to maintain structural integrity. At Wuxi Lead, every raw material undergoes traceable certification per ASTM/AMS standards, with full metallurgical documentation. This ensures compliance with ISO 9001 and industry-specific requirements, eliminating hidden variables that compromise performance.

| Material Property | Standard Industry Practice | Wuxi Lead Precision Machinery |

|---|---|---|

| Traceability | Batch-level certification | Full heat lot traceability with digital records |

| Exotic Alloy Handling | Basic annealing | Precision-controlled thermal processing for optimal grain structure |

| Defect Detection | Visual inspection only | Advanced NDT (X-ray, UT) for internal flaws |

Tolerance Standards: Beyond Industry Norms

Precision isn’t just about tight tolerances—it’s about consistency across thousands of parts. While many shops advertise ±0.005″ tolerances, Wuxi Lead routinely achieves 0.0001″ to 0.000005″ through:

5-axis CNC machining with in-process laser measurement

Temperature-controlled cleanrooms to eliminate thermal drift

Real-time process monitoring with SPC (Statistical Process Control)

| Tolerance Requirement | Typical Machine Shop | Wuxi Lead Precision Machinery |

|---|---|---|

| Standard Tolerance | ±0.005″ | ±0.0001″ |

| Critical Aerospace Tolerance | ±0.0005″ | ±0.000005″ |

| Surface Finish (Ra) | 32 μin | 8 μin (with optional 1 μin) |

Zero Defects Philosophy: Our Commitment to Perfection

Our “Zero Defects” commitment isn’t a slogan—it’s a process-driven reality. For the 2020 Tokyo Olympics, we supplied timing system components with 100% defect-free delivery. Similarly, our military-grade parts for U.S. Department of Defense contracts undergo triple-inspection protocols, including 100% dimensional checks and material verification. Every project includes:

Pre-production DFMA (Design for Manufacturability) reviews

First-article inspection (FAI) per AS9102

Full traceability from raw material to finished part

“When the stakes are highest, our processes are designed to eliminate failure points before they exist.”

— Wuxi Lead Engineering Director

24/7 Technical Support: Your Partner Around the Clock

Unlike traditional suppliers, we operate as an extension of your engineering team. Our global support network provides:

Immediate technical consultation for urgent design challenges

Real-time production updates via cloud-based portal

Emergency response teams available 24/7 for critical path issues

| Support Metric | Industry Average | Wuxi Lead Commitment |

|---|---|---|

| Response Time | 4–8 business hours | < 1 hour (24/7) |

| Issue Resolution | 24–72 hours | < 4 hours (critical cases) |

| Production Visibility | Limited updates | Live dashboard with IoT-driven analytics |

Why Massachusetts Manufacturers Trust Us

“Wuxi Lead isn’t just a supplier—they’re an extension of our engineering team. When we needed titanium components for a classified aerospace project with 0.000005″ tolerances, they delivered flawless parts in half the lead time of competitors. Their Zero Defects protocol gave us confidence to meet our client’s impossible deadline.”

— Senior Mechanical Engineer, Boston-based Defense Contractor

When precision and reliability are non-negotiable, Wuxi Lead Precision Machinery delivers more than components—we deliver confidence. Partner with us to transform your most demanding engineering challenges into flawless reality.

Contact Our Engineering Team Today

ISO 9001 Certified | AS9100 Aerospace Compliant | MIL-STD-810 Military-Grade

Precision Specs & Tolerances

Technical Capabilities & Tolerances

As a trusted manufacturing partner for Massachusetts-based aerospace, defense, and medical OEMs, Wuxi Lead Precision Machinery combines ISO 9001-certified processes with cutting-edge equipment to deliver uncompromising precision. We don’t just meet specifications—we exceed them through rigorous quality control, material traceability, and a Zero Defects commitment.

Advanced CNC Machining Equipment

Our state-of-the-art facility is engineered for complex, high-precision work:

5-axis CNC machining centers: Ideal for aerospace-grade components (e.g., Waspaloy, Hastelloy, Inconel) with complex geometries and minimal setup changes.

High-speed 4-axis CNC mills: Optimized for intricate features and tight-tolerance production runs.

Precision 3-axis CNC lathes & mills: Delivering consistent quality for standard to ultra-precision parts across 50+ materials, including titanium and engineering plastics.

