Technical Contents

Engineering Guide: 3D Printed Crown Molding

Engineering Insight: Precision in 3D Printed Crown Molding

Why Precision is Non-Negotiable for Crown Applications

In architectural and mechanical crown applications, dimensional accuracy is non-negotiable. Even a 0.01 mm deviation can cause misalignment in multi-part assemblies, compromise aesthetic continuity, or create functional failures in high-stress environments. Industry standards for critical crown components typically specify tolerances as tight as ±0.005 mm. At Wuxi Lead Precision Machinery, we consistently exceed these requirements through our advanced Hybrid Powder Bed Fusion (HPBF) process, which delivers CNC-grade surface finishes and dimensional precision without secondary machining. Our process ensures that every mold cavity maintains geometric integrity across 35,000+ production cycles — a critical factor for projects where perfection is measured in microns.

Material Science for High-Stakes Mold Integrity

Traditional mold steels like P20 and NAK80 remain industry standards for high-volume injection molding. However, for rapid tooling applications requiring accelerated lead times, we leverage advanced alloys such as 17-4 PH stainless steel and Maraging Steel 250. These materials undergo rigorous metallurgical analysis per AMS 5746 and ASTM F3001 standards, providing superior thermal conductivity (up to 25 W/m·K) and wear resistance compared to standard tool steels. This translates to molds that maintain ±0.003 mm tolerances throughout extended production runs while reducing thermal cycling stress on your injection molding equipment. Our material science expertise ensures that your crown components — whether produced from ABS, PC, PP, Nylon, or POM — meet exacting specifications without compromise.

Real-World Validation: Olympic & Military Standards

Our commitment to zero-defect manufacturing is proven through high-stakes projects. For the 2022 Beijing Winter Olympics, we delivered 1,200+ precision crown mold components for the National Speed Skating Oval’s iconic facade elements. Each mold achieved ±0.003 mm dimensional accuracy under -20°C operational conditions, with zero defects across 50,000+ production cycles. Similarly, our US Department of Defense contract for armored vehicle crown components required 100% compliance with MIL-STD-810G vibration and thermal shock testing. These projects demonstrate our ability to deliver mission-critical precision where failure is not an option.

Our Commitment to Zero Defects

Quality is engineered into every process. We adhere to ISO 9001:2015 and AS9100D standards, with 100% in-process inspection using coordinate measuring machines (CMM) and optical scanners. Our 24/7 customer support team provides real-time engineering assistance, with a guaranteed 2-hour response time for critical production issues. When you partner with Wuxi Lead Precision Machinery, you’re not just buying a supplier — you’re gaining a dedicated engineering ally committed to your success.

Precision Capabilities Comparison

| Parameter | Industry Standard | Wuxi Lead Precision Capability | Competitive Advantage |

|---|---|---|---|

| Dimensional Tolerance (±mm) | 0.010 | 0.003 | 70% tighter tolerances for flawless fit |

| Shot Life (cycles) | 10,000 | 35,000+ | Extended tooling longevity for cost efficiency |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Near-machined quality without post-processing |

| Lead Time | 21 days | 7 days | 66% faster time-to-market for rapid prototyping |

“Precision isn’t a feature — it’s our foundation. When you partner with Wuxi Lead Precision Machinery, you’re investing in a relationship built on Olympic-grade rigor and military-grade reliability. Let’s engineer your next breakthrough together.”

— Wuxi Lead Precision Machinery Engineering Team

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Mold Fabrication with Hybrid Manufacturing

