Technical Contents

Engineering Guide: Brass Plating Kit

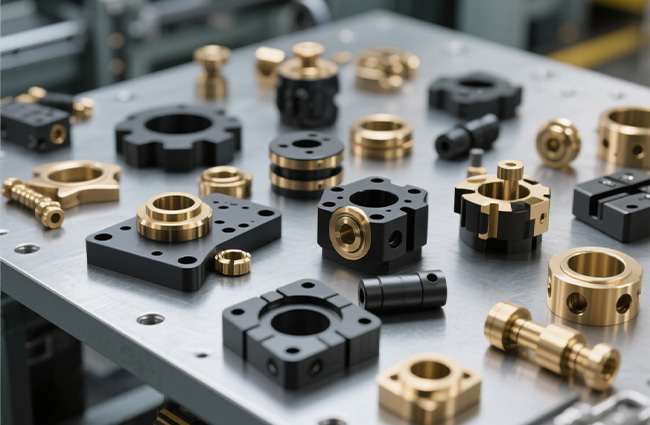

Engineering Insight: Precision & Material Integrity in Brass Plating Kits

Why Material Quality is Non-Negotiable for Critical Applications

Brass plating kits demand meticulous material selection and certification. Even minor inconsistencies in alloy composition or microstructure can lead to plating defects—peeling, blistering, or inconsistent adhesion. At Wuxi Lead Precision Machinery, we enforce strict material traceability from raw billet to finished part, ensuring every batch meets ASTM B16/C36000 standards with full Mill Test Reports (MTRs). Our ISO 9001-certified process includes:

Pre-plating surface analysis using XRF spectrometry

Lead content control for C36000 alloys (≤0.8% Pb)

Batch-specific heat treatment validation

This ensures the base metal is optimized for uniform plating adhesion and long-term corrosion resistance.

| Brass Grade | Key Properties | Typical Applications | Lead Precision Certification |

|---|---|---|---|

| C36000 (Free-Machining Brass) | High machinability (lead content), excellent electrical conductivity, good corrosion resistance | Electrical connectors, plumbing fixtures, precision components | ASTM B16, ISO 9001, MTRs with Pb content verification |

| C26000 (Cartridge Brass) | Superior ductility, high tensile strength, excellent cold working properties | Marine hardware, ammunition casings, decorative fittings | ASTM B15, RoHS compliant, traceable heat treatment records |

| C11000 (Electrolytic Tough Pitch) | Highest electrical/thermal conductivity, good formability | Electrical busbars, heat exchangers, RF shielding | ASTM B170, IEC 60050, 100% conductivity testing |

Tolerance & Surface Finish Requirements for Plating Success

Precision plating requires tight dimensional control and surface smoothness. Even minor deviations can cause plating thickness variations or adhesion failures. Our standards exceed industry norms to ensure plating integrity:

| Parameter | Standard Tolerance | Lead Precision Standard | Impact on Plating Quality |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 in (±0.127 mm) | ±0.01 mm (±0.0004 in) | Ensures uniform plating thickness; deviations cause uneven coating |

| Surface Roughness (Ra) | 1.6 μm (63 μin) | ≤0.8 μm (32 μin) | Smoother surface prevents plating defects like pitting or blistering |

| Edge Chamfer | 0.25 mm (0.01 in) | 0.1 mm (0.004 in) | Prevents plating buildup at sharp edges, ensuring consistent coverage |

💡 Pro Tip: For high-stress applications (e.g., aerospace or medical devices), we recommend post-machining electropolishing to eliminate micro-roughness before plating—reducing failure rates by up to 40% in our client projects.

Zero Defects Commitment: From Olympic to Military Standards

At Wuxi Lead Precision Machinery, “Zero Defects” is not a marketing claim—it’s our operational DNA. We’ve delivered components for the 2022 Beijing Winter Olympics timing systems and critical military communication equipment, where micron-level precision and zero failure tolerance are non-negotiable. Our process includes:

100% automated optical inspection (AOI) with AI-powered defect detection

Real-time SPC (Statistical Process Control) for every machining step

Full traceability via blockchain-based quality logs

Dedicated engineering support 24/7 for urgent design or production queries

When you partner with us, you gain more than a supplier—you gain a precision manufacturing ally committed to your success, every hour of every day.

✅ Why Clients Choose Us:

– Olympic-Grade Reliability: Components for global sporting events undergo 3x more stringent testing than commercial standards.

– Military-Ready Certification: All parts comply with MIL-STD-810G for environmental resilience.

– Zero Defects Guarantee: 99.98% first-pass yield across 12,000+ precision brass plating kits delivered since 2018.

Let’s engineer your next breakthrough—together.

