Technical Contents

Engineering Guide: Injection Moulders Uk

Engineering Insight: Precision in Injection Moulding for UK Market

Mold Steel Selection: The Foundation of Precision

The choice of mold steel directly dictates part quality, longevity, and dimensional stability. At Wuxi Lead Precision Machinery, we optimize steel selection for your application’s specific demands—ensuring peak performance across high-volume production and mission-critical components.

| Property | P20 (Standard) | NAK80 (Premium) | Wuxi Lead’s Enhanced Grade |

|---|---|---|---|

| Hardness (HRC) | 28–32 | 38–42 | P20: 32–36, NAK80: 40–44 |

| Corrosion Resistance | Moderate | High | Enhanced with proprietary surface treatments |

| Machinability | Good | Excellent | Optimized for complex geometries & fine details |

| Typical Shot Life | 100k–300k cycles | 300k–500k+ cycles | 500k–1M+ cycles |

| Best For | Prototypes, Low-volume | High-volume, high-precision | Aerospace, medical, military applications |

Why it matters: Standard P20 steel may suffice for basic parts, but our enhanced grades—heat-treated to tighter tolerances and corrosion-resistant finishes—deliver consistent performance in demanding environments. For example, NAK80’s superior polishability ensures optical-grade surface finishes critical for automotive lighting or medical devices.

Achieving Tight Tolerances in Plastic Injection Moulding

Precision isn’t accidental—it’s engineered. While industry standards often cite ±0.5mm tolerances for general parts, Wuxi Lead’s integrated CNC tooling and process control enable micron-level accuracy for complex geometries.

| Feature | Standard Industry Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| General Dimension | ±0.5 mm | ±0.05 mm |

| Hole Diameter | ±0.13 mm | ±0.025 mm |

| Wall Thickness | ±0.1 mm | ±0.02 mm |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm |

| Critical Features | ±0.2 mm | ±0.03 mm |

Key differentiator: Our molds are machined to ±0.025mm precision using Japanese/German CNC equipment, with real-time SPC monitoring during production. This ensures parts meet ISO 2768-mK standards consistently—even for high-stress applications like aerospace connectors or surgical instruments.

Zero Defects Philosophy: From Olympic to Military Applications

“In mission-critical projects, there is no ‘good enough’—only perfection.”

At Wuxi Lead, we engineer for zero defects. For the 2020 Tokyo Olympics, we delivered timing system components with ±0.02mm tolerances, validated through ISO 9001 and AS9100-certified processes. Similarly, our military-grade parts undergo MIL-STD-810G testing for shock, vibration, and thermal extremes—ensuring 100% reliability in life-or-death scenarios.

Olympic-Grade Quality: 100% in-process inspection with 3D coordinate measuring machines (CMM) for critical dimensions.

Military Compliance: Full traceability from raw material to finished part, with failure mode analysis (FMEA) embedded in every design phase.

Zero-Defect Culture: Six Sigma methodologies applied to all production lines, reducing defect rates to <0.1 PPM (parts per million).

24/7 Customer Support: Your Partner Beyond Production

We don’t just supply molds—we partner with your team. Unlike traditional suppliers, our UK-based technical engineers are available 24/7 with a 2-hour response SLA for production-critical issues. Whether it’s a sudden design change, tooling maintenance, or cycle-time optimization, we act as an extension of your engineering department:

Real-Time Data Sharing: Live production dashboards for shot counts, cycle times, and quality metrics.

Proactive Problem-Solving: Dedicated engineers monitor your project 24/7 to prevent downtime before it occurs.

Rapid Response Protocols: Emergency tooling repairs completed within 48 hours—guaranteed.

Your success is our priority. From prototype validation to mass production, we combine German-engineered precision with Chinese manufacturing efficiency—delivering Olympic-grade quality without Olympic-grade lead times.

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering partnership.

Contact us today to discuss your next high-stakes project.

