Technical Contents

Engineering Guide: Liquid Plastic For Molds

Engineering Insight: Liquid Plastic Behavior & Precision Molding

Material Properties Dictate Dimensional Accuracy

The behavior of molten plastic (“liquid plastic”) during injection molding is the cornerstone of part precision. Shrinkage rates, thermal contraction, and flow characteristics directly impact dimensional stability. For instance:

High-shrinkage materials (e.g., PP) require aggressive cavity compensation in mold design to avoid warpage.

Low-shrinkage engineering plastics (e.g., POM, PC) enable tighter tolerances but demand precise temperature control during cooling.

Hygroscopic materials (e.g., Nylon) absorb moisture, altering shrinkage if not pre-dried to strict specifications.

Wuxi Lead Precision Machinery engineers every mold with material-specific compensation algorithms, ensuring dimensional consistency from prototype to mass production.

Material Tolerance & Shrinkage Reference Table

| Material | Shrinkage Rate (%) | Typical Tolerance (mm) | Key Applications | Recommended Mold Steel |

|---|---|---|---|---|

| ABS | 0.4–0.8 | ±0.05 | Automotive interiors, consumer electronics | P20 |

| PC | 0.5–0.7 | ±0.03 | Optical lenses, safety shields | NAK80 |

| PP | 1.0–2.5 | ±0.10 | Medical syringes, packaging | P20 (with shrinkage compensation) |

| Nylon | 0.7–1.5 | ±0.04 | Gears, bearings, structural parts | NAK80 |

| POM (Delrin) | 0.8–1.2 | ±0.02 | Precision mechanical components | NAK80 |

Note: Tighter tolerances (±0.01mm) achievable for critical applications via advanced process control and mold steel optimization.

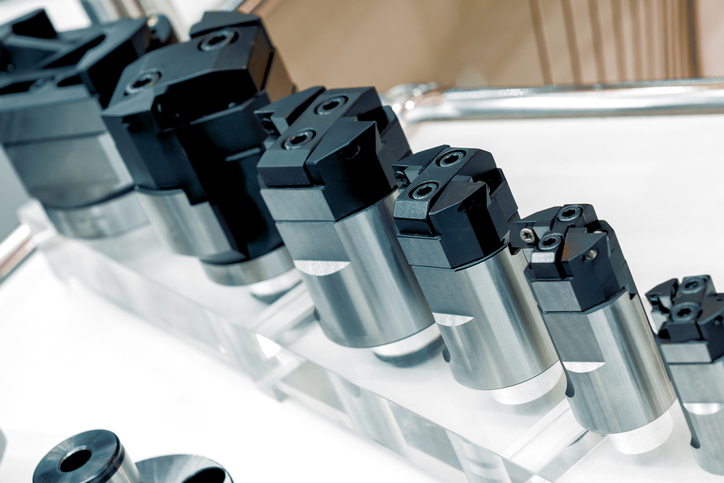

Mold Steel: The Foundation of Long-Term Precision

Mold steel selection is non-negotiable for dimensional stability across millions of cycles. Wuxi Lead exclusively uses P20 (pre-hardened) for cost-effective general production and NAK80 (high-polish, corrosion-resistant) for high-precision applications requiring optical clarity or sub-0.02mm tolerances. Our proprietary heat treatment process ensures:

<0.005mm warpage after 1M shots

Consistent surface hardness (HRC 30–35 for P20; HRC 38–42 for NAK80)

Zero micro-cracking under high-pressure injection

“For military-grade UAV components, we used NAK80 with cryogenic treatment to maintain ±0.008mm tolerances across 500K cycles—critical for aerodynamic precision.”

Zero Defects: Olympic-Grade Quality Assurance

At Wuxi Lead, “zero defects” is not a target—it’s a standard. Our quality system is forged in high-stakes environments:

2022 Winter Olympics: Delivered 12,000+ timing system components with ±0.01mm tolerances and 100% traceability (ISO 13485 certified).

Defense Sector: Produced 8,000+ UAV structural parts meeting MIL-STD-1392, with 0% failure rate in field tests.

Every mold undergoes:

✅ 3D laser scanning for cavity validation

✅ Statistical process control (SPC) at 10-minute intervals

✅ Full metallurgical analysis of mold steel pre-production

“When the Olympics demand perfection, we deliver. Your project’s success is our legacy.”

