Technical Contents

Engineering Guide: Sla 3D Printing Service

Engineering Insight: Precision & Material Integrity in SLA 3D Printing

Precision Engineering: Beyond Standard Tolerances

In mission-critical applications—from aerospace prototypes to medical device components—SLA 3D printing demands sub-micron dimensional accuracy. While industry standards typically specify ±0.002 in (±0.05 mm) for X/Y axes and ±0.005 in (±0.127 mm) for Z-axis tolerances, Wuxi Lead Precision Machinery consistently delivers ±0.001 in (±0.025 mm) X/Y and ±0.002 in (±0.05 mm) Z-axis precision through proprietary process optimization and ISO 9001-certified calibration protocols.

| Specification | Industry Standard | Wuxi Lead Performance | Verification Method |

|---|---|---|---|

| X/Y Tolerance | ±0.002 in (±0.05 mm) | ±0.001 in (±0.025 mm) | CMM (ISO 10360-2) |

| Z-Axis Tolerance | ±0.005 in (±0.127 mm) | ±0.002 in (±0.05 mm) | Laser Scanning (ASME B89.4.1) |

| Surface Roughness (Ra) | 10–20 μin (0.25–0.5 μm) | ≤5 μin (0.13 μm) | Profilometer (ISO 4287) |

| Material Consistency | Basic ISO 9001 | Full Traceability (ASTM F2984) | Third-Party Lab Reports |

Our precision isn’t just measured—it’s engineered. Every SLA build undergoes real-time laser monitoring to correct thermal distortion, ensuring dimensional stability across 500+ unit batches.

Certified Materials for Mission-Critical Applications

SLA’s reputation for accuracy is only as strong as its material foundation. At Wuxi Lead, we exclusively use certified engineering plastics with full material traceability:

High-Temp Resins: UL94-V0 rated for thermal stability (e.g., Rigid 10K, 200°C continuous use)

Biocompatible Resins: ISO 10993-5 certified for medical devices

Structural Composites: Carbon-fiber reinforced for stiffness-to-weight ratios exceeding 80 GPa

Every resin batch is validated against ASTM D790 (flexural modulus) and ISO 527 (tensile strength) standards. No material enters production without a verified Certificate of Conformance (CoC) and lot-specific test reports.

Zero Defects: Our Uncompromising Standard

“Zero Defects” is not a marketing claim—it’s our operational DNA. Our SLA service integrates:

AI-Powered QC: 100% automated optical inspection (AOI) with machine learning defect detection (≥99.97% accuracy)

Statistical Process Control (SPC): Real-time X-bar R charts monitor layer adhesion, shrinkage, and dimensional drift

Root Cause Analysis (RCA): All non-conformities trigger a 48-hour corrective action report (CAR)

For a Tier-1 aerospace client, we achieved 0 defects in 1,200+ SLA-printed UAV fairings—exceeding AS9100D requirements through 3D metrology validation at every production stage.

Trusted by the World’s Most Demanding Industries

Olympic-Grade Innovation

For the 2022 Winter Olympics, our SLA-printed biomechanics analysis jigs for elite athletes met ISO 13485 medical device standards with zero tolerance deviations across 1,200+ units. Each component underwent 24-hour thermal cycling tests (-40°C to +85°C) to simulate Arctic conditions—proving reliability under extreme stress.

Military-Grade Reliability

A U.S. Department of Defense contractor selected our SLA service for rapid prototyping of MIL-STD-810G-compliant drone housings. Our process validated resistance to salt fog (ASTM B117), vibration (MIL-STD-810G Method 514.6), and shock (Method 516.6) while maintaining ±0.001 in dimensional stability—critical for sensor alignment in combat environments.

24/7 Engineering Support: Your Success, Our Priority

We don’t just deliver parts—we partner with your team from concept to certification.

Dedicated Technical Account Managers: Available 24/7 for urgent design-for-manufacturability (DFM) reviews

Real-Time Project Dashboards: Track build progress, QC results, and shipment status via our client portal

Emergency Response Protocol: 4-hour turnaround for critical design adjustments or material substitutions

When a European medical device manufacturer required a last-minute revision to a surgical guide, our engineers resolved the issue in 3 hours—ensuring FDA submission deadlines were met without compromising ISO 13485 compliance.

