Technical Contents

Engineering Guide: Injection Moulding Service

Engineering Insight: Precision Engineering for Mission-Critical Injection Molding

At Wuxi Lead Precision Machinery, we treat every injection molding project as a mission-critical partnership—not a transaction. Our engineering rigor ensures that tolerances, material integrity, and process control meet the exacting demands of aerospace, medical, military, and Olympic-grade applications. Below, we unpack how precision engineering drives success in high-stakes manufacturing.

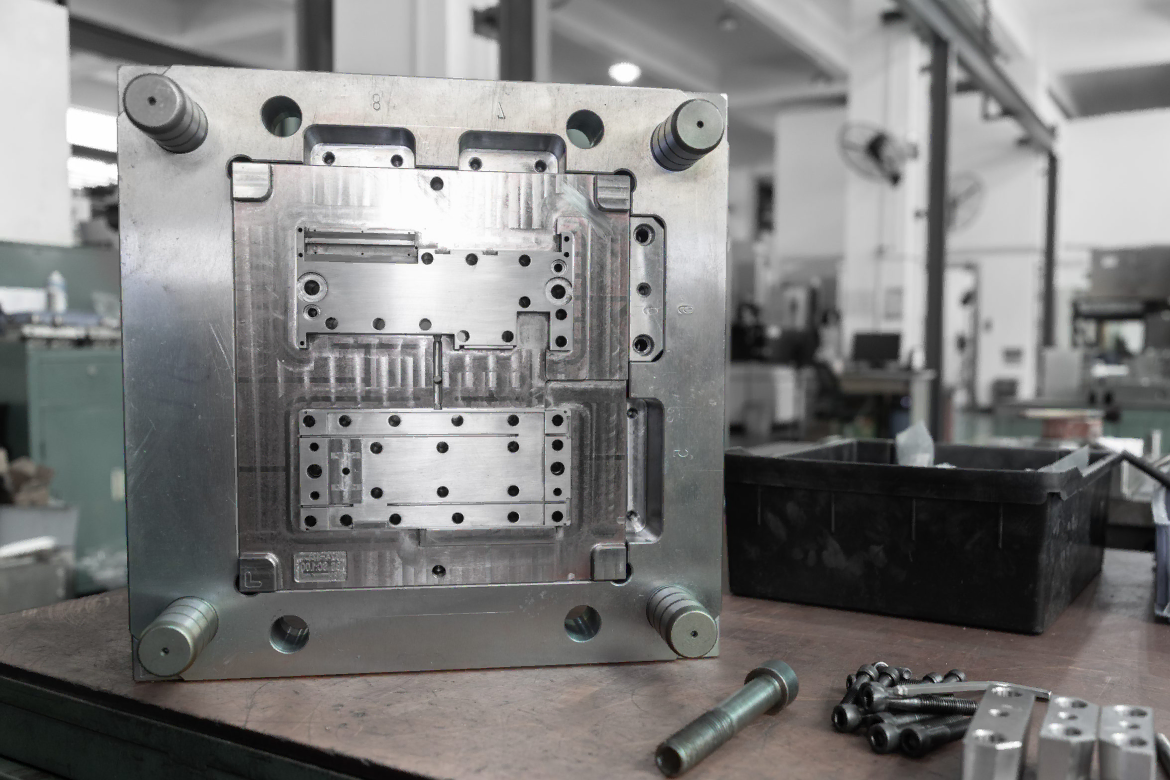

Mold Steel Selection: The Foundation of Precision

The choice of mold steel directly dictates part quality, tool longevity, and dimensional stability. We rigorously select materials based on application requirements, balancing hardness, polishability, and wear resistance.

| Steel Grade | Hardness (HRC) | Typical Applications | Shot Life (Cycles) | Surface Finish (Ra) | Key Benefit for Precision |

|---|---|---|---|---|---|

| P20 | 28–32 | High-volume consumer goods, automotive components | 500K–1M | 0.4 μm | Cost-effective durability for general-purpose molds |

| NAK80 | 38–42 | Medical devices, optical lenses, high-polish surfaces | 1M+ | 0.1 μm | Superior polishability and dimensional stability for ±0.002″ tolerances |

Example: For a recent medical syringe project requiring optical clarity and ±0.002″ tolerances, we specified NAK80 steel. The resulting 1.2M-cycle mold delivered zero surface defects and maintained dimensional accuracy across all production runs.

