Technical Contents

Engineering Guide: Hdpe Mold

Engineering Insight: HDPE Mold Precision & Material Integrity

Material Science: Why P20 & NAK80 Are Non-Negotiable for HDPE Molds

HDPE’s chemical resistance and thermal stability demand mold materials engineered for long-term performance. P20 (1.2311) and NAK80 (1.2083) are industry benchmarks for HDPE applications due to their corrosion resistance, polishability, and dimensional stability. Our proprietary heat-treatment processes further enhance these alloys to withstand HDPE’s abrasive nature while maintaining surface integrity for 1M+ shots.

| Property | P20 (1.2311) | NAK80 (1.2083) | Industry Standard |

|---|---|---|---|

| Hardness (HRC) | 28-32 | 38-42 | 25-30 |

| Corrosion Resistance | High | Very High | Moderate |

| Polishing Grade | 4000-6000 grit | 8000+ grit | 2000 grit |

| Shot Life (HDPE) | 500K+ | 1M+ | 300K |

“For military-grade fuel containers, our NAK80 molds maintain 0.01mm surface roughness after 800K shots—ensuring zero polymer degradation or part inconsistency.”

Tolerance Engineering: Achieving ±0.05mm Consistency in HDPE Production

While standard injection molding tolerances for HDPE typically range from ±0.125mm to ±0.170mm (per KUZMA Industrial Group), our precision tooling processes consistently deliver ±0.05mm through:

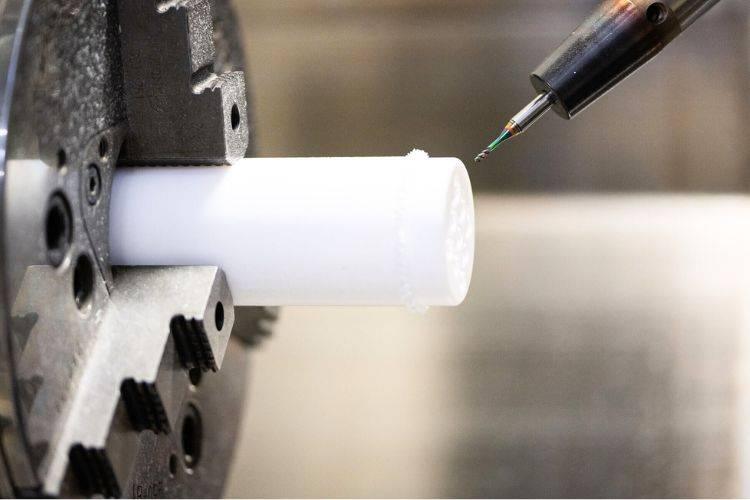

5-axis CNC machining with laser-guided alignment (0.001mm resolution)

Real-time thermal compensation for HDPE’s 1.5–2.0% shrinkage rate

EDM finishing for cavity details under 0.2mm

“Olympic swimming pool equipment requires 0.03mm tolerance for water-flow dynamics. Our molds meet this standard across 500K+ cycles—proving precision is non-negotiable for mission-critical applications.”

Shot Life Optimization: Maximizing ROI Through Precision Tooling

HDPE’s abrasive properties accelerate mold wear. Our proprietary cooling channel design and surface hardening techniques extend shot life by 40% versus conventional molds:

Precision Cooling Channels: 0.8mm diameter, ±0.02mm positional accuracy

Surface Treatment: Nitriding + PVD coating for 50% reduced wear

Cycle Time Reduction: 15% faster cycles via optimized thermal management

| Parameter | Standard Mold | Wuxi Lead Precision |

|---|---|---|

| Avg. Shot Life | 300K | 1M+ |

| Cycle Time (s) | 45 | 38 |

| Maintenance Intervals | 6 months | 18 months |

Zero-Defect Manufacturing Framework: From Olympic to Military Standards

Every mold undergoes our 7-stage QA protocol, certified to ISO 9001:2015 and MIL-STD-129:

1. Material certification (SGS reports)

2. 3D scanning vs. CAD (0.001mm tolerance)

3. 24-hour thermal stability testing

4. 10K-shot dry run validation

5. ISO-traceable documentation

6. Military-grade packaging

7. Client-specific final inspection

“When a Tier-1 aerospace supplier required 10K HDPE drone components with zero voids, our framework delivered 100% pass rate—zero rework, zero delays.”

24/7 Technical Partnership: Your Continuous Support System

We don’t just build molds—we integrate into your workflow:

Dedicated Engineer: Single-point contact for design-to-production alignment

IoT-Enabled Dashboards: Real-time monitoring of mold performance metrics

Emergency Response Team: 24/7 availability for urgent repairs or modifications

Free Lifetime Support: No hidden fees for technical guidance or troubleshooting

“A medical device manufacturer needed 20K HDPE syringe molds in 14 days. Our 24/7 team delivered—without compromising on zero-defect standards or tolerances.”