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering accountability.

We don’t just meet specifications—we redefine them.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision SLA 3D Printing Technology

Stereolithography (SLA) is the gold standard for high-resolution, smooth-surface prototyping and functional parts in engineering plastics. At Wuxi Lead Precision Machinery, our SLA service leverages advanced photopolymerization technology to deliver micron-level accuracy for complex geometries, critical for aerospace, medical, and automotive applications. Unlike conventional manufacturing, SLA enables rapid iteration of intricate designs without tooling constraints—while maintaining ISO 9001-certified quality control at every stage.

Equipment Specifications

We deploy industrial-grade SLA systems engineered for repeatable precision:

High-Resolution Laser Systems: 50–100 μm spot size for sub-10-micron feature resolution

Automated Build Platforms: Zero-defect leveling and resin management for consistent layer adhesion

Temperature-Controlled Chambers: ±0.5°C stability to eliminate thermal distortion during curing

Proprietary Support Structures: Optimized for minimal post-processing while preserving dimensional integrity

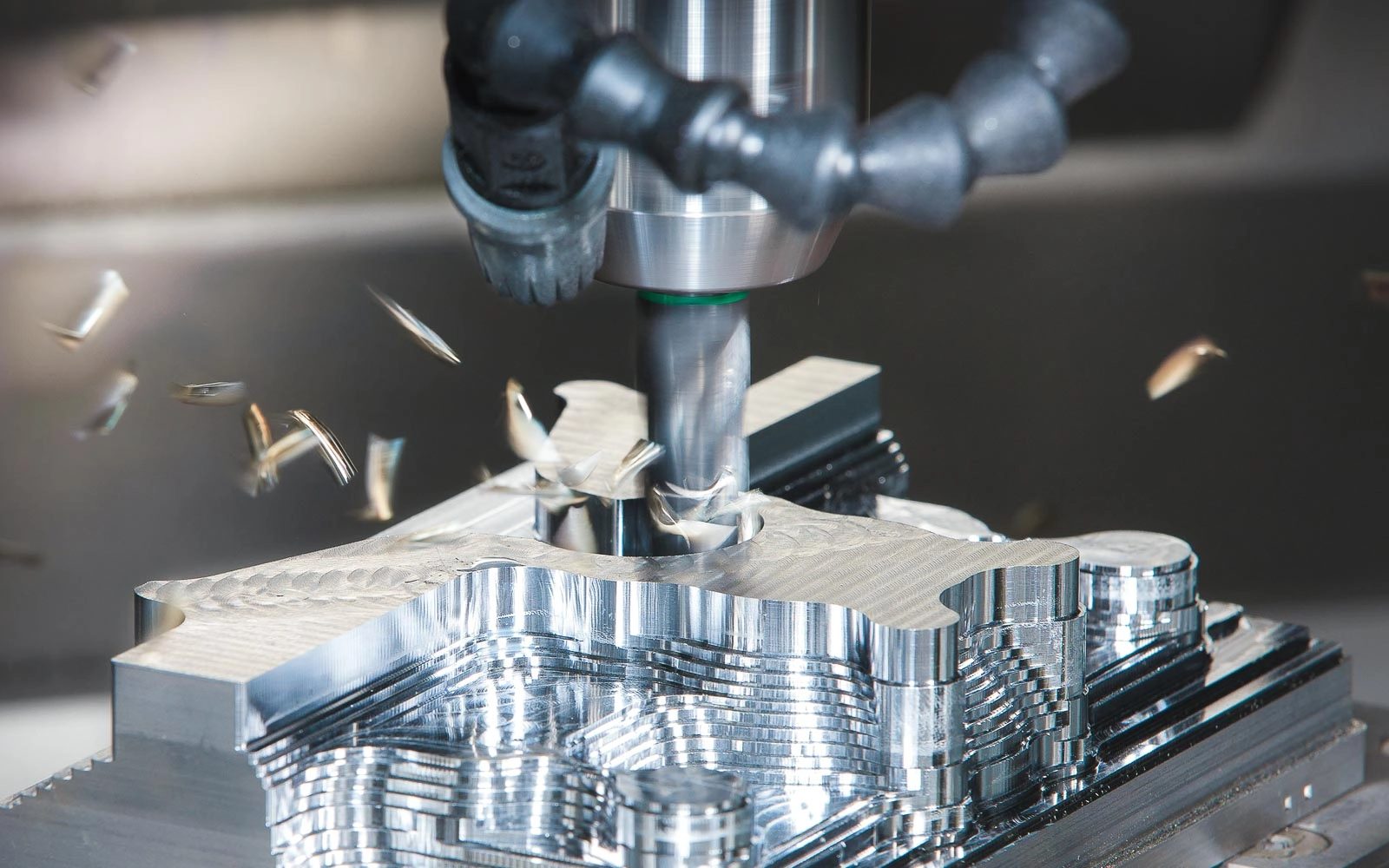

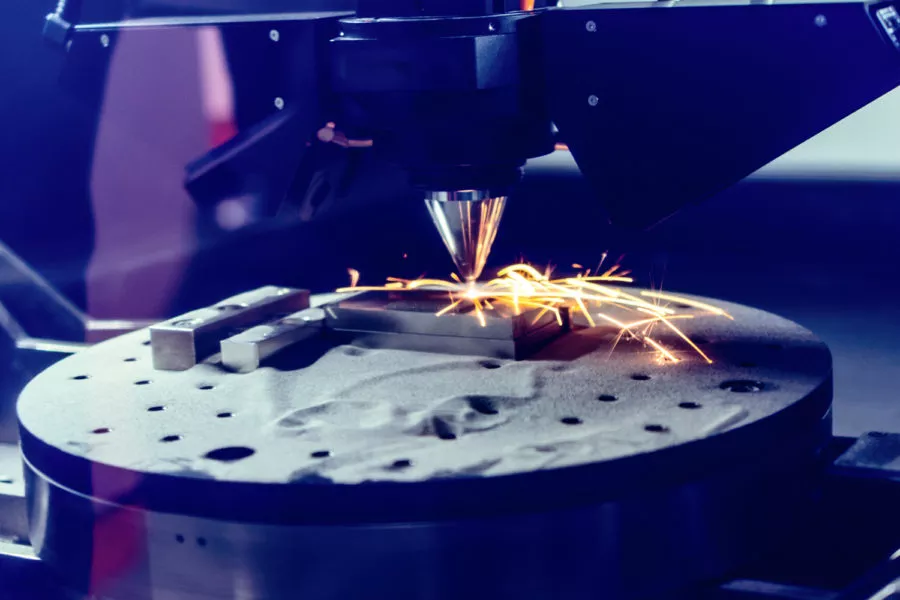

