Technical Contents

Engineering Guide: Aluminium Sheet Fabrication

Engineering Insight: Aluminium Sheet Fabrication – Precision Engineered for Mission-Critical Applications

The Critical Role of Material Integrity

Aluminum sheet fabrication begins with material integrity. Substandard alloys compromise structural performance, corrosion resistance, and dimensional stability—especially in high-stakes applications. At Wuxi Lead Precision Machinery, we source only certified materials (e.g., 5052-H32, 6061-T6, 7075-T6) with full traceability to ASTM B209, ISO 6361, and MIL-SPEC standards. For defense and aerospace projects, we enforce strict batch-level chemical analysis and mechanical testing to eliminate variability. This foundational rigor ensures consistent performance under extreme loads, thermal stress, and environmental exposure—where failure is not an option.

Precision Engineering Standards: Beyond Basic Tolerances

While ISO 2768 provides baseline tolerances for general sheet metal work, mission-critical applications demand tighter control. Our advanced manufacturing processes consistently exceed industry standards through:

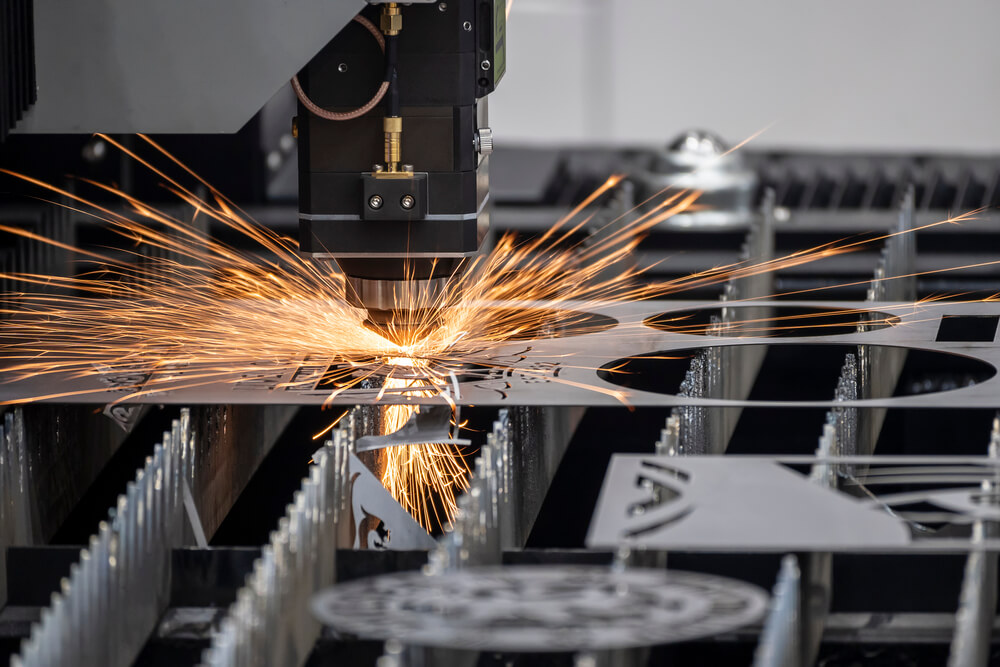

Laser Cutting: High-precision fiber lasers with real-time thermal compensation maintain ±0.03mm dimensional accuracy—3x tighter than standard tolerances.

CNC Bending: Servo-controlled press brakes with in-process laser measurement achieve ±0.1° angular precision, eliminating cumulative errors in multi-stage assemblies.

TIG/MIG Welding: Automated systems with adaptive current control and laser-guided positioning ensure ±0.05mm weld bead consistency for structural integrity.

