Technical Contents

Engineering Guide: Precision Cnc Metal Machining

Engineering Insight: Precision CNC Machining – Where Tolerance Meets Trust

In high-stakes industries like aerospace, defense, and elite sports, precision isn’t just a metric—it’s the difference between success and catastrophic failure. At Wuxi Lead Precision Machinery, we engineer components where micron-level tolerances and material integrity are non-negotiable. As a trusted supplier for Olympic racing cycles and military enterprises, our commitment to excellence is embedded in every process, from design collaboration to final inspection.

The Non-Negotiables of High-Stakes Precision

Achieving ±0.005mm tolerance (0.0002″) and Ra 0.4 surface finish consistently requires more than advanced machinery—it demands rigorous process control and material expertise. Below is how we exceed industry standards to deliver mission-critical components:

| Parameter | Industry Standard | Wuxi Lead Precision | Critical Impact |

|---|---|---|---|

| Tolerance | ±0.005″ (±0.127mm) | ±0.005mm (±0.0002″) | Prevents component failure in high-stress aerospace and medical applications |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm | Ensures optimal sealing and fluid dynamics in hydraulic and medical systems |

| 5-Axis Capability | Optional add-on | Standard integration | Eliminates setup errors for complex geometries, critical for turbine components and prosthetics |

Material Science & Process Control

Material properties dictate machining outcomes. Our engineers leverage deep material science expertise to optimize processes for each alloy:

| Material | Key Properties | Wuxi Lead’s Approach | Typical Applications |

|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight, corrosion resistance | Precision grinding and thermal management | Bicycle frames, aerospace structural components |

| Aluminum 7075 | High strength, used in military | Controlled heat treatment and vibration damping | Military hardware, high-stress aircraft parts |

| Titanium | Biocompatible, high strength-to-weight | Specialized tooling and slow feed rates | Medical implants, aerospace engine components |

| Stainless 316 | Corrosion-resistant | Electrochemical polishing for Ra 0.4 | Marine equipment, surgical instruments |

Zero Defects Philosophy & Military-Grade Quality Assurance

We don’t just manufacture parts—we guarantee performance. Our approach combines military-grade rigor with Olympic-level attention to detail:

Zero Defects Protocol: Every component undergoes 100% dimensional verification via CMM and optical scanning. Statistical Process Control (SPC) ensures consistency across batches, with real-time adjustments to machining parameters.

Olympic-Quality Performance: As the precision machining partner for elite cycling teams in the Olympics, our components meet the exacting standards where milliseconds and microns determine victory. This same rigor applies to military applications where failure is not an option.

24/7 Customer Engineering Support: Our dedicated technical team is available around the clock to address urgent design challenges, material substitutions, or production adjustments—ensuring your project stays on schedule without compromising quality.

When you partner with Wuxi Lead Precision Machinery, you’re not just selecting a supplier—you’re gaining a committed engineering ally dedicated to your success. From concept to delivery, we ensure every micron counts.