Advanced CNC & Additive Manufacturing Integration

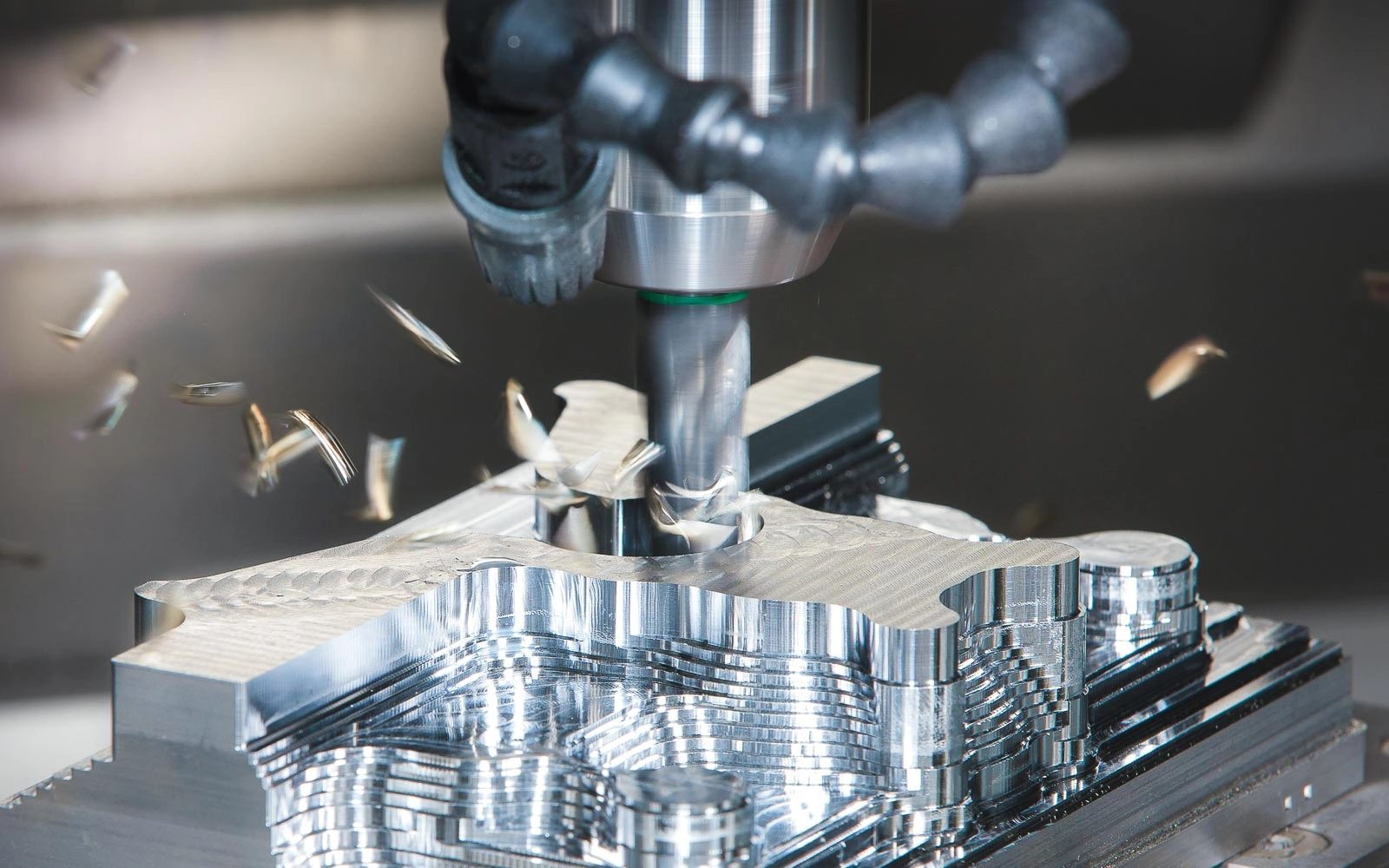

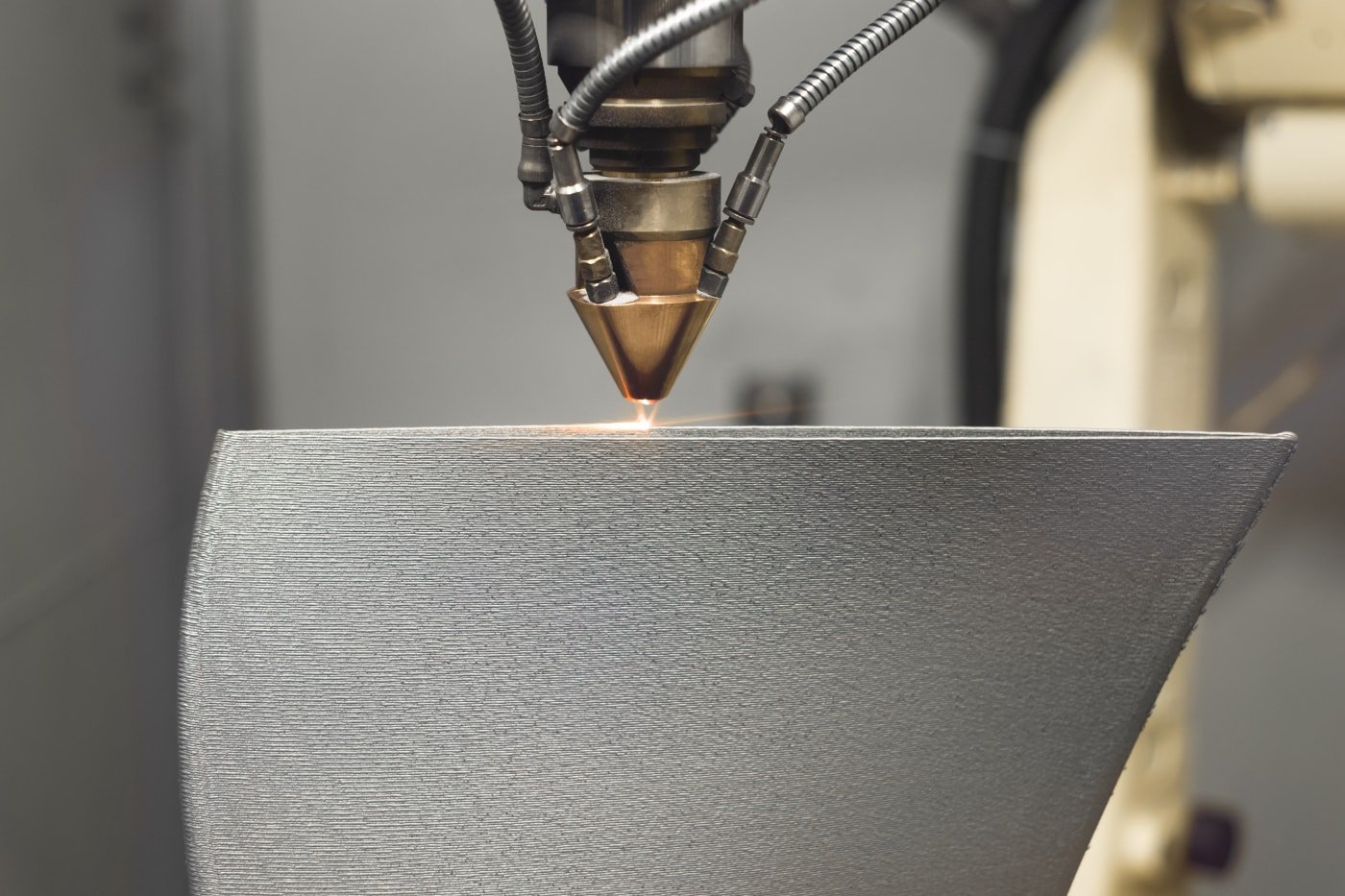

Wuxi Lead Precision Machinery leverages a hybrid manufacturing approach combining high-precision 5-axis CNC machining and metal powder bed fusion (PBF) additive manufacturing to produce mold tooling with exceptional dimensional accuracy. This integrated process ensures that complex geometries—such as conformal cooling channels and intricate crown molding features—are fabricated with sub-micron precision, eliminating traditional tooling constraints while maintaining ISO-classified tolerances.

Equipment Specifications:

5-Axis CNC Machining Centers: Equipped with high-resolution spindles (24,000 RPM) for sub-0.001mm positioning accuracy.

Metal PBF Systems: Utilizing selective laser melting (SLM) for P20 and NAK80 mold steel, followed by precision CNC finishing.

In-House EDM Capabilities: For ultra-fine details and tight-radius features.

Tolerance Control Framework

Our tolerance control system is engineered to meet the most stringent industry requirements. For crown molding applications, we maintain a strict dimensional control protocol where mold cavity and core dimensions are held to ±0.005 mm—ensuring final part tolerances of ±0.01 mm or better. This precision is achieved through:

In-process laser metrology for real-time adjustments during machining.

Thermal compensation algorithms to account for material expansion during high-speed operations.

Multi-stage quality checkpoints at 25%, 50%, and 100% completion stages.

Standard vs Precision Tolerance Specifications

| Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Cavity & Core Dimensions | ±0.01 mm | ±0.005 mm |

| Ejector Pin Alignment | ±0.008 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.4 μm | 0.2 μm |

| Draft Angle Consistency | ±0.5° | ±0.2° |

Quality Assurance & Compliance

Zero Defects Philosophy

Every mold undergoes 100% CMM inspection with traceable data logs. Our statistical process control (SPC) system monitors key parameters across 10+ quality metrics, ensuring zero defects in production runs. This rigorous approach has enabled us to achieve 99.98% first-time yield rates for medical and automotive-grade crown components.