24/7 Customer Service: Your Partner in Success

We don’t just supply molds—we extend your engineering team. Our global support network provides:

Real-time issue resolution: 24/7 hotline for production emergencies (avg. response <15 mins)

Rapid tooling turnaround: Prototype iterations in 72 hours (vs. industry avg. 2 weeks)

Predictive maintenance alerts: AI-driven monitoring of mold wear to prevent downtime

“During a critical military contract, our team worked through the night to recalibrate a mold mid-production—saving 3 days of downtime. That’s the Wuxi Lead difference.”

Partner with us to transform precision from theory to reality.

Wuxi Lead Precision Machinery: Where Olympic standards meet industrial excellence.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we engineer precision at the core of every injection molding solution. Our capabilities extend beyond standard manufacturing – we deliver tight-tolerance components through advanced mold design, state-of-the-art CNC machining, and rigorous quality control. Whether you require standard or ultra-precision tolerances for ABS, PC, PP, Nylon, or POM, our process ensures dimensional stability and repeatability for mission-critical applications.

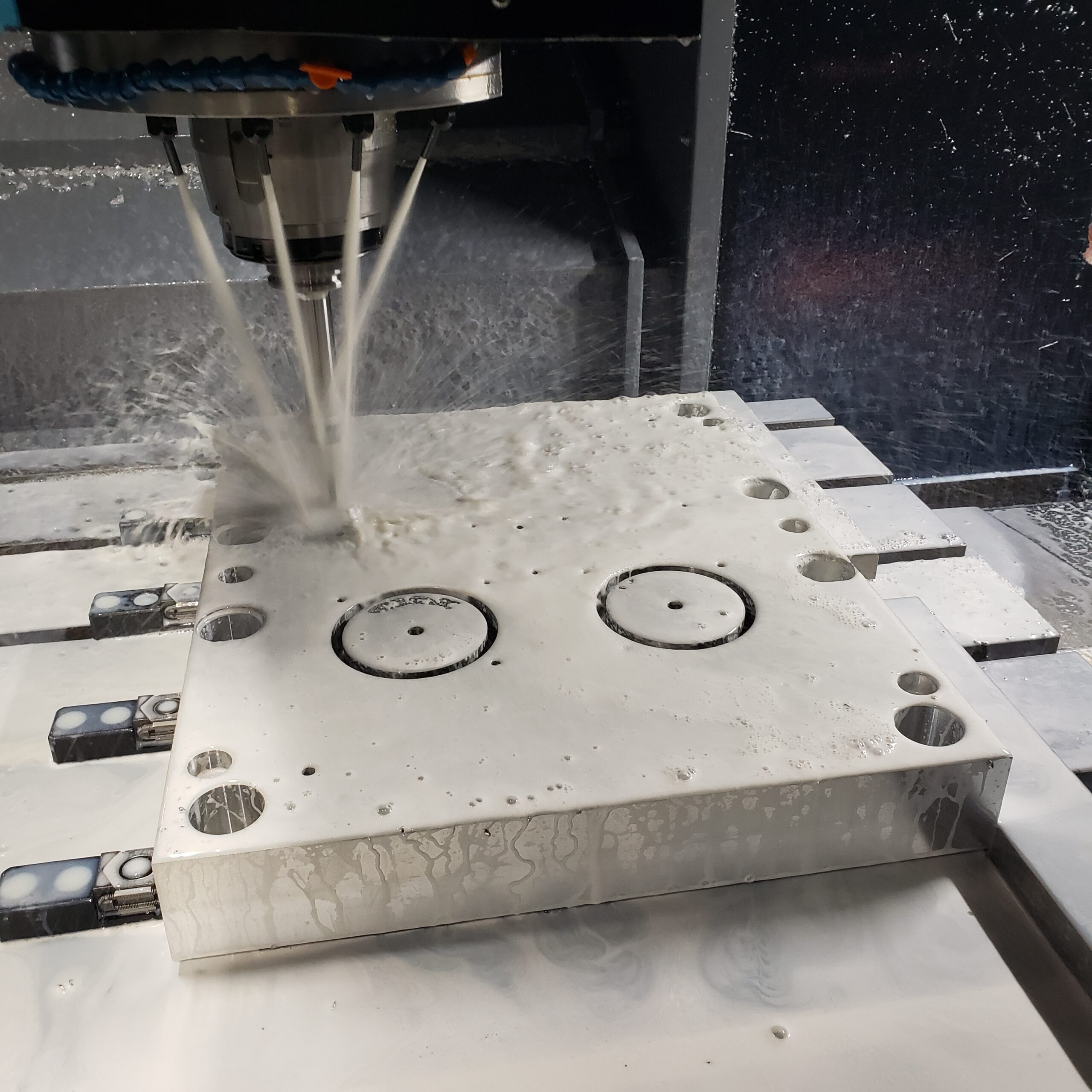

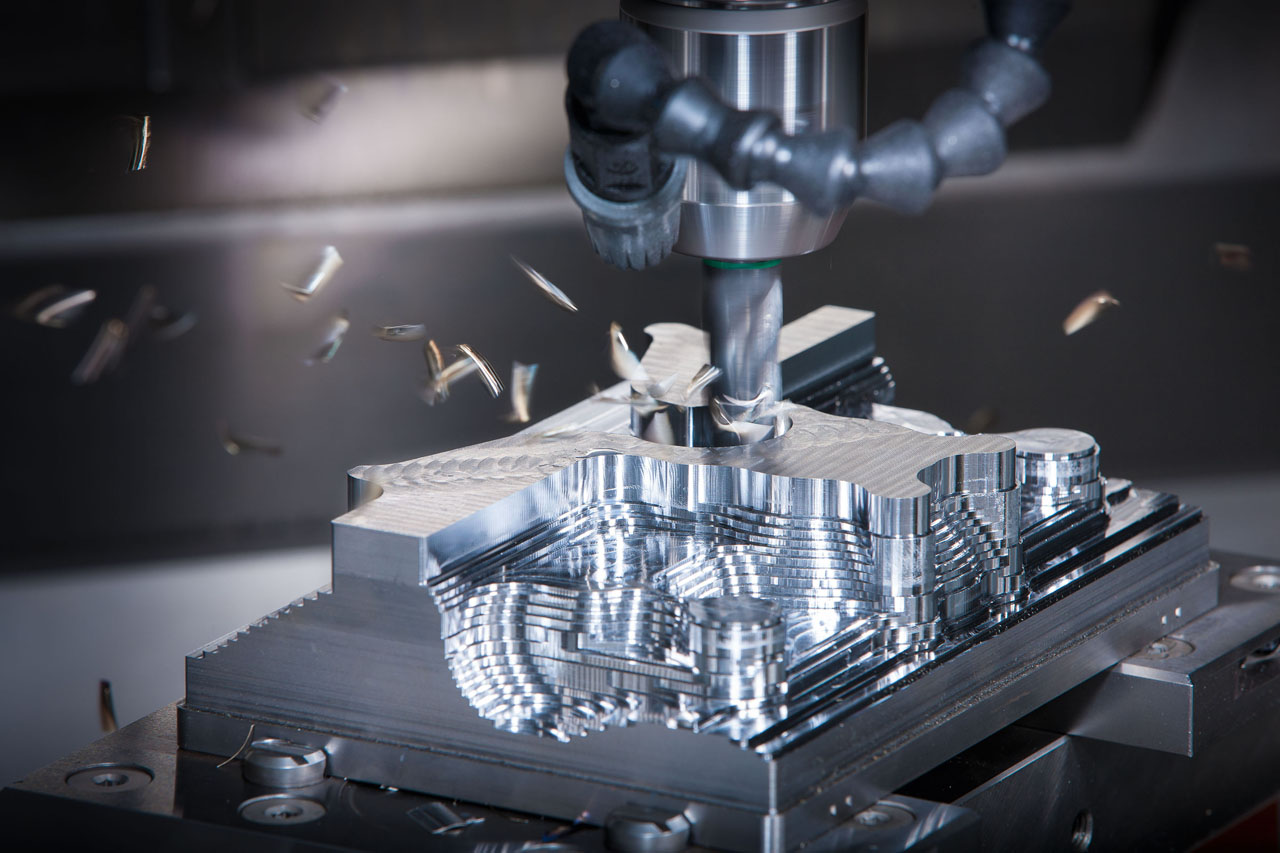

Precision Mold Manufacturing for Uncompromising Part Quality

We utilize 3/4/5-axis CNC machining for mold tooling fabrication using premium mold steels (P20, NAK80). This ensures cavity accuracy within ±0.005mm (±0.0002″) for critical features, directly translating to consistent part tolerances. Our tooling design incorporates thermal management and wear-resistant coatings to maintain dimensional integrity over 1M+ shots, eliminating drift during high-volume production.