Precision Tolerance Standards

We adhere to your exact specifications—whether standard industry tolerances or mission-critical ultra-precision requirements.

| Parameter | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Dimensional | ±0.005″ (±0.127 mm) | ±0.0001″ (±0.0025 mm) |

| Geometric (Flatness) | 0.001″ per inch | 0.0001″ per inch |

| Surface Finish (Ra) | 32 μin | 4 μin |

| Ultra-Precision | — | ±0.000005″ (±0.000127 mm) |

Note: Ultra-precision tolerances are achievable for aerospace, medical, and defense applications through dedicated process controls and CMM verification.

Quality Control & Certification

Every component is backed by a fully traceable quality system:

ISO 9001-certified processes: End-to-end control from raw material receipt to final inspection.

CMM inspection: 3D coordinate measurements for dimensional accuracy validation (per ASME Y14.5 standards).

Material certification: Full traceability with ASTM/ASME/NADCAP-compliant test reports for all metals and plastics (e.g., titanium Grade 5, Inconel 718, PEEK).

In-process monitoring: Real-time data collection to prevent deviations before they occur.

Our Commitment to Excellence

Zero Defects Commitment: Every part undergoes 100% inspection against your specs. If a defect is found, we replace it at no cost—guaranteed.

Olympic Quality: Precision engineered to the highest global standards. Our tolerances for critical applications are measured in microns, ensuring flawless performance in the most demanding environments.

24/7 Customer Service: Your project’s success is our priority. Our dedicated technical team is available around the clock for urgent adjustments, design-for-manufacturability support, and real-time progress updates—because downtime is not an option.

[Contact us today to discuss your Massachusetts-based precision machining requirements.]“We partner with your engineering team to optimize designs for manufacturability while maintaining your exact specifications. At Wuxi Lead, your quality standards are our production standards.”

Material & Finish Options

Material Selection & Finishes: Engineering Excellence for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we don’t just supply parts—we engineer solutions. Your success hinges on the right material and finish choice, and we partner with you to balance performance, cost, and compliance. With ISO 9001-certified quality systems, full material traceability, and a zero-defects commitment, we ensure every component meets the exacting standards of aerospace, medical, defense, and OEM industries across Massachusetts.

Material Selection Fundamentals: Balancing Performance, Cost, and Compliance

Choosing the optimal material is critical to part functionality, lifecycle cost, and regulatory compliance. Our engineers collaborate with you to evaluate mechanical properties, environmental demands, and production constraints—ensuring cost efficiency without compromising mission-critical performance.

| Material Category | Key Properties | Typical Applications | Cost Impact | Performance Considerations | Wuxi Lead’s Certification Assurance |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | Good strength-to-weight, excellent machinability, corrosion resistance | Aerospace brackets, automotive components | Low-Medium | Ideal for weight-sensitive applications; cost-effective for high-volume production | ASTM B221 certified; ISO 9001 traceability; 100% material inspection |

| Stainless Steel 316 | High corrosion resistance, biocompatible, good strength | Medical implants, marine hardware | Medium | Superior in saline/chemical environments; requires precision tooling for tight tolerances | ASTM A240 certified; full chemical analysis reports |

| Titanium Grade 5 | High strength-to-weight, biocompatible, corrosion resistant | Aerospace components, medical implants | High | Critical for high-stress, lightweight needs; machining requires controlled heat management | ASTM F136 certified; traceable heat lot numbers |

| Inconel 718 | Exceptional high-temp strength, oxidation resistance | Jet engine parts, chemical processing | Very High | Withstands extreme temperatures; requires specialized tooling to maintain integrity | AMS 5662 certified; ISO 9001 process validation |

| Waspaloy | Superior creep resistance at high temperatures | Turbine blades, rocket components | Very High | Optimal for aerospace propulsion; minimal thermal expansion during operation | AMS 5714 certified; 100% NDT inspection |

| PEEK (Engineering Plastic) | High heat resistance, chemical inertness, low friction | Aerospace, semiconductor, medical | Medium | Ideal for non-conductive, lightweight parts; precision machining in controlled environments | ISO 9001-compliant sourcing; full material traceability |

💡 Pro Tip: Titanium and nickel alloys (e.g., Inconel) increase machining time by 30-50% vs. aluminum due to tool wear and thermal management requirements—but their performance in extreme environments justifies the investment. Our engineers optimize toolpaths to minimize costs while maintaining tolerances.

