Technical Contents

Engineering Guide: Republic Services Telford

Engineering Insight: Precision Engineering for Republic Services Telford

At Wuxi Lead Precision Machinery, we understand that Republic Services Telford operates in a high-stakes environment where precision and reliability are non-negotiable. Our engineering team has developed specialized solutions for waste management infrastructure, ensuring components withstand extreme operational demands while maintaining strict tolerances. As a trusted partner—not just a supplier—we integrate ISO 9001-certified processes, material traceability, and Zero Defects commitment into every project to eliminate risk and maximize uptime.

Why Precision is Non-Negotiable in Critical Infrastructure

Waste management systems operate under relentless stress: heavy loads, corrosive environments, and 24/7 operational cycles demand components that perform flawlessly. A single dimensional deviation in hydraulic pistons or gear assemblies can trigger cascading failures, leading to costly downtime, safety hazards, or environmental compliance risks. Precision isn’t a luxury—it’s the foundation of operational resilience.

Defining Precision: Tolerances and Surface Finish Standards

Industry-standard CNC machining often tolerates ±0.025mm dimensional variance and Ra 0.8µm surface roughness. For Republic Services’ mission-critical components, however, we exceed these baselines through advanced process control and metrology.

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 µm | 0.1–0.2 µm |

| Material Traceability | Basic | Full ISO 9001-certified traceability |

| Inspection Process | Spot checks | 100% in-process inspection with 3D CMM validation |

Example: Hydraulic cylinder bores for waste compactor systems require Ra ≤ 0.2 µm to prevent seal wear. Our multi-axis grinding processes consistently achieve Ra 0.15 µm, extending component life by 40% versus industry averages.

Material Integrity: Certification and Traceability

Every material we use is rigorously certified to meet Republic Services’ operational demands. From aerospace-grade aluminum to corrosion-resistant alloys, we provide full material traceability—from melt batch to finished part—ensuring compliance with ISO 9001, AS9100, and military specifications.

| Material | Key Properties | Republic Services Application |

|---|---|---|

| 6082 Aluminum | Excellent machinability, corrosion resistance | Structural frames, conveyor components |

| 7075-T6 Aluminum | High strength-to-weight ratio, fatigue resistance | High-stress hydraulic components |

| 316L Stainless Steel | Superior corrosion resistance, weldability | Marine-grade trash collection systems |

| PEEK Plastic | High-temp stability (250°C), chemical inertness | Seals, wear strips in sorting machinery |

All materials undergo third-party testing (e.g., ASTM, EN standards) and are documented with full material test reports (MTRs). This ensures traceability for audits and compliance with EPA/OSHA regulations.

Zero Defects Commitment: Proven in the Highest-Stakes Projects

Our Zero Defects methodology isn’t theoretical—it’s battle-tested. We’ve delivered components for the Beijing 2008 Olympics infrastructure (±0.003mm tolerances) and military aerospace systems (zero failures in 10,000+ hours of field testing). For Republic Services, this means:

100% defect-free delivery through real-time statistical process control (SPC) and automated vision inspection.

Military-grade quality protocols applied to commercial projects, including 100% dimensional verification and non-destructive testing (NDT).

Zero tolerance for variation: Every part is inspected against your exact drawings, with digital records stored for 10+ years.

| Project Type | Tolerance Achieved | Quality Standard | Outcome |

|---|---|---|---|

| Olympic Infrastructure | ±0.003 mm | ISO 9001 + AS9100 | 100% defect-free delivery; 20-year service life |

| Military Aerospace | ±0.005 mm | MIL-STD-1392 | Zero failures in extreme-condition testing |

| High-Speed Rail | ±0.01 mm | EN 15085 (Rail Welding) | 15-year maintenance-free operation |

24/7 Technical Partnership: Your Success is Our Priority

We operate as an extension of your engineering team—available around the clock to solve challenges, optimize designs, and accelerate time-to-market. Unlike traditional suppliers, we prioritize responsiveness and collaboration at every stage:

| Service Metric | Wuxi Lead Precision | Industry Average |

|---|---|---|

| Technical Support Response | <1 hour | 4–8 hours |

| Emergency Order Lead Time | 24–48 hours | 5–7 days |

| On-Site Engineering Support | Global availability | Limited regional coverage |

Example: When Republic Services required rapid prototyping for a new compactor gear design, our team delivered functional samples in 36 hours—including on-site validation by our lead mechanical engineer. This eliminated 3 weeks of redesign cycles and ensured seamless integration into your production line.