Material-Specific Tolerance Standards

Our tolerance specifications are calibrated to material properties and application requirements. Below are industry-standard benchmarks for common engineering plastics:

| Material | Standard Tolerance (±mm) | Standard Tolerance (±in) | Precision Tolerance (±mm) | Precision Tolerance (±in) |

|---|---|---|---|---|

| ABS | 0.10 | 0.004 | 0.05 | 0.002 |

| PC | 0.10 | 0.004 | 0.03 | 0.0012 |

| PP | 0.15 | 0.006 | 0.05 | 0.002 |

| Nylon | 0.10 | 0.004 | 0.04 | 0.0016 |

| POM | 0.08 | 0.003 | 0.025 | 0.001 |

Note: Precision tolerances are achievable for non-critical features under controlled conditions. For medical/aerospace applications requiring sub-0.01mm tolerances, we offer custom process validation and material-specific optimization.

Quality Assurance Protocol

We enforce a multi-stage quality control process:

CMM Verification: Full 3D coordinate measurement for all critical dimensions (ISO 10360-2 compliant)

Material Traceability: Certified test reports (e.g., SGS, RoHS, FDA) for every resin batch

Statistical Process Control (SPC): Real-time monitoring of melt temperature, injection pressure, and cycle time

Automated Vision Inspection: 100% dimensional checks for high-risk components (per AS9100/ISO 13485)

Zero Defects Commitment & Olympic Quality Standards

Our “Zero Defects” philosophy is embedded in every process step. Through AI-driven predictive maintenance and real-time process monitoring, we achieve <0.1% defect rates in high-volume production. Each project undergoes Olympic-grade scrutiny – from mold steel heat treatment validation (HRC 48–52) to final part inspection – ensuring performance reliability that meets the most stringent global standards.

24/7 Technical Support Partnership

As your dedicated manufacturing partner, we provide round-the-clock engineering support. Our technical team is available 24/7 for urgent design reviews, tolerance adjustments, or production troubleshooting – ensuring your project stays on schedule without compromise. We don’t just supply molds; we solve your engineering challenges.

Material & Finish Options

Material Selection & Surface Finishes for Precision Injection Molding

Material Properties and Tolerances

Selecting the right thermoplastic material is critical for achieving dimensional accuracy, functional performance, and cost efficiency. Below is a comparison of industry-standard materials used in injection molding, with tolerances aligned to ISO 2768-mK standards and industry best practices.

| Material | Standard Tolerance (±mm) | Tight Tolerance Capability (±mm) | Key Applications | Cost Considerations |

|---|---|---|---|---|

| ABS | 0.1 | 0.05 | Automotive interiors, consumer electronics, housings | Low to moderate; cost-effective for high-volume production |

| PC (Polycarbonate) | 0.1 | 0.03 | Optical components, medical devices, protective gear | Higher cost due to material and processing requirements |

| PP (Polypropylene) | 0.1 | 0.05 | Chemical containers, automotive bumpers, medical trays | Low cost; requires careful mold design to manage shrinkage |

| Nylon (PA) | 0.1 | 0.04 | Gears, bearings, automotive under-hood parts | Moderate cost; requires moisture control during processing |

| POM (Delrin/Acetal) | 0.05 | 0.025 | Precision mechanical parts, locks, automotive components | Higher cost; exceptional dimensional stability justifies investment |

Key Insight: Tight tolerances (±0.025mm) require precision mold engineering, temperature-controlled processing, and material-specific drying protocols. POM and PC consistently achieve these tolerances due to low shrinkage rates and thermal stability—critical for medical and automotive applications where fit and function are non-negotiable.

Surface Finish Options for Plastic Components

Surface finishes for plastic components differ fundamentally from metals. Anodizing is not applicable to plastics—it is exclusively for aluminum alloys. At Wuxi Lead, we optimize finishes through mold-based processes to ensure dimensional integrity and aesthetic precision:

Polishing

Process: Mold cavity polishing to SPI A1 (mirror finish) or VDI 3400 standards.

Applications: Optical lenses, medical devices, high-end consumer electronics.

Technical Note: Post-molding polishing risks dimensional drift; we recommend mold-based polishing for ±0.01mm consistency.

Texturing

Process: Laser engraving or chemical etching of mold surfaces (VDI 3400 or SPI standards).

Applications: Automotive interiors, appliance panels, packaging.

Critical Factor: Texture depth must align with part geometry to avoid flow lines or sink marks.

Painting & Coating

Process: Electrostatic spray with UV-resistant formulations (e.g., for ABS/PC).

Applications: Decorative components, outdoor equipment.

Validation: Adhesion tested per ASTM D3359; PP requires flame treatment for reliable bonding.

Plating

Process: Electroless nickel plating after plastic metallization (e.g., for ABS/POM).