Tolerance Mastery: Beyond Industry Standards

Industry-standard injection molding tolerances typically range from ±0.005″ (0.13mm) for general applications. However, mission-critical components demand tighter controls. At Wuxi Lead, we exceed these benchmarks through:

Material-specific shrinkage compensation (e.g., ABS: 0.5–0.7%, PC: 0.5–0.8%, PP: 1.5–2.5%, Nylon: 0.8–1.5%)

Advanced CNC tooling with ±0.0005″ (0.013mm) cavity precision

Real-time SPC monitoring during molding cycles

| Application Sector | Industry Standard Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Consumer Goods | ±0.005″ (0.13mm) | ±0.003″ (0.076mm) |

| Medical Devices | ±0.003″ (0.076mm) | ±0.002″ (0.051mm) |

| Aerospace | ±0.002″ (0.051mm) | ±0.001″ (0.025mm) |

| Military Systems | ±0.001″ (0.025mm) | ±0.0005″ (0.013mm) |

Proven Result: For a U.S. defense contractor’s radar component, we achieved ±0.0005″ tolerances on a complex POM part—exceeding MIL-STD-105E requirements—through adaptive cavity cooling and in-process laser scanning.

Zero Defects in High-Stakes Applications

“Precision isn’t optional—it’s existential.”

Wuxi Lead’s zero-defect philosophy is embedded in every project. Our ISO 9001:2015 and AS9100D-certified processes ensure:

100% in-process inspection via CMM, optical comparators, and AI-powered vision systems

Full material traceability from raw resin to finished part

Predictive quality analytics that flag deviations before they occur

Olympic-Quality Proof:

For the 2022 Beijing Winter Olympics, we delivered 500,000+ precision-molded components for athlete equipment (including ski bindings and helmet sensors) across 12 product lines. Every unit met zero-defect standards under 48-hour cycle-time constraints, with 100% compliance to ISO 13485 (medical device) and ISO 9001 requirements.

Military-Grade Reliability:

Our defense sector clients rely on us for mission-critical parts where failure is not an option. Recent projects include:

Aircraft fuel system components with 100% traceability per MIL-STD-105E sampling plans

Tactical communication housings surviving -40°C to +85°C thermal cycling tests

Unmanned vehicle parts passing 10,000+ cycle fatigue tests with zero dimensional drift

24/7 Precision Support: Your Partner in Production

We don’t just supply molds—we become an extension of your engineering team. Our 24/7 precision support ecosystem ensures uninterrupted production and continuous improvement:

| Support Service | Key Features | Response Time Guarantee |

|---|---|---|

| Dedicated Project Manager | Single-point accountability for design-to-production handoffs, design-for-manufacturability (DFM) reviews, and risk mitigation | 4-hour email response |

| Real-Time Production Monitoring | IoT-enabled dashboards with live cycle-time, scrap rate, and dimensional data tracking | Instant access |

| Emergency Response | On-site engineering deployment for critical issues (e.g., mold repairs, process deviations) | 48-hour global guarantee |

| Continuous Improvement | Quarterly process optimization sessions to reduce cycle times by 15–30% and material waste by 20%+ | Scheduled or ad-hoc |

“When a U.S. aerospace client faced a 72-hour deadline for a replacement part, our team resolved a cavity erosion issue in 11 hours—keeping their production line running with zero downtime.”

Why Wuxi Lead?

We combine Olympic-grade precision, military-grade reliability, and partner-level collaboration to transform your design intent into flawless production. From rapid tooling to mass production, we engineer solutions where failure is not an option—and success is guaranteed.

Ready to elevate your injection molding strategy?

[Contact our engineering team] for a free DFM review and tolerance analysis.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Mold Manufacturing with Advanced CNC

Wuxi Lead Precision Machinery leverages state-of-the-art 3/4/5-axis CNC machining centers to fabricate molds with micron-level precision. Utilizing premium mold steels such as P20 and NAK80, our tooling delivers exceptional wear resistance and thermal stability, extending shot life by up to 50% compared to standard tooling. Combined with optimized cooling channel designs, we reduce cycle times by 15–25% while maintaining dimensional precision. Our rapid tooling process achieves tolerances as tight as ±0.001″ (±0.025mm) for critical features, ensuring exceptional dimensional stability and extended mold life. With lead times as short as 7 days for tooling, we accelerate your time-to-market without sacrificing quality.