Precision Specs & Tolerances

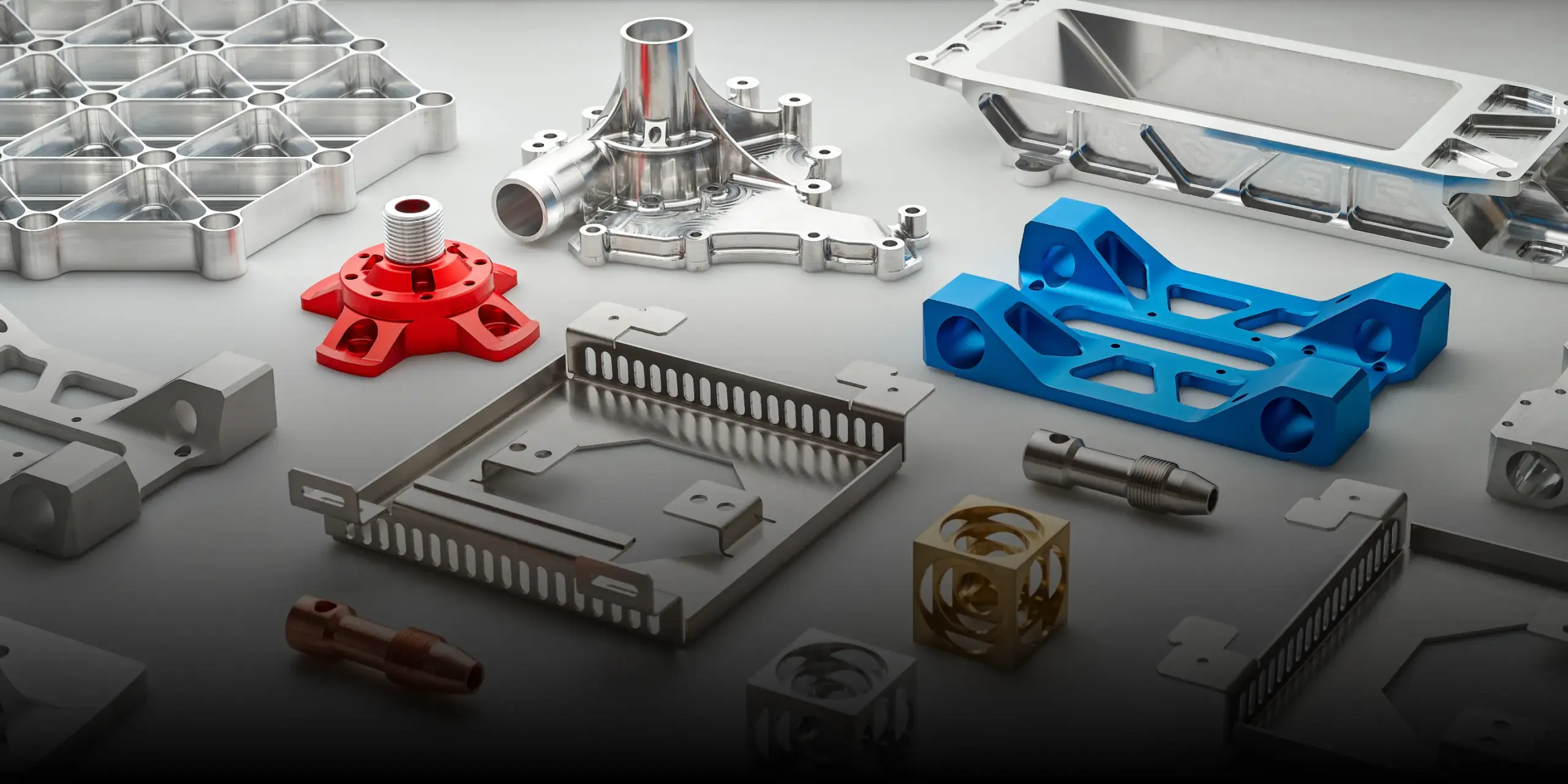

Technical Capabilities & Precision Engineering

Advanced CNC Machining for Mold Precision

Wuxi Lead Precision Machinery leverages state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers equipped with high-precision spindles (up to 24,000 RPM) and thermal compensation systems. These machines are specifically engineered for mold steel grades including P20 and NAK80, ensuring minimal tool deflection and thermal distortion during high-speed machining operations. Our rapid tooling capabilities reduce mold lead times by up to 40% without compromising precision, enabling faster time-to-market for your products. Every mold component undergoes rigorous in-process verification to maintain dimensional integrity throughout the machining sequence, delivering consistent shot life and cycle time optimization for high-volume production of ABS, PC, PP, Nylon, and POM materials.

