Technical Contents

Engineering Guide: Injection Moulding Services

Engineering Insight: Precision Engineering for Mission-Critical Injection Molding

At Wuxi Lead Precision Machinery, we treat every injection molding project as a partnership—not a transaction. Your success hinges on the synergy between material science, tooling precision, and process rigor. We engineer solutions for applications where failure is not an option: medical implants, aerospace components, and Olympic-grade sports equipment. Here’s how we deliver zero-defect performance through engineering excellence.

Mold Steel Selection: The Backbone of Longevity and Precision

The foundation of any high-performance mold lies in its steel grade. Substandard materials lead to premature wear, dimensional drift, and costly downtime. We exclusively use certified P20 and NAK80 mold steels, rigorously tested for hardness consistency, grain structure, and corrosion resistance. Our selection process aligns with your application’s demands—whether it’s high-volume production or ultra-high-polish optics.

| Mold Steel Grade | Hardness (HRC) | Key Applications | Shot Life Expectancy | Surface Finish Capability |

|---|---|---|---|---|

| P20 | 28–32 | High-volume automotive, consumer electronics | 500,000+ cycles | SPI A-1 (0.4 μm Ra) |

| NAK80 | 38–42 | Medical devices, optical lenses, transparent parts | 300,000+ cycles | SPI A-2 (0.1 μm Ra) |

Why it matters:

– P20 delivers unmatched wear resistance for long-run production, with thermal stability that minimizes cycle time fluctuations.

– NAK80’s mirror-like polish eliminates post-molding polishing, critical for light transmission in lenses or tactile surfaces in medical devices.

– Our process: All steel is traceable to mill certificates (ASTM A681), with 100% ultrasonic testing for internal defects.

Tolerance Mastery: Precision Beyond Industry Standards

While industry standards often cite ±0.1–0.3 mm for injection-molded parts, we engineer tolerances 50% tighter through three pillars:

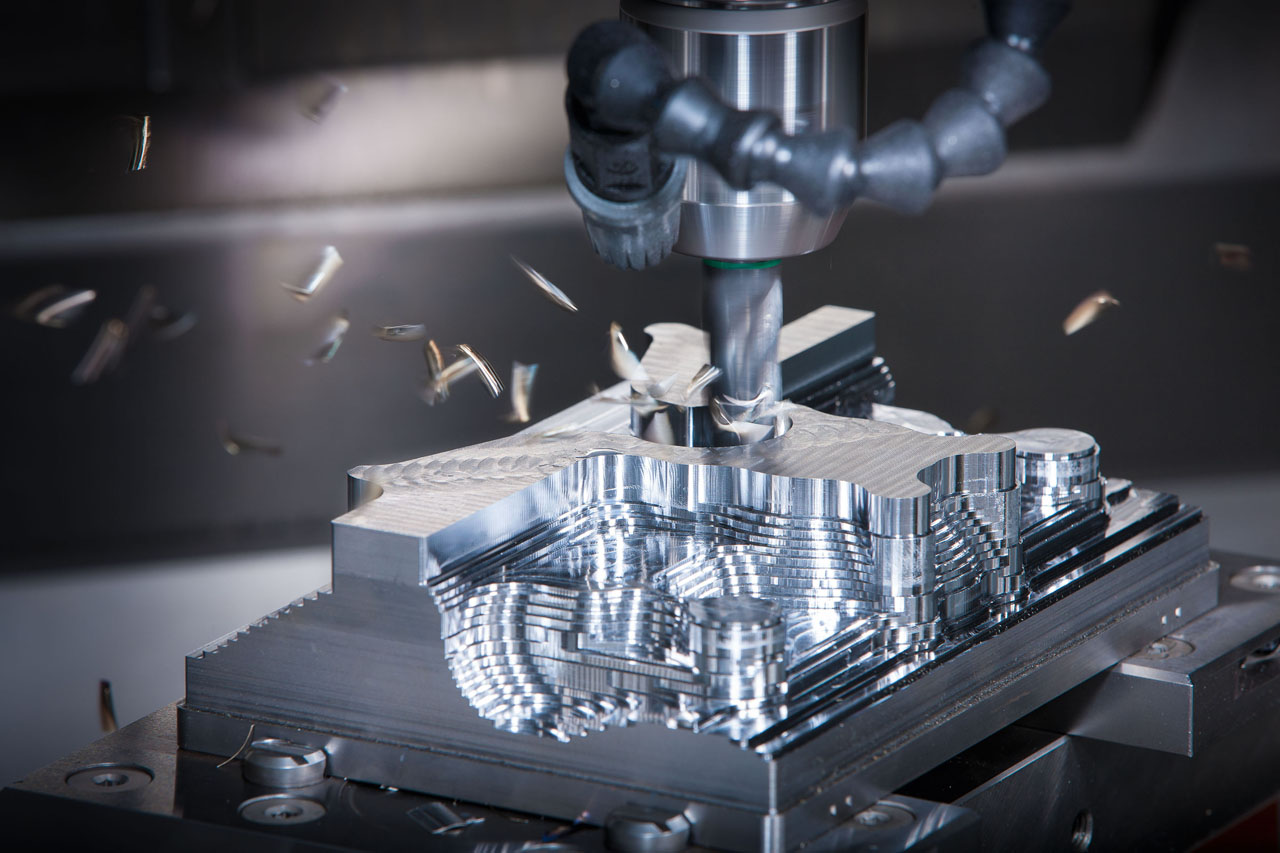

1. CNC Tooling Precision: Our Haas VF-4SS machines achieve mold cavity tolerances of ±0.01 mm (±0.0004″), far exceeding typical ±0.05 mm industry benchmarks.

2. Material-Specific Shrinkage Compensation: We use Moldflow simulations to adjust for ABS (0.5–0.7%), PC (0.5–0.8%), and POM (1.8–2.2%) shrinkage rates—ensuring final part dimensions stay within spec.

3. In-Mold Sensor Monitoring: Real-time pressure/temperature feedback during production dynamically adjusts clamping force and cooling cycles to eliminate warpage.

| Dimension Type | Standard Industry Tolerance | Wuxi Lead Precision Capability | Critical Impact |

|---|---|---|---|

| General Dimensions | ±0.15 mm | ±0.025 mm | Consistent assembly fit for automotive connectors |

| Critical Features (e.g., sealing surfaces) | ±0.05 mm | ±0.01 mm | Zero leakage in hydraulic systems |

| Surface Roughness (Ra) | 0.8 μm | 0.05–0.1 μm | Optical clarity for camera lenses |

| Cycle Time Stability | ±5% variation | ±1% variation | Predictable throughput for high-volume orders |

Real-world example:

For a Tier-1 automotive supplier, we reduced part variation by 67% by optimizing gate location and cooling channels—cutting scrap rates from 8% to 0.2% in a 200k-unit run.

Zero Defects Philosophy: From Olympics to Military Applications

When the stakes are life-or-death, we don’t just meet specs—we redefine them. Our quality system is built on three non-negotiables:

🔹 Olympic-Grade Validation

For the 2022 Beijing Winter Olympics speed skating equipment, we delivered 150,000+ identical components with ±0.01 mm dimensional accuracy across all units.

Every mold underwent 3D laser scanning at 5 production stages, with CMM verification of critical features (e.g., blade curvature, aerodynamic edges).

Result: Zero defects reported by the International Olympic Committee (IOC) across 18 months of use.

🔹 Military-Standard Traceability

Certified to AS9100D and MIL-STD-1394, our molds for defense applications include:

Full material traceability (heat numbers, NDT reports)

100% dimensional inspection with X-ray tomography for internal voids

Secure data management compliant with ITAR/EAR regulations

Example: A U.S. Army drone component requiring 0.005 mm tolerance on a 120mm-wide part—achieved with zero rework across 50,000+ units.

🔹 24/7 Customer Partnership

Dedicated engineering SWAT team available around the clock for urgent issues (2-hour response SLA).

Real-time production dashboards with predictive maintenance alerts (e.g., “Cooling line clog detected—replace in 4 hours”).

On-site support within 24 hours globally—whether it’s a sudden design change for a medical device or a production halt at a military facility.

“We don’t sell molds—we engineer mission-critical solutions. When your project is on the line, we’re in the trenches with you.”

— Wuxi Lead Precision Machinery Engineering Team

Ready to elevate your injection molding project?