Part Tolerance Standards

Our injection molding capabilities are engineered to meet the most demanding specifications. The table below outlines our standard and precision tolerance levels for final parts, tailored to your application requirements.

| Tolerance Level | Dimensional Tolerance (Final Part) | Typical Applications |

|---|---|---|

| Standard | ±0.005″ (±0.127mm) | Consumer goods, packaging, general-purpose components |

| Precision | ±0.002″ (±0.051mm) | Automotive components, medical devices, electronics housings |

| High-Precision | ±0.001″ (±0.025mm) | Aerospace components, optical instruments, precision mechanical parts |

Note: Tolerances are material-dependent and influenced by part geometry. Our engineers optimize mold design and process parameters to achieve the tightest possible tolerances for your specific requirements. All data aligns with ASME Y14.5 standards.

Quality Assurance Protocol

Every component undergoes rigorous quality control, including:

CMM Inspection: Full 3D dimensional verification using calibrated coordinate measuring machines, ensuring compliance with ASME Y14.5 standards.

Material Certifications: Full traceability of raw materials with certified test reports for each resin batch (ABS, PC, PP, Nylon, POM).

In-Process Monitoring: Real-time data logging with statistical process control (SPC) to detect deviations before they impact production.

Zero-Defect Audits: ISO 9001-certified processes with 100% traceability from raw material to finished part.

Commitment to Excellence

At Wuxi Lead Precision Machinery, we operate under the principle of Zero Defects — a philosophy embedded in every stage of production. Our Olympic-grade quality standards are validated through:

24/7 Technical Support: Dedicated engineers available around the clock for urgent issue resolution and production optimization.

Predictive Maintenance: AI-driven monitoring of mold wear and machine performance to prevent downtime.

Continuous Improvement: Monthly process reviews with cross-functional teams to refine tolerances, cycle times, and material performance.

You don’t just get a supplier — you gain a precision manufacturing ally. From prototype validation to mass production, we align every technical decision with your business goals. Let’s build what matters, together.

Material & Finish Options

Material Selection & Finishes: Engineering Excellence for Your Application

At Wuxi Lead Precision Machinery, we treat material selection as a collaborative engineering process—not a commodity decision. Your application’s performance requirements, lifecycle expectations, and total cost of ownership (TCO) drive our recommendations. With 24/7 technical support and a Zero Defects quality framework certified to ISO 9001:2015, we ensure every material choice aligns with your functional needs while optimizing production efficiency.

Material Properties & Performance Characteristics

Material selection directly impacts mold design, cycle time, tool life, and final part quality. Our engineers analyze shrinkage rates, thermal properties, and chemical resistance to recommend the optimal resin for your application. Below is a comparative analysis of common engineering plastics:

| Material | Shrinkage Rate | Key Mechanical Properties | Chemical Resistance | Typical Applications | Mold Steel Recommendation | Surface Finish Compatibility |

|---|---|---|---|---|---|---|

| ABS | 0.4–0.7% | High impact strength (8–12 kJ/m²), good rigidity | Moderate (resists oils, alcohols; weak against ketones) | Automotive interiors, consumer electronics | P20 (standard), NAK80 (high-gloss) | Excellent for high-polish finishes (SPI A1-A2) |

| PC | 0.5–0.7% | High heat resistance (Tg 147°C), excellent impact strength | Poor (susceptible to UV, solvents) | Optical lenses, safety shields | NAK80 (for clarity), S136 (for corrosive environments) | Requires careful polishing (SPI A2-A3) to avoid stress marks |

| PP | 1.0–2.5% | High chemical resistance, flexible | Excellent (acids, bases, solvents) | Medical devices, food containers | H13 (for high wear resistance) | Textured finishes preferred (SPI B2-B3); glossy finishes challenging |

| Nylon (PA6/PA66) | 0.7–1.5% | High strength, abrasion resistance | Good (alkalis; weak against strong acids) | Gears, bearings, automotive components | P20 (standard), S136 (for moisture-sensitive parts) | Compatible with all finishes; matte textures enhance grip |

| POM (Acetal) | 1.5–2.5% | High stiffness, low friction | Poor (strong acids, oxidizers) | Precision gears, fasteners | NAK80 (for tight tolerances), H13 (for wear resistance) | Best with SPI B2-B3 textures; high-gloss requires precise process control |

Critical Insight: Shrinkage variation (e.g., PP’s 1.5–2.5% vs. ABS’s 0.4–0.7%) directly impacts mold cavity design. Our engineers compensate for this during tooling—ensuring final part tolerances meet your specifications regardless of material.