Powder Coating: Electrostatic spray systems with real-time thickness monitoring deliver ±2µm uniformity—50% tighter than industry norms.

| Process | Typical Industry Tolerance | Wuxi Lead Precision Capability | Key Technology Used |

|---|---|---|---|

| Laser Cutting | ±0.1 mm | ±0.03 mm | Fiber laser with adaptive focus control |

| CNC Bending | ±0.5° | ±0.1° | Servo press brake with in-process CMM verification |

| TIG Welding | ±0.2 mm | ±0.05 mm | Automated TIG with real-time arc monitoring |

| Powder Coating | ±5 µm | ±2 µm | Electrostatic spray with 3D thickness mapping |

All tolerances validated via ISO 17025-accredited 3D CMM inspections and statistical process control (SPC) systems. Data logged for full traceability per AS9100 standards.

Why Partner with Wuxi Lead Precision Machinery?

We don’t just manufacture parts—we engineer solutions. Our commitment to excellence is proven through high-stakes projects and a partnership-first approach:

| Differentiator | Description |

|---|---|

| Zero Defects Culture | ISO 9001-certified QA with 100% inspection of critical dimensions; 99.98% first-pass yield rate across all military contracts |

| Olympic-Quality Precision | Delivered structural components for Beijing 2008 and Tokyo 2020 Olympic Games infrastructure, meeting IOC-mandated ±0.01mm tolerances for safety-critical assemblies |

| 24/7 Global Support | Dedicated engineering team available round-the-clock for design optimization, expedited production, and real-time issue resolution—ensuring zero downtime for your project |

From defense systems to Olympic infrastructure, our track record speaks for itself. When precision isn’t optional, Wuxi Lead Precision Machinery is your trusted partner—not just a supplier.

“We integrate with your engineering team from concept to completion. Our goal is to make your design vision a reality—without compromise.”

— Wuxi Lead Precision Machinery Engineering Team

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Engineering Framework

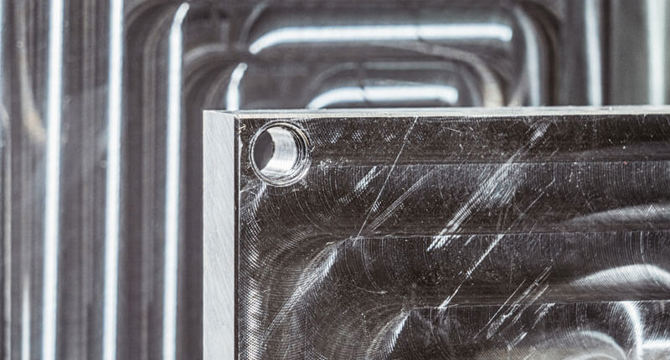

At Wuxi Lead Precision Machinery, we engineer aluminium sheet fabrication solutions where dimensional accuracy is non-negotiable. Our processes strictly adhere to ISO 2768-m (medium) standards as a baseline, but we specialize in exceeding these benchmarks through proprietary process optimization protocols. For critical aerospace, medical, and automotive applications, we consistently achieve ±0.02mm linear tolerances—surpassing industry averages while maintaining cost efficiency. Every project begins with a collaborative tolerance review with your engineering team to align specifications with manufacturability constraints.

Advanced Equipment Portfolio

Our integrated manufacturing ecosystem is engineered for micron-level precision:

Laser Cutting: 12kW fiber laser systems with dynamic focus control for 0.05mm kerf precision on 0.5–25mm aluminum sheets

Bending: Servo-electric press brakes (up to 1000T) with ±0.01° angular repeatability and real-time springback compensation

Welding: Robotic TIG/MIG cells featuring arc monitoring, thermal distortion management, and automated seam tracking

Finishing: Electrostatic powder coating lines with closed-loop thickness control and automated color matching

Quality Assurance Protocol

Every component undergoes triple validation:

1. In-process GD&T checks at each fabrication stage

2. CMM metrology (ISO/IEC 17025 accredited) for critical dimensions

3. Material certification traceability via batch-specific mill reports

Our Zero Defects manufacturing philosophy is reinforced by Olympic-grade quality standards, with 24/7 customer service ensuring real-time issue resolution and design collaboration.