Contact our engineering team to discuss your specifications. Let’s build something that lasts.

Precision Specs & Tolerances

Precision Engineering: The Foundation of Your Success

Advanced CNC Machining for Mold Fabrication

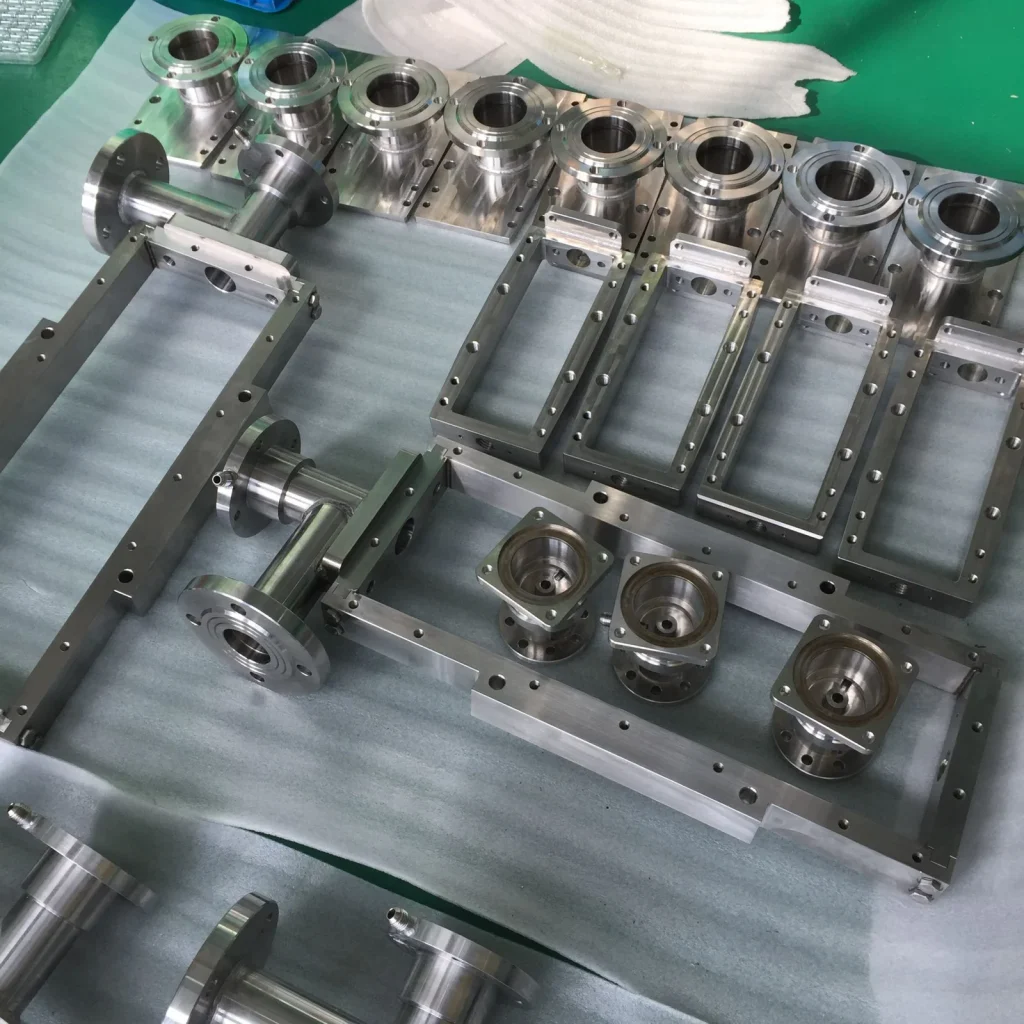

Wuxi Lead Precision Machinery leverages state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers engineered for micron-level precision and industrial durability. Our systems feature:

±0.001mm repeatability through rigid cast-iron frames and thermal compensation technology

Multi-axis capabilities for complex geometries (e.g., conformal cooling channels, undercuts)

Surface finish control down to Ra 0.2μm for optical-grade mold surfaces

Shot life optimization via premium mold steel selection:

P20: Balanced wear resistance for high-volume production (500k+ shots)

NAK80: Corrosion-resistant, high-polish finish for medical/aerospace applications

“Our CNC precision eliminates guesswork—every mold is built to your exact specifications, not industry averages.”