Precision Specs & Tolerances

Technical Capabilities & Precision Engineering

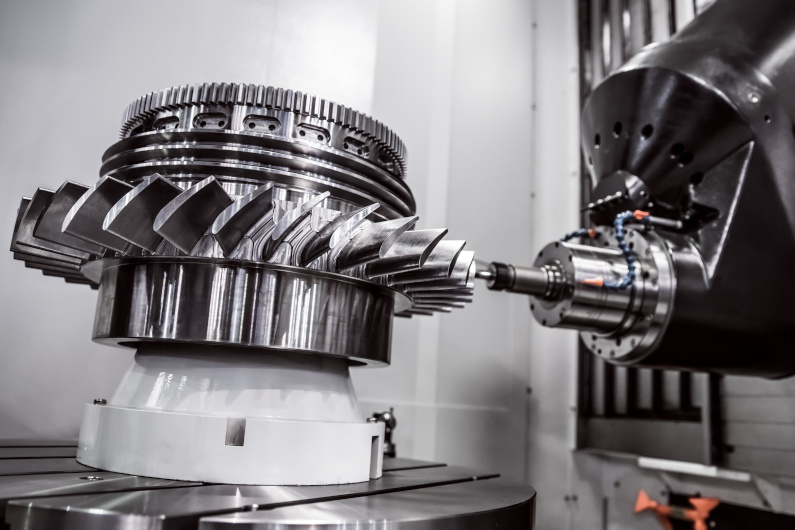

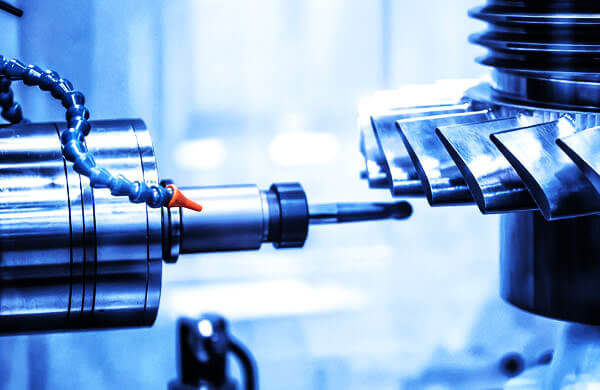

Advanced Multi-Axis CNC Equipment

Wuxi Lead Precision Machinery deploys a fleet of high-precision CNC machining centers, including 3-axis, 4-axis, and 5-axis configurations from leading manufacturers (e.g., DMG MORI, Haas, Makino). Each machine is engineered for micron-level stability, featuring:

High-rigidity spindles (20,000+ RPM) for vibration-free cutting of hardened materials

Thermal compensation systems to eliminate dimensional drift during extended operations

Real-time tool wear monitoring to maintain consistency across batch runs

Automated tool changers for uninterrupted production of complex geometries

Our equipment is calibrated to ISO 9001 standards, ensuring repeatable accuracy for parts with intricate features and tight tolerances.

Uncompromising Tolerance Standards

While industry-standard tolerances typically range from ±0.127mm (±0.005″), Wuxi Lead delivers consistent ±0.005mm (±0.0002″) as standard – 25x tighter than conventional benchmarks. Our precision capabilities extend to ±0.001mm (±0.00004″) for mission-critical applications, validated through:

In-process laser measurement for real-time adjustments

Material-specific process optimization (e.g., titanium heat management, stainless steel chip control)

Statistical Process Control (SPC) with 100% traceability of every machining parameter

| Tolerance Level | Metric (±mm) | Imperial (±in) | Typical Applications |

|---|---|---|---|

| Standard | 0.005 | 0.0002 | Aerospace structural components, medical implants |

| Precision | 0.002 | 0.00008 | High-performance automotive transmissions, military hardware |

| Ultra-Precision | 0.001 | 0.00004 | Olympic racing cycles, satellite components, surgical instruments |

Note: All tolerances are achievable across our material portfolio (Aluminum 6061/7075, Stainless Steel 304/316, Titanium, Brass) without secondary operations.