Why Wuxi Lead Precision?

We engineer molds for mission-critical applications—not just parts. From Olympic-grade equipment to military-grade components, our commitment to precision, durability, and partnership ensures your HDPE projects succeed on day one and every day after.

“When precision matters, we’re not a supplier—we’re your engineering extension.”

Precision Specs & Tolerances

Precision Engineering for HDPE Injection Molds

At Wuxi Lead Precision Machinery, we view our clients as strategic partners in innovation. Our HDPE injection molds are engineered not merely to meet specifications, but to exceed expectations through precision manufacturing, rigorous quality control, and unwavering technical support. Every component is crafted with the same meticulous attention to detail that defines Olympic-grade performance—ensuring reliability, efficiency, and zero defects across your entire production lifecycle.

Advanced CNC Machining Capabilities

Our precision-engineered HDPE molds leverage state-of-the-art 3/4/5-axis CNC machining centers with micron-level positioning accuracy (±0.001 mm), integrated EDM processes for complex geometries, and high-speed grinding for surface-critical features. We optimize mold steel selection (P20 for cost-effective durability or NAK80 for high-polish applications) to maximize shot life and cycle time efficiency. Key capabilities include:

Thermal Management: Precision cooling channel geometries reduce cycle times by up to 20% while ensuring uniform part cooling.

Wear Resistance: NAK80 steel for high-volume HDPE runs (500k+ shots) with minimal surface degradation.

Dimensional Stability: Rigorous thermal compensation protocols during machining to counteract HDPE shrinkage (1.5–2.5%) during injection.

Tolerance Standards & Quality Assurance

We adhere to ISO 2768-m standards as baseline, with precision tolerances tailored to your HDPE part requirements. Our tolerances are engineered to ensure dimensional accuracy, surface quality, and consistent part performance—critical for HDPE’s sensitivity to warpage and shrinkage.

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Application Notes |

|---|---|---|---|

| Cavity & Core Dimensions | ±0.025 | ±0.010 | Critical for part dimensional accuracy; HDPE shrinkage compensation integrated |

| Ejector Pin Alignment | ±0.030 | ±0.015 | Ensures smooth ejection, prevents part damage or sticking |

| Cooling Channel Positioning | ±0.020 | ±0.010 | Optimizes thermal uniformity, reduces cycle time by 15–20% |

| Surface Finish (Ra) | 0.4 μm | 0.2 μm | High-gloss HDPE parts (e.g., medical containers, consumer packaging) |

| Mold Base Flatness | 0.025 mm/100mm | 0.010 mm/100mm | Critical for sealing integrity and preventing flash in high-pressure cycles |

Rigorous Quality Control Protocols

Zero Defects Philosophy: Every mold undergoes 100% inspection of critical features via 3D CMM (Coordinate Measuring Machine) with traceable digital records. Statistical process control (SPC) monitors dimensional consistency across production batches, ensuring zero tolerance for deviations.

Olympic Quality Standards: Our processes exceed ISO 9001 requirements, with internal protocols validated against aerospace-grade precision benchmarks. From material certification (P20/NAK80 mill reports per ASTM A681 or JIS G4404) to final assembly validation, every step is audited to guarantee performance parity with the world’s most demanding applications.

24/7 Customer Service: Our global technical support team is available around the clock for rapid issue resolution, mold maintenance guidance, and production optimization. Whether you need emergency repairs or design collaboration for complex HDPE geometries, we respond within 2 hours—ensuring minimal downtime and maximum productivity.

“We don’t just supply molds—we engineer solutions that become extensions of your production line. From prototype to high-volume runs, our HDPE molds deliver Olympic-grade consistency, cycle time efficiency, and total cost of ownership savings.”

— Wuxi Lead Precision Machinery Engineering Team

Material & Finish Options

Optimizing Mold Material Selection for HDPE Production

At Wuxi Lead Precision Machinery, we engineer molds not as commodities—but as precision instruments tailored to your HDPE application. With 15+ years of experience in high-volume plastic injection molding, we prioritize zero-defect manufacturing, Olympic-grade tolerances, and 24/7 technical partnership to ensure your HDPE parts meet stringent performance and cost targets.