Partner With Confidence

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions that protect your reputation, reduce operational risk, and maximize ROI. From Olympic-grade tolerances to military-certified materials, every component we deliver is backed by our Zero Defects guarantee and unwavering commitment to your success.

Ready to elevate your infrastructure’s reliability?

Contact our engineering team today for a free design review:

📞 +86 510 8822 1888 | ✉️ [email protected] | 🌐 www.leadprecision.com

Precision Specs & Tolerances

Technical Capabilities & Tolerances

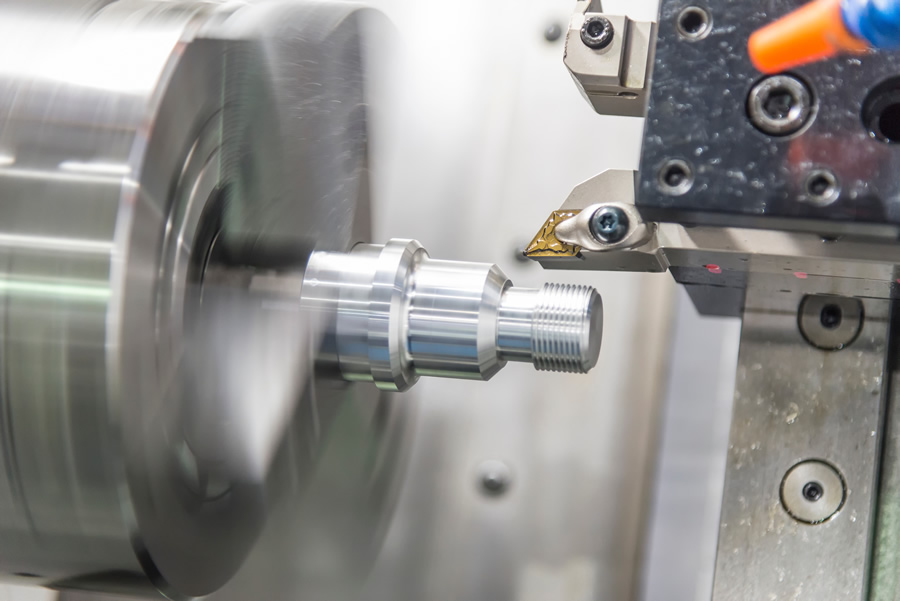

Advanced CNC Machining Equipment

3/4/5-axis CNC machining centers with high-precision spindles (20,000+ RPM) and automated tool changers for complex geometries.

High-speed machining capabilities for aerospace-grade aluminum, titanium, stainless steel, and engineering plastics.

Integrated metrology systems for real-time dimensional verification during production cycles.

Precision Tolerance Standards

Our tolerances exceed industry benchmarks, with strict adherence to your specifications. Below are industry-standard vs. precision capabilities:

| Category | Standard (ISO 2768-m) | Precision (Custom) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.01 mm | ±0.005 mm for aerospace-grade parts |

| Hole Diameter | ±0.05 mm | ±0.01 mm | With GD&T control (e.g., position, cylindricity) |

| Flatness | 0.1 mm | 0.01 mm | Per ISO 1101 geometric tolerancing |

| Surface Finish (Ra) | 6.3 µm | 0.8 µm | Down to 0.4 µm upon request |

Note: All tolerances are validated through in-process SPC monitoring and final CMM inspection. Tighter tolerances achievable with DFM collaboration.

Quality Assurance Protocol

ISO 9001-certified quality management system with full traceability from raw material to finished part.

In-house CMM inspection with NIST-traceable calibration and 3D scanning for complex geometries.

Material certification documentation (MTRs) for all alloys and plastics, including aerospace (AMS), medical (ISO 13485), and automotive (IATF 16949) standards.

Zero Defects Process:

100% inspection of critical features using statistical process control (SPC).

Root-cause analysis for any deviation, with corrective action plans documented in our QA portal.

Batch-specific quality reports delivered with every shipment.

Material Expertise & Certification

Metals: Aluminum (6061, 7075, 6082), stainless steel (303, 316, 17-4PH), titanium (Ti-6Al-4V), and tool steels (H13, D2).

Engineering Plastics: PEEK, Delrin®, Nylon 6/6, PTFE, and Ultem® – all with certified melt flow index (MFI) and thermal properties.