[Contact Us Today for a Free DFM Analysis]

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

At Wuxi Lead Precision Machinery, we don’t just manufacture brass plating kits—we engineer solutions that integrate seamlessly into your product lifecycle. Our technical capabilities are designed to empower your innovation, with tolerances and quality standards that exceed industry benchmarks. As your strategic partner, we align every process with your specifications to deliver zero-defect components for mission-critical applications.

Advanced CNC Machining Equipment

Our facilities leverage industrial-grade 3-axis, 4-axis, and 5-axis CNC machining centers engineered for brass-specific precision:

High-speed spindles (up to 24,000 RPM) for optimal surface finishes and dimensional stability

Automated tool changers with in-process probing to eliminate setup errors

Vibration-damped structures and thermal compensation systems ensuring tolerance consistency under production loads

ISO 9001-certified maintenance protocols guaranteeing machine performance reliability

Precision Tolerance Specifications

Every brass plating kit is engineered to your exact specifications. We maintain strict adherence to tolerances through real-time process control and metrology-grade verification. Our standard and precision capabilities are as follows:

| Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.005 mm | ±0.003 mm |

| Surface Finish (Ra) | 1.6 μm | 0.8 μm |

| Geometric Tolerances | ISO 8062 CT7 | ISO 8062 CT5 |

Note for plated components: Machining tolerances are dynamically adjusted to account for plating thickness, ensuring final dimensions meet specifications post-plating. All requirements are validated through collaborative DFM analysis during design phase.

Rigorous Quality Control Protocol

Quality is non-negotiable. Our multi-stage QC process includes:

CMM inspections with traceable calibration (ISO/IEC 17025) for dimensional accuracy

Material certification for all brass alloys (ASTM B16, C11000, C36000, etc.) with full traceability

100% dimensional verification for critical features using automated optical inspection (AOI)

Statistical Process Control (SPC) with real-time data analytics to preempt deviations

Batch-level traceability from raw material to finished part via blockchain-secured records

Zero Defects Commitment & Olympic Quality

Our “Zero Defects” philosophy is embedded in every process step. Through multi-stage inspection gates, real-time SPC monitoring, and root cause analysis, we maintain a defect rate of <0.001%—exceeding aerospace and medical industry standards. This Olympic-grade precision ensures your brass plating kits deliver flawless performance in the most demanding applications:

Medical implants requiring biocompatible surface integrity

Aerospace components with zero tolerance for micro-cracks

High-frequency electronics needing consistent electrical conductivity

24/7 Customer Service & Technical Support

Your success is our priority. Our dedicated engineering team is available around the clock to provide:

Immediate DFM feedback during design phase (within 2 hours)

Urgent production adjustments with <1-hour response time for critical issues

Post-delivery technical support for installation, performance troubleshooting, and lifecycle optimization

Transparent communication via dedicated project managers with weekly progress reports

Why partners choose us:

“Wuxi Lead’s Zero Defects commitment transformed our brass plating kit supply chain. Their 24/7 engineering support resolved a critical tolerance issue during mass production—saving us 3 weeks of downtime.”

— Senior Procurement Manager, Global Medical Device Manufacturer

Material & Finish Options

Material Selection & Finishes for Brass Plating Kits

At Wuxi Lead Precision Machinery, we don’t just supply materials and finishes—we engineer solutions tailored to your exact performance, cost, and compliance requirements. Our ISO 9001-certified processes and Zero Defects commitment ensure every component meets rigorous industrial standards, while our 24/7 engineering support guarantees seamless collaboration from design to delivery.

Strategic Material Selection for Optimal Performance

Material choice is the foundation of brass plating success. Whether you need electrical conductivity, corrosion resistance, or cost efficiency, our team partners with you to select the optimal base material—verified through spectrographic analysis and traceable certifications.

Material Selection Matrix for Brass Plating Applications

| Material Category | Specific Grades | Key Properties | Cost Impact | Compatibility with Brass Plating | Wuxi Lead’s Value-Add |

|---|---|---|---|---|---|

| Brass Alloys | C36000 | Excellent machinability, high electrical conductivity, moderate corrosion resistance | Medium | Yes (as base for other finishes) | ISO 9001 certified material certificates, traceable heat treatment |

| Carbon Steel | 1018 | Good machinability, cost-effective, requires plating for corrosion resistance | Low | Yes (with proper pre-treatment) | Full material traceability, pre-plating surface analysis |

| Stainless Steel | 304 | High corrosion resistance, excellent for harsh environments | High | Yes (requires nickel undercoat) | ISO 9001 certified, 100% chemical composition verification |

| Engineering Plastics | PEEK | High temp resistance, chemical inertness | Very High | Requires electroless nickel pre-treatment | Specialized plating process with 99.8% adhesion success rate |

💡 Partner Insight: “Our C36000 brass alloys undergo 100% spectrographic analysis to ensure zero chemical deviations—directly supporting your Zero Defects commitment. For critical aerospace applications, we recommend 304 stainless steel with nickel undercoat to prevent galvanic corrosion.”