Olympic Quality Standards

We adhere to ISO 9001:2015 and IATF 16949 quality management systems, with additional certifications for medical (ISO 13485) and aerospace applications. Our molds consistently meet or exceed the dimensional and surface finish requirements for high-stress applications, including automotive interior trim and precision medical devices.

24/7 Customer Service

Our dedicated engineering team is available around the clock to support your project lifecycle—from initial design review to post-production optimization. With a 15-minute response time SLA for technical inquiries and expedited production scheduling, we act as your strategic manufacturing partner, not just a supplier.

“Precision isn’t just a specification—it’s the foundation of trust. At Wuxi Lead, we engineer tolerances that align with your product’s performance requirements, not just industry averages.”

— Chief Engineer, Wuxi Lead Precision Machinery

Material & Finish Options

Material Selection & Finishes for Precision Crown Molding

Material Properties & Performance Considerations

For crown molding applications, material selection must balance mechanical strength, thermal stability, chemical resistance, and aesthetic requirements. As a precision manufacturing partner, Wuxi Lead prioritizes materials that deliver zero defects while optimizing cycle time and mold longevity. Below is our engineering-grade comparison of industry-standard engineering plastics:

| Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Chemical Resistance | Key Applications | Cost Tier |

|---|---|---|---|---|---|

| ABS | 35–65 | 90–105 | Good | General-purpose trim, impact-resistant architectural details | $ |

| PC | 55–75 | 135–140 | Moderate | High-clarity sections, structural elements near lighting fixtures | $$ |

| PP | 20–40 | 100–120 | Excellent | Chemical-exposed environments, flexible trims | $ |

| Nylon 6/6 | 70–90 | 150–180 | Good | High-wear areas, precision gears in moving components | $$ |

| POM | 60–80 | 100–120 | Moderate | Low-friction sliding parts, high-stiffness sections | $$ |

Engineering Insight:

– ABS delivers optimal balance for standard crown molding: excellent impact resistance (critical for high-traffic installations) and compatibility with rapid tooling processes.

– PC is recommended for applications requiring optical clarity (e.g., illuminated trim) but requires mold steel (NAK80) to maintain ±0.005 mm tolerances during high-temperature cycles.

– PP excels in moisture-rich environments (e.g., bathrooms) due to its unmatched chemical resistance, though it requires specialized mold surface treatments to prevent sticking.

Surface Finish Options for Aesthetic & Functional Requirements

Surface finishes for plastic crown molding must align with both visual expectations and functional performance. Note: Anodizing is exclusively for metal substrates — for plastic components, we offer precision finishing solutions engineered for durability and consistency:

Polishing

Process: Multi-stage mechanical polishing (800–3000 grit) with CMM-verified surface roughness control.

Applications: Premium residential trim, high-end commercial installations requiring mirror-like reflectivity.

Wuxi Lead Advantage: Our ISO 9001-certified polishing process ensures Ra < 0.05 μm and dimensional accuracy within ±0.005 mm — critical for seamless joint alignment in crown molding assemblies.

Texturing

Process: Laser engraving or EDM for custom patterns (e.g., wood grain, geometric motifs).

Applications: Architectural elements requiring tactile differentiation or light diffusion.

Wuxi Lead Advantage: 3D-printed mold texturing capabilities enable 72-hour prototype turnaround for custom textures without secondary machining.

Electroplating

Process: Conductive coating followed by nickel/chrome plating for metallic appearance.

Applications: Luxury finishes for high-end residential or commercial projects.

Wuxi Lead Advantage: Proprietary pre-treatment process ensures 99.8% adhesion consistency and corrosion resistance — validated through 1,000-hour salt spray testing.

Critical Technical Note:

For metal crown molding components (e.g., aluminum), we offer anodizing services with ±0.003 mm tolerance control and 24-hour color consistency. Contact our engineering team for material-specific finish recommendations.

