Technical Contents

Engineering Guide: Custom Metal Fabrication Parts