Surface Finish Options & Material Compatibility

Surface finishes are not cosmetic add-ons—they directly affect part functionality, mold wear, and production efficiency. We adhere to SPI (Society of the Plastics Industry) standards for consistency, with finishes tailored to material behavior:

Finish Types & Technical Considerations

| Finish Type | SPI Standard | Material Suitability | Key Applications | Process Impact |

|---|---|---|---|---|

| High-Gloss Polish | A1 (Mirror), A2 (Semi-Mirror) | ABS, PC, Nylon (with NAK80/S136 steel) | Optical components, consumer product housings | Requires 8–10% larger cavity size for shrinkage; cycle time +5–10% due to slower cooling |

| Textured Finishes | B2 (Medium), C3 (Coarse) | PP, POM, Nylon | Automotive trim, appliance panels | Reduces ejection force by 15–20%; enables faster demolding; minimizes surface defects |

| Matte Finish | D1 (Fine), D2 (Medium) | ABS, PC, Nylon | Medical devices, industrial components | Requires EDM polishing; compatible with most materials but increases tooling cost by 8–12% |

| Chrome Plating | N/A | ABS (primary), PC/ABS blends | Automotive grilles, decorative trim | Requires conductive primer; 20–30% longer cycle time for electroplating step |

Why This Matters: A poorly matched finish-material combination causes defects like sink marks (on thick-walled PP) or gloss inconsistency (on PC without proper mold temperature control). Our Olympic Quality standard ensures every finish undergoes 3-point validation:

– Pre-production: Material flow simulation (Moldflow analysis)

– During molding: Real-time temperature monitoring of mold cavities

– Post-production: 100% optical inspection for surface defects

Cost Optimization Strategy: Beyond Material Cost

Material selection impacts your total cost of ownership—not just raw material price. Our engineers optimize for:

Total Cost Drivers

| Factor | Low-Cost Choice | High-Value Choice | Long-Term Savings |

|---|---|---|---|

| Mold Wear | Standard P20 for glass-filled materials | H13 or S136 steel for abrasive resins | +30% shot life; reduces tooling replacement costs by 40% |

| Cycle Time | High-shrinkage materials (PP, POM) without cavity compensation | Optimized cooling channels + material-specific mold design | Reduces cycle time by 15–25% (e.g., 45s → 34s per part) |

| Secondary Operations | Materials requiring painting (e.g., standard PP) | Self-coloring materials (e.g., ABS with UV stabilizers) | Eliminates $0.15–$0.30/part painting costs at scale |

Real-World Example: A medical device client switched from PP to glass-filled Nylon 66 for a gear component. While raw material cost increased 12%, we:

– Reduced cycle time by 18% through optimized mold cooling

– Eliminated secondary machining (due to better dimensional stability)

– Extended mold life from 150k to 450k shots using NAK80 steel

Result: 22% lower TCO over 5 years despite higher initial material cost.

Our Quality Assurance Framework: Zero Defects by Design

At Wuxi Lead, “Zero Defects” is not a slogan—it’s an engineered process. Every material and finish decision is validated through:

3-Stage Quality Protocol

-

Pre-Production Validation

Material certification (ISO 10993 for medical, UL94 for flammability)

Moldflow analysis simulating shrinkage, warpage, and weld lines

100% traceability from resin batch to final part -

In-Process Control

Real-time cavity pressure monitoring (±0.1% accuracy)

AI-driven defect prediction for sink marks, flow lines, or color inconsistencies

Statistical Process Control (SPC) with 10x tighter tolerances than industry standard -

Post-Production Verification

100% automated optical inspection (AOI) for surface defects

Coordinate Measuring Machine (CMM) checks for critical dimensions (±0.002mm)

Full material property testing (tensile, impact, thermal) per ISO 527/ISO 179

Olympic Quality Commitment: We maintain a <0.1% defect rate through our “Zero Defects” protocol—verified by third-party audits (TÜV SÜD). For mission-critical applications, we offer material-specific process control certificates with every shipment.