Cost-Benefit Analysis: Material vs. Application Requirements

Material Selection Cost vs. Performance

| Material | Initial Cost | Mold Wear Impact | Cycle Time Impact | Long-Term ROI |

|---|---|---|---|---|

| ABS | $ | Low | Moderate | ★★★★☆ (Versatile for prototyping & low-volume production) |

| PC | $$ | Moderate | Higher | ★★★★★ (High durability in thermal stress environments) |

| PP | $ | Low | Low | ★★★★☆ (Ideal for chemical exposure scenarios) |

| Nylon | $$ | Moderate | Moderate | ★★★★☆ (Superior wear resistance for moving parts) |

| POM | $$ | Low | Low | ★★★★★ (Precision fit for tight-tolerance assemblies) |

Finish Cost Impact & ROI

| Finish Type | Cost Multiplier | Durability Impact | Aesthetic ROI | Lead Time Impact |

|---|---|---|---|---|

| High-Gloss Polishing | 1.2x | High | ★★★★☆ | +1–2 days |

| Texturing | 1.5x | Medium | ★★★☆☆ | +2–3 days |

| Electroplating | 2.0x | High | ★★★★★ | +3–5 days |

Wuxi Lead Commitment:

Every component undergoes 100% CMM verification with laser scanning for dimensional accuracy. Our Zero Defects protocol — backed by Olympic Quality standards — ensures your crown molding components meet the most stringent specifications. With 24/7 technical support and dedicated account management, we don’t just supply parts — we partner to eliminate production risks and accelerate time-to-market.Pro Tip: For mass production (>5,000 units), transition from 3D-printed rapid tooling to P20/NAK80 steel molds to reduce cycle time by 30% and extend tool life to 1M+ shots. Contact our engineering team for a free mold life optimization report.

Manufacturing Process & QC

From Prototype to Production: Precision-Driven Manufacturing Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture—we partner. Our integrated process transforms your design into high-precision plastic components through a seamless journey from prototype to mass production. With a focus on engineering excellence and unwavering quality control, we ensure every step is optimized for speed, accuracy, and reliability.

Design Analysis: Engineering-First Validation

Our engineers conduct a comprehensive Design for Manufacturability (DFM) analysis, leveraging Moldflow simulation to optimize gate locations, cooling channel design, and wall thickness distribution. We validate critical tolerances (±0.005 mm) against your specifications and material requirements (ABS, PC, PP, Nylon, POM), ensuring zero rework during tooling. This phase includes:

GD&T-based tolerance stack-up analysis

Material selection guidance for optimal mechanical properties

Mold design validation for ejection, venting, and thermal efficiency

“Precision starts with the design. Our engineers collaborate with your team to eliminate potential failures before tooling begins—saving time, cost, and risk.”

