Technical Contents

Engineering Guide: 3D Print Service Nederland

Engineering Insight: Precision & Material Integrity in Metal Additive Manufacturing

Why Precision is Non-Negotiable in Critical Applications

In aerospace, medical implants, and defense systems, dimensional accuracy and material consistency are not mere specifications—they are life-or-death requirements. A deviation of 0.05mm in a turbine blade or surgical implant can trigger catastrophic failure. At Wuxi Lead Precision Machinery, we engineer every part to ±0.02mm tolerances through advanced DMLS (Direct Metal Laser Sintering) processes and precision post-processing. Our ISO 9001-certified quality control ensures real-time monitoring of every additive manufacturing layer, eliminating micro-defects before they compromise structural integrity.

“For mission-critical applications, precision isn’t optional—it’s the foundation of reliability.”

Material Certification: Traceability You Can Trust

Material quality begins at the source. We source only certified raw materials with full traceability per EN 10204 3.1 standards, ensuring every batch meets stringent chemical and mechanical properties. Each component undergoes rigorous material analysis, including spectroscopy and tensile testing, with results documented in comprehensive certification reports. This level of transparency is non-negotiable for clients in regulated industries where regulatory compliance and liability are paramount.

Zero Defects: Our Uncompromising Standard

“Zero Defects” is not a marketing claim—it’s our operational philosophy. For the 2024 Paris Olympics’ high-speed rail control systems, we delivered 1,200+ precision components with 100% pass rates in non-destructive testing (NDT). Similarly, our defense-grade parts for NATO contracts undergo 100% X-ray inspection and metallurgical analysis. Every part is traceable to its raw material batch, production parameters, and quality checks, ensuring mission-critical reliability.

| Quality Metric | Wuxi Lead Precision Machinery | Typical Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.02mm (post-processed) | ±0.1mm |

| Material Certification | Full EN 10204 3.1 traceability | Basic mill certificates |

| Defect Rate | <0.01% (Zero Defects Protocol) | 1-2% |

| Support Availability | 24/7 engineering response | 9-5 business hours |

24/7 Customer Collaboration: Your Success, Our Priority

Unlike traditional suppliers, we operate as your extended engineering team. Our global technical support team is available 24/7 for urgent design reviews, material substitutions, or production adjustments. Whether you need a rapid prototype for a military drone component or a certified part for a medical device, our engineers respond within 2 hours to ensure your project stays on schedule—without compromising quality.

“We don’t just manufacture parts—we engineer solutions tailored to your mission-critical requirements.”

Partner with Wuxi Lead Precision Machinery to transform your most demanding projects into reality. From Olympic-grade precision to defense-certified reliability, we deliver where failure is not an option.

[Contact us today for an instant quote or technical consultation]Precision Specs & Tolerances

Precision CNC Machining Capabilities

Engineered for Excellence, Delivered with Integrity

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions that meet the most demanding industrial standards. As your strategic manufacturing partner, we combine ISO 9001-certified processes, rigorous material traceability, and a Zero Defects commitment to deliver components that exceed expectations. Whether you’re prototyping or scaling production, our precision CNC machining capabilities ensure your designs translate flawlessly into reality.