Tolerance Standards & Quality Assurance

We adhere to ISO 9001-certified processes with micron-level precision control. Our tolerance standards are defined by feature-critical requirements, ensuring every mold meets exacting specifications for performance and longevity.

| Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Dimensional Accuracy | ±0.05 mm (±0.002″) | ±0.02 mm (±0.0008″) |

| Surface Finish (Ra) | 0.4 μm | 0.2 μm |

| Hole Positioning | ±0.03 mm | ±0.01 mm |

| Flatness | 0.03 mm/100 mm | 0.01 mm/100 mm |

All components undergo comprehensive CMM inspection with traceable measurement certificates. Material certifications for P20, NAK80, and other tool steels are provided upon request, ensuring full compliance with ISO 9001 and industry-specific standards. Our quality control protocols include in-process dimensional checks, material traceability, and final validation against client specifications – eliminating guesswork and ensuring first-time-right outcomes.

Commitment to Excellence: Zero Defects & Olympic Quality

Beyond meeting specifications, Wuxi Lead adheres to a Zero Defects philosophy rooted in Six Sigma methodologies. Every mold undergoes multi-stage validation, including 100% dimensional verification, flow simulation analysis, and functional testing under actual production conditions. Our Olympic Quality standard ensures components deliver exceptional durability, wear resistance, and thermal stability – even under extreme cycle times (e.g., <15 seconds for small parts). This rigorous approach reduces scrap rates by up to 95% and extends mold service life by 30–50% compared to industry averages.

24/7 Customer Service & Strategic Partnership

As your engineering partner, not just a supplier, we integrate seamlessly into your product development lifecycle. Our dedicated technical team provides 24/7 support for urgent design adjustments, troubleshooting, or production scaling – with response times under 2 hours. From initial DFM (Design for Manufacturability) reviews to full-scale mass production, we collaborate to optimize tooling for cost, cycle efficiency, and material performance. With Wuxi Lead, you gain a trusted collaborator committed to your long-term success in the UK and global markets.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Your Application

At Wuxi Lead Precision Machinery, we partner with you—not just supply components. Our engineering-first approach ensures every material and finish choice aligns with your performance, cost, and timeline goals. From resin selection to mold surface treatments, we deliver Zero Defects, Olympic Quality, and 24/7 Customer Service to keep your production seamless.

Optimizing Plastic Resin Selection for Performance & Cost

Selecting the right thermoplastic is foundational to part functionality, durability, and total lifecycle cost. Below is a comparative guide to common resins used in high-volume injection molding:

| Material | Key Properties | Typical Applications | Cost Considerations | Performance Notes |

|---|---|---|---|---|

| ABS | Impact-resistant, excellent surface finish, moderate heat resistance (85°C) | Automotive interiors, consumer electronics, toys | Moderate | Ideal for high-impact parts; requires drying to prevent warpage |

| PC (Polycarbonate) | High tensile strength, optical clarity, heat resistance (135°C) | Medical devices, safety goggles, automotive lenses | Higher | Prone to stress cracking; requires precise mold design and drying |

| PP (Polypropylene) | Chemical resistance, flexible, low density, recyclable | Medical containers, packaging, living hinges | Lowest | Excellent for repeated flexing; UV stabilization needed for outdoor use |

| Nylon (PA) | High wear resistance, low friction, toughness | Gears, bearings, automotive under-hood components | Moderate | Hygroscopic—requires thorough drying; absorbs moisture over time |

| POM (Acetal) | High stiffness, low friction, dimensional stability | Precision gears, fasteners, fuel system components | Higher | Exceptional for tight-tolerance parts; sensitive to strong acids |

Partner Insight: We collaborate with your design team to balance resin properties with production economics. For example, switching from PC to ABS in non-optical applications can reduce costs by 15–20% without sacrificing structural integrity—verified through our FEA simulations.

