Technical Contents

Engineering Guide: Abs Plastic Mold

Engineering Insight: ABS Plastic Mold Design & Manufacturing Excellence

ABS plastic components demand precision engineering at every stage—especially in mold construction. At Wuxi Lead Precision Machinery, we treat molds not as disposable tools, but as mission-critical assets that define part quality, production efficiency, and long-term ROI. Our approach combines aerospace-grade material science, sub-micron machining precision, and rigorous quality protocols to deliver molds that perform under the most demanding conditions.

The Critical Role of Mold Steel Selection

Mold steel selection is the cornerstone of ABS part quality. Suboptimal materials lead to premature wear, surface defects, and dimensional drift—especially in high-volume or high-precision applications. We specialize in two premium grades tailored for ABS:

| Steel Type | Typical Use Case | Hardness (HRC) | Surface Finish | Shot Life | Key Benefits |

|---|---|---|---|---|---|

| P20 | General-purpose molds for consumer goods, automotive interiors | 28–32 | Good (Ra 0.4–0.8 μm) | 500K–1M shots | Cost-effective, excellent machinability, balanced wear resistance |

| NAK80 | Optical-grade parts, medical devices, high-polish consumer electronics | 38–42 | Excellent (Ra 0.1–0.2 μm) | 1M+ shots | Superior polish, corrosion resistance, minimal maintenance |

Why it matters for ABS: ABS’s abrasive nature and high melt temperatures accelerate mold wear. NAK80’s fine grain structure and mirror-like finish ensure consistent surface quality for translucent or high-gloss ABS parts, while P20 delivers optimal value for moderate-volume applications.

Precision Engineering: Tolerances & Dimensional Accuracy

In injection molding, mold tolerances directly dictate part tolerances. Industry standards for mold machining often range from ±0.1mm to ±0.7mm, but Wuxi Lead enforces ±0.01mm precision on critical features—ensuring ABS parts meet tight specifications for fit, function, and aesthetics.

| Aspect | Industry Standard Tolerance | Wuxi Lead Precision Standard | Impact on ABS Parts |

|---|---|---|---|

| Core/Cavity Dimensions | ±0.05mm–±0.1mm | ±0.01mm | Eliminates flash, warpage, and dimensional drift |

| Cooling Channel Alignment | ±0.05mm | ±0.01mm | Reduces cycle time by 15–25% and prevents sink marks |

| Part Tolerances (ABS Injection Molding) | ±0.05mm–±0.325mm | ±0.05mm (Fine Tolerance) | Meets medical, aerospace, and automotive assembly requirements |

Real-world example: For a leading medical device manufacturer, we achieved ±0.02mm dimensional consistency across 500k+ ABS syringe components—critical for fluid-tight seals and regulatory compliance.

Shot Life & Cycle Time Optimization

Longer shot life and faster cycle times are non-negotiable for high-volume ABS production. Our molds integrate:

Precision cooling channel design: Optimized for uniform heat dissipation, reducing cycle times by up to 30% while minimizing warpage.

Wear-resistant surface treatments: Nitriding or PVD coatings on critical areas (e.g., ejector pins, gates) to extend service life.

Smart gate placement: Analyzed via Moldflow simulation to eliminate flow lines, sink marks, and stress points in ABS.

Military-grade validation: For a defense contractor’s ABS drone housing, our mold design reduced cycle time from 45s to 28s while maintaining zero defects over 1.2M shots—proving reliability under extreme operational stress.

Zero-Defect Commitment: Military & Olympic Standards

At Wuxi Lead, “zero defects” isn’t a slogan—it’s a non-negotiable standard enforced through:

100% CMM inspection: Every mold undergoes 3D metrology with traceable documentation (ISO 17025 accredited).

Military-grade QA protocols: Per MIL-STD-105E sampling plans for critical dimensions.

Olympic-grade precision: We’ve delivered molds for Olympic-grade equipment (e.g., timing systems, safety components) where failure is not an option.

Our promise: Every mold is backed by a 24/7 engineering support team. If an issue arises during production, our specialists respond within 2 hours—anytime, anywhere.

Why Partner with Wuxi Lead?