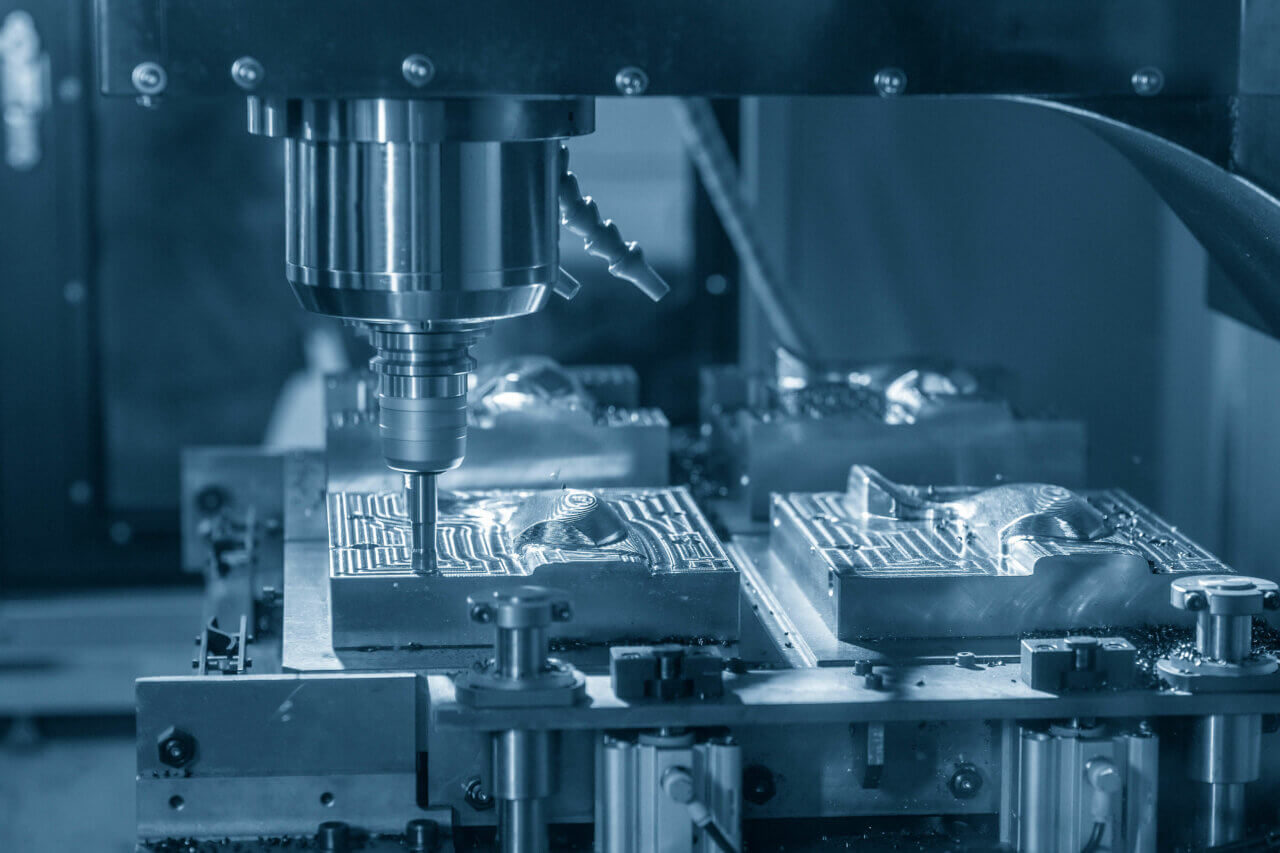

Precision Surface Finish Control

We consistently achieve Ra 0.4μm as standard surface finish – even on complex 5-axis geometries – through:

Optimized cutting parameters (feed rate, spindle speed, tool path) tailored to material hardness

Diamond-turning capabilities for optical-grade finishes (Ra 0.1μm) on critical surfaces

No secondary polishing required for most applications, reducing lead times and cost

Surface finish consistency is verified via profilometer testing at every production stage, ensuring compliance with ISO 4287 standards.

Rigorous Quality Assurance Protocol

Every component undergoes a triple-layer quality verification process:

1. CMM Inspection: 3D coordinate measurements with ±0.001mm accuracy, certified to ISO 17025

2. Material Traceability: Full certification (ASTM, EN, JIS) for raw materials, including heat treatment reports

3. Zero-Defect Manufacturing: AI-driven visual inspection systems and statistical process control to eliminate defects before shipping

Our quality system has enabled 99.98% first-pass yield for military-grade components and Olympic cycling parts – where failure is not an option.