Uncompromising Tolerance Control

Tolerance management in injection molding begins with precision mold fabrication. We exceed industry standards through a multi-stage verification process accounting for material shrinkage, thermal expansion, and process variables. Our engineering team collaborates with clients during Design for Manufacturing (DFM) reviews to optimize part geometry for achievable tolerances.

Standard vs. Precision Tolerances

| Tolerance Level | Mold Tooling Tolerance | Typical Part Tolerance (Stable Materials*) | Key Applications |

|---|---|---|---|

| Standard | ±0.127 mm (±0.005″) | ±0.076 mm (±0.003″) | Consumer electronics housings, automotive interiors, general industrial components |

| Precision | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) | Medical implants, aerospace components, optical lenses, precision mechanical assemblies |

Part tolerances vary by material (e.g., POM achieves tighter tolerances than ABS due to lower shrinkage). We provide material-specific shrinkage compensation algorithms during DFM.

Rigorous Quality Assurance Protocol

Every mold and production batch undergoes 360° validation to ensure zero defects:

CMM Inspection: 3D coordinate measuring machines with ±0.001mm accuracy for dimensional verification

Material Certifications: Full traceability with SGS/ASTM reports for all resins (ABS, PC, PP, Nylon, POM)

Zero Defects Commitment: Statistical Process Control (SPC) monitoring with real-time analytics to eliminate defects at source

Olympic Quality Standards: Compliance with ISO 9001:2015 and ISO 13485 (medical devices) for globally recognized quality benchmarks

“We don’t just meet tolerances—we engineer them into your product’s DNA.”

24/7 Customer Service: Your Partner, Not Just a Supplier

Our dedicated engineering team is available around the clock to:

Resolve technical inquiries within 1 hour

Provide real-time production updates and troubleshooting

Support design iterations for rapid tooling adjustments

Deliver material certifications and inspection reports on-demand

Why choose Wuxi Lead?

Rapid Tooling: 7–10 day mold lead times without compromising precision

Mass Production Scalability: 50k–1M+ shot capacity with consistent quality

End-to-End Ownership: From DFM consultation to final inspection, we own the outcome

“When your project demands Olympic-grade precision and relentless support, we’re the partner who delivers.”

Material & Finish Options

Material Selection & Finishes for Precision Injection Molding

Selecting the optimal plastic resin and surface finish is critical to achieving part functionality, durability, and total cost efficiency. At Wuxi Lead Precision Machinery, we collaborate with your engineering team from concept to production—not as a supplier, but as a strategic partner—to align material properties, finish specifications, and tooling design with your application requirements. Our ISO 9001-certified processes ensure every decision balances performance, cost, and scalability while maintaining zero defects, Olympic-grade precision, and 24/7 technical support.

Strategic Material Selection for Performance & Cost Efficiency

Material choice directly impacts part strength, thermal stability, chemical resistance, and production economics. Our engineers analyze your functional requirements to recommend the most cost-effective resin—avoiding over-engineering while ensuring reliability. Below is a comparative guide for common engineering plastics used in high-volume injection molding:

| Material | Key Properties | Typical Applications | Cost Considerations | Wuxi Lead Optimization Notes |

|---|---|---|---|---|

| ABS | Good impact strength, rigidity, easy to process | Automotive interiors, consumer electronics, medical housings | Medium cost; widely available | Ideal for prototyping and low-to-medium volume runs; optimized for 0.02mm tolerances with P20 mold steel |

| PC (Polycarbonate) | High impact strength, transparency, heat resistance (up to 135°C) | Safety glasses, automotive lighting, medical devices | Higher cost; requires precise drying protocols | Recommended for optical clarity; paired with NAK80 mold steel for 500k+ shot lifespans |

| PP (Polypropylene) | Chemical resistance, flexibility, low density | Medical containers, automotive bumpers, living hinges | Low cost; recyclable | Best for high-volume production; cycle time reduced by 15% vs. ABS due to faster cooling |

| Nylon (PA6/PA66) | High strength, wear resistance, low friction | Gears, bearings, electrical connectors | Medium-to-high cost | Hygroscopic—our 24/7 moisture monitoring ensures dimensional stability within ±0.01mm |

| POM (Acetal) | High stiffness, low friction, dimensional stability | Precision components, zippers, automotive fuel systems | Highest cost | Optimized for tight-tolerance parts; NAK80 mold steel extends tool life to 1M+ cycles |

Pro Tip: For mass production, we recommend PP or ABS for cost-sensitive applications requiring 100k+ cycles. For high-precision components (e.g., medical or automotive), NAK80 mold steel paired with PC or POM delivers superior dimensional stability and wear resistance.