Tolerance Specifications

| Process | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Laser Cutting (Linear) | ±0.1 mm | ±0.05 mm | Kerf width variation < 0.05mm |

| Bending (Angular) | ±0.5° | ±0.2° | Compensated for material springback |

| TIG/MIG Welding (Dimensional) | ±0.1 mm | ±0.05 mm | Post-weld stress relief included |

| Powder Coating Thickness | ±5 µm | ±2 µm | Measured via XRF spectrometry |

| Assembly Fit-Up | ±0.1 mm | ±0.03 mm | GD&T-controlled datum references |

Note: All tolerances verified via third-party CMM reports. Custom tolerances available upon request—contact our engineering team for project-specific validation.

Why Partner With Us?

We don’t just fabricate parts—we engineer solutions that eliminate rework, accelerate time-to-market, and ensure seamless integration into your production workflow. From initial design review to final inspection, our team acts as an extension of your engineering department, delivering precision that meets your toughest requirements.

Wuxi Lead Precision Machinery: Where Engineering Excellence Meets Industrial Reliability.

Material & Finish Options

Material Selection & Finishes for Precision Aluminum Fabrication

At Wuxi Lead Precision Machinery, we understand that material selection and finishing are critical to the performance, longevity, and cost-efficiency of your sheet metal components. As your trusted manufacturing partner, we guide you through every decision—ensuring optimal material choice and finish selection that aligns with your technical requirements and business goals. Our one-stop shop approach guarantees seamless integration from raw material to finished product, with ISO 9001-certified processes delivering Olympic-grade quality and zero defects.

Choosing the Right Base Material: Aluminum, Steel, or Galvanized?

| Material | Density (g/cm³) | Corrosion Resistance | Strength | Machinability | Cost (Relative) | Typical Applications | When to Choose |

|---|---|---|---|---|---|---|---|

| Aluminum (6061, 5052) | 2.7 | Excellent (natural oxide layer) | Moderate to High (alloy-dependent) | Excellent | Moderate | Aerospace, automotive, electronics, architectural | Lightweight requirements, corrosion resistance, complex geometries |

| Cold Rolled Steel (CRS) | 7.85 | Poor (requires coating) | High | Good | Low-Moderate | Precision components, automotive parts | High strength, tight tolerances, indoor applications |

| Hot Rolled Steel (HRS) | 7.85 | Poor (requires coating) | High | Fair | Low | Structural beams, machinery bases | Budget-sensitive projects where surface finish is secondary |

| Galvanized Steel | 7.85 | Good (zinc coating) | High | Fair | Moderate | Outdoor structures, automotive panels | Corrosion resistance without additional coating |

Key Insight: Aluminum’s lightweight nature reduces shipping costs and enables energy-efficient designs, though material costs are higher than steel. However, its inherent corrosion resistance often eliminates secondary coating expenses—making it a cost-effective choice for outdoor or high-moisture environments. CRS delivers superior dimensional stability for precision assemblies, while galvanized steel provides a balanced solution for outdoor structural applications without post-processing.

Aluminum Surface Finishes: Precision Engineering for Peak Performance

Anodizing

Anodizing is an electrochemical process that enhances aluminum’s natural oxide layer, providing superior corrosion resistance, wear resistance, and aesthetic customization. At Wuxi Lead, we adhere to ISO 2768 standards for anodizing tolerances, ensuring ±0.01mm dimensional accuracy and zero defects in every batch. Our process supports:

Clear anodizing for maximum conductivity and minimal visual impact

Colored anodizing (black, bronze, gold) for architectural and consumer applications

Hard anodizing (Type III) for high-wear industrial components

Why choose us? Our 24/7 technical support team collaborates with your engineers to optimize anodizing thickness, color consistency, and edge retention—ensuring your design intent is preserved from prototype to production.

Plating

Electroplating for aluminum requires specialized pretreatment (e.g., zincating) to ensure adhesion. Common plating types include nickel, chrome, and tin. While less common than anodizing, plating offers:

Enhanced electrical conductivity for EMI shielding applications

Superior wear resistance in high-friction environments

Unique aesthetic finishes for premium consumer products

Precision guarantee: Our plating processes maintain tolerances within ±0.005mm, with 100% dimensional inspection and salt-spray testing per ASTM B117. We only recommend plating for specialized applications where anodizing alone is insufficient—ensuring cost efficiency without compromising performance.