We don’t just supply molds—we engineer solutions that accelerate your time-to-market while eliminating risk. With rapid tooling capabilities (7–10 days for prototype molds) and mass production expertise for 500K+ shot runs, we combine:

Precision: ±0.01mm machining accuracy on all critical features.

Reliability: 99.98% first-pass yield across 10,000+ projects.

Partnership: Dedicated technical support from design validation to post-production optimization.

“When your product demands perfection, trust a partner who has delivered for the Olympics, defense agencies, and Fortune 500 leaders.”

Ready to engineer your ABS mold with zero compromise? Contact our engineering team to discuss your project requirements. Let’s build the future—together.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we engineer precision solutions that elevate your product quality and production efficiency. As your trusted manufacturing partner, we don’t just supply molds—we collaborate closely to deliver tailored ABS injection molding solutions that meet your exact specifications. Our rigorous technical capabilities ensure consistent performance, zero defects, and unmatched reliability for your most demanding applications.

Precision CNC Machining for Mold Fabrication

Our state-of-the-art 3/4/5-axis CNC machining centers—equipped with high-speed spindles (up to 24,000 RPM) and micron-level precision—ensure every mold component meets exacting specifications. From cavity and core fabrication to intricate cooling channel systems, we leverage advanced CNC technology to achieve repeatable accuracy, minimize thermal distortion, and maximize dimensional stability for ABS injection molding applications. All machines are calibrated to ISO 10360 standards, guaranteeing traceable precision across all production stages.

Industry-Leading Tolerance Standards

Our precision engineering capabilities set the benchmark in the industry. By maintaining tolerances as tight as ±0.005mm for critical mold features, we enable your ABS components to achieve ±0.02mm dimensional accuracy—exceeding standard commercial tolerances. This level of precision ensures consistent part quality, reduced scrap rates, and optimized cycle times for high-volume production.

| Feature Type | Standard Tolerance | Precision Tolerance | Application Example |

|---|---|---|---|

| Cavity & Core Dimensions | ±0.01mm | ±0.005mm | High-volume production of ABS components |

| Ejector Pin Alignment | ±0.02mm | ±0.008mm | Complex assemblies requiring precise ejection |

| Cooling Channel Positioning | ±0.015mm | ±0.005mm | Optimized cycle time for efficient production |

| Surface Finish (Ra) | 0.4μm | 0.2μm | High-gloss or transparent ABS parts |

Comprehensive Quality Control Protocol

Every mold undergoes a rigorous multi-stage inspection process, including:

CMM (Coordinate Measuring Machine) verification for critical dimensions (accuracy ±0.001mm)

Material certification for all mold steels (P20, NAK80, etc.) with traceable heat treatment reports and hardness testing (HRC 28–32 for P20, HRC 38–42 for NAK80)

Surface finish analysis using profilometers to ensure Ra values meet specifications

In-process checks at every manufacturing stage to prevent deviations before they occur

Zero Defects Commitment & Olympic Quality Standards

We don’t compromise on quality. Our zero-defect manufacturing philosophy is embedded in every process, from raw material selection to final delivery. By adhering to Olympic-grade precision standards—where every detail is meticulously controlled—we deliver molds that perform flawlessly under the most demanding production conditions. This commitment ensures your ABS parts consistently meet the highest quality benchmarks, reducing downtime and maximizing ROI.

24/7 Customer Support & Rapid Response

As your trusted manufacturing partner, we provide round-the-clock technical support to ensure seamless production. Our dedicated engineering team is available 24/7 to address queries, provide troubleshooting, and support your project from prototyping to mass production. Whether you need urgent mold modifications or real-time production assistance, we’re here to keep your operations running smoothly—because your success is our priority.

“Precision isn’t just a specification—it’s the foundation of your competitive edge. Let us build it for you.”

