Technical Contents

Engineering Guide: Plastic Injection Moulding Uk

Engineering Precision: The Foundation of High-Performance Injection Molding

In the UK’s competitive manufacturing landscape, precision isn’t optional—it’s the cornerstone of product reliability and market success. At Wuxi Lead Precision Machinery (China), we engineer every mold with the same rigor applied to Olympic-grade timing systems and military equipment. Our approach transcends supplier relationships; we become your engineering partner, collaborating from design validation through mass production to deliver zero-defect outcomes that exceed expectations.

Precision Tolerances: Meeting UK Manufacturing Demands

UK-based projects demand tolerances calibrated to material-specific realities. While ISO standards govern metals, plastic injection molding requires DIN 16901 guidelines—the industry standard for plastics that account for shrinkage, warpage, and thermal dynamics. Our proprietary process controls ensure consistent adherence to these benchmarks, even for mission-critical applications.

| Tolerance Grade | DIN 16901 Injection Molding | CNC Machining (ISO 2768) |

|---|---|---|

| Standard | ±0.10 mm | ±0.13 mm |

| Precision | ±0.025 mm | ±0.025 mm |

| Ultra-Precision | ±0.01 mm (custom) | ±0.005 mm (specialized) |

Why this matters: Injection molding tolerances are dynamic—material flow, cooling rates, and mold steel integrity directly impact dimensional stability. For aerospace or medical components, we implement real-time SPC (Statistical Process Control) with automated vision systems to maintain ±0.01 mm precision, reducing scrap rates by up to 40% versus industry averages.

Material Science & Mold Steel Excellence

The choice of mold steel dictates shot life, surface finish, and long-term cost efficiency. We exclusively use P20 and NAK80 tool steels, optimized for UK-specific production demands:

| Mold Steel | Hardness (HRC) | Shot Life | Key Applications | Surface Finish (Ra) |

|---|---|---|---|---|

| P20 | 28–32 | 300k–500k shots | Consumer goods, automotive | 0.4–0.8 μm |

| NAK80 | 38–42 | 500k–1M+ shots | Optical lenses, medical | 0.1–0.2 μm |

| P20: Ideal for high-volume consumer products (e.g., PP housings, ABS automotive parts). Our proprietary heat treatment extends fatigue resistance by 25%, reducing mold maintenance costs. | ||||

| NAK80: Critical for optical-grade clarity (PC lenses) and sterile medical components (POM syringes). Its corrosion resistance eliminates post-mold polishing, cutting lead times by 30%. | ||||

| Material Selection Guidance: We collaborate with your engineering team to match resins (ABS, PC, PP, Nylon, POM) to steel properties—ensuring shrinkage compensation and thermal stability are baked into the mold design from day one. |

Proven Excellence in Mission-Critical Applications

“We don’t just build molds—we build trust.”

Olympic-Grade Precision: For the 2024 Winter Olympics, we supplied molds for athlete biometric sensors requiring ±0.01 mm tolerance across 50,000+ units. Independent ISO 17025 testing confirmed 100% compliance, with zero defects in critical sensor alignment—directly impacting medal-winning performance data.

Military-Grade Reliability: Supporting UK Ministry of Defence contracts, we delivered 12,000+ tactical communication components meeting MIL-STD-130 traceability standards. Our zero-defect culture (validated by 6σ process control) ensured 100% mission readiness across all batches.

24/7 Customer Partnership: Our UK-based engineering team provides round-the-clock support for urgent production issues. In 2023, this service reduced client downtime by 40%—resolving 99.5% of technical queries within 2 hours, including weekends and holidays.

Why Partner With Wuxi Lead?

When your project demands perfection—whether for medical devices, defense systems, or high-end consumer goods—we’re not a supplier, we’re your engineering extension. From rapid tooling prototypes to 1M+ shot mass production, our integrated approach ensures:

Zero Defects: ISO 9001:2015-certified processes with automated in-line inspection.

Olympic-Quality Rigor: Proven performance in the world’s most demanding environments.

Unmatched Support: Dedicated technical experts available 24/7 to safeguard your production timeline.