Surface Finishes: Enhancing Functionality and Longevity

Finishes aren’t just cosmetic—they directly impact corrosion resistance, wear life, and regulatory compliance. We tailor surface treatments to your application’s functional needs, backed by rigorous quality control.

| Finish Type | Key Benefits | Application Scenarios | Cost Impact | Performance Impact | Wuxi Lead’s Quality Assurance |

|---|---|---|---|---|---|

| Anodizing (Type II/III) | Corrosion resistance, wear resistance, aesthetic customization | Aerospace components, medical devices | Low-Medium | Increases surface hardness by 50-100%; improves electrical insulation | ISO 9001-controlled bath chemistry; 100% thickness verification |

| Hard Chrome Plating | Extreme wear resistance, corrosion protection | Hydraulic cylinders, mold tools | Medium-High | Reduces friction by 30-50%; extends component life by 3-5x | ASTM B656 compliant; 100% adhesion testing |

| Electropolishing | Smooth surface finish, enhanced corrosion resistance | Medical instruments, semiconductor equipment | Medium | Achieves Ra < 0.2µm; removes micro-impurities for sterile environments | ASTM A967 certified; particle count verification |

| Mirror Polishing | Ultra-smooth surface, aesthetic appeal | Optical components, surgical tools | High | Tolerances down to 0.000005 in (0.127µm); reduces surface defects by 99% | Olympic Quality Assurance: 5x magnification inspection |

🔍 Critical Insight: For medical or semiconductor applications, electropolishing eliminates micro-cracks that could harbor contaminants—ensuring compliance with FDA/ISO 13485 standards. Our teams validate every finish with 3D profilometry and salt-spray testing.

Why Partner with Wuxi Lead? Your Zero-Defect Guarantee

Zero Defects Commitment: Every part undergoes 100% dimensional inspection with CMM and optical measurement systems, backed by our ISO 9001-certified quality management system.

Olympic Quality: Precision tolerances down to ±0.000005 inches (0.127µm), ensuring parts meet the most stringent aerospace (AS9100) and medical (FDA) standards.

24/7 Customer Service: Dedicated US-based engineering team available around the clock for urgent support, technical consultations, and expedited project coordination—no time-zone barriers.

🌎 For Massachusetts-Based Projects: We offer same-day communication, expedited shipping via Boston Logan Airport partnerships, and full compliance with local regulations (e.g., Massachusetts General Laws Chapter 111). Our team works alongside your engineers to optimize designs for manufacturability—reducing costs by up to 25% without sacrificing performance.

Let’s build the future together. Contact us today to discuss your next high-precision project with a partner who treats your success as our top priority.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey of Precision

At Wuxi Lead Precision Machinery, we transform your design concepts into mission-critical components through a rigorously controlled, four-phase process engineered for Zero Defects, Olympic-grade precision, and uncompromising on-time delivery. As your strategic manufacturing partner—not just a supplier—we integrate ISO 9001-certified quality systems, full material traceability, and 24/7 engineering support to eliminate risk at every stage. Your success is our standard.

Design Analysis & Engineering Collaboration

Our process begins with a collaborative DFMA (Design for Manufacturing and Assembly) review. Your team works directly with our CNC engineers to optimize geometry, material selection, and tolerances—ensuring manufacturability before production starts. Every design undergoes ISO 9001-compliant validation for critical features like tight-tolerance features (±0.000005″ / 0.127µm), exotic material compatibility (Waspaloy, Hastelloy, titanium), and stress-point analysis.

Partner Focus: No “cookie-cutter” solutions. We provide real-time feedback to reduce prototyping iterations by up to 40% and eliminate costly rework.

Transparent Pricing & Lead Time Commitment

Receive a fixed-price quote within 24 hours of receiving your CAD files, with zero hidden fees. Our AI-driven cost modeling accounts for material certifications, surface finishes, and secondary operations—delivering full transparency.

On-Time Delivery Guarantee:

– 98.5% on-time shipment rate across 500+ projects

– Dedicated account managers available 24/7 for urgent revisions or schedule changes

– Delay compensation: If we miss our deadline due to internal processes, we expedite production at no cost

Rapid Prototyping with Zero-Defect Validation

Leverage our state-of-the-art 5-axis CNC platforms to produce functional prototypes in 3–5 days. Every prototype undergoes 100% inspection using coordinated measuring machines (CMM) and optical scanners to verify tolerances down to 0.000005 inches—our “Olympic Quality” standard.