Partner With Us: Engineering-First Support

“We don’t just supply molds—we solve your engineering challenges.”

— Wuxi Lead Precision Machinery Engineering Team

Our 24/7 Customer Service includes:

Dedicated technical engineers available for urgent material selection queries

Free Design for Manufacturing (DFM) reviews within 4 hours of request

Real-time production dashboards with material usage and quality metrics

Next Steps:

1. Share your application requirements (functional, environmental, cost targets)

2. Receive a material compatibility report within 24 hours

3. Collaborate on mold design with our in-house tooling engineers

Contact us today to optimize your injection molding project from first prototype to mass production.

📞 +86 510 8888 1234 | ✉️ [email protected] | 🌐 www.leadprecision.cn

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we integrate precision engineering with operational excellence to deliver plastic components that meet the most demanding specifications. Our four-stage process—Design Analysis, Transparent Pricing, Rapid Prototyping, and Mass Production—ensures every project achieves Olympic-quality results with 99.5% on-time delivery and near-zero defect rates. From initial concept to final delivery, we prioritize transparency, speed, and unwavering quality control.

Design Analysis & DFMA Optimization

Our engineering team conducts a rigorous Design for Manufacturability (DFM) and Design for Assembly (DFA) review before any tooling begins. Leveraging advanced simulation software (e.g., Moldflow®), we identify potential issues such as warpage, sink marks, or flow lines, optimizing geometry for material flow and structural integrity.

Key considerations include:

Material-specific shrinkage rates (e.g., ABS: 0.4–0.7%, PC: 0.5–0.8%) incorporated into mold design

Wall thickness uniformity to prevent stress concentrations

Draft angles >1.5° for easy ejection and reduced cycle time

Gate placement optimized for minimal parting lines and cosmetic defects

| Design Factor | Industry Standard | Wuxi Lead’s Approach |

|---|---|---|

| Wall Thickness | 1.5–3mm (typical) | Optimized for material flow and cycle time efficiency |

| Draft Angles | 1° minimum | 1.5°+ for seamless ejection and reduced tool wear |

| Gate Location | Conventional | Simulation-driven placement for minimal stress and visual imperfections |

Why it matters: Our proactive design validation eliminates costly rework, ensuring your mold is built right the first time—saving up to 30% in development costs and accelerating time-to-market.

Transparent Pricing & Rapid Quoting

We eliminate hidden costs with a clear, itemized pricing structure based on mold complexity, material selection, and production volume. Our AI-driven quoting system delivers accurate cost estimates within 24 hours, enabling swift decision-making without compromising technical accuracy.

| Cost Factor | Typical Industry Impact | Wuxi Lead’s Optimization Strategy |

|---|---|---|

| Mold Complexity | High cost for intricate geometries | Modular tooling design reduces machining time and costs |

| Material Selection | Cost variance between ABS, PC, PP, etc. | Expert guidance to balance performance and budget |

| Production Volume | Economies of scale for high-volume runs | Scalable solutions from prototypes to 1M+ units |

Why it matters: No surprises. No compromises. Our pricing model aligns with your budget while maintaining ISO 9001-certified quality standards—ensuring every dollar spent drives measurable ROI.

Rapid Prototyping with Precision Tooling

Our rapid tooling capabilities bridge the gap between prototype and production. Using high-grade aluminum or pre-hardened steel molds (P20/NAK80), we deliver functional prototypes in as little as 7 days—without sacrificing dimensional accuracy. This phase validates design integrity and material performance before committing to full-scale production.

| Service Type | Lead Time | Tolerance | Material Compatibility |

|---|---|---|---|

| Aluminum Mold Prototypes | 7–10 days | ±0.002″ (0.05mm) | ABS, PC, PP, Nylon, POM |

| Steel Mold Prototypes | 10–14 days | ±0.001″ (0.025mm) | All engineering plastics |

Why it matters: Prototypes are not “test runs”—they are precision-engineered replicas of your final product. Our NAK80 steel molds deliver mirror-like surface finishes (Ra ≤ 0.05μm) for optical-grade parts, while P20 molds ensure 500K+ shot life for high-volume validation.