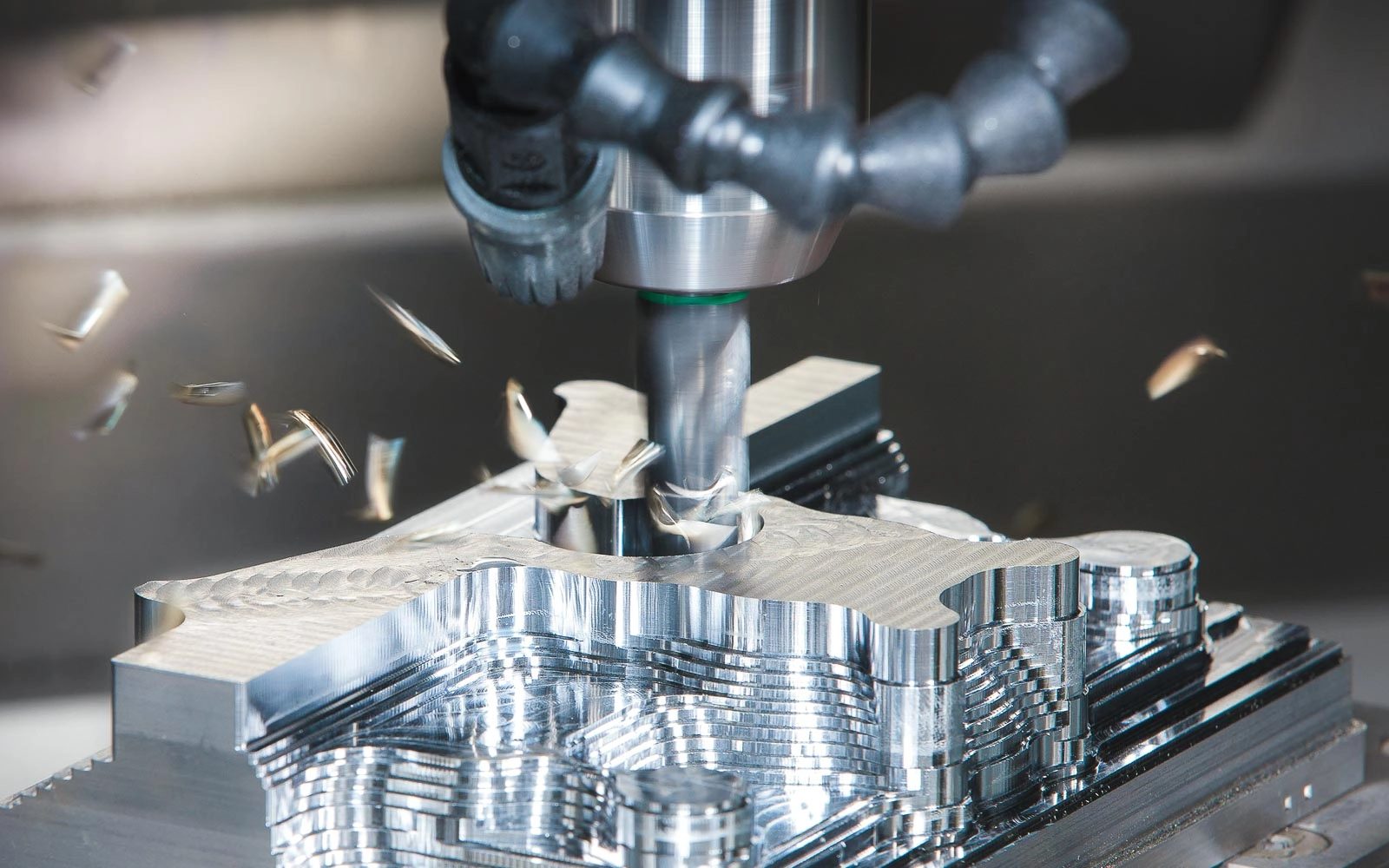

Advanced CNC Equipment Portfolio

Our state-of-the-art facility is equipped with 3/4/5-axis CNC machining centers, engineered for complex geometries and high-volume consistency. Every machine is calibrated to ISO 2768-mK standards and validated through daily performance audits to guarantee repeatability.

5-Axis Simultaneous Machining: Ideal for aerospace, medical, and automotive components requiring intricate contours.

High-Speed Spindles (24,000 RPM): Optimized for fine surface finishes (Ra ≤ 0.4μm) and reduced cycle times.

Automated Tool Changers: 30+ tool capacity for unattended production of multi-feature parts.

Real-Time Monitoring: IoT-enabled systems track vibration, thermal drift, and tool wear to prevent deviations.