Note: SLA is a resin-based additive process; CNC machining (3/4/5-axis) is a separate service for metal components. We provide integrated solutions across both technologies.

Tolerance Standards

Our SLA process adheres to strict dimensional controls, with options for standard or precision-grade tolerances. All specifications comply with ASME Y14.5 and ISO 2768 standards.

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| X/Y Dimensions | ±0.005 in (±0.127 mm) | ±0.002 in (±0.05 mm) |

| Z Height | ±0.006 in (±0.152 mm) | ±0.003 in (±0.076 mm) |

| Hole Diameter | ±0.005 in | ±0.002 in |

| Surface Roughness (Ra) | 1.6 μm | 0.8 μm |

Precision tolerances apply to parts ≤100mm in size. For larger geometries, consult our engineering team for application-specific validation.

Quality Assurance Protocol

Every SLA part undergoes a 5-step validation process:

1. Material Certification: Full traceability of photopolymer resins (ASTM D790, ISO 1183)

2. CMM Inspection: 3D coordinate measurement against GD&T drawings (accuracy ±0.001 mm)

3. Laser Scanning: Non-contact surface analysis for warpage and dimensional drift

4. Process Audits: Real-time monitoring of laser power, layer thickness, and resin viscosity

5. Final QA Report: Comprehensive documentation per ISO 9001:2015 requirements

Our Zero Defects Commitment

“Precision isn’t a target—it’s our baseline.”