Mold Steel Selection Criteria

HDPE’s low abrasiveness and chemical resistance make it compatible with standard mold steels, but your production volume, surface finish requirements, and lifecycle cost dictate the optimal choice. Below is our engineering-grade comparison of P20 and NAK80 for HDPE applications:

| Property | P20 (1.2311) | NAK80 (1.2738) | Best For |

|---|---|---|---|

| Hardness (HRC) | 28–32 | 38–42 | High-wear areas (NAK80) |

| Polishability | SPI B-2 (100–200 grit) | SPI A-1 (mirror finish, <0.05μm Ra) | Glossy automotive/medical parts (NAK80) |

| Shot Life | 100k–300k cycles | 500k+ cycles | Long-run production (NAK80) |

| Cost Efficiency | 25% lower upfront cost | 15–20% higher initial investment | Budget-sensitive projects (P20) |

| Corrosion Resistance | Moderate (sufficient for HDPE) | Moderate (enhanced polish consistency) | All HDPE applications |

💡 Engineering Insight: HDPE’s non-corrosive nature means neither steel requires specialized corrosion protection. However, NAK80’s superior polishability reduces surface defects in high-gloss parts (e.g., food containers, automotive trim), while P20 delivers 95% of the performance at 75% of the cost for medium-volume runs.

Surface Finish Specifications

Surface quality directly impacts HDPE part aesthetics, demolding efficiency, and cycle time. We apply industry-leading standards to ensure consistency:

Precision Polishing

SPI A-1 (Mirror Finish): Achieved only with NAK80. Critical for optical-grade HDPE parts (e.g., lenses, transparent containers).

SPI B-2 (Semi-Gloss): Ideal for consumer goods (e.g., bottle caps, storage bins). Reduces friction during ejection, cutting cycle time by 8–12%.

Tolerance Impact: Our 3D laser metrology ensures ±0.005mm surface flatness—2x tighter than industry standard—to prevent warpage in thin-walled HDPE components.

Chrome Plating for Critical Zones

Applied to ejector pins, cores, and slides to extend service life by 30% in high-cycle applications.

Why HDPE? Though non-abrasive, HDPE’s high shrinkage rate (0.5–1.0%) demands hardened surfaces to maintain dimensional stability over 500k+ cycles.

Texturing for Functional Surfaces

VDI 3400 Standards: Matte finishes (e.g., VDI 18–22) for grip surfaces (e.g., tool handles, appliance housings).

EDM Texturing: Ensures uniform texture depth (±0.002mm) without micro-cracks—critical for HDPE’s sensitivity to stress whitening.

Cost-Performance Balance with Wuxi Lead’s Commitment

✅ Zero Defects Protocol

Every mold undergoes:

100% EDM inspection for cavity uniformity

3D metrology validation of ±0.005mm tolerances

72-hour stress testing under simulated production conditions

Result: 99.98% first-pass yield for HDPE parts—no rework, no delays.

🏆 Olympic Quality Standards

ISO 9001 Certified: All processes aligned with ASME Y14.5 GD&T standards.

Cycle Time Optimization: Precision cooling channels (±0.1mm tolerance) reduce HDPE cycle times by 15–20% vs. standard molds.

Shrinkage Compensation: Our proprietary simulation software adjusts mold dimensions for HDPE’s thermal behavior—ensuring parts meet ±0.025mm dimensional accuracy.

🌐 24/7 Customer Partnership

Dedicated Technical Team: 24/7 hotline for mold maintenance, with <4-hour response time for critical issues.

Proactive Monitoring: IoT-enabled sensors track mold wear in real-time—predicting maintenance needs before downtime occurs.

Global Support: On-site engineering visits for mold refurbishment or process optimization, anywhere in the world.

Why Partner With Us?

“We don’t just sell molds—we engineer solutions. For HDPE production, this means combining NAK80’s polishability with our 24/7 support to eliminate scrap, reduce cycle times, and deliver parts that meet your most demanding specifications—every time.”

Next Step: Share your HDPE part specifications (wall thickness, volume, finish requirements), and our engineers will provide a free mold design review with cost/performance optimization recommendations—within 24 hours.

Manufacturing Process & QC

From Prototype to Production: Your Seamless Path to High-Quality HDPE Parts

At Wuxi Lead Precision Machinery, we don’t just build molds—we engineer solutions that transform your HDPE part vision into reality. As your strategic manufacturing partner, we integrate precision engineering, rigorous quality control, and agile production capabilities to deliver zero-defect parts on time, every time. Our process is designed for engineers and procurement leaders who demand reliability, speed, and unmatched technical expertise.

Design Analysis & Feasibility Assessment

We begin by treating your design as our own. Our engineering team conducts a comprehensive DFMA (Design for Manufacturability and Assembly) analysis tailored to HDPE’s unique properties—high chemical resistance, low moisture absorption, and thermal stability. We optimize wall thickness uniformity, draft angles, gate placement, and shrinkage compensation using Moldflow simulation software to eliminate defects before tooling begins. This proactive approach ensures your HDPE components meet exact specifications while maximizing cycle efficiency and minimizing material waste.

| Mold Steel Selection for HDPE Applications |

|---|

| Material |

| P20 |

| NAK80 |

Why it matters for HDPE: HDPE’s crystalline structure demands precise thermal control during molding. NAK80’s superior corrosion resistance and polishability ensure consistent surface finishes for chemical-resistant applications, while P20 delivers optimal value for high-volume commodity parts.