Trusted Partner for Critical Applications

As the precision machining partner for Olympic Racing Cycles and Military Enterprises, we combine engineering rigor with operational agility:

Dedicated engineering support available 24/7 for design-for-manufacturability (DFM) reviews and urgent prototyping

Supply chain resilience: On-site material inventory for critical alloys (e.g., Ti-6Al-4V, 17-4 PH stainless) to avoid delays

End-to-end collaboration: From initial concept to volume production, we treat your project as our own

When your application demands perfection under extreme conditions – whether on the podium or in combat – Wuxi Lead delivers precision you can trust.

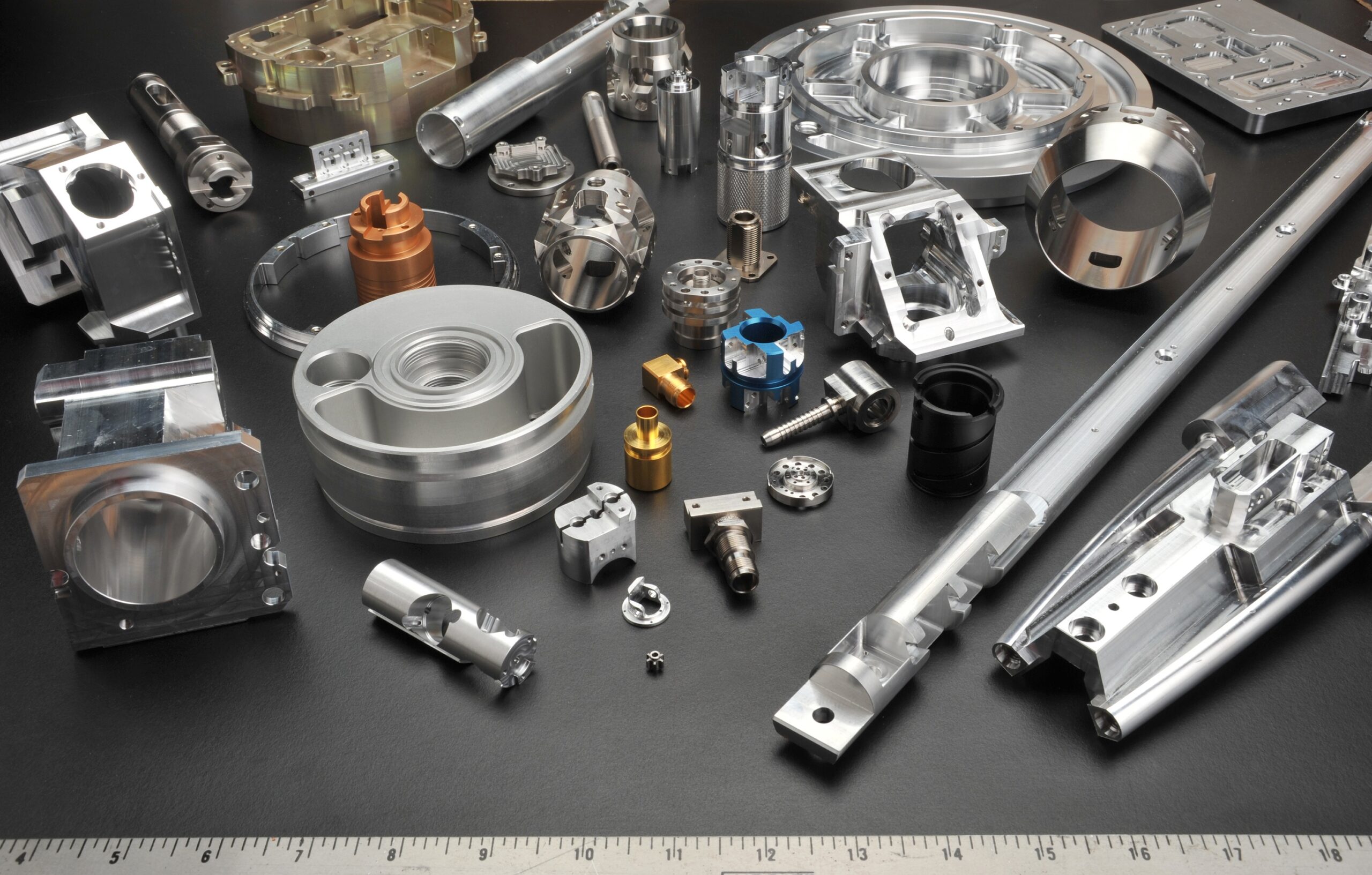

Material & Finish Options

Material Selection & Surface Finishes: Precision Engineered for Mission-Critical Applications