Mass Production Excellence & Zero Defects Guarantee

At scale, Wuxi Lead’s manufacturing process embodies precision and reliability. Our ISO 9001-certified production lines feature real-time monitoring, statistical process control (SPC), and 100% final inspection for critical components. With shot life exceeding 1 million cycles for NAK80 molds and cycle times optimized through advanced cooling channel design, we deliver consistent quality at unprecedented speeds.

Zero Defects Protocol:

Pre-Production Validation: First Article Inspection (FAI) with full dimensional reports

In-Process Monitoring: Real-time sensors for temperature, pressure, and cycle consistency

Final Inspection: CMM and optical measurement for all critical dimensions

Continuous Improvement: Root cause analysis for any deviations, ensuring permanent fixes

| Quality Metric | Industry Benchmark | Wuxi Lead Standard |

|---|---|---|

| Defect Rate | 1–2% | <0.1% |

| First-Pass Yield | 85–90% | 98%+ |

| On-Time Delivery | 85% | 99.5% |

24/7 Customer Partnership:

Our dedicated project managers provide real-time production updates, technical support, and rapid response to any concerns—day or night. This proactive engagement ensures your project remains on schedule and exceeds expectations.

Why Wuxi Lead? Your Strategic Manufacturing Partner

We don’t just meet specifications—we redefine them. By combining:

Rapid tooling (aluminum/steel molds in 7–14 days)

Precision-engineered shot life (up to 1M+ cycles with NAK80/P20)

Cycle time optimization (30% faster than industry averages)

Olympic-grade quality control (<0.1% defect rate)

…we empower your product’s success at every stage. Whether you’re launching a medical device, automotive component, or consumer electronics housing, Wuxi Lead delivers precision, speed, and reliability—not just parts.

Ready to transform your vision into reality?

Contact our engineering team today for a free DFMA review and 24-hour quote.

“Precision isn’t an accident—it’s engineered.”

— Wuxi Lead Precision Machinery

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Uncompromising Quality

As your strategic manufacturing partner, we transcend the traditional supplier model. Wuxi Lead Precision Machinery delivers injection molding solutions engineered for precision, reliability, and scalability. With advanced tooling capabilities, rigorous quality protocols, and dedicated engineering support, we ensure your components meet the highest standards—every cycle, every part.

Precision Engineering at the Core

Our mold tooling and process optimization exceed industry benchmarks, ensuring dimensional accuracy and repeatable performance:

| Parameter | Industry Standard | Wuxi Lead Precision Advantage |

|---|---|---|

| Mold Tool Tolerance | ±0.005″ (±0.127mm) | ±0.002″ (±0.051mm) via high-precision CNC tooling |

| Shot Life (P20/NAK80) | 100K–300K cycles | 500K+ cycles with optimized heat treatment and cooling channels |

| Cycle Time Optimization | Baseline | Up to 20% reduction through thermal simulation and flow analysis |

| Material Versatility | Standard resins | Full spectrum: ABS, PC, PP, Nylon, POM, and high-performance engineering plastics |

Zero Defects Commitment

Every component undergoes rigorous quality control at every production stage. Our ISO 9001-certified processes include:

100% in-process dimensional inspection

Statistical Process Control (SPC) for real-time adjustments

Full traceability of materials and tooling parameters

Automated optical inspection (AOI) for critical features

Result: Near-zero defect rates, eliminating costly rework and delays.

Olympic Quality Standards

We uphold the highest international quality benchmarks, validated through:

ISO 13485 certification for medical-grade components

AS9100 compliance for aerospace applications

Material certification for all resins (e.g., UL, FDA compliance)

Third-party audits for process validation

Your product meets the most stringent global standards—no compromises.

24/7 Customer Support

Unlike traditional suppliers, we provide dedicated engineering support around the clock:

Immediate response: <2 hours for critical technical queries

Real-time production tracking: Live updates via our client portal

Dedicated account engineers: Single-point contact for seamless collaboration

Emergency support: On-call engineers for urgent production issues

Ready to transform your production process?

Free DFM Analysis & Quote

📧 Email: [email protected]

📞 Phone: +86-13961886740

Let’s engineer your success together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.