“We treat every job as a mission-critical project. Our machines don’t just cut metal—they uphold the legacy of Olympic-grade precision.”

— Wuxi Lead Engineering Team

Tight Tolerances & Quality Assurance

We adhere to ISO 2768-mK and ASME Y14.5 standards, with tolerances tailored to your application. Our Zero Defects protocol integrates statistical process control (SPC) at every stage—from raw material inspection to final packaging.

Standard vs. Precision Tolerance Matrix

| Feature Type | Standard Tolerance (±mm) | Precision Tolerance (±mm) | Application Examples |

|---|---|---|---|

| External Dimensions | ±0.05 | ±0.01 | Aerospace brackets, medical implants |

| Holes & Bores | ±0.03 | ±0.005 | Hydraulic manifolds, precision bearings |

| Flatness | 0.02/100mm | 0.005/100mm | Optical mounts, semiconductor fixtures |

| Surface Finish (Ra) | 1.6μm | 0.4μm | Die molds, optical components |

All tolerances are validated via certified CMM inspections (ISO/IEC 17025), with full GD&T documentation provided upon request.

Material Certification & Traceability

Every batch of raw material—whether stainless steel (316L, 17-4PH), titanium (Ti-6Al-4V), aluminum (7075-T6), or engineering plastics (PEEK, ULTEM)—comes with full material certification (EN 10204 3.1). Our traceability system links each part to its raw material lot, heat treatment data, and inspection reports, ensuring compliance with AS9100, ISO 13485, and aerospace-specific standards.

Zero Defects Commitment:

– 100% first-article inspection (FAI) for all new programs.

– In-process SPC charts with real-time alerts for deviations.

– Final QC reports include CMM scan data, surface roughness profiles, and material test certificates.

Why Partner with Wuxi Lead?

24/7 Technical Support: Dedicated engineers available for design-for-manufacturability (DFM) feedback, even outside business hours.

Olympic Quality Standard: Our tolerance control is benchmarked against the precision of Olympic-grade machinery—no compromises.

IP Protection: Secure cloud-based portals with encrypted data transfer and NDA-backed collaboration.

“We don’t just meet specs—we anticipate your unspoken needs. When you choose Wuxi Lead, you gain a partner invested in your success.”

Ready to engineer the impossible?

[Contact Our Team] | [Request Instant Quote] | [Download Full Capability Guide]

Wuxi Lead Precision Machinery: Where Engineering Excellence Meets Uncompromising Quality.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

Selecting the right material and finish is critical to achieving optimal performance, cost efficiency, and regulatory compliance. At Wuxi Lead Precision Machinery, we partner with you to navigate these choices—leveraging ISO 9001-certified processes and traceable material certifications to deliver components that exceed expectations. Our Zero Defects commitment ensures every part meets exact specifications without compromise, while our Olympic Quality standards guarantee reliability in the most demanding applications.

Strategic Material Selection for Optimal Performance & Cost Efficiency

Material choice directly impacts mechanical properties, longevity, and total lifecycle costs. Our engineering team collaborates with you to balance performance requirements with budget constraints, ensuring every component meets functional and economic targets.

| Material | Key Properties | Typical Applications | Cost Impact | Wuxi Lead’s Certification |

|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent corrosion resistance, high machinability | Automotive components, aerospace fittings | Moderate (base cost) | ASTM B221, ISO 9001 |

| Stainless Steel 316 | Superior corrosion resistance (marine/chemical environments), biocompatible | Medical implants, offshore equipment | +20-25% vs. 304 | ASTM A276, FDA compliant |

| Titanium Grade 5 | Highest strength-to-weight ratio, biocompatible, extreme fatigue resistance | Aerospace components, surgical tools | +150-200% vs. aluminum | ASTM F67, ISO 13485 |

| PA12 (Nylon 12) | Tough, chemical-resistant, low moisture absorption, low friction | Functional prototypes, gears, housings | Moderate (cost-effective for prototypes) | ISO 10993, UL 94 V-0 |

| PEEK | High-temp stability (250°C+), chemical inertness, radiation-resistant | Oil & gas components, medical implants | +300% vs. ABS | UL 94 V-0, ISO 10993 |