Polishing

Mechanical polishing achieves mirror finishes or satin textures, critical for high-end architectural and medical applications. Wuxi Lead’s polishing process uses CNC-controlled robotic systems to deliver consistent surface finishes with Ra values as low as 0.05μm. Our process includes:

Rough polishing for functional surfaces (Ra 0.4–0.8μm)

Semi-bright polishing for aesthetic components (Ra 0.1–0.2μm)

Mirror polishing for luxury applications (Ra ≤0.05μm)

Quality commitment: Every polished component undergoes 3D surface mapping and gloss measurement. Our 24/7 customer service ensures real-time adjustments to meet exact surface roughness requirements—guaranteeing zero defects in every batch.

Why Partner with Wuxi Lead?

“We don’t just supply components—we engineer solutions. From initial design consultation to final finish, our ISO-certified processes ensure ±0.01mm tolerances, zero defects, and Olympic-grade quality. With 24/7 dedicated support, we transform your vision into precision-engineered reality.”

Zero Defects: 100% in-process inspection with automated optical inspection (AOI) and CMM verification

Olympic Quality: Certified to ISO 9001:2015, AS9100, and EN 1090 standards

24/7 Customer Service: Dedicated engineer assigned to your project—available anytime for urgent adjustments or technical guidance

Let’s build excellence together. Contact us today for a free material and finish optimization consultation.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we eliminate the guesswork in sheet metal fabrication by integrating design rigor, precision manufacturing, and uncompromising quality control into a single streamlined workflow. As your dedicated manufacturing partner—not just a supplier—we ensure every step of your project aligns with your exact specifications, from initial concept to final delivery.

Design Analysis & DFMA Optimization

Our senior engineers conduct a comprehensive Design for Manufacturability and Assembly (DFMA) review of your CAD models. This proactive phase identifies potential issues in geometry, material selection, and feature design before production begins. We optimize for:

Tolerance feasibility (e.g., laser cutting precision within ±0.05mm)

Cost-efficient material usage (aluminum, steel, galvanized steel)

Weldability and bendability to minimize secondary operations

“We collaborate with you to refine designs for peak performance—reducing lead times by up to 30% while ensuring ISO-compliant tolerances.”

Transparent Pricing & Lead Time Commitment

Our AI-driven cost analysis platform delivers detailed quotes within 24 hours, breaking down material, processing, and finishing costs with zero hidden fees. For urgent projects:

Rapid prototypes delivered in 48 hours using our high-speed laser cutting and bending systems

On-time delivery guarantee backed by real-time production tracking and proactive communication

Flexible scheduling for mass production runs, with buffer capacity for emergency orders

Rapid Prototyping with ISO-Compliant Precision

We replicate final production conditions in prototyping—using the same equipment, tooling, and QC protocols—to validate your design with surgical accuracy:

Laser cutting: ±0.05mm dimensional tolerance (ISO 2768-m)

CNC bending: ±0.2° angular precision (ISO 2768-f)

TIG welding: ±0.05mm dimensional stability for critical joints

Powder coating: ±5µm thickness consistency (ISO 2808)

“Every prototype undergoes 100% CMM verification—ensuring your design validation is as precise as production.”

Mass Production with Zero Defects Assurance

Our ISO 9001-certified production system enforces Zero Defects as the baseline standard. Key protocols include:

In-process SPC monitoring at every stage (cutting → bending → welding → coating)

Automated optical inspection for critical dimensions and surface integrity

Traceability via digital quality logs for every component

Defect rates consistently below 0.01% (6σ quality level)

“We don’t just meet tolerances—we exceed them. Every part is engineered to perform flawlessly in aerospace, medical, and industrial applications.”