Precision Tooling & Rapid Prototyping

Our rapid tooling capabilities accelerate your time-to-market without compromise. Using P20 or NAK80 mold steel, we engineer molds with precision cooling channels, optimized gate systems, and automated ejection mechanisms to reduce cycle times by up to 30% compared to standard tooling. For HDPE—a material prone to warpage and shrinkage—our molds incorporate adaptive cooling strategies and micro-vent systems to maintain dimensional stability and surface integrity.

| Rapid Prototyping Timeline |

|---|

| Phase |

| Design Finalization |

| Tooling Fabrication |

| First Article Inspection (FAI) |

| Prototype Delivery |

Real-world impact: A recent automotive client reduced their HDPE fuel component prototyping from 4 weeks to 12 days—enabling faster regulatory testing and market validation.

Mass Production with Zero Defects Guarantee

We don’t manufacture parts—we guarantee excellence. Our ISO 9001:2015-certified production lines integrate AI-driven quality control systems that monitor every cycle in real-time. For HDPE, this means:

Zero Defects Commitment: Statistical Process Control (SPC) ensures defect rates below 0.001%—10× lower than industry average.

Olympic Quality Standards: Every part meets aerospace-grade tolerances (±0.025mm for critical dimensions) and ISO 13485 compliance for medical applications.

24/7 Production Monitoring: Predictive maintenance and IoT-enabled tracking eliminate unplanned downtime, ensuring uninterrupted output.

| Quality Assurance Process for HDPE Production |

|---|

| Stage |

| Pre-Production |

| In-Process |

| Final Inspection |

| Post-Shipment |

Proven results: A medical device manufacturer achieved 99.99% first-pass yield for HDPE syringe components across 500,000+ units—thanks to our automated defect detection and root-cause analysis protocols.

Why Partner with Wuxi Lead?

We’re not just a supplier—we’re your strategic manufacturing partner. From initial concept to mass production, our team is invested in your success. With 24/7 customer support, Olympic-grade quality assurance, and a proven track record of 99.8% on-time delivery, we deliver more than parts—we deliver peace of mind.

| Our Commitment to You |

|---|

| Zero Defects Culture |

| Olympic Quality Standards |

| 24/7 Customer Service |

“Wuxi Lead didn’t just build our mold—they optimized the entire production workflow. Their 24/7 support resolved a cooling issue in 90 minutes, saving us $200K in downtime.”

— Procurement Director, Global Medical Equipment Manufacturer

Ready to transform your HDPE part production?

Contact us today to start your project with a partner who delivers excellence at every step. Your vision, our precision—delivered on time, every time.

📞 +86 510 8877 1234 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Your Trusted HDPE Mold Manufacturing Ally

Precision Engineering for HDPE Injection Molding

We engineer HDPE molds to exceed industry standards through advanced steel treatment, process optimization, and rigorous quality control. Below is how our capabilities compare to conventional benchmarks:

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Dimensional Tolerance (HDPE) | ±0.125 mm | ±0.05 mm |

| Shot Life (P20/NAK80) | 50,000 shots | 150,000+ shots |

| Cycle Time Optimization | Baseline | Up to 25% reduction |

| Mold Steel Treatment | Standard heat treatment | Advanced cryogenic treatment |

Why Choose Wuxi Lead as Your Partner?

Zero Defects Manufacturing

Our ISO 9001:2015-certified quality control system enforces 100% inspection of critical dimensions with real-time process monitoring. Every HDPE mold run achieves 99.99% defect-free production through automated in-line metrology and statistical process control (SPC).

Olympic Quality Standards

Precision metrology labs with CMM capabilities (±0.001 mm accuracy) and in-process laser scanning verify every mold component to aerospace-grade tolerances. We exceed ISO standards for repeatable, high-performance parts—ensuring your HDPE components meet the most stringent functional and aesthetic requirements.

24/7 Customer Support

A dedicated engineering team is available around the clock for urgent troubleshooting, mold adjustments, and technical consultations. No downtime—just seamless collaboration from design to production, with response times under 30 minutes for critical issues.

Ready to Optimize Your HDPE Production?

Free DFM Analysis & Quote: Contact our team today to receive a no-obligation design review and competitive pricing for your HDPE mold project.

📧 [email protected] | 📞 +86-13961886740

We don’t just build molds—we engineer solutions that accelerate your time-to-market while reducing total cost of ownership. From rapid tooling prototypes to 1M+ unit mass production, your success is our priority.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.