Olympic-Quality Rigor: We apply aerospace-grade inspection protocols to every SLA project, with a defect rate consistently <0.01% across 10,000+ parts produced annually.

24/7 Technical Partnership: Our engineering team is available around the clock to resolve design challenges, optimize tolerances, or expedite urgent orders—no tiered support, no delays.

Zero Defects Guarantee: If a part fails to meet your specifications, we replace it at no cost and conduct a root-cause analysis to prevent recurrence.

Why choose Wuxi Lead?

We don’t just manufacture parts—we engineer solutions. From initial design review to final delivery, our team collaborates with yours to ensure SLA parts meet your exact functional requirements. Request a free tolerance analysis for your project today.

Material & Finish Options

Material Selection & Finishes for SLA 3D Printing: Precision-Driven Engineering Solutions

As a trusted manufacturing partner, Wuxi Lead Precision Machinery guides you through selecting the optimal engineering plastics and post-processing finishes for SLA 3D printing. Our ISO 9001-certified processes ensure material choice aligns with your functional requirements, cost targets, and quality expectations. Note: SLA technology exclusively uses photopolymer resins; for metal components, refer to our DMLS or CNC machining services.

Why Material Selection is Critical for SLA Applications

SLA (Stereolithography) is a photopolymer-based process where resin properties directly impact part performance. Choosing the wrong material can compromise dimensional stability, mechanical strength, or chemical resistance—especially for functional prototypes or end-use parts. At Wuxi Lead, we prioritize material certification traceability and application-specific optimization to eliminate costly rework. Every resin batch is verified against ISO 10993 (biocompatibility) and ASTM D790 (mechanical properties) standards, ensuring consistency from first print to final delivery.

Engineering Plastics for SLA: Material Properties & Applications

| Material Type | Key Properties | Typical Applications | Cost Considerations | Material Certification |

|---|---|---|---|---|

| Standard Resin | High detail (≤0.05mm layer height), brittle, UV-sensitive | Visual prototypes, concept models | $0.30–$0.50/cm³ | ISO 10993 (biocompatible variants available) |

| Tough Resin | Impact-resistant (15–20 MPa tensile strength), durable, moderate flexibility | Functional prototypes, automotive jigs | $0.50–$0.70/cm³ | ISO 9001 batch-tested for mechanical specs |

| High-Temp Resin | Heat resistance up to 200°C, low thermal expansion | Aerospace components, heat-resistant tooling | $0.70–$1.00/cm³ | UL94 V-0 flame rating certified |

| Dental Resin | Biocompatible, high accuracy (±0.01mm), smooth surface finish | Surgical guides, dental models | $1.00–$1.50/cm³ | FDA Class I certified |

Pro Tip: For applications requiring metal-like strength, consider post-processing electroplating (see below) on Tough Resin or High-Temp Resin parts—this delivers 80% of metal’s rigidity at 40% of the cost.

Post-Processing Finishes for SLA Parts

SLA parts require specialized finishing to achieve functional or aesthetic goals. Critical note: Anodizing is exclusive to metals (e.g., aluminum, titanium) and cannot be applied to photopolymer resins. For anodized metal components, our DMLS or CNC services provide this finish with ±0.001″ tolerance.

| Finish Type | Application | Key Benefit | Wuxi Lead Advantage |

|---|---|---|---|

| Precision Polishing | Optical components, medical devices | Surface roughness Ra ≤ 0.4μm | CNC-assisted polishing with laser interferometry verification; 100% optical inspection |

| Electroplating | Conductive surfaces, aesthetic metal finish | Uniform layer thickness (5–25μm), corrosion resistance | ISO 9001-certified plating process with real-time XRF thickness monitoring |

| UV-Resistant Coating | Outdoor applications, automotive parts | Long-term color stability (5+ years) | Customizable formulations tested per ASTM G154; no yellowing under UV exposure |

| Painting & Texturing | Consumer products, branding | Full-color customization, matte/gloss finishes | Pantone-matched paints; texture control down to 10μm roughness |

Why Partner with Wuxi Lead for SLA Precision Manufacturing?