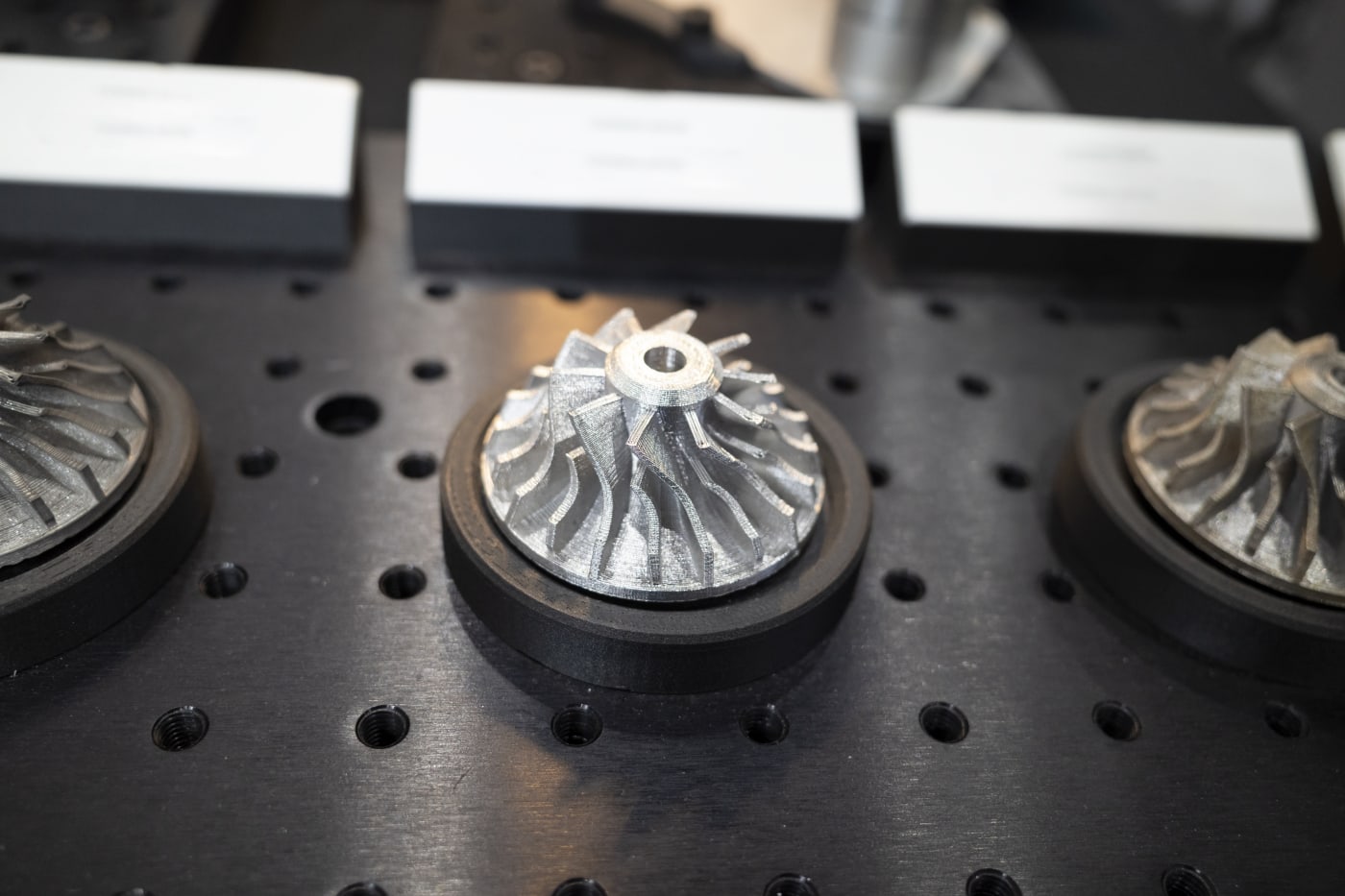

Rapid Prototyping: Hybrid Mold Fabrication for Accelerated Validation

We utilize advanced additive manufacturing (HP Multi Jet Fusion, SLS) combined with precision CNC finishing to produce mold tooling with CNC-grade dimensional accuracy and surface finish. This hybrid approach delivers functional prototypes in 72 hours with production-quality characteristics:

±0.005 mm dimensional tolerance across all features

Surface roughness (Ra) ≤ 0.1 μm for critical surfaces

500–2,000 cycle shot life for validation testing

Real-time feedback loop for design iteration

| Parameter | Rapid Prototyping | Mass Production |

|---|---|---|

| Mold Material | Hybrid PBF + CNC Machined | P20/NAK80 (Hardened) |

| Tolerance | ±0.005 mm | ±0.005 mm |

| Shot Life | 500–2,000 cycles | 500,000+ cycles |

| Lead Time | 72 hours | 14–21 days |

| Surface Finish | Ra 0.1 μm | Ra 0.05 μm |

| Key Advantage | Accelerated validation with production-grade quality | Scalable, cost-effective high-volume production |

Mass Production: Precision Tooling for High-Volume Excellence

Transitioning to hardened tool steel (P20/NAK80) molds with nitride treatment, our production lines achieve unmatched consistency for high-volume runs:

500,000+ shot life with minimal wear and thermal stability

Closed-loop process control maintaining ±0.005 mm tolerances across 10,000+ parts

Cycle time optimization via AI-driven thermal management (reducing per-part costs by up to 35%)

Automated inline inspection for real-time defect detection

“We engineer molds for longevity—not just function. Our P20/NAK80 tooling ensures consistent performance even under 24/7 production demands.”

Our Commitment: Zero Defects, Olympic Quality, 24/7 Partnership

✅ Zero Defects

ISO 9001:2015 certified quality systems with 100% automated optical inspection (AOI) and statistical process control (SPC). Our defect rate consistently remains below 0.001% across all production batches.

✅ Olympic Quality

Every component undergoes third-party validation against aerospace (AS9100) and medical (ISO 13485) standards. We guarantee dimensional accuracy, material integrity, and performance for mission-critical applications.

✅ 24/7 Customer Service

Dedicated technical account managers provide:

Real-time production tracking via cloud-based dashboards

Issue resolution within <15 minutes (SLA-backed)

Proactive communication across global time zones

On-site engineering support for urgent escalations

“We’re not a supplier—we’re your extended engineering team. When you succeed, we succeed.”