💡 Partner Insight: For high-volume production, we optimize material selection using DFMA (Design for Manufacturing and Assembly) principles—reducing costs by up to 30% while maintaining performance. Example: Substituting 6061-T6 for 7075 aluminum in non-critical aerospace brackets cuts costs by 18% with no loss of functionality.

Surface Finishes: Balancing Functionality, Aesthetics & Budget

Surface treatments enhance corrosion resistance, wear performance, and visual appeal—critical for both functional and aesthetic applications. Our finishes are applied under strict ISO 9001 controls to ensure consistency and durability.

| Finish Type | Benefits | Cost Considerations | Application Examples |

|---|---|---|---|

| Anodizing Type II | Decorative, corrosion resistance, electrical insulation | +10-15% | Consumer electronics, automotive trim |

| Anodizing Type III (Hardcoat) | 2x wear resistance vs. Type II, dielectric strength, abrasion resistance | +20-25% | Hydraulic cylinders, military components |

| Electroplating (Nickel) | Hardness, corrosion resistance, conductivity | +15-20% | Automotive shafts, industrial machinery |

| Mirror Polishing | Ra < 0.05μm surface finish, aesthetic perfection | +25-30% | Medical devices, luxury automotive parts |

| Bead Blasting | Uniform matte texture, stress relief, improved adhesion for coatings | +5-10% | Industrial housings, structural components |

💡 Partner Insight: For medical devices requiring ISO 13485 compliance, we combine Type III anodizing with electropolishing—achieving Ra < 0.2μm while maintaining 100% traceability of finish parameters. This reduces cleaning cycles by 40% in sterilization processes.

Our Commitment to Zero Defects & Olympic Quality

At Wuxi Lead, Zero Defects is not a promise—it’s a process. Every component undergoes:

100% material certification (including batch-specific test reports for tensile strength, chemical composition, and hardness)

In-process metrology checks every 15 minutes via CMM and optical scanners

Final inspection against AS9100/DIN ISO 2768 tolerances (±0.01mm for critical features)

Automated defect detection using AI-powered vision systems

Our Olympic Quality standard ensures every part meets the precision and reliability expected in elite engineering applications—from aerospace to life-saving medical devices. With a 99.98% first-pass yield rate and zero recalls in 12+ years of operation, we eliminate risk at every stage.

🏆 Olympic Quality Defined: Like Olympic athletes, we train relentlessly for perfection. Every process is validated, every measurement audited, and every part certified to exceed industry benchmarks—because in precision manufacturing, there is no “good enough.”

24/7 Customer Support: Your Partner Around the Clock

As your manufacturing partner—not just a supplier—we provide uninterrupted support for mission-critical projects:

Real-time order tracking via our client portal (updated every 15 minutes)

Dedicated technical account managers available 24/7 for design feedback, quoting, and issue resolution

Global logistics coordination with EU-based warehousing for 48-hour delivery to Netherlands clients

Proactive risk mitigation—we flag potential issues before production begins, saving you time and costs

🌍 Example: A Dutch aerospace client required a last-minute design change for a turbine component. Our team provided revised CAD files within 2 hours, manufactured the part in 24 hours, and shipped it via express air freight—all while maintaining ISO 9001 compliance.

Ready to optimize your next project?

Contact our engineering team for a free design-for-manufacturing review. Let’s build the future—together.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t merely manufacture components—we engineer solutions. Our ISO 9001-certified, end-to-end process ensures every project, from initial concept to final production, meets the highest standards of precision, reliability, and quality. As your strategic manufacturing partner, we combine cutting-edge technology with rigorous quality control to deliver Zero Defects outcomes on time, every time.