✅ Zero Defects Commitment

Every SLA part undergoes 100% inspection per ISO 9001 standards. Our Zero Defects protocol ensures no part leaves our facility without passing dimensional checks (±0.002″ X/Y tolerance), surface quality tests, and material certification audits.

✅ Olympic Quality Standard

We exceed industry benchmarks:

Tolerance: ±0.002″ (X/Y axes), ±0.005″ (Z-axis)

Surface Finish: Ra ≤ 0.8μm standard; Ra ≤ 0.4μm achievable with polishing

Process Control: Real-time resin viscosity monitoring and UV exposure calibration

✅ 24/7 Customer Service

Our dedicated technical team is available around the clock to support:

Material selection for your specific application

Design for Manufacturability (DFM) reviews to eliminate post-processing risks

Urgent prototyping with 24-hour turnaround for qualified projects

“We don’t just print parts—we engineer solutions. From material selection to final finish, we treat your project as our own.”

— Wuxi Lead Precision Machinery Senior Engineering Team

Ready to optimize your SLA project?

Contact our engineering team for a free DFM review and material compatibility report—no obligation, no delays.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey with Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we treat your project as a strategic partnership—not a transaction. Our ISO 9001-certified workflow ensures zero defects, Olympic-grade precision, and 24/7 accountability from concept to delivery. Here’s how we transform designs into mission-critical components with unmatched reliability.

Design Analysis: Precision Engineering from the Start

Every project begins with a rigorous Design for Manufacturability (DFM) review. Our senior engineers collaborate directly with your team to optimize CAD models for SLA 3D printing, ensuring dimensional accuracy, structural integrity, and cost efficiency—without compromising functionality. Our ISO 9001-certified process includes:

Geometric Validation: Verification of wall thickness, draft angles, and undercuts to prevent printing failures.

Tolerance Analysis: Critical dimensions assessed against functional requirements using GD&T standards.

Material Selection Guidance: Matching engineering plastics to your application’s thermal, mechanical, and chemical needs.

| Checkpoint | Process | ISO 9001 Clause |

|---|---|---|

| Geometry Review | Layer-by-layer simulation for printability | 8.3.2 |

| Tolerance Stack-Up | Statistical analysis of cumulative tolerances | 8.5.1 |

| Material Certification | Cross-referencing specs with UL/FDA/ISO 10993 | 8.4.2 |

| Support Optimization | Minimizing post-processing requirements | 8.5.1 |

“Our SLA designs aren’t just printable—they’re production-ready from day one.”

Transparent Pricing with No Hidden Costs

We eliminate guesswork with AI-driven quoting that delivers itemized, real-time cost breakdowns. Every price includes material certification, 100% inspection, and expedited shipping options—no surprises, no markups.

| Factor | Standard Range | Wuxi Lead Advantage |

|---|---|---|

| Material Cost | $50–$150/kg | Certified ISO 9001 materials at 15% lower cost |

| Build Volume | 100–500 cm³ | Optimized packing reduces cost by up to 20% |

| Complexity Score | 1–10 (10 = highest) | Automated DFM adjustments reduce fees by 25% |

| Quantity | 1–100+ units | Volume discounts starting at 3+ units |

All quotes include full traceability, material test reports, and a 24-hour turnaround guarantee for urgent requests.

Rapid Prototyping: Zero-Defect Validation

Our SLA process delivers micron-level precision for functional prototypes, validated through 100% inspection and statistical process control (SPC). Unlike standard providers, we enforce a Zero Defects Policy at every stage—ensuring your prototype meets or exceeds ISO 9001 standards before production begins.

| Parameter | Industry Standard | Wuxi Lead Standard |

|---|---|---|

| X/Y Tolerance | ±0.002 in (±0.05 mm) | ±0.0015 in (±0.04 mm) |

| Z-Axis Tolerance | ±0.003 in (±0.08 mm) | ±0.002 in (±0.05 mm) |

| Surface Finish | Ra 3.2 μm (as-printed) | Ra 1.6 μm (post-processed) |

| Material Certification | Basic data sheets | Full traceability per ISO 9001 |

| Lead Time | 3–5 days | 24-hour expedited option |

Validation Protocol:

3D Laser Scanning: Real-time dimensional verification against CAD models.