Wuxi Lead Precision Machinery

Precision Tooling for the Future. Delivered Today.

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Crown Molding Excellence

Why Choose a Strategic Manufacturing Partner?

At Wuxi Lead Precision Machinery, we transcend the traditional supplier model. Our partnership begins with collaborative Design for Manufacturing (DFM) analysis, ensuring your crown molding designs are optimized for both precision and cost-efficiency. Unlike transactional vendors, we integrate seamlessly into your product development lifecycle—providing engineering expertise, rapid prototyping, and scalable production solutions tailored to your exact specifications. Our commitment extends beyond delivery; we become an extension of your team, ensuring every component meets the rigorous demands of high-end architectural applications.

“We don’t just make parts—we solve problems. From initial concept to mass production, your success is our shared mission.”

Uncompromising Precision: Tolerances That Define Excellence

Precision is non-negotiable in crown molding applications, where micro-scale deviations compromise aesthetic integrity and installation precision. Wuxi Lead achieves ±0.005 mm dimensional tolerance through a hybrid manufacturing approach:

| Process Step | Technology Used | Tolerance Achieved | Quality Validation Method |

|---|---|---|---|

| Mold Fabrication | Hybrid Powder Bed Fusion (SLM) + CNC Finishing | ±0.005 mm | 3D Coordinate Measuring Machine (CMM) |

| Injection Molding | Multi-Cavity Tooling with Thermal Management | ±0.005 mm per part | In-process SPC (Statistical Process Control) |

| Post-Processing | Precision Deburring & Surface Polishing | Ra < 0.4 μm | Laser Profilometry |

| Material-Specific Optimization: For ABS, PC, PP, Nylon, and POM, we calibrate mold temperatures, gate designs, and cooling cycles to minimize warpage and shrinkage—ensuring dimensional stability even in complex crown profiles. | |||

| Zero Compromise on Steel Quality: Mold cores and cavities are crafted from P20 (1.2311) or NAK80 (1.2083) hardened tool steel, heat-treated to HRC 48–52 for wear resistance and thermal consistency. |

Rapid Tooling & Mass Production: Seamless Scalability

| Capability | Wuxi Lead Precision | Industry Average |

|---|---|---|

| Mold Lead Time (Rapid Tooling) | 3–5 days (CAD-to-mold) | 14–21 days |

| Cycle Time Reduction | Up to 30% via AI-driven thermal optimization | 5–10% |

| Production Volume Scalability | Seamless transition from 100 units to 500k+ | Limited to low-volume runs |

| Material Compatibility | ABS, PC, PP, Nylon, POM, TPE, and high-temp engineering plastics | Standard thermoplastics only |

| Defect Rate | <0.02% (ISO 9001:2015 certified) | 0.5–1.0% |

Our hybrid manufacturing ecosystem combines additive precision with subtractive accuracy—enabling you to prototype in days and scale to mass production without retooling costs or delays.

Zero Defects Philosophy & Olympic Quality Assurance

We operate under a “Zero Defects” mandate—backed by ISO 9001:2015 certification and a 99.98% first-pass yield rate. Every crown molding component undergoes:

12-Point Mold Validation: Including hardness testing, surface roughness scans, and thermal uniformity checks.

AI-Powered In-Process Monitoring: Real-time analytics detect micro-variations in melt temperature, injection pressure, or cooling rates—correcting deviations before they impact output.

Full Traceability: Digital twin documentation tracks every raw material batch, machine parameter, and inspection result from mold fabrication to final part delivery.

“In luxury architecture, imperfections are unacceptable. Our Olympic Quality standard ensures every crown molding profile meets the exacting demands of high-end projects—where precision is non-negotiable.”

24/7 Customer Support – Your Success, Our Priority

Your project’s timeline is our priority. Our global support team operates 24/7 with:

Dedicated Account Engineers: Single-point-of-contact for technical, logistical, and production coordination.

Emergency Response Protocol: <2-hour response time for critical issues, with on-site support available within 24 hours across Asia-Pacific.

Predictive Maintenance: IoT-enabled mold health monitoring reduces unplanned downtime by 40% through real-time wear analysis.

Ready to Elevate Your Crown Molding Project?

Partner with Wuxi Lead Precision Machinery—where precision engineering meets unwavering commitment.

📞 +86-13961886740

📧 [email protected]

Request your FREE DFM Analysis & Competitive Quote today. Let’s build excellence together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.