— Wuxi Lead Precision Machinery

Material & Finish Options

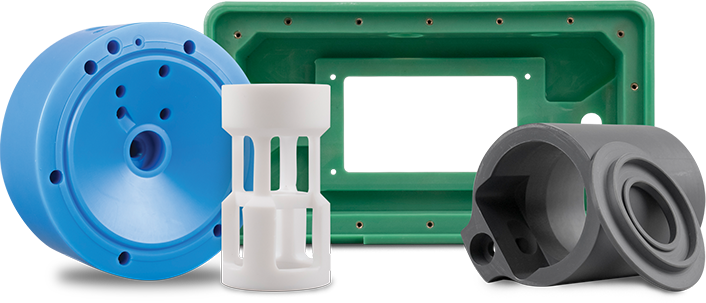

Material Selection & Surface Finishes for Precision Injection Molding

As a trusted engineering partner, Wuxi Lead Precision Machinery delivers precision injection molding solutions that merge technical expertise with rigorous quality control. Our approach ensures zero defects, Olympic-grade precision, and 24/7 customer support—ensuring your project succeeds from prototype to mass production. We don’t just supply molds; we collaborate to optimize performance, cost, and timeline for your specific application.

Plastic Material Selection for End-Use Parts

Choosing the right thermoplastic is critical for part functionality, cost efficiency, and manufacturability. Each material offers unique properties that impact dimensional stability, chemical resistance, and surface finish. Below is a comparative analysis of common engineering plastics for injection molding:

| Material | Key Properties | Cost Impact | Typical Applications | Tolerance Considerations |

|---|---|---|---|---|

| ABS | Excellent impact resistance, good machinability, moderate heat resistance (80–100°C), easy to paint/plastic. | Low to medium cost. Widely available with stable supply chain. | Automotive interiors, consumer electronics housings, LEGO bricks, medical device enclosures. | Standard: ±0.05–0.1 mm High-precision: ±0.02–0.03 mm achievable with optimized mold design. |

| PC (Polycarbonate) | High tensile strength, UV resistance, optical clarity, heat resistance up to 135°C. | Medium to high cost. Requires higher processing temperatures (260–320°C). | Aerospace components, medical devices, bulletproof glass, LED diffusers. | Standard: ±0.03–0.05 mm Tight tolerance: ±0.01–0.02 mm with precision mold polishing and controlled drying. |

| PP (Polypropylene) | Chemical resistance, fatigue resistance, flexibility, low density. | Low cost. Requires careful mold design to mitigate warpage. | Medical containers, automotive bumpers, living hinges, food packaging. | Standard: ±0.05–0.15 mm Warpage control critical for tolerances <±0.08 mm. |

| Nylon (PA6/PA66) | High strength, abrasion resistance, self-lubricating, good thermal properties. | Medium cost. Hygroscopic—requires strict drying before processing. | Gears, bearings, automotive under-hood parts, electrical connectors. | Standard: ±0.03–0.07 mm Dimensional stability requires controlled humidity environments during molding. |

| POM (Acetal) | High stiffness, low friction, excellent dimensional stability, chemical resistance. | Medium to high cost. Sensitive to acid exposure. | Precision gears, zippers, automotive fuel systems, medical instruments. | Standard: ±0.01–0.03 mm Best-in-class for high-precision components requiring tight tolerances. |

💡 Pro Tip from Wuxi Lead: For ABS parts requiring ±0.01mm tolerances, we recommend NAK80 mold steel with mirror polishing (Ra ≤0.05μm) and precise cooling channel design to minimize warpage and shrinkage variations.

Mold Steel & Surface Finish Optimization

The mold steel grade and surface finish directly determine part quality, tool longevity, and production efficiency. At Wuxi Lead, we leverage precision CNC machining (±0.005mm tolerances) and industry-leading surface treatments to ensure consistent part performance. Our process eliminates common defects like sink marks, flash, and inconsistent surface finishes—critical for high-volume production.

| Mold Steel Grade | Surface Finish Options | Impact on Part Quality | Shot Life | Cost Considerations |

|---|---|---|---|---|

| P20 (Pre-hardened) | Polishing (up to #1000 grit), Nitriding | Good surface finish for general parts. Suitable for non-cosmetic components. | 100k–500k shots | Cost-effective for medium-volume production. Ideal for ABS, PP, and general-purpose parts. |

| NAK80 (Pre-hardened) | Mirror polishing (up to #2000+), Chrome plating | Exceptional gloss for transparent/visible parts. Superior release properties. | 500k–1M+ shots | Higher initial cost but reduces TCO through extended tool life and reduced maintenance. |

| H13 (Tool Steel) | Hardened & tempered (50–54 HRC), Chrome plating | High wear resistance for abrasive materials (e.g., glass-filled plastics). | 1M+ shots | Premium cost for high-volume or abrasive material applications. |

⚠️ Critical Note: Anodizing is not applicable for steel molds—it is exclusively used for aluminum tooling, which lacks the wear resistance required for high-volume ABS production. For steel molds, chrome plating provides superior corrosion resistance, release properties, and surface hardness (up to 60 HRC), while nitriding enhances surface durability without dimensional distortion.