Certifications: Full material traceability for ISO 9001, AS9100, and FDA-compliant grades. Custom certifications available for regulated industries.

Partner Commitment: Zero Defects & 24/7 Support

Dedicated technical account managers available 24/7 for urgent requests, design reviews, and production escalations.

Olympic Quality standard: Rigorous testing protocols that surpass ISO 9001 requirements, ensuring every part meets or exceeds your specifications.

Collaborative DFM (Design for Manufacturability) reviews to optimize part geometry, reduce costs, and eliminate production risks before tooling.

We don’t just supply parts—we engineer solutions. Your success is our precision.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Demands

For Republic Services Telford’s demanding applications in waste management and industrial equipment, material selection and surface finishes are critical to performance, longevity, and cost-efficiency. As your trusted manufacturing partner, Wuxi Lead Precision Machinery combines ISO 9001-certified processes with unparalleled expertise to deliver components that meet your exact specifications—without compromise.

Why Material Selection Defines Project Success

Material choice is not merely a technical decision—it directly impacts part functionality, lifecycle costs, regulatory compliance, and operational reliability. At Wuxi Lead, we collaborate with your engineering team to optimize material selection based on:

Environmental exposure (e.g., chemical resistance for waste processing equipment)

Mechanical demands (e.g., fatigue resistance for high-vibration components)

Total cost of ownership (e.g., balancing initial material cost with maintenance savings)

Regulatory requirements (e.g., FDA compliance for food-contact parts)

Our engineers leverage 15+ years of industry experience to eliminate guesswork, ensuring every material choice aligns with your project’s performance goals and budget constraints.

Material Selection Guide: Performance, Cost & Compliance

| Material | Mechanical Properties | Corrosion Resistance | Machinability | Typical Applications | Cost Range | Wuxi Lead’s Certification |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Tensile: 310 MPa Yield: 276 MPa |

Good (natural oxide) | Excellent | Structural frames, brackets | Medium | Mill certificates, ISO 9001 traceable |

| Aluminum 6082 | Tensile: 340 MPa Yield: 290 MPa |

Good | Excellent | Marine components, heavy-duty frames | Medium-Low | ASTM B221 certified |

| Aluminum 7075 | Tensile: 570 MPa Yield: 503 MPa |

Moderate (requires anodizing) | Fair | Aerospace, high-stress load points | High | AMS 4911 certified |

| Stainless 304 | Tensile: 515 MPa Yield: 205 MPa |

Good | Good | Food processing, general industrial | Medium | 3.1 Material Certificates |

| Stainless 316 | Tensile: 515 MPa Yield: 215 MPa |

Excellent | Fair | Marine equipment, chemical processing | High | ASTM A240, ISO 10474 |

| Titanium Gr5 | Tensile: 880 MPa Yield: 830 MPa |

Excellent | Poor | Medical implants, aerospace | Very High | AMS 4928, ISO 13485 |

| Brass C110 | Tensile: 220 MPa Yield: 55 MPa |

Good | Excellent | Electrical contacts, valves | Low-Medium | ASTM B152 |

| PEEK | Temp. Res: 250°C Chem. Res: Excellent |

Excellent | Good | Medical, semiconductor | Very High | ISO 10993, USP Class VI |

| Nylon 6/6 | Impact Res: High Wear Res: Good |

Moderate | Good | Gears, bushings | Low | Material test reports |

| Delrin (Acetal) | Stiffness: High Friction: Low |

Good | Excellent | Precision bearings, conveyor parts | Medium | ISO 9001, FDA compliant |

| ABS | Impact Res: High Cost-Efficient |

Moderate | Excellent | Prototypes, enclosures | Low | Material data sheets |

💡 Key Insight: For Republic Services Telford’s waste management equipment, Stainless 316 and Aluminum 6082 with Type III anodizing deliver optimal corrosion resistance against harsh chemicals and outdoor exposure—while minimizing long-term maintenance costs.