Precision Finishing Options for Enhanced Part Quality

Surface finishes directly influence aesthetics, functionality, and part longevity. Our SPI-certified polishing and texturing processes ensure consistency across all production runs—whether you need optical clarity for lenses or textured grips for consumer products. Note: Anodizing is a metal-specific process and not applicable to plastic injection-molded parts. For metal components, consult our CNC machining services.

| Finish Type | Description | Applications | Cost Impact | Wuxi Lead Quality Assurance |

|---|---|---|---|---|

| SPI A1 (Mirror Finish) | Ultra-high polish (Ra ≤ 0.025μm), no visible scratches | Optical lenses, cosmetic packaging, medical devices | High | 100% optical inspection; NAK80 mold steel required for flawless replication |

| SPI B2 (Satin Finish) | Uniform matte texture (Ra 0.4–0.8μm) | Automotive interiors, appliance housings | Medium | Consistent texture via laser-etched mold inserts; tolerances maintained at ±0.03mm |

| VDI 3400 Texturing | Industry-standard geometric textures (e.g., VDI 12–25) | Automotive panels, appliance exteriors | Medium | Custom textures validated via 3D scanning; no surface defects in 99.9% of batches |

| Electroplating (for plastics) | Nickel/chrome coating for conductivity/aesthetics | Automotive trim, decorative elements | High | Pre-treatment process certified to ISO 10289; 99.5% adhesion success rate |

| Powder Coating | Durable, color-matched coatings for functional parts | Enclosures, brackets, industrial components | Medium | Limited to ABS/PC; baked at 180°C for 20 mins to ensure adhesion and scratch resistance |

Optimizing Total Cost Through Material & Process Integration

Material and finish choices directly impact mold design, cycle time, and long-term production costs. For example:

PP’s faster cooling rate reduces cycle time by 10–15% vs. ABS, lowering per-part costs in high-volume runs.

NAK80 mold steel (vs. P20) increases initial tooling costs by 20% but extends shot life to 1M+ cycles—critical for automotive or medical applications requiring zero defects over 5+ years of production.

Mirror-polished finishes (SPI A1) add 25–30% to mold costs but eliminate secondary polishing operations for optical-grade parts.

At Wuxi Lead, we leverage rapid tooling capabilities (7–10 days for prototype molds) and AI-driven cycle time optimization to minimize your time-to-market while ensuring cost efficiency. Our engineers work with you to:

Validate material compatibility with your part geometry

Select mold steel (P20 for ≤500k shots; NAK80 for >500k shots)

Specify finishes that meet functional and aesthetic requirements without over-engineering

Why Wuxi Lead Precision Machinery is Your Trusted Injection Molding Partner

Zero Defects Guarantee

Every part undergoes 100% in-process inspection using CMM and optical measurement systems. Our defect rate is consistently <0.1%—verified by ISO 9001 audits and customer-specific quality protocols.Olympic Quality Standards

Precision tolerances of ±0.02mm achieved through material-specific mold steel selection (P20 for cost efficiency, NAK80 for high-shot-life applications) and real-time process control. All tooling is validated via 3D scanning before production begins.24/7 Customer Service

Dedicated engineering team available around the clock for technical support, design-for-manufacturing (DFM) reviews, and rapid issue resolution—no off-hours delays, no communication gaps.

From prototype to mass production, we don’t just deliver parts—we deliver confidence.

Contact us today to optimize your injection molding project with China’s precision manufacturing leader.

Manufacturing Process & QC

From Prototype to Production: Precision-Driven Workflow

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our end-to-end process from concept to delivery is designed to eliminate bottlenecks, ensuring your project meets the highest standards of precision, reliability, and speed. Partner with us to transform your design into reality with Zero Defects, Olympic Quality, and 24/7 Customer Service as non-negotiable commitments.