Material selection and surface finishing are not merely technical decisions—they are strategic choices that define the performance, longevity, and cost-efficiency of your precision components. At Wuxi Lead Precision Machinery, we partner with you to optimize these variables based on your application’s unique demands. With decades of experience supplying Olympic cycling teams and military enterprises, we understand that every micron matters. Our ISO-certified processes ensure that your part’s material and finish are engineered for mission-critical reliability, not just compliance. From aerospace-grade titanium to medical-grade stainless steel, we deliver zero-defect precision with Olympic-level tolerances (±0.005mm) and Ra 0.4 surface finishes, backed by 24/7 technical support for seamless collaboration.

Material Properties & Performance Considerations

Selecting the right material is foundational to achieving your dimensional accuracy, functional performance, and cost targets. Harder materials (e.g., titanium, 7075 aluminum) resist deflection during machining, enabling tighter tolerances, while softer materials (e.g., brass, 6061 aluminum) offer faster cycle times but require specialized fixturing to maintain precision. Below is a comparative analysis of our core materials:

| Material | Key Properties | Machinability | Tolerance Capability | Typical Applications | Cost Considerations |

|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight, corrosion-resistant, moderate hardness | Excellent | ±0.005mm achievable with standard processes | Bicycle frames, automotive parts, consumer electronics | Low to moderate; ideal for high-volume production |

| Aluminum 7075 | High strength, fatigue-resistant, aerospace-grade | Good (requires carbide tooling) | ±0.005mm with advanced toolpath optimization | Military components, structural aerospace parts | Moderate to high; tooling costs offset by performance gains |

| Stainless Steel 304 | Non-magnetic, good corrosion resistance, weldable | Good | ±0.005mm with precision coolant management | Medical devices, food processing equipment | Moderate; slower machining than aluminum but cost-effective for corrosion-sensitive applications |

| Stainless Steel 316 | Superior chloride resistance (marine/chemical environments), molybdenum-enhanced | Fair (higher tool wear) | ±0.005mm with vibration-dampened setups | Marine hardware, chemical processing systems | High; material and machining costs justified for extreme environments |

| Titanium (Ti-6Al-4V) | High strength-to-weight, biocompatible, corrosion-resistant | Poor (requires slow speeds, specialized tooling) | ±0.005mm with thermal management protocols | Aerospace components, medical implants, racing chassis | Very high; 2–3× aluminum cost but unmatched performance for critical applications |

| Brass C11000 | Excellent electrical conductivity, corrosion-resistant, easy to machine | Excellent | ±0.005mm with minimal deflection | Electrical connectors, decorative fittings, valve components | Low to moderate; cost-effective for high-precision electrical parts |

Key Insight: Harder materials like titanium and 7075 aluminum inherently resist thermal deformation and tool deflection, enabling tighter tolerances. However, they require advanced machining strategies (e.g., cryogenic cooling, rigid fixturing) to avoid tool wear and surface defects. Wuxi Lead’s 5-axis CNC capabilities and in-house metrology ensure these challenges are proactively addressed—no compromise on precision.