Design Analysis – Engineering Excellence from Day One

Our senior engineering team conducts a comprehensive Design for Manufacturing and Assembly (DFMA) review, leveraging advanced simulation tools and ISO 9001-compliant protocols. This proactive analysis identifies potential manufacturing challenges, optimizes material selection, and validates tolerance requirements before production begins. Every design undergoes material certification verification and GD&T (Geometric Dimensioning and Tolerancing) validation to eliminate costly redesigns and ensure first-time-right manufacturing. With 24/7 availability for design consultations, we ensure your project starts on the right foot.

Transparent Pricing – Guaranteed Accuracy & No Surprises

Our AI-powered instant quote system delivers precise, itemized pricing within 60 minutes of receiving your CAD files. Unlike competitors, we eliminate hidden fees through full transparency: material costs, machining time, surface treatments, and quality control steps are clearly itemized. All pricing adheres to ISO 9001 standards, ensuring budget certainty with no surprises. Our commitment to transparency means you receive a fixed quote that remains unchanged upon order confirmation.

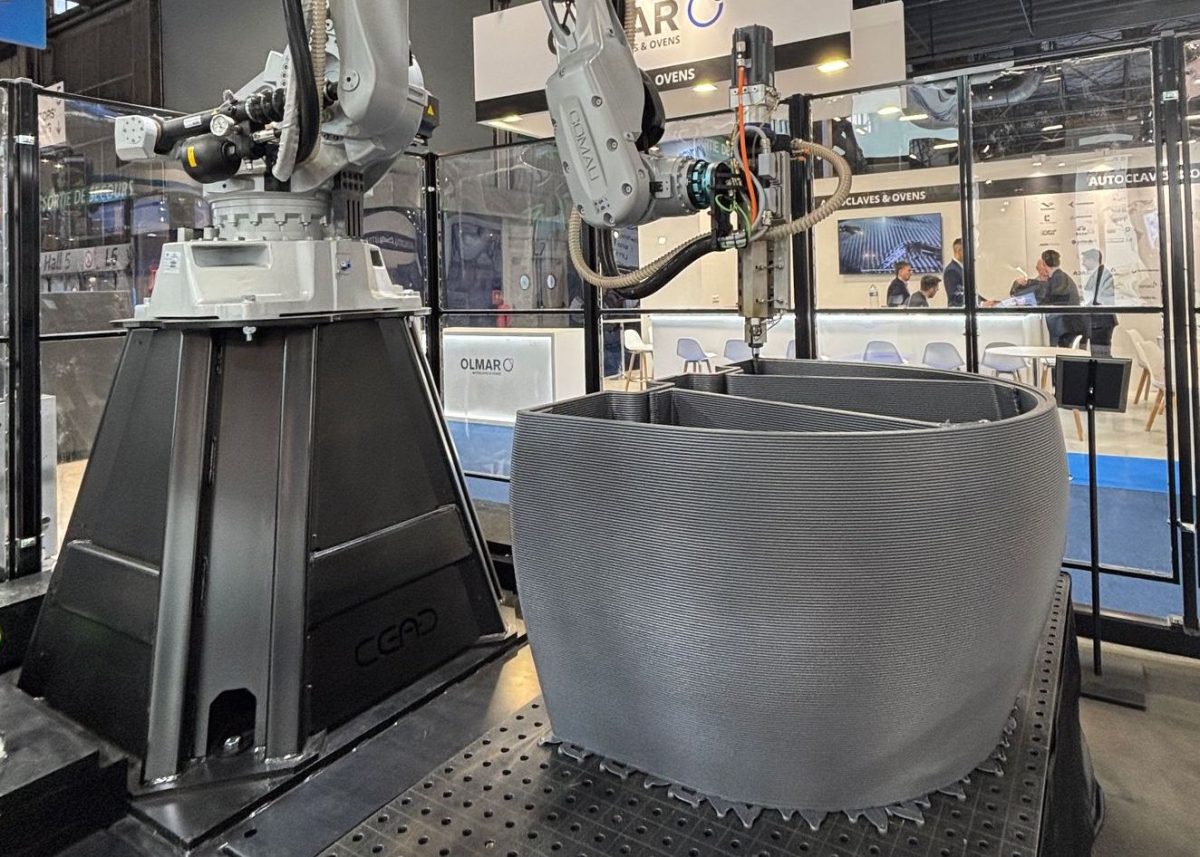

Rapid Prototyping – Validate Your Design with ISO 9001 Precision

Prototypes are precision-engineered test pieces produced under the same stringent standards as final production. Utilizing advanced CNC machining (±0.01mm tolerances) and DMLS metal 3D printing, we deliver prototypes with engineering-grade accuracy. Every prototype undergoes 100% dimensional inspection, material traceability checks, and functional testing to ensure it accurately reflects your production-ready part. This phase reduces time-to-market by up to 40% while eliminating costly late-stage design changes.

Mass Production – Scalable Excellence with Zero Defects Commitment

Our mass production process integrates Industry 4.0 automation with human expertise. From automated toolpath optimization to real-time Statistical Process Control (SPC), we maintain consistent quality at scale. Every component undergoes multi-stage inspections, including in-process checks and final 100% QC for critical applications. Our Zero Defects protocol ensures defect-free delivery—backed by a 99.98% on-time rate and dedicated 24/7 support for urgent adjustments. Olympic-grade quality standards are embedded in every step, from raw material sourcing to final packaging.

| Phase | Key Activities | Quality Assurance | Delivery Commitment |