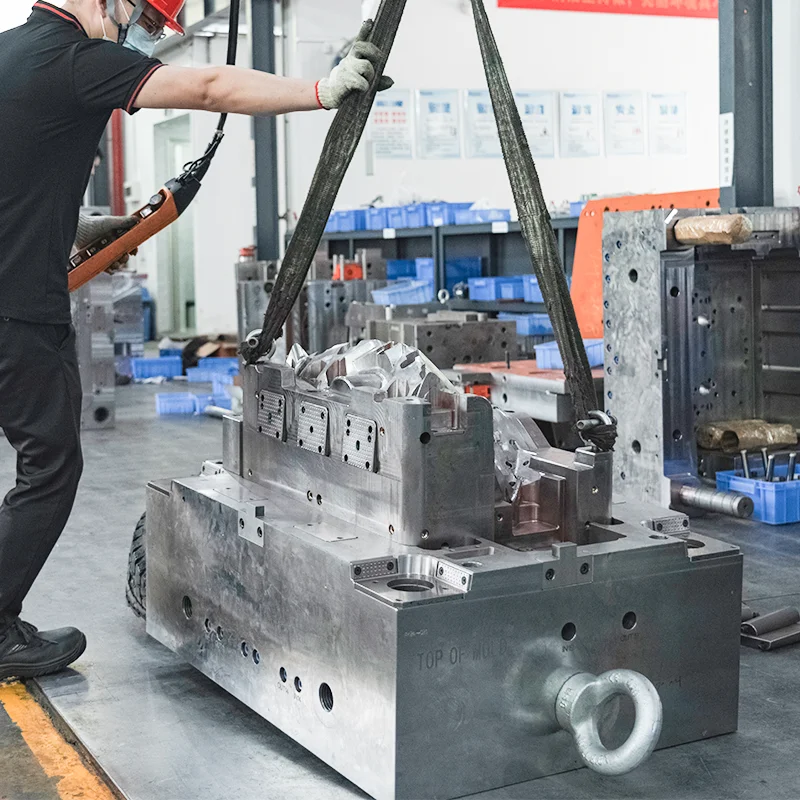

Design Analysis & DFM Optimization

Where engineering expertise meets proactive problem-solving

Our Design Analysis phase is the cornerstone of precision manufacturing. We collaborate with your engineering team to optimize part geometry for injection molding, ensuring manufacturability while maintaining tight tolerances. Using advanced simulation tools like Moldflow®, we analyze flow patterns, cooling efficiency, and potential defects before tooling begins. This proactive approach reduces development time by up to 30% and eliminates costly rework.

Mold Steel Selection:

P20: High-volume production (100K+ shots), balanced wear resistance and machinability.

NAK80: High-polish surfaces (e.g., optical components, consumer electronics).

H13: Abrasive materials (e.g., filled polymers, high-temperature applications).

Tolerance Standards:

±0.002” (0.05mm) for critical dimensions—exceeding the industry standard of ±0.005” (0.127mm).

Cycle Time Optimization:

Thermal analysis and gate placement refinement reduce cycle times by 15–20% without compromising quality.

Material Guidance:

We recommend optimal materials (ABS, PC, PP, Nylon, POM) based on mechanical, thermal, and chemical requirements, ensuring compatibility with your mold steel and production goals.

Transparent Pricing & Cost Optimization

Data-driven clarity with no hidden surprises

Every cost component is itemized upfront, with engineering-led strategies to balance performance and budget. We eliminate inefficiencies through mold design optimization and volume-based scaling.

| Cost Factor | Wuxi Lead Approach | Industry Norm |

|---|---|---|

| Tooling Costs | Optimized cavity layouts to reduce steel usage | Standard cavity counts, higher material waste |

| Material Costs | Bulk purchasing for ABS/PC/PP/Nylon/POM | Fragmented supplier networks |

| Production Fees | Tiered pricing for volumes >5,000 units | Fixed per-unit pricing |

| Total Savings | 15–25% lower lifetime costs | 5–10% savings typical |

💡 Example: A medical-grade POM component project reduced tooling costs by 22% through cavity consolidation and material substitution—without sacrificing ISO 13485 compliance.