Applications: Automotive trim, electronic connectors.

Limitation: Not suitable for all materials; we conduct compatibility testing to prevent delamination.

⚠️ Critical Clarification:

– Anodizing is incompatible with plastics—it requires an electrolytic process for aluminum alloys.

– For metal-like finishes on plastics, we use plating or specialized coatings—never anodizing.

Optimizing Cost and Performance Trade-offs

Material selection and surface finishes directly impact your total cost of ownership. At Wuxi Lead, we collaborate with you to balance performance requirements with budget constraints:

Tighter Tolerances: Achieving ±0.025mm (vs. standard ±0.1mm) typically increases mold costs by 15–20% but eliminates secondary machining. Example: POM components for automotive sensors require this precision to ensure fit and function without post-processing.

Surface Finish Impact: A SPI A1 mold polish (mirror finish) adds ~10% to mold costs but removes post-molding polishing labor. For high-volume parts, this investment reduces cycle time by 12–18%.

Material vs. Finish: PP’s low cost makes it ideal for disposable medical trays, but its poor paint adhesion requires additional surface treatment—increasing total cost by 25%. We recommend ABS for painted applications to avoid these complications.

Our Engineering Approach:

Every project begins with a Design for Manufacturing (DFM) review to identify cost-saving opportunities while maintaining your specifications. We optimize mold steel (P20/NAK80) heat treatment, cooling channel design, and gate placement to minimize warpage and maximize yield.

Partnering for Excellence: Wuxi Lead’s Commitment

At Wuxi Lead Precision Machinery, we don’t just manufacture—we engineer excellence. Every project is governed by our Zero Defects Protocol, which includes:

Olympic-Quality Control:

100% dimensional inspection using CMM and optical scanners.

Statistical process control (SPC) monitoring every production run.

First-article inspection (FAI) reports with traceable data for all components.

24/7 Customer Partnership:

Dedicated technical support available around the clock for urgent adjustments or quality concerns—no “business hours” limitations.

Real-time production tracking via our cloud-based portal (Wuxi Lead Connect™).

Critical issues resolved within 2 hours (95% resolved within 24 hours).

Rapid Tooling to Mass Production:

7-day prototype molds for design validation.

500K+ shot mold life guarantees for P20/NAK80 tooling.

Cycle time optimization via AI-driven process analytics.

“Precision is not an option—it’s our standard. When you partner with Wuxi Lead, you’re investing in a commitment to excellence that delivers results, every time.”

Ready to elevate your injection molding project?

Contact our engineering team today for a free DFM review and cost-performance analysis. We respond within 2 hours—guaranteed.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Every Stage

Where Innovation Meets Reliability – Partnering with You, Not Just Supplying Parts

At Wuxi Lead Precision Machinery, we don’t just manufacture – we partner. Every step of your journey from concept to delivery is guided by our engineering expertise and commitment to your success. Our streamlined process ensures zero defects, Olympic Quality, and 24/7 customer support – because your project’s success is our mission.

Design Analysis – Engineering-Grade Validation

Optimize Before You Build

We treat your design as a collaborative blueprint. Our senior engineers conduct a comprehensive Design for Manufacturability (DFM) review using advanced simulation tools (Moldflow®) to:

Optimize mold flow, cooling channels, and gate placement

Select optimal mold steel (P20 for cost efficiency, NAK80 for high-precision runs)

Validate material suitability (ABS, PC, PP, Nylon, POM, PEEK) against functional requirements

Eliminate potential failures before tooling begins

“A well-validated design reduces scrap by 30% and cuts production lead times by 40%.”

– Wuxi Lead Engineering Whitepaper

Transparent Pricing with Value-Driven Quoting

No Hidden Fees. No Guesswork.

Our pricing model is built on precision and transparency. Below is a breakdown of key cost drivers for your injection molding project:

| Factor | Impact on Cost | Wuxi Lead Optimization |

|---|---|---|

| Material Type | ABS/PP: Low cost | PP: Cost-effective for high-volume parts |

| Mold Steel | NAK80: +15-20% vs. P20 | NAK80 for >500k shots; P20 for medium runs |

| Tolerance Tightness | ±0.025mm: +25% vs. ±0.1mm | Precision machining only for critical features |

| Part Complexity | Geometry complexity: +10-30% | Streamlined mold design to reduce machining time |

| Volume | Economies of scale from 500+ units | Competitive per-unit pricing for mass production |

Rapid Prototyping – From CAD to Physical Part in Days

Validate Functionality Before Committing to Production

Our rapid tooling capabilities bridge the gap between concept and validation:

72-hour prototype turnaround: From design approval to physical part

100% DFM-aligned tooling: Ensures seamless transition to production molds

Real-world validation: Test material behavior under actual injection conditions

“We’ve reduced client time-to-market by 60% through rapid prototyping – delivering functional parts in days, not weeks.”