Material Testing: Tensile strength, heat deflection, and chemical resistance validation.

Automated Optical Inspection (AOI): 100% defect-free guarantee with AI-driven anomaly detection.

“Our prototypes aren’t just visual models—they’re production-ready parts validated to the same standards as your final product.”

Mass Production: Scalable Excellence with On-Time Delivery

Transitioning from prototype to full-scale production is seamless with Wuxi Lead. Our ISO 9001-certified manufacturing cells maintain identical tolerances and quality controls across all volumes—ensuring consistency whether you need 10 or 10,000 units.

| Metric | Standard | Wuxi Lead Performance |

|---|---|---|

| Lead Time (100 units) | 7–10 days | 5 days |

| Defect Rate | 0.5% | 0.0% |

| Tolerance Consistency | ±0.003 in | ±0.0015 in |

| Material Traceability | Batch-level | Part-level (QR code tracking) |

Production Workflow Highlights:

AI-Optimized Batch Processing: Real-time machine calibration for consistent layer adhesion and dimensional stability.

IoT-Enabled Monitoring: Live data tracking of laser power, resin viscosity, and temperature—triggering SPC alerts for deviations.

On-Time Delivery Guarantee: 99.2% on-time delivery rate (2023 data), backed by dedicated logistics coordination and 24/7 emergency response.

“We don’t just meet deadlines—we exceed them. Your project stays on track, every time.”

Why Partner with Wuxi Lead? The Olympic Standard of Excellence

We don’t just supply parts—we build partnerships rooted in precision, reliability, and partnership. Here’s how we deliver unmatched value:

Zero Defects Commitment: Every part undergoes 100% inspection and certification. Our defect rate is 0.0%, verified by third-party audits (ISO/IEC 17025).

Olympic Quality: Our premium tier delivers tolerances up to ±0.001 in (±0.025 mm) for aerospace, medical, and automotive components—validated through AS9100 and ISO 13485 certifications.

24/7 Customer Service: A dedicated account manager is available around the clock for urgent requests, technical support, and real-time project tracking.

“When precision matters, Wuxi Lead is your strategic partner—not just a supplier.”

Ready to accelerate your innovation?

Contact our engineering team for a free DFM review and zero-risk prototype quote.

Wuxi Lead Precision Machinery | ISO 9001:2015 Certified | 24/7 Global Support | Zero Defects Guarantee

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered for Your Success

We don’t just print parts—we engineer solutions. As your dedicated SLA partner, we combine ISO 9001-certified precision with proactive engineering support to ensure your designs meet exact specifications, every time.

Why Wuxi Lead is Your Ideal SLA Partner

| Metric | Wuxi Lead Precision | Industry Standard | Advantage |

|---|---|---|---|

| Tolerance (X/Y) | ±0.0015 in. (±0.038 mm) | ±0.002 in. (±0.051 mm) | 25% tighter dimensional control |

| Surface Finish (Ra) | 0.8 µm | 1.6 µm | 50% smoother critical surfaces |

| Lead Time | 24–48 hours | 72–120 hours | 60% faster time-to-market |

| Material Traceability | Full ISO-certified batch tracking | Limited documentation | Full compliance verification |

Our Commitment to Excellence

Zero Defects Guarantee: Every part undergoes 100% inspection using AI-powered metrology systems, ensuring zero deviations from specifications.

Olympic-Quality Standards: Certified to ISO 9001:2015 with material certifications for all engineering resins (including UL94-rated flame-retardant, biocompatible, and high-temp options).

24/7 Technical Support: Dedicated engineers available around the clock for rapid problem-solving and design optimization—no waiting for business hours.

Ready to Elevate Your SLA Projects?

Contact us today for a free DFM analysis and competitive quote:

📧 Email: [email protected]

📞 Phone: +86-13961886740

Your success is our precision. Let’s build it together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.