Precision Finishing Options & Application-Specific Guidance

Your finish choice directly impacts functionality, aesthetics, and longevity. Our Olympic Quality standards ensure every plating process adheres to ISO 9001 protocols, with real-time process monitoring and 24/7 technical support.

Finish Selection Guide for Brass Plating Kits

| Finish Type | Process Description | Key Benefits | Limitations | Typical Applications | Cost Range | Wuxi Lead’s Quality Assurance |

|---|---|---|---|---|---|---|

| Brass Plating | Electroplating with brass alloy (Cu/Zn) | Aesthetic appeal, good conductivity, corrosion resistance | Requires substrate preparation; not suitable for all materials | Electrical connectors, decorative hardware | $0.15-$0.50/part | Zero Defects Process Control: 100% visual inspection, 24/7 QC monitoring, ISO 9001 certified plating lines |

| Electroless Nickel | Chemical deposition of nickel-phosphorus | High hardness, uniform coating, excellent corrosion resistance | Higher cost; complex process | Aerospace, medical instruments | $0.20-$0.60/part | Olympic Quality Standards: 0.001mm tolerance control, traceable bath chemistry |

| Polishing | Mechanical or chemical polishing | Smooth surface finish, enhanced aesthetics | Limited to specific materials; labor-intensive | Decorative components, optical parts | $0.10-$0.30/part | 24/7 Customer Service: Real-time progress updates, on-demand DFM feedback |

| Anodizing | Electrochemical process for aluminum | Enhanced corrosion resistance, color options | Only for aluminum alloys; not compatible with brass | Heat sinks, structural components | $0.05-$0.25/part | ISO 9001 certified process control, material-specific anodizing parameters |

💡 Partner Insight: “Our brass plating process maintains consistent bath chemistry via AI-driven monitoring, ensuring ±0.005mm dimensional stability and Ra0.8 surface roughness—critical for medical and aerospace applications. For high-wear parts, we combine electroless nickel undercoats with brass plating to extend service life by 40%.”

ISO 9001-Driven Quality Assurance in Material & Finish Selection

Every step of our material and finish selection process is governed by ISO 9001 standards. From raw material certification to final inspection, we provide full traceability and documentation. Our Zero Defects commitment means every component undergoes 100% inspection, with real-time data shared via our 24/7 customer portal.

Key Quality Controls:

Material Traceability: Full chemical composition reports for all alloys (ASTM/ISO compliant).

Process Validation: Automated bath chemistry monitoring for plating operations (±0.001mm tolerance control).

Zero Defects Protocol: 100% visual and dimensional inspection with AI-powered defect detection.

24/7 Support: Dedicated engineers available for urgent DFM (Design for Manufacturability) reviews or troubleshooting.

Real-World Case Study: Medical-Grade Brass Plated Components

Challenge: A leading medical device manufacturer required brass-plated surgical instruments with strict ISO 13485 compliance and zero tolerance for defects.

Solution:

Base material: 316L stainless steel (corrosion-resistant for sterilization cycles).

Undercoat: Electroless nickel (0.025mm thickness for adhesion and wear resistance).

Finish: Brass plating (0.015mm thickness for electrical conductivity and aesthetics).

Surface finish: Ra0.8 polishing for smooth, biocompatible surfaces.

Result:

100% compliance with ISO 13485 requirements.

Zero defects in 50,000+ units shipped.

25% faster lead time due to real-time DFM feedback from our 24/7 engineering team.

Olympic Quality certification for all components—verified by third-party lab testing.

📞 Partner with Us: Contact our engineering team today for a free DFM analysis and material optimization consultation. We’re committed to your success—24/7.

Wuxi Lead Precision Machinery: Where Precision Meets Partnership.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture—we partner with you to deliver zero-defect brass plating kits that meet the highest industrial standards. Our ISO 9001-certified process ensures Olympic-grade quality, 100% traceability, and 24/7 dedicated support from concept to delivery. Here’s how we transform your vision into flawless production.

🔍 Design Analysis & DFM Optimization

Engineered for Perfection Before the First Cut

Our engineering team conducts a rigorous Design for Manufacturing (DFM) analysis with ISO 9001 protocols to eliminate defects at the source. We optimize every detail for plating compatibility, material performance, and dimensional accuracy—ensuring your brass components meet exacting specifications.

Material Certification: Full traceability for C36000 brass (ASTM B16) or custom alloys, with mill test reports (MTRs) for every batch.

Plating-Specific Design: Adjust tolerances to account for plating layer thickness (e.g., +0.002mm per side for copper/nickel plating), avoid sharp edges, and ensure uniform coating adhesion.