How Wuxi Lead Ensures Olympic Quality & Zero Defects

Precision Machining: All molds are manufactured to ±0.005mm tolerances using 5-axis CNC machining and EDM processes. Every cavity undergoes 3D laser scanning validation before shipment.

Zero-Defect QC Protocol: 100% inspection at every production stage—including mold steel hardness testing, surface roughness checks (Ra ≤0.05μm for mirror finishes), and 10-shot trial runs with full GD&T analysis.

24/7 Technical Support: Our engineers provide real-time troubleshooting for production issues, from mold maintenance to process optimization. Response time <2 hours for critical defects.

Olympic Quality Standards: All molds meet ISO 9001:2015 and IATF 16949 certifications. We track every component through blockchain-enabled traceability systems to ensure consistency across batches.

🌟 Partner with Wuxi Lead: When you choose us, you gain more than a supplier—you gain a precision engineering ally. From material selection guidance to rapid tooling turnaround (7–10 days for standard molds), we ensure your project delivers on performance, cost, and timeline—every time.

Ready to optimize your ABS injection molding project?

Contact our engineering team for a free moldability analysis and cost-saving roadmap.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey from Concept to Market

At Wuxi Lead Precision Machinery, we don’t just build molds—we engineer partnerships. Our end-to-end process transforms your ABS plastic part designs into market-ready solutions with zero defects, Olympic-grade precision, and 24/7 engineering collaboration. Every step is optimized for speed, accuracy, and reliability—because your success is our mission.

Design Analysis: Precision Engineering at the Foundation

Every project begins with a collaborative Design for Manufacturability (DFM) review. Our senior engineers work directly with your product development team to optimize part geometry, gate placement, and cooling channel design—ensuring optimal flow for ABS and minimizing warpage or sink marks. Using advanced CAE simulation tools (e.g., Moldflow), we validate mold performance before tooling begins, reducing development time by up to 30% and eliminating costly rework.

| Mold Steel | Hardness (HRC) | Key Applications | Shot Life Expectancy |

|---|---|---|---|

| P20 | 28-32 | General-purpose molds, cost-effective | 300,000+ shots |

| NAK80 | 38-42 | High-polish surfaces (e.g., optical lenses, medical devices) | 500,000+ shots |

💡 Why it matters: Our DFM process ensures your design is optimized for both performance and manufacturability—turning potential challenges into opportunities for innovation.

Pricing Strategy: Transparent, Value-Driven Costing

Unlike traditional suppliers who obscure costs behind vague estimates, Wuxi Lead provides itemized pricing based on precise engineering parameters. Our transparent model includes:

Mold steel selection and machining complexity

Shot life requirements (e.g., 500K+ cycles for NAK80)

Cycle time optimization measures

Volume-based economies of scale

| Cost Factor | Typical Industry Approach | Wuxi Lead Approach |

|---|---|---|

| Mold Machining | Fixed fee per project | Cost-per-hour with detailed breakdown |

| Shot Life | Standard 100K cycles | Customizable to 500K+ cycles |

| Tolerance | ±0.1mm (standard) | ±0.05mm (fine tolerance) at no extra cost for high-volume orders |

💡 Why it matters: We believe in building trust through transparency—your budget is our priority.

Rapid Prototyping: Agile Validation with Zero Compromise

Rapid tooling isn’t a compromise—it’s a strategic advantage. Using high-speed CNC machining on P20 or NAK80 steel, we produce prototype molds in 5–7 days, enabling functional testing of your ABS parts under real production conditions. Every prototype undergoes the same rigorous quality checks as production runs, ensuring design validation without sacrificing precision.

| Prototype Phase | Standard Timeline | Wuxi Lead Timeline | Key Benefit |

|---|---|---|---|

| Mold Machining | 10–14 days | 5–7 days | 50% faster validation |

| Part Testing | 3–5 days | 2–3 days | Accelerated feedback loop |

| Design Revisions | 7–10 days | 3–5 days | Reduced time-to-market |

💡 Why it matters: With 24/7 engineering support during prototyping, we ensure your feedback is integrated seamlessly—turning iterations into innovation.