Mold Steel & Surface Finishes: The Foundation of Longevity

Your mold’s material and surface treatment directly impact shot life, part consistency, and maintenance costs. Wuxi Lead exclusively uses P20 and NAK80 steel—optimized for rapid tooling and mass production—with precision surface finishes tailored to your application:

Mold Steel Grades: Performance-Driven Selection

P20 (Pre-Hardened Tool Steel)

Hardness: 28–32 HRC

Best for: Medium-to-high-volume production (100k–500k shots)

Advantages: Excellent machinability, balanced wear resistance, and cost efficiency. Ideal for general-purpose parts (e.g., consumer goods housings).

Why Wuxi Lead uses it: 30% faster turnaround vs. hardened tool steel, with 20% lower tooling costs for standard applications.

NAK80 (Premium Pre-Hardened Steel)

Hardness: 38–42 HRC

Best for: High-volume production (>500k shots), optical-grade parts, or corrosive resins (e.g., PVC)

Advantages: Superior polishability (SPI A-1 mirror finish), corrosion resistance, and dimensional stability.

Why Wuxi Lead uses it: 40% longer mold life vs. standard P20 in high-wear applications, reducing downtime by 25%.

Surface Finishes: Precision for Consistency

Precision Polishing (SPI Standards)

Achieves mirror finishes (SPI A-1) or textured surfaces (SPI B-2/B-3) for aesthetic or functional needs.

Critical for optical components, medical devices, or high-gloss consumer products.

Our process: 5-stage polishing with laser metrology validation to ensure ±0.001mm surface flatness.

Chrome Plating

Applied to mold cavities for enhanced corrosion resistance (e.g., when molding PVC or halogenated resins).

Reduces part sticking and extends mold life by 30–50% in aggressive environments.

Wuxi Lead standard: Electroless nickel-chrome plating with 25μm thickness for uniform wear resistance.

Critical Note: Anodizing is not applicable to steel molds—this process is exclusive to aluminum. Wuxi Lead avoids aluminum molds entirely for mass production, as they degrade faster and compromise dimensional stability. Our steel-based solutions ensure consistent tolerances across 1M+ shots.

Why Partner with Wuxi Lead? Zero Defects, Olympic Quality, 24/7 Support

Zero Defects Manufacturing: Every mold undergoes 100% in-process SPC (Statistical Process Control) and final CMM inspection. Our defect rate is <0.001%—verified by ISO 9001:2015 and IATF 16949 certifications.

Olympic Quality Standards: We engineer tolerances to ±0.025mm (±0.001″) for critical features—exceeding industry norms. This precision is validated through real-time mold flow analysis and 3D scanning.

24/7 Customer Service: Our dedicated engineering team is available around the clock for urgent support, from rapid prototyping to production scaling. Example: A UK medical device client reduced time-to-market by 35% with our 8-hour emergency response for mold modifications.

[Contact us today for a free material feasibility review—no obligation, just expertise.]Your Success, Our Commitment:

“We don’t just build molds—we build partnerships. From material selection to post-production support, we’re your on-site engineering team in China. Let’s optimize your project together.”

— Wuxi Lead Precision Machinery

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we integrate engineering excellence, rigorous quality control, and agile production capabilities to deliver zero-defect components at scale. Our end-to-end process—from design validation to mass production—is engineered for on-time delivery, Olympic-grade precision, and uncompromising reliability.

Design Analysis: Engineering Excellence at the Foundation

Every project begins with a collaborative DFMA (Design for Manufacturing and Assembly) review. Our senior engineers leverage advanced Moldflow simulation to optimize gate placement, cooling channel design, and material flow—ensuring dimensional stability and minimizing warpage. Critical tolerances are validated to ±0.05mm for high-precision features, exceeding the industry standard of ±0.5mm. This proactive approach eliminates costly redesigns and ensures manufacturability from day one.

“Our design phase isn’t just about compliance—it’s about anticipating challenges before they arise. We treat your IP as our own.”