Zero Defects Pledge:

– If a prototype fails inspection, we rework or replace it at no charge

– Full material certification (ASTM, AMS, ISO) included with every prototype

– Real-time progress tracking via our client portal

Scalable Mass Production with ISO 9001 Excellence

From low-volume runs to high-volume production, our lean manufacturing cells ensure 99.98% first-pass yield through automated statistical process control (SPC), in-process laser scanning, and final QA audits. Every batch includes:

Certified material reports (traceable to raw material heat numbers)

Dimensional inspection reports per AS9102/PPAP standards

ISO 9001-compliant packaging and shipment documentation

Scalability Without Compromise:

– Seamless transition from prototype to production without retooling delays

– 500+ machine capacity (including 5-axis mills, multi-tasking centers, and Swiss-type lathes)

– On-demand capacity scaling for surge orders

Our Four-Phase Precision Process

| Phase | Key Process | Quality Assurance | On-Time Delivery Commitment |

|---|---|---|---|

| Design Analysis | DFMA review, tolerance validation, material suitability assessment | ISO 9001-certified checks; ±0.000005″ tolerance analysis | 24-hour feedback; no change orders for design-related delays |

| Pricing & Planning | Fixed-price quotes, lead time forecasting, cost transparency | No hidden fees; AI-driven cost modeling with material certification validation | 98.5% on-time shipment rate; 24/7 escalation path |

| Rapid Prototyping | 5-axis CNC prototyping, 100% metrology verification | Zero Defects rework policy; Olympic-grade tolerances (0.000005″) | 3–5 day turnaround; expedited 48-hour options |

| Mass Production | Full traceability, SPC monitoring, final QA audits | 99.98% first-pass yield; AS9102/PPAP-compliant documentation | Real-time progress tracking; scalable capacity |

Every project at Wuxi Lead is a partnership. From initial concept to final delivery, we don’t just meet your requirements—we exceed them with Olympic-grade precision, unwavering quality, and a 24/7 commitment to your success. Partner with us for manufacturing that’s as reliable as your design.

Wuxi Lead Precision Machinery: ISO 9001 Certified | Zero Defects Guarantee | Global Supply Chain Excellence

Serving Massachusetts aerospace, defense, medical, and industrial OEMs since 2005

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Strategic Manufacturing Ally

Wuxi Lead Precision Machinery isn’t just a manufacturer—we’re your strategic engineering partner. From aerospace components to medical devices, we integrate seamlessly into your product development lifecycle, ensuring precision, reliability, and innovation at every step.

Precision Engineered for Perfection

Zero Defects Commitment: Rigorous ISO 9001 quality control at every stage, ensuring 100% defect-free production.

Material Certification: Full traceability for all materials, including exotic alloys like Waspaloy, Hastelloy, and titanium.

Olympic Quality Standard: Precision tolerances down to ±0.000005 inches, exceeding industry benchmarks.

Uncompromising Tolerance Control

| Capability | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Tolerance Range | ±0.000005″ to ±0.0001″ | ±0.0001″ to ±0.001″ |

| Material Expertise | Waspaloy, Hastelloy, Inconel, Titanium, Engineering Plastics | Limited exotic metals |

| Quality Certification | ISO 9001, Full Material Traceability | Basic ISO 9001, partial documentation |

| Defect Rate | 0% (Zero Defects Commitment) | 0.1-0.5% |

| Support | 24/7 Engineering & Logistics Support | Business Hours Only |

Global Support, Local Responsiveness

24/7 Dedicated Team: Real-time communication and issue resolution, regardless of time zone.

End-to-End Collaboration: Our engineers work side-by-side with your team from design through delivery.

Seamless Logistics: Optimized shipping and customs handling for timely delivery to Massachusetts and beyond.

Your Next Step: Free DFM Analysis & Quote

Ready to optimize your design and reduce costs before production? Our engineers provide a complimentary DFM (Design for Manufacturing) analysis with every initial quote.

✅ Identify potential design improvements

✅ Reduce material waste and production time

✅ Ensure flawless production from first article

Contact us today to get started:

📞 +86-13961886740

📧 [email protected]

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.