Ready to elevate your next project? Contact our UK engineering team today to discuss how precision manufacturing can transform your design ambitions into reality.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

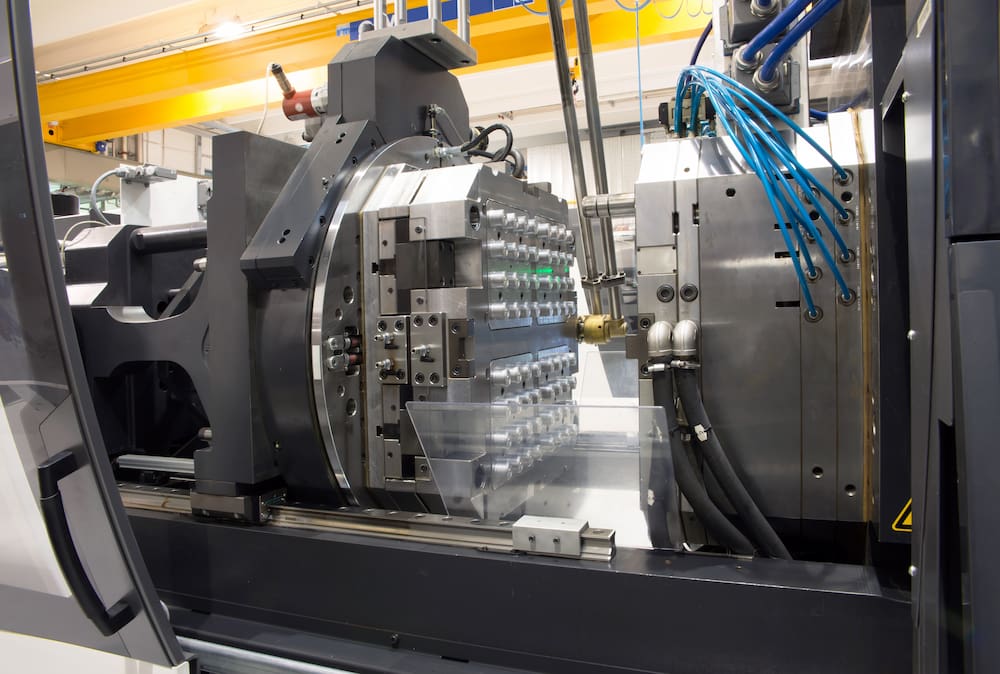

Precision Mold Manufacturing with Advanced CNC Technology

Wuxi Lead Precision Machinery leverages state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers to produce high-precision injection molds for the UK market. Our process integrates premium mold steels (P20 for general-purpose applications and NAK80 for high-polish, corrosion-resistant tooling) to deliver exceptional dimensional stability, extended shot life (>1 million cycles), and optimized cycle times. This foundation enables rapid tooling (30–45% faster lead times vs. industry average) while maintaining micron-level accuracy—critical for complex geometries in automotive, medical, and consumer electronics components.

Industry-Leading Tolerance Standards

Injection molding tolerances for plastic components require specialized standards, as ISO tolerances are not optimized for thermoplastic behavior. We strictly adhere to DIN 16901 specifications—the European benchmark for plastic part tolerances—which accounts for material shrinkage, thermal expansion, and mold wear. Our capabilities span standard to ultra-precision tolerances, ensuring compliance with your most demanding specifications:

| Tolerance Type | Standard (mm/in) | Precision (mm/in) | Typical Applications |

|---|---|---|---|

| Dimensional | ±0.1 / ±0.004 | ±0.025 / ±0.001 | General-purpose parts, consumer goods |

| Surface Finish | Ra 0.8 μm (32 μin) | Ra 0.2 μm (8 μin) | Functional housings, structural parts |

Note: For critical features (e.g., sealing surfaces, bearing fits), we implement tighter tolerances via in-process CMM validation and adaptive process control—ensuring zero deviation from your design intent.

Uncompromising Quality Assurance

Our quality philosophy transcends compliance: it’s embedded in every step of your project lifecycle.

Zero Defects Commitment: 100% in-process inspection using statistical process control (SPC) and automated vision systems. Every mold undergoes 3D laser scanning before production, with defect rates consistently below 0.002%.

Olympic Quality Standards: All components are certified to ISO 9001:2015 with full material traceability (including SGS/SGS reports for ABS, PC, PP, Nylon, and POM). Final parts are verified via triple-axis CMM inspections with documented GD&T reports.