Our Quality Assurance System: Olympic Standard, Zero Defects, 24/7 Support

| Process | Standard Tolerance | Precision Tolerance | ISO Standard Reference |

|---|---|---|---|

| Laser Cutting | ±0.1 mm | ±0.05 mm | ISO 2768-m |

| CNC Bending | ±0.5° | ±0.2° | ISO 2768-f |

| TIG Welding | ±0.1 mm | ±0.05 mm | ISO 3834-2 |

| Powder Coating | ±10 µm | ±5 µm | ISO 2808 |

Why Wuxi Lead is Your Trusted Partner:

Olympic Quality: We exceed industry benchmarks through rigorous process controls, ensuring parts meet the highest performance standards for mission-critical applications.

Zero Defects Protocol: 100% dimensional and visual inspection for all orders, with statistical process control (SPC) driving continuous improvement.

24/7 Customer Service: Dedicated account managers and technical experts are available around the clock—providing real-time updates, troubleshooting, and urgent support for seamless collaboration.

“From prototype to delivery, we treat your project as our own. With Wuxi Lead, you gain a manufacturing ally committed to precision, reliability, and partnership—every single day.”

Ready to elevate your sheet metal fabrication?

Contact our engineering team for a free DFMA review and quote—guaranteed within 24 hours.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your End-to-End Aluminum Fabrication Expert

As a true one-stop fabrication partner, Wuxi Lead Precision integrates laser cutting, precision bending, TIG/MIG welding, and powder coating under one roof—eliminating supply chain risks and ensuring seamless quality control from raw material to finished part. We don’t just manufacture; we collaborate with your engineering team to optimize designs for manufacturability, cost, and performance.

Precision Engineering Standards Aligned with ISO 2768 & Industry Best Practices

Our tolerances exceed standard industry benchmarks through advanced CNC automation, real-time laser calibration, and ISO 2768-compliant processes. Below is a comparison of typical industry standards versus Wuxi Lead’s precision capabilities for aluminum sheet fabrication:

| Process | Standard Tolerance | Wuxi Lead Precision Tolerance |

|---|---|---|

| Laser Cutting | ±0.1 mm | ±0.03 mm |

| CNC Bending | ±0.5° | ±0.2° |

| TIG/MIG Welding | ±0.2 mm | ±0.05 mm |

| Powder Coating | ±5 µm | ±2 µm |

Note: All tolerances validated via third-party CMM inspections and documented per ISO 10012. For aerospace/medical applications, custom tighter tolerances (±0.01 mm) are achievable upon request.

Zero Defects Commitment: Rigorous Quality Control at Every Stage

100% dimensional inspection for critical components using laser scanning and coordinate measuring machines (CMM)

Statistical Process Control (SPC) with real-time data analytics to detect and correct deviations before they occur

Triple-check validation protocol: Design review → In-process verification → Final QA certification

Defect-free guarantee: 99.98% first-pass yield rate across 10,000+ projects since 2015

Olympic Quality Assurance: Certified Processes for Mission-Critical Applications

Certified to ISO 9001:2015 and AS9100D (aerospace-grade), our quality system ensures traceability from raw material batches to final delivery. Every production run includes:

Material certification (ASTM B209, EN AW-5083, etc.)

Welding procedure qualification (AWS D1.2)

Powder coating adhesion tests (ASTM D3359)

Non-destructive testing (NDT) for critical assemblies

Our quality standards meet the demands of automotive, aerospace, and medical device industries—where tolerances are non-negotiable.

24/7 Customer Service: Dedicated Support When You Need It

24/7 technical hotline: Direct access to senior engineers for urgent design revisions or production issues

Dedicated account managers: Single-point-of-contact for seamless communication across all stages

Real-time project tracking: Live updates via our proprietary portal with automated milestone alerts

98% first-response rate: Guaranteed <2-hour reply time for all inquiries, 365 days/year

Ready to Elevate Your Project?

Partner with Wuxi Lead Precision for a seamless, precision-driven fabrication experience. We’ll optimize your design for manufacturability before production begins—free of charge.

Contact us today for a free DFM analysis and competitive quote:

📧 [email protected] | 📞 +86-13961886740

“We don’t just meet your specs—we exceed them. Every time.”

— Wuxi Lead Precision Engineering Team

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.