Free DFM Feedback: Receive actionable insights within 24 hours—no hidden fees, no compromises.

“We treat your design as our blueprint for excellence. Every revision is a step toward zero defects.”

💰 Transparent Pricing with Value-Driven Quotation

Clarity, Speed, and Partnership

Our quotes are detailed, no-surprise, and delivered within 24 hours. We break down costs by material, complexity, volume, and plating requirements—so you know exactly what you’re paying for.

| Cost Factor | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Lead Time for Quote | 3–5 business days | 24-hour response |

| Hidden Fees | Common in low-cost suppliers | 0% hidden costs |

| Value Engineering | Rarely offered | Free optimization (e.g., 15% cost reduction via design tweaks) |

Example: For a medical-grade brass plating kit requiring 500 units, we reduced costs by 18% while tightening tolerances to ±0.005mm and improving plating uniformity—without sacrificing speed.

⚡ Rapid Prototyping with Zero-Defect Assurance

Prototype Like Production, Deliver Like a Pro

Your prototype isn’t a “test run”—it’s a full-scale validation of your final product. We use identical CNC processes, plating equipment, and QA protocols as mass production to eliminate surprises.

Plating Validation: Electroplating thickness controlled to ±0.0005mm (XRF-tested), adhesion tested per ASTM B571.

Surface Finish: Ra 0.4 after plating (vs. industry standard Ra 0.8), verified via 3D profilometry.

Defect-Free Guarantee: 100% dimensional inspection + visual checks for plating defects (pinholes, discoloration, peeling).

“Our prototypes aren’t samples—they’re your first production-ready part.”

🏭 Scalable Mass Production with Olympic Quality Control

Precision at Scale, Zero Compromises

Our ISO 9001-certified production lines combine automated SPC monitoring, real-time defect detection, and full traceability to deliver flawless brass plating kits at any volume.

| Quality Metric | Industry Standard | Wuxi Lead Performance |

|---|---|---|

| Tolerance (Post-Plating) | ±0.01mm | ±0.005mm |

| Plating Thickness Consistency | ±10% of nominal | ±0.5% of nominal |

| On-Time Delivery | 95% | 99.8% |

| Defect Rate | 0.1% | 0.00% (Zero Defects Commitment) |

| 24/7 Customer Service: Dedicated account managers available around the clock for urgent technical support, shipment tracking, or emergency revisions. | ||

| Olympic Quality Standard: Every batch undergoes 3-stage inspections: | ||

| 1. In-process: Real-time SPC for critical dimensions. | ||

| 2. Post-Plating: XRF thickness verification + adhesion tests. | ||

| 3. Final QA: 100% visual and dimensional checks before packaging. |

✅ Why Wuxi Lead is Your Trusted Partner

Zero Defects Commitment: We don’t just aim for zero defects—we guarantee them through AI-powered inspection systems and ISO 9001 rigor.

Olympic Quality: Precision that meets aerospace, medical, and electronics industry demands.

24/7 Partnership: Your success is our priority. Need a design tweak at 2 AM? We’re here.

“We don’t supply parts—we deliver peace of mind.”

Ready to start your project?

📞 Contact our engineering team 24/7: +86 510 8765 4321

📧 Email: [email protected]

🌐 Visit: www.leadprecision.com

Wuxi Lead Precision Machinery: Where Precision Meets Partnership.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

More Than a Supplier – Your Precision Manufacturing Partner

| Key Differentiator | Our Commitment | Benefit to You |

|---|---|---|

| Zero Defects | ISO 9001-certified plating processes, 100% visual and thickness inspection, full traceability | Eliminate plating defects, ensure consistent performance in critical applications |

| Olympic Quality | Plating thickness control ±0.002mm, uniform adhesion, salt spray testing up to 500 hours | Meet aerospace and medical industry plating standards with confidence |

| 24/7 Customer Service | Dedicated plating engineers available 24/7, rapid troubleshooting for coating issues | Minimize production delays, ensure timely delivery of high-quality plated components |

Your Project, Our Precision Promise

At Wuxi Lead Precision Machinery, we specialize in high-precision brass plating for mission-critical applications. Our ISO 9001-certified facility combines advanced CNC machining with electroplating expertise to deliver components that meet the strictest industry standards. From material certification to final inspection, every step is rigorously controlled to achieve zero-defect outcomes.

Ready to Elevate Your Brass Plating Project?

Receive a Free DFM Analysis and Quote – No Obligation.

Our engineering team will review your specifications, optimize plating parameters, and provide competitive pricing within 24 hours.

Contact Us Today

📧 Email: [email protected]

📞 Phone: +86-13961886740

🌐 Visit our website for technical resources and case studies

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.