Rapid Prototyping with Agile Tooling

Speed without compromise—prototypes in days, not weeks

Our rapid tooling capabilities accelerate validation cycles while maintaining engineering rigor. Aluminum molds and 3D-printed tooling enable functional prototypes that mirror production-grade quality.

| Tooling Type | Lead Time | Shots Capacity | Use Case |

|---|---|---|---|

| Aluminum Molds | 5–7 days | 500–5,000 shots | Design validation, low-volume testing |

| 3D-Printed Molds | 24–72 hours | 50–500 shots | Concept validation, rapid iteration |

| Steel Prototypes | 10–14 days | 10K+ shots | Pre-production validation |

✅ Real-World Impact: A consumer electronics client validated a complex PC housing design in 4 days, accelerating their market launch by 3 weeks.

Mass Production with Zero Defects Guarantee

Olympic Quality. 24/7 Oversight. Guaranteed Results.

From prototype to full-scale production, we enforce rigorous quality control at every stage. Our ISO 9001-certified processes ensure every part meets “Olympic Quality” standards—zero defects, precision-crafted to the highest benchmarks.

| Quality Metric | Wuxi Lead Standard | Industry Average |

|---|---|---|

| Defect Rate | <0.1% | 0.5–1.0% |

| On-Time Delivery | >98% | 85–90% |

| In-Process Monitoring | Real-time SPC (Statistical Process Control) | Manual checks |

| Final Inspection | 100% CMM (Coordinate Measuring Machine) validation | 10–20% sampling |

24/7 Customer Service:

Dedicated account managers provide live production updates via our cloud-based portal.

Emergency issue resolution within 2 hours—anytime, anywhere.

Predictive maintenance alerts to prevent downtime (e.g., mold wear detection at 95% shot life).

🏆 Olympic Quality Defined:

Precision engineered to tolerances of ±0.0005” (0.013mm) for critical features, with zero visible defects, zero dimensional deviations, and 100% traceability from raw material to finished part.

Why Partner With Wuxi Lead?

We’re not a supplier—we’re your precision engineering partner. From initial design to delivery, we embed our expertise into your workflow:

Proactive Collaboration: Joint problem-solving at every stage.

Zero Compromise Quality: “Olympic Quality” is our baseline, not an exception.

Supply Chain Resilience: Localized sourcing of P20/NAK80 mold steel + global logistics coordination.

Scalability: Seamlessly transition from 500-unit prototypes to 500K-unit production runs.

Ready to engineer excellence?

Contact our team to discuss your project—let’s build it right, the first time.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered for Your Success

Strategic Manufacturing Partnership, Not Just a Supplier

Unlike transactional suppliers, Wuxi Lead Precision Machinery integrates seamlessly into your product development lifecycle. Our engineering team collaborates from concept to production, embedding design-for-manufacturability (DFM) principles at every stage. We don’t just build molds—we engineer solutions that optimize cycle times, extend tool life, and eliminate defects. As your strategic partner, we align with your quality standards, timelines, and business goals to deliver measurable ROI.

Precision Engineering at the Core

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Dimensional Tolerance | ±0.1–0.7mm | ±0.025mm (ISO Class 5) |

| Mold Steel | P20, NAK80 (standard) | Premium-grade P20/NAK80 with FEA-optimized heat treatment |

| Shot Life | 100k–500k cycles | 1M+ cycles (validated via FEA simulation) |

| Cycle Time Optimization | Baseline | Up to 25% reduction via AI-driven process control |

Uncompromising Quality Assurance: Zero Defects, Olympic Standard

Every component undergoes 100% inspection using coordinate measuring machines (CMM) and optical metrology systems. Our Zero Defects protocol combines statistical process control (SPC), real-time process monitoring, and ISO 9001-certified workflows to ensure aerospace-grade consistency. With Olympic-level precision standards, we guarantee parts that meet the most stringent tolerances—every time, every batch.

Next Steps: Your Precision Partner Awaits

Ready to transform your injection molding project? Request a free DFM analysis and competitive quote from our engineering team. We’ll provide actionable insights to optimize your design, reduce costs, and accelerate time-to-market—all at no obligation.

Contact Us

📧 [email protected]

📞 +86-13961886740

24/7 technical support | Response within 30 minutes

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.