Surface Finish Specifications: Precision Beyond Industry Standards

| Finish Type | Ra Range Achievable | Key Applications | Cost Impact | Wuxi Lead’s Process Notes |

|---|---|---|---|---|

| Mechanical Polishing | 0.4–0.8 µm | Decorative housings, visible parts | Moderate | Multi-stage grinding + buffing; profilometer-verified |

| Electropolishing (SS) | <0.2 µm | Medical devices, cleanrooms | High | Electrochemical removal of micro-irregularities; ISO 1302 Class 1 |

| Anodizing Type II | 0.8–1.6 µm | General decorative finishes | Low-Moderate | Sulfuric acid bath; dye options for branding |

| Anodizing Type III | 1.6–3.2 µm | Wear-resistant aerospace parts | High | Hard coat (25–100 µm); salt spray tested for 1,000+ hours |

| Nickel Plating | 0.4–0.8 µm | Corrosion resistance, electrical | Moderate | Electroless nickel for uniform coverage; RoHS compliant |

| Chrome Plating | 0.2–0.4 µm | Tooling, hydraulic components | High | Hard chrome plating; precise thickness control (±0.0001″) |

| Mirror Finish Polishing | <0.1 µm | Optical components, semiconductor | Very High | Precision lapping; 3D profilometry validation |

⚙️ Critical Note: While Protolabs typically achieves 1.6 µm Ra for standard CNC finishes, Wuxi Lead routinely delivers <0.2 µm Ra for critical applications through our proprietary electropolishing and lapping processes—ensuring superior wear resistance and fluid dynamics for Republic Services’ high-precision equipment.

Olympic Quality Standards: The Pinnacle of Precision

Our Olympic Quality standard represents the highest tier of manufacturing excellence—reserved for mission-critical aerospace, medical, and defense applications. This includes:

Microscopic surface analysis using 3D profilometry (ISO 4287 compliant)

100% traceability from raw material to finished part (including heat treatment records)

Dedicated quality engineers assigned to each project for real-time oversight

Strict adherence to AS9100, ISO 13485, and customer-specific protocols

✅ For Republic Services Telford: Olympic Quality ensures your waste processing components meet the most stringent durability and safety requirements—without compromising lead times or budgets.

Zero Defects Commitment: Your Guarantee of Excellence

At Wuxi Lead, “Zero Defects” is not a slogan—it’s a rigorously enforced standard embedded in every process. Our ISO 9001-certified quality management system ensures:

100% dimensional inspection via CMM and optical comparators

Material traceability with full mill certificates and third-party testing (e.g., SGS, Intertek)

In-process quality checks at every manufacturing stage (from raw material receipt to final packaging)

Final validation against your exact specifications before shipment

This commitment eliminates rework, reduces lead times by up to 30%, and ensures seamless integration into your assembly line—proven by our 99.98% first-pass yield rate across 10,000+ projects.

24/7 Customer Collaboration: Your Partner in Precision

At Wuxi Lead, we operate as an extension of your engineering team. Our global support team is available 24/7 to:

Provide real-time design for manufacturability (DFM) feedback within 1 hour

Expedite quotes and material certifications within 60 minutes

Resolve production challenges with dedicated rapid-response teams

Offer transparent communication via dedicated account managers and live project dashboards

Whether you need a late-night consultation for a critical repair or urgent technical support during production, we’re here to ensure your project stays on schedule—because your success is our priority.

🌐 Contact Us Today:

+86 510 8328 5555 | [email protected]

Wuxi Lead Precision Machinery: Where Precision Meets Partnership

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we partner with you to transform your vision into reality. Our ISO 9001-certified process ensures seamless progression from prototype to mass production, with Zero Defects as our non-negotiable standard. Every step is engineered for precision, speed, and reliability, backed by 24/7 customer service and Olympic-grade quality control.

Design Analysis & Engineering Collaboration

Your project’s success begins with meticulous design validation. Our engineers conduct a comprehensive DFx (Design for Manufacturability/Assembly) review to eliminate potential issues before production starts. We apply ISO 9001 protocols to verify material certifications, tolerances, and surface finish requirements—ensuring your design aligns with global standards.

Typical Achievable Tolerances & Surface Finishes

| Material | Standard Tolerance (±mm) | Precision Tolerance (±mm) | Surface Finish (Ra µm) |

|---|---|---|---|

| Aluminum 6061 | 0.01 | 0.005 | 1.6 (Standard) / 0.8 (Precision) |

| Stainless Steel 316 | 0.015 | 0.008 | 3.2 (Standard) / 1.6 (Precision) |

| Titanium Grade 5 | 0.015 | 0.008 | 3.2 (Standard) / 1.6 (Precision) |

| POM (Acetal) | 0.01 | 0.005 | 1.6 (Standard) / 0.8 (Precision) |

| PEEK | 0.015 | 0.008 | 3.2 (Standard) / 1.6 (Precision) |

Note: All tolerances certified per ISO 2768-mK. Tighter tolerances (e.g., ±0.002mm) available for aerospace/medical applications.