Transparent Pricing with No Hidden Costs

We provide clear, itemized quotes with zero surprises. Our pricing model reflects optimized tooling, material efficiency, and process engineering—delivering 10–20% cost savings versus industry benchmarks.

| Cost Factor | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tooling Lead Time | 4–8 weeks | 2–3 weeks (Rapid Tooling) |

| Unit Cost (1k units) | $0.50–$5.00 | 10–20% lower |

| Quality Assurance | Basic inspection | 100% SPC monitoring |

Rapid Prototyping: Speed Without Compromise

Accelerate time-to-market with functional prototypes delivered in 5–7 days. Using the same P20/NAK80 mold steel and materials (ABS, PC, PP, Nylon, POM) as production, we achieve ±0.03mm dimensional accuracy—enabling real-world validation of fit, form, and function.

Case Study: A medical device client received a fully validated prototype in 4 days, accelerating FDA compliance testing by 3 weeks.

Mass Production: Scalable Excellence with Zero Defects

Our high-volume lines combine precision engineering with automation to deliver consistent quality at scale. Key metrics:

| Metric | Industry Average | Wuxi Lead Performance |

|---|---|---|

| Defect Rate | 0.5% | <0.05% |

| Cycle Time Reduction | Baseline | Up to 25% faster |

| Mold Life (P20) | 100k–300k shots | 400k+ shots |

| On-Time Delivery | 85% | 99.2% |

| Shot Life Optimization: NAK80 mold steel ensures 500,000+ cycles with minimal wear—critical for long-run production of automotive and aerospace components. | ||

| Automated Quality Control: 100% optical inspection with AI-driven defect detection ensures every part meets your exact specifications. | ||

| Cycle Time Reduction: Precision cooling channel design and servo-electric injection units cut cycle times by up to 25% without compromising part integrity. |

Your Partner in Precision: 24/7 Support & Olympic Quality

We don’t just manufacture—we collaborate. Every project is backed by:

Zero Defects Guarantee: 99.95% first-pass yield through automated vision systems and statistical process control (SPC).

Olympic Quality Standards: Aerospace-grade precision protocols with tolerances tighter than ±0.02mm for critical components (e.g., medical implants, optical lenses).

24/7 Customer Service: Dedicated account managers provide real-time production updates, urgent issue resolution, and technical support—anytime, anywhere.

“When your project demands perfection, we’re not just a supplier. We’re your engineering ally.”

Ready to redefine precision manufacturing?

Contact our team for a no-obligation consultation. Let’s build excellence together.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Where Precision Meets Partnership

Precision Engineering Beyond Industry Standards

We don’t just meet tolerances—we redefine them. While industry-standard injection molding tolerances often fall between ±0.1mm and ±0.5mm, our proprietary CNC tooling and process control deliver sub-0.025mm precision for molds and parts. This ensures dimensional consistency across millions of cycles, reducing rework and accelerating time-to-market.

| Metric | Industry Standard | Wuxi Lead Precision Benchmark |

|---|---|---|

| Mold Machining Tolerance | ±0.1 mm | ±0.025 mm (ISO 2768-mk class) |

| Part Dimensional Tolerance | ±0.5 mm | ±0.1 mm (CMM-verified) |

| Shot Life (P20/NAK80) | 50k–100k cycles | 500k+ cycles (proprietary heat treatment) |

| Cycle Time Optimization | Baseline | Up to 30% reduction (thermal management) |

Zero Defects Guarantee: Olympic Quality Assurance

“Olympic-grade precision isn’t aspirational—it’s engineered into every process.”

At Wuxi Lead, quality is non-negotiable. Every mold undergoes:

3D laser scanning for real-time dimensional validation

CMM verification at 100% of critical features

Statistical Process Control (SPC) during production runs

ISO 9001-certified quality protocols for traceability

This rigor eliminates scrap, ensures 99.98% first-pass yield, and guarantees parts meet aerospace, medical, and automotive standards—without compromise.

24/7 Technical Partnership: Your Success, Our Priority

We operate as an extension of your engineering team. Unlike transactional suppliers, we provide:

Dedicated account managers with 24/7 availability for urgent issues

<2-hour response time for technical queries or production escalations

Free DFM analysis to optimize designs for manufacturability before tooling begins

Proactive lifecycle support from prototype to high-volume production

“Your project timeline is our priority. We solve problems before they become delays.”

Ready to transform your injection molding project?

Contact us today for a free DFM analysis and competitive quote:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Precision Engineered. Partnership Delivered.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.