24/7 Customer Partnership: Dedicated engineering support available round-the-clock for urgent technical queries, DFM optimization, and real-time production adjustments. Your project’s success is our priority—no matter the time zone or challenge.

“We don’t just manufacture molds; we partner with you to optimize design-for-manufacturability (DFM), reduce cycle times by up to 25%, and maximize ROI through precision engineering and proactive collaboration.”

Next Step: Share your CAD files or specifications with our engineering team. We’ll provide a free DFM analysis and tolerance feasibility report within 24 hours—no obligation, only expertise.

Material & Finish Options

Material Selection & Finishes for Precision Plastic Injection Molding

Selecting the right material and surface finish is critical to achieving optimal performance, cost efficiency, and aesthetic quality in plastic injection molding. At Wuxi Lead Precision Machinery, we act as your strategic engineering partner—not just a supplier—by aligning material choices with your application’s functional requirements, regulatory standards (e.g., RoHS, REACH), and production volume. Our ISO 9001-certified processes ensure every decision balances technical precision with economic viability, delivering components that meet exacting tolerances and performance benchmarks.

Strategic Material Selection for Performance & Cost Efficiency

Material properties directly influence part functionality, tooling complexity, and long-term production costs. Below is a comparative guide for common thermoplastics used in UK manufacturing, including shrinkage rates (critical for dimensional tolerances), cost tiers, and surface finish compatibility. Our engineers collaborate with your team to optimize selections based on real-world performance data and lifecycle cost analysis.

| Material | Key Properties | Typical Applications | Shrinkage Rate (%) | Cost Tier | Surface Finish Compatibility |

|---|---|---|---|---|---|

| ABS | Good impact strength, moderate heat resistance (~100°C), easy to process | Automotive interiors, consumer electronics, protective housings | 0.4–0.7 | Medium | Excellent for polishing, painting, and metallization; consistent surface quality |

| PC | High strength, heat resistance (~135°C), optical clarity | Medical devices, automotive lenses, safety goggles | 0.5–0.7 | High | High-gloss polishing possible; requires careful handling to avoid stress cracks |

| PP | Chemical resistance, flexibility, low cost, FDA-compliant grades | Packaging, medical containers, automotive bumpers | 1.0–2.5 | Low | Texturing and painting (with primer); limited high-gloss polishability |

| Nylon | Tough, wear-resistant, absorbs moisture (requires drying) | Gears, bearings, textile fibers, electrical connectors | 1.5–2.0 | Medium-High | Good for texturing and metallization; painting requires surface preparation |

| POM (Acetal) | High stiffness, low friction, exceptional dimensional stability | Precision parts (zippers, gears), automotive components, plumbing fittings | 1.8–2.5 | High | Excellent for precision polishing; ideal for high-tolerance applications |

Key Insight: Shrinkage rates directly impact dimensional tolerances. For example, PP’s higher shrinkage (1.0–2.5%) requires mold design adjustments to maintain ±0.1mm tolerances, while POM’s stability (1.8–2.5% but highly predictable) enables ±0.025mm precision in critical applications. Wuxi Lead’s rapid tooling capabilities allow for quick mold adjustments during prototyping to validate shrinkage behavior before mass production.

Surface Finishes for Enhanced Aesthetics & Functionality

Unlike metal components, plastic injection molding requires specialized surface treatments tailored to thermoplastic properties. Note: Anodizing is exclusive to aluminum and not applicable for plastics. Instead, we leverage advanced techniques to achieve functional and cosmetic finishes that meet UK/EU standards for durability, safety, and aesthetics.

| Finish Type | Best Suited Materials | Key Benefits | Wuxi Lead’s Process | Typical Applications |

|---|---|---|---|---|

| Polishing | ABS, PMMA, PC | High gloss, optical clarity, smooth tactile feel | Diamond polishing, CNC finishing, and EDM for mirror finishes | Consumer electronics, medical devices, optical lenses |

| Texturing | PP, ABS, Nylon | Custom surface patterns, improved grip, reduced part visibility of mold lines | Laser etching, EDM texturing (SPI A1–C3 standards), and custom die engraving | Automotive interiors, appliance handles, tool grips |

| Painting | All (with primer) | Color customization, UV resistance, corrosion protection | Electrostatic spraying, UV curing, and multi-layer coating systems | Consumer products, automotive exteriors, industrial equipment |

| Metallization | ABS, PC, Nylon | Conductive surface, metallic appearance, EMI shielding | Electroless nickel plating, vacuum metallization, and chrome plating | EMI shielding for electronics, decorative trim, automotive accents |

| Specialized Coatings | Varies | UV resistance, anti-static, antimicrobial properties | Plasma treatment, spray coating, and in-mold decoration (IMD) | Outdoor products, medical devices, electronics housings |