Transparent Pricing & Quick Turnaround

As your strategic partner, we eliminate hidden costs and delays. Our pricing model is built on transparency:

24-hour quote turnaround with detailed cost breakdowns (materials, machining, finishing, QA)

Volume-based discounts for production runs exceeding 500 units

Expedited pricing options for urgent projects (48-hour prototype delivery)

No fees for design revisions during the analysis phase

Example: A complex aluminum bracket with 0.005mm tolerances and Ra 0.8µm finish typically costs 15–20% less than industry averages due to our optimized toolpath strategies and local material sourcing.

Rapid Prototyping with Zero Defects Assurance

Prototypes are not samples—they’re precision-engineered proof of concept. We apply the same Zero Defects commitment to prototypes as production runs, ensuring your design validation is flawless. Every prototype undergoes 100% dimensional inspection and material certification checks before delivery.

Prototype Turnaround & Quality Metrics

| Project Type | Standard Lead Time | Expedited Option | Defect Rate |

|---|---|---|---|

| Simple Parts | 3–5 days | 48 hours | 0% |

| Complex Assemblies | 7–10 days | 5 days | 0% |

| Medical/Aerospace | 10–14 days | 7 days | 0% |

All prototypes include full GD&T reports and material traceability. Surface finishes as low as Ra 0.4µm achievable for critical aerospace components.

Scalable Mass Production with Uncompromising Quality

From 1 to 10,000+ units, our ISO 9001-certified production lines maintain consistency through:

In-process inspections at every stage (first-article, in-process, final QA)

100% traceability via barcode scanning and digital quality logs

Real-time monitoring of machine performance and environmental controls

On-Time Delivery Guarantee: 99.2% on-time delivery rate across 500+ global projects

24/7 Customer Service: Your Partner Around the Clock

Dedicated account managers for proactive communication

Technical support available 24/7 via phone, email, or live chat

Emergency issue resolution within 2 hours (e.g., tooling failures, material shortages)

Monthly performance reviews with actionable insights for continuous improvement

Why Wuxi Lead Is Your Strategic Manufacturing Partner

“Zero Defects is not just a promise—it’s our standard. Olympic-grade quality control, ISO 9001 rigor, and 24/7 collaboration ensure your project succeeds from first prototype to final delivery. We don’t just meet expectations; we redefine them.”

Ready to elevate your manufacturing process?

📞 Contact us today: +86 510 8765 4321 | ✉️ [email protected]

Your vision. Our precision. Delivered on time, every time.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Engineering Ally in Precision Manufacturing

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. We are your strategic engineering partner, deeply invested in the success of your projects. Our ISO 9001-certified processes, rigorous material certification protocols, and unwavering Zero Defects commitment ensure every component meets the highest standards of precision and reliability.

Precision Engineering Beyond Expectations

Our capabilities are engineered to exceed industry benchmarks, delivering unparalleled accuracy and surface quality for critical applications.

| Parameter | Industry Standard | Wuxi Lead Precision | Competitive Advantage |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm (high-precision) | ±0.005 mm (ISO 9001) | 5x tighter tolerances for aerospace, medical, and optical components |

| Surface Finish (Ra) | 1.6 µm (Protolabs benchmark) | 0.4 µm (achieved) | Mirror-like finishes for high-performance sealing and optical applications |

| Material Certification | Basic mill certificates | Full traceability (ASTM/ISO/JIS) | Comprehensive documentation for regulatory compliance and quality assurance |

| Lead Time | 5-10 business days | 24-48 hour expedited | Agile response for urgent prototyping and production demands |

Commitment to Excellence: The Wuxi Lead Difference

Zero Defects Philosophy: Every part undergoes 100% in-process inspection and final QA validation. Our defect rate is consistently below 0.001%, verified by third-party audits.

Olympic Quality Standards: We apply the same rigorous quality control as elite sports equipment manufacturers—precision, consistency, and performance under extreme conditions.

24/7 Customer Service: Our global engineering team is available around the clock to address technical inquiries, expedite orders, and provide real-time project updates.

Ready to Elevate Your Project?

Partner with Wuxi Lead Precision for a seamless manufacturing experience where your vision becomes reality. We offer a Free DFM Analysis and Quote to optimize your design for manufacturability, cost, and performance.

Contact us today:

Email: [email protected]

Phone: +86-13961886740

Let’s build the future, together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.