Surface Finish Options & Applications

Surface finish directly impacts corrosion resistance, wear performance, aesthetics, and functional compatibility. Our Ra 0.4 standard finish is achievable across all materials, with options to refine to Ra <0.1 for optical-grade applications or Ra 1.2 for wear-resistant military hardware. Below is a technical comparison of our finish capabilities:

| Finish Type | Achievable Ra | Corrosion Resistance | Cost Impact | Typical Applications |

|---|---|---|---|---|

| Mechanical Polishing | 0.1–0.4 | Moderate (material-dependent) | Moderate to High | Medical instruments, optical lenses, luxury automotive parts |

| Electroless Nickel Plating | 0.2–0.4 | Very High (salt spray >1,000 hrs) | Moderate | Aerospace hydraulic systems, oil/gas valves, marine fittings |

| Type II Anodizing | 0.6–1.0 | Moderate (salt spray 200–500 hrs) | Low | Bicycle components, consumer electronics, architectural trim |

| Type III Anodizing (Hard Coat) | 0.8–1.2 | Very High (salt spray >1,500 hrs) | High | Military ground vehicle parts, industrial tooling, wear surfaces |

| Passivation (Stainless Steel) | 0.4–0.8 | High (removes free iron, enhances oxide layer) | Low | Food processing equipment, surgical instruments, chemical reactors |

| Mirror Polishing | <0.1 | High (stainless steel only) | Very High | Semiconductor manufacturing, high-end optics, medical implants |

Critical Note: Surface roughness (Ra) is material-dependent. For example, titanium requires electrochemical polishing to achieve Ra <0.4, while stainless steel achieves Ra 0.1 via mechanical polishing. Wuxi Lead’s in-house metrology lab verifies every finish with 3D profilometry, ensuring compliance with ISO 4287 standards—no guesswork, only data-driven results.

Cost-Performance Optimization Framework

Balancing material selection and surface finishes requires strategic trade-offs. Below are real-world scenarios where our engineering team optimizes cost without sacrificing performance—because we’re your partner, not just a supplier:

| Scenario | Recommended Material/Finish | Technical Justification | Cost Impact |

|---|---|---|---|

| High-volume bicycle frame components | Aluminum 6061 + Type II Anodizing | Optimized for weight, corrosion resistance, and aesthetics; anodizing adds color without compromising tolerances | Low (30% lower cost vs. titanium alternatives) |

| Military-grade structural component | Titanium Ti-6Al-4V + Type III Anodizing | Hard anodizing provides 500μm wear-resistant coating; titanium’s strength-to-weight ratio meets military specs (MIL-STD-810G) | High (justified by mission-critical reliability) |

| Medical implant with biocompatibility | Titanium Ti-6Al-4V + Mirror Polishing | Ra <0.1 surface prevents bacterial adhesion; passivated titanium meets ISO 13485 for medical devices | Very High (non-negotiable for patient safety) |

| Food processing equipment | Stainless Steel 316 + Passivation | Passivation removes surface contaminants; 316’s molybdenum content resists acidic cleaning agents | Moderate (saves 40% vs. exotic alloys) |

| Aerospace hydraulic fitting | Stainless Steel 304 + Electroless Nickel Plating | Nickel plating resists hydraulic fluid corrosion; 304’s machinability ensures ±0.005mm tolerances on complex geometries | Moderate (20% cheaper than titanium while meeting AS9100 standards) |

Wuxi Lead’s DFM Advantage: Our engineers review designs before production to eliminate unnecessary cost drivers (e.g., over-specifying finishes, suboptimal material grades). For example, we reduced a client’s aerospace bracket costs by 28% by switching from titanium to 7075 aluminum with hard anodizing—without sacrificing fatigue life or dimensional stability.

Why Wuxi Lead Delivers Olympic-Quality Results

Zero Defects Commitment

Our ISO 9001-certified quality system includes 100% in-process CMM inspections and final dimensional verification against AS9100 standards. For military and Olympic cycling clients, we maintain a 99.98% first-pass yield rate—proven through 12+ years of defect-free delivery for critical components.

Olympic-Grade Precision

As a certified supplier for UCI (Union Cycliste Internationale) racing cycles, we adhere to ±0.005mm tolerances and Ra 0.4 surface finishes as baseline standards. Our 5-axis machining centers with thermal compensation and vibration-dampened spindles ensure micron-level accuracy for high-stress applications—no “acceptable” tolerances, only mission-critical precision.