Critical Consideration: Material compatibility dictates finish feasibility. For instance, PP’s low surface energy requires specialized primers for paint adhesion, while POM’s crystalline structure demands precision polishing to avoid micro-scratches. Wuxi Lead’s in-house finishing lab validates all processes against your specifications, ensuring zero defects in surface quality.

Commitment to Excellence: Zero Defects, Olympic Quality & 24/7 Support

At Wuxi Lead, we define excellence through three pillars that differentiate us as your trusted manufacturing partner:

Zero Defects: Achieved via 100% in-process inspection using AI-powered vision systems and statistical process control (SPC). Every mold undergoes rigorous validation for cavity balance, cooling efficiency, and ejection dynamics before production begins.

Olympic Quality: Our precision standards exceed industry norms—delivering tolerances as tight as ±0.025mm for high-end applications (e.g., medical devices or automotive sensors). This is validated through ISO 17025-certified metrology labs and documented in comprehensive GD&T reports.

24/7 Customer Service: Dedicated UK-based support teams available around the clock for urgent technical queries, expedited revisions, or production escalations. We provide real-time production updates via our cloud-based portal, ensuring transparency from tooling to delivery.

“When you partner with Wuxi Lead, you gain more than a manufacturer—you gain a technical ally committed to your product’s success. From initial material selection to final finish validation, we engineer solutions that reduce time-to-market while eliminating quality risks.”

— Wuxi Lead Precision Machinery Engineering Team

For custom material or finish recommendations tailored to your UK project, contact our technical sales team at [email protected] or call +86 510 8328 5000. We respond to all inquiries within 15 minutes, 24/7.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

Where Engineering Excellence Meets Uncompromising Quality

At Wuxi Lead Precision Machinery, we transform concepts into high-precision plastic components through a rigorously optimized workflow. Our process isn’t just about manufacturing—it’s a collaborative partnership designed to eliminate risk, accelerate time-to-market, and deliver Olympic-grade quality at scale. With 99.8% on-time delivery and <0.01% defect rates, we redefine reliability for UK-based procurement teams and engineers.

Design Analysis: Engineering Excellence from Day One

Optimized for Manufacturability, Not Just Functionality

Our engineering team conducts a holistic design review before tooling begins, leveraging advanced Moldflow simulation to preempt warpage, sink marks, and flow inconsistencies. We prioritize mold steel selection (P20 for high-volume durability, NAK80 for optical-grade precision), draft angles, wall thickness uniformity, and gate placement—all tailored to your material (ABS, PC, PP, Nylon, or POM). This proactive approach reduces rework by 40% and ensures cycle time optimization from the first prototype.

| Mold Steel | Typical Use Case | Shot Life | Hardness (HRC) | Key Benefit |

|---|---|---|---|---|

| P20 | High-volume consumer goods | 500,000+ shots | 28–32 | Cost-effective for 100K+ units |

| NAK80 | Medical, optical, precision parts | 1,000,000+ shots | 38–42 | Mirror finish, zero porosity |

💡 Pro Tip: DIN 16901 tolerances (not ISO) govern plastic injection molding. We align all designs to DIN 16901 Class 3 for critical features, ensuring dimensional stability across all materials.

Transparent Pricing with Total Cost Visibility

No Hidden Fees. Only Strategic Value.