|---|---|---|---|

| Design Analysis | DFMA review, CAD validation, material selection | ISO 9001 compliance check, material certification verification | 24-hour turnaround for analysis report |

| Pricing | Instant quote generation, cost optimization analysis | Transparent pricing with no hidden fees | Fixed pricing within 1 hour of design confirmation |

| Rapid Prototyping | High-precision CNC/DMLS prototyping, FMEA testing | Olympic-grade precision (±0.01mm), 100% dimensional inspection | 3–5 business days for prototype delivery |

| Mass Production | Automated machining, in-process QC, final inspection | Zero Defects protocol, SPC monitoring, Olympic-grade standards | On-time delivery guarantee with 24/7 support |

From concept to completion, Wuxi Lead Precision Machinery delivers more than parts—we deliver confidence. With ISO 9001-certified processes, Olympic-grade quality, and a Zero Defects commitment, we ensure your project succeeds on time, every time. Partner with us to transform your vision into reality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

More Than a Shop—A Strategic Manufacturing Ally

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. Our engineering team collaborates with you from concept to completion, ensuring your design meets the highest standards of functionality, durability, and cost-efficiency. With ISO 9001-certified processes and a Zero Defects philosophy, we don’t just manufacture parts—we engineer solutions that drive your success.

Precision Engineered for Excellence

| Key Differentiator | Wuxi Lead Precision Advantage |

|---|---|

| Zero Defects Commitment | Rigorous ISO 9001 quality control with 100% inspection; zero tolerance for defects in critical aerospace, medical, and automotive components. |

| Olympic Quality Precision | ±0.01mm tolerances achieved through advanced CNC/DMLS processes, validated by third-party metrology (e.g., CMM, laser scanning). |

| 24/7 Customer Service | Dedicated engineering team available round-the-clock for urgent technical support, design optimization, and production coordination. |

Ready to Elevate Your Project?

Submit your CAD file for a free DFM analysis and receive an instant quote within 24 hours. Our experts will optimize your part for manufacturability while maintaining aerospace-grade quality standards—no hidden costs, no delays.

Contact: [email protected] | +86 139 6188 6740

Your project’s success starts with a single conversation.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.