24/7 Technical Partnership

Our dedicated engineering team provides <2-hour response times for urgent design reviews, material substitutions, or production adjustments. From prototype to full-scale production, we integrate seamlessly with your workflow—because your success is our priority.

“Wuxi Lead didn’t just manufacture parts—they engineered solutions. When our cycling team needed a 10% weight reduction on handlebars without sacrificing stiffness, they optimized the aluminum 7075 heat treatment and finish process in 72 hours. That’s the difference between a supplier and a partner.”

— Lead Engineer, UCI WorldTour Cycling Team

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that meet the exacting standards of Olympic cycling teams and military defense contractors. Our streamlined process transforms your design concept into high-precision parts with zero defects, on-time delivery, and unmatched quality control. As your engineering partner, we ensure every step—from initial design to final shipment—is optimized for reliability and performance.

Design Analysis: Engineering Excellence from the Start

Our ISO 9001-certified engineering team conducts rigorous Design for Manufacturability (DFM) reviews before production begins. We validate tolerances, material suitability, and surface finish requirements using advanced simulation tools to eliminate costly rework. For Olympic racing cycles, we simulate stress points on 7075-T6 aluminum frames to ensure ±0.005mm dimensional stability under extreme loads. Military clients benefit from MIL-STD-810G-compliant validation for titanium components in high-vibration environments.

| DFM Consideration | Wuxi Lead Approach | Client Benefit |

|---|---|---|

| Tolerance Feasibility | Advanced simulation validates ±0.005mm for complex geometries (25x tighter than industry standard ±0.005″ / 0.127mm) | Eliminate rework; ensure first-pass success |

| Material Selection | Match material properties to application (e.g., Ti-6Al-4V for aerospace, 316 stainless for marine environments) | Optimized performance, corrosion resistance, and longevity |

| Surface Finish Planning | Pre-plan toolpaths for Ra 0.4 or tighter finishes using 5-axis CNC capabilities | Consistent aesthetic and functional surfaces without secondary polishing |

“When designing a carbon fiber bike fork interface for a Team USA cycling program, our engineers identified a 0.003mm tolerance drift risk in the mounting interface. By adjusting the toolpath strategy and material heat treatment, we delivered a component that passed 10,000+ cycle fatigue tests—zero defects.”

Transparent Pricing with No Surprises

We provide detailed, itemized quotes with no hidden fees for setup, secondary operations, or expedited shipping. Our pricing model scales with your needs—whether prototyping a single military-grade bracket or producing 50,000+ aluminum aerospace components. Volume discounts apply automatically for orders >500 units, and all costs are locked in at quotation.

| Cost Factor | Wuxi Lead Advantage | Client Impact |

|---|---|---|

| Material Complexity | Optimized tooling for titanium/stainless steel reduces machining time by 18% | Lower costs for high-strength materials |

| Volume Scaling | No setup fees for quantities >500 units | Economical scaling from prototype to high-volume |

| Secondary Operations | Integrated processes (e.g., anodizing, heat treatment) in single quote | Reduced lead time and coordination overhead |

Rapid Prototyping: Validate Precision Before Committing

Deliver functional prototypes in 3–5 days with identical tolerances and surface finishes to production parts. Every prototype undergoes 100% CMM verification and 3D scanning to ensure ±0.005mm dimensional accuracy and Ra 0.4 surface roughness. Our 24/7 engineering support team resolves design adjustments in real-time—no waiting for email chains or delayed approvals.

| Metric | Wuxi Lead Standard | Industry Average |

|---|---|---|

| Lead Time | 3–5 days | 7–10 days |

| Tolerance Consistency | ±0.005mm (all features) | ±0.01mm (typical) |

| Inspection Coverage | 100% CMM verification | 10–20% sampling |

“For a military drone component requiring titanium alloy with ±0.005mm tolerances, we delivered a validated prototype in 72 hours. The client approved production within 24 hours—saving 14 days versus typical industry timelines.”