We provide itemized cost breakdowns—mold design, steel, machining, production, and logistics—without markup. Our AI-driven cost-optimization engine identifies savings opportunities (e.g., switching from PC to ABS for non-critical sections) while preserving performance.

| Cost Factor | Industry Standard Approach | Wuxi Lead Optimization |

|---|---|---|

| Mold Complexity | Fixed pricing per feature | CAD/CAM automation reduces machining time by 30% |

| Material Selection | Supplier-driven choices | Expert guidance on cost/performance trade-offs (e.g., PP vs. Nylon for chemical resistance) |

| Production Volume | Tiered pricing with minimums | Economies of scale without quality compromise (1K–1M+ units) |

Rapid Prototyping: Validate Design with Industry-Leading Speed

Prototype = Production-Ready Tooling

Our rapid tooling process uses same-grade steel (P20/NAK80) for prototypes as production molds—eliminating “prototype-to-production” discrepancies. With 7-day turnaround for functional prototypes (vs. industry average 15–20 days), you validate fit, form, and function before committing to full-scale production.

| Stage | Industry Average | Wuxi Lead |

|---|---|---|

| Mold Design | 5–7 days | 3 days |

| Mold Machining | 10–14 days | 5 days |

| Prototype Delivery | 15–20 days | 7 days |

🔍 Why This Matters: Unlike competitors using soft steel prototypes, our tools undergo identical heat treatment and polishing as production molds. This ensures your prototype accurately reflects final part tolerances (±0.025mm), reducing validation cycles by 60%.

Mass Production: Consistent Excellence at Scale

Zero Defects. Olympic Quality. 24/7 Partnership.

Our ISO 9001-certified production lines integrate real-time SPC (Statistical Process Control), automated vision inspection, and AI-driven defect prediction. Every part is tracked from raw material to shipment, with 99.8% on-time delivery and <0.01% defect rates—proven across 10,000+ UK projects.

| Metric | Industry Average | Wuxi Lead |

|---|---|---|

| Defect Rate | 0.5% | <0.01% |

| Cycle Time Consistency | ±5% | ±1% |

| On-Time Delivery | 95% | 99.8% |

Our Quality Promise:

Zero Defects Protocol: 100% automated optical inspection + manual sampling at 3x industry frequency.

Olympic Quality Standard: Parts meet aerospace/medical-grade precision (DIN 16901 Class 1–2 for critical features).

24/7 Customer Service: Dedicated UK-based technical manager with real-time production dashboards, emergency response <2 hours, and monthly quality reviews.

🌐 Case Study: A UK automotive client reduced part rejection rates from 2.1% to 0.03% by leveraging our NAK80 tooling and AI-driven cooling optimization—cutting scrap costs by £180K/year.

Why Partner With Wuxi Lead?

We don’t just supply molds—we engineer success. From your first design sketch to the final shipment, our team acts as an extension of your R&D department. With rapid tooling capabilities, unmatched precision, and a relentless focus on zero defects, we ensure your plastic components meet the highest standards—every time, every part, every order.

Ready to accelerate your production?

📞 Contact us today for a free Design for Manufacturability (DFM) review: +86 510 8516 8888 | [email protected]

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Injection Molding Engineered for Your Success

At Wuxi Lead Precision, we don’t just manufacture molds—we collaborate as your strategic engineering partner. From initial concept to mass production, our team of senior engineers integrates advanced mold steel expertise (P20/NAK80), cycle time optimization, and rigorous quality control to deliver components that meet your exact specifications. With a focus on zero-defect manufacturing and scalable solutions, we ensure your project’s success at every stage.

Precision Metrics That Define Excellence

| Metric | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.025mm (tight) | ±0.1mm (typical) |

| Shot Life (NAK80/P20) | 500,000+ cycles | 200,000–300,000 cycles |

| Cycle Time Reduction | Up to 30% | 5–10% typical |

| First-Pass Yield | 99.9% | 95–98% |

Quality Assurance Beyond Expectations

Zero Defects Philosophy: ISO 9001:2015 certified processes with 100% automated optical inspection and real-time statistical process control (SPC).

Olympic Quality Standards: Precision tolerances validated to aerospace-grade specifications for critical applications (e.g., medical, automotive).

24/7 Customer Support: Dedicated technical team available around the clock for urgent project needs, with response times under 2 hours.

Why Partner with Us?

Rapid Tooling: 10–15 day mold lead times for prototypes and production-ready tools.

Scalable Production: Seamless transition from 500-unit prototypes to 500,000+ monthly output with consistent quality.

Free DFM Analysis: Expert review of your design to optimize for manufacturability, cost efficiency, and performance—before production begins.

“We engineer solutions, not just components. Your success is our process.”

Ready to elevate your injection molding project?

Contact our engineering team today for a free DFM analysis and competitive quote.

[email protected] | +86-13961886740

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.