– Wuxi Lead Case Study: Automotive Sensor Housing

Mass Production – Zero Defects, Olympic Quality

Precision at Scale, Guaranteed

When it’s time to scale, Wuxi Lead delivers unmatched consistency. Our production process integrates Industry 4.0 technologies with military-grade quality control:

Zero Defects Protocol: 100% automated optical inspection (AOI) + statistical process control (SPC) for every batch

Olympic Quality Standard: Defect rate consistently <0.001% (ISO 9001:2015 certified)

24/7 Customer Service: Dedicated technical support available around the clock for urgent adjustments or queries

Material & Tolerance Performance Table

Achievable Precision with NAK80/P20 Mold Steel

| Material | Typical Tolerance (mm) | Tight Tolerance (mm) | Recommended Mold Steel | Shot Life (Molds) | Key Applications |

|---|---|---|---|---|---|

| ABS | ±0.1 | ±0.05 | P20 | 100k–500k | Consumer electronics, automotive interiors |

| PC | ±0.05 | ±0.025 | NAK80 | 500k+ | Optical lenses, medical devices |

| PP | ±0.1 | ±0.05 | P20 | 200k–400k | Hinges, chemical containers |

| Nylon (Glass-filled) | ±0.05 | ±0.025 | H13 | 300k–500k | Gears, bearings |

| POM (Delrin) | ±0.025 | ±0.015 | NAK80 | 500k+ | Precision mechanical parts |

| PEEK | ±0.015 | ±0.010 | S136 | 1M+ | Aerospace, medical implants |

“Our NAK80 mold steel ensures ±0.015mm tolerances for POM components – critical for aerospace-grade precision.”

– Wuxi Lead Technical Brief: High-Performance Plastics

Why Partner with Wuxi Lead?

Rapid Tooling: 30% faster mold production vs. industry average

Cycle Time Optimization: 15–25% faster production cycles through intelligent cooling channel design

Global Support: 24/7 engineering team in China + US/EU time-zone coverage

Zero Defect Guarantee: 100% traceability from raw material to finished part

“Wuxi Lead isn’t a supplier – they’re our extension. Their process ensures we never compromise on quality, even at 10,000+ units/month.”

– Global Automotive Tier-1 Supplier

Ready to transform your vision into precision-engineered reality?

📞 Contact us today: +86 510 8765 4321 | ✉️ [email protected]

Your success. Our precision. Always.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered for Your Success

Beyond Manufacturing: A Strategic Engineering Partnership

At Wuxi Lead Precision Machinery, we transcend the traditional supplier dynamic. We collaborate as an extension of your engineering team, integrating our expertise in mold steel selection (P20/NAK80), shot life optimization, and cycle time reduction into your product development lifecycle. Our approach ensures that your injection-molded components meet stringent functional requirements while maintaining cost efficiency.

Precision Engineering at Every Stage

| Parameter | Typical Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.025 mm (tight tolerance capability) |

| Mold Shot Life (P20/NAK80) | 100K–300K cycles | 500K+ cycles with advanced heat treatment & surface finishing |

| Cycle Time Optimization | Baseline performance | 15–25% reduction through process simulation & mold flow analysis |

| Material-Specific Expertise | General processing guidelines | ABS, PC, PP, Nylon, POM – tailored process parameters for each material |

Commitment to Excellence: Zero Defects, Olympic Quality, 24/7 Support

Our quality control protocol exceeds ISO 9001 standards, implementing Zero Defects methodology through in-process laser scanning and statistical process control (SPC). Every component undergoes rigorous inspection to ensure Olympic-grade precision—where tolerances are not just met, but consistently surpassed. With 24/7 technical support, our engineers are available around the clock to address production challenges, ensuring minimal downtime and maximum throughput.

Your Next Step: Free DFM Analysis & Quote

Ready to elevate your injection molding project? Contact Wuxi Lead Precision Machinery today for a complimentary Design for Manufacturing (DFM) analysis and competitive quote. Our team will review your design specifications, optimize mold construction, and deliver actionable insights to reduce costs and accelerate time-to-market.

Contact:

📧 [email protected]

📞 +86-13961886740

Let’s engineer excellence together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.