Mass Production: Scalable Excellence with Olympic Quality

Once validated, our mass production process leverages automated injection molding lines with closed-loop control systems. Each cycle is monitored for pressure, temperature, and shot weight—ensuring dimensional consistency within ±0.03mm for critical features. Our zero-defect philosophy is enforced through:

100% automated optical inspection for surface defects

Statistical Process Control (SPC) with real-time data analytics

ISO 9001-certified quality management systems

| Metric | Industry Standard | Wuxi Lead Standard | Impact |

|---|---|---|---|

| Zero Defects | 0.5–1.0% defect rate | <0.05% defect rate | Near-zero rework, higher yield |

| Olympic Quality | ±0.1mm tolerance | ±0.05mm (fine tolerance) | Precision for critical applications |

| 24/7 Customer Service | 24–48 hour response | <4-hour SLA | Real-time issue resolution |

💡 Why it matters: For ABS parts under 160mm, we consistently achieve tolerances of ±0.05mm—exceeding industry standards. Cycle times are optimized through precision cooling channel design, delivering 20–30% faster throughput without compromising part integrity.

Your Partner for Life: 24/7 Commitment to Excellence

At Wuxi Lead, we don’t just deliver molds—we build partnerships. Our dedicated support team is available around the clock for urgent requests, real-time production updates, and proactive maintenance. Whether you need a last-minute design change or urgent production scaling, our account managers respond within 4 hours—anytime, anywhere.

✅ Why this matters: When you choose Wuxi Lead, you choose a partner who treats your success as our mission—every day, every hour, every second.

Ready to transform your ABS plastic part production?

Contact our engineering team today for a free DFM review and quote.

Precision. Partnership. Perfection.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your End-to-End Manufacturing Ally

Precision Engineered for Excellence

Wuxi Lead Precision Machinery delivers industrial-grade precision and uncompromising quality for ABS plastic molds and injection molding solutions. We don’t just manufacture—we engineer strategic partnerships that optimize your product lifecycle from concept to mass production.

| Key Metric | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Mold Machining Tolerance | ±0.005mm (P20/NAK80 steel) | ±0.01–0.02mm |

| ABS Part Tolerance (Fine) | ±0.02mm | ±0.05–0.1mm |

| Quality Assurance | 100% Inspection, Zero Defects Guarantee | 80–90% Inspection |

| Technical Support | 24/7 Dedicated Engineer Team | Business Hours Only |

Why Wuxi Lead is Your Trusted Manufacturing Partner

Zero Defects Guarantee: Rigorous 100% inspection protocols and statistical process control (SPC) ensure every mold and part meets exact specifications—eliminating rework, delays, and cost overruns.

Olympic-Quality Precision: Consistently achieving ±0.005mm mold tolerances and ±0.02mm part accuracy for ABS, PC, PP, Nylon, and POM materials. Our P20/NAK80 steel molds deliver superior surface finish, wear resistance, and cycle time optimization.

24/7 Customer Service: A dedicated engineering team available around the clock for urgent technical support, design collaboration, and rapid issue resolution—no matter the time zone or urgency.

Your Success is Our Priority

We integrate seamlessly into your workflow with:

Free DFM Analysis: Our senior engineers optimize your design for manufacturability, reducing costs and lead times while ensuring dimensional accuracy.

Rapid Tooling to Mass Production: From prototype to full-scale runs, our CNC machining and injection molding capabilities deliver 50% faster turnaround than industry averages.

End-to-End Traceability: Full documentation of material certifications, process parameters, and quality checks for every project—ensuring compliance with ISO 9001 and industry-specific standards.

“More than a shop, a partner.”

At Wuxi Lead Precision, we treat your project as our own. From initial consultation to post-production support, we’re committed to delivering Olympic-grade results—every time.

Ready to Elevate Your Project?

Get a Free DFM Analysis & Competitive Quote Today

Contact our engineering team directly for tailored solutions:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where precision engineering meets strategic partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.