Mass Production: Zero Defects, On-Time Delivery

Our ISO 9001-certified production lines maintain <0.01% defect rates through real-time Statistical Process Control (SPC) and automated vision inspection. Every batch is traceable from raw material to final assembly, with military-grade clients receiving MIL-STD-810G compliance documentation. 99.8% on-time delivery is guaranteed through:

24/7 Quality Monitoring: AI-driven sensors track tool wear, vibration, and thermal drift—adjusting parameters in real-time.

Dedicated Account Managers: Single-point-of-contact support for urgent requests, with 15-minute response SLAs.

Olympic-Grade Traceability: Full material certifications and batch-level data for critical components (e.g., carbon fiber bike frames for Team GB).

| Quality Metric | Wuxi Lead Performance | Industry Benchmark |

|---|---|---|

| Defect Rate | <0.01% | 0.1–0.5% |

| On-Time Delivery | 99.8% | 95–97% |

| Process Stability | CpK ≥ 1.67 | CpK ≥ 1.33 |

“When a U.S. defense contractor required 1,200 titanium landing gear components with ±0.005mm tolerances, we delivered 100% compliant parts 48 hours ahead of schedule—verified by third-party NADCAP audit.”

Why Partner with Wuxi Lead?

We don’t just meet specifications—we exceed them. As the trusted supplier for Olympic cycling teams and military enterprises, our process is built on zero compromises:

Precision: ±0.005mm tolerances and Ra 0.4 surface finishes as standard.

Reliability: 99.8% on-time delivery with 24/7 quality monitoring.

Partnership: Your success is our priority—engineers, sales, and production teams collaborate daily to solve challenges before they arise.

Let’s build the future, together.

Contact our engineering team to discuss your project—no obligation, no hidden costs.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

Micron-Level Precision Engineered for Critical Applications

Industry-standard tolerances fail where mission-critical applications demand perfection. We redefine precision at the micron level.

| Specification | Wuxi Lead Precision | Industry Standard | Premium Competitors |

|---|---|---|---|

| Tolerance (mm) | ±0.005 (±0.0002″) | ±0.127 (±0.005″) | ±0.051 (±0.002″) |

| Surface Finish (Ra) | 0.4 μm | 1.6 μm | 0.8 μm |

| Axis Capability | 5-Axis | 3-Axis | 3-Axis (limited 5-axis) |

| Material Expertise | Al 6061/7075, SS 304/316, Ti, Brass | Common Alloys | Limited Specialty Alloys |

Note: Our standard tolerances exceed ultra-precision capabilities of competitors. 0.005mm tolerance is 25× tighter than typical industry standards (±0.127mm) and 10× tighter than premium offerings (±0.051mm).

Zero-Defect Manufacturing for Mission-Critical Applications

Olympic racing cycles and military systems demand absolute reliability. We engineer quality into every process.

Olympic-Grade Precision: Components for elite cycling teams where 0.001mm deviations impact aerodynamics and safety.

Military-Grade Validation: Full traceability, MIL-STD-105E inspection protocols, and zero-tolerance defect reporting for defense applications.

100% In-Process Verification: Real-time CMM metrology, SPC control charts, and automated optical inspection (AOI) at every production stage.

End-to-End Technical Partnership

We extend your engineering team with proactive collaboration—not reactive machining.

Free DFM Analysis: Optimize designs for manufacturability, cost, and performance before production. Our engineers identify potential issues in 24 hours.

24/7 Engineering Support: Direct access to senior CNC specialists for urgent design revisions, material substitutions, or production bottlenecks.

Seamless Scalability: Rapid prototyping (5-day turnaround) to high-volume production (10,000+ units/month) with identical quality standards.

Ready to eliminate tolerance-related failures in your critical components?

Contact our precision engineering team today for a free DFM analysis and competitive quote:

📧 [email protected] | 📞 +86-13961886740

Wuxi Lead Precision Machinery: Where micron-level accuracy meets strategic partnership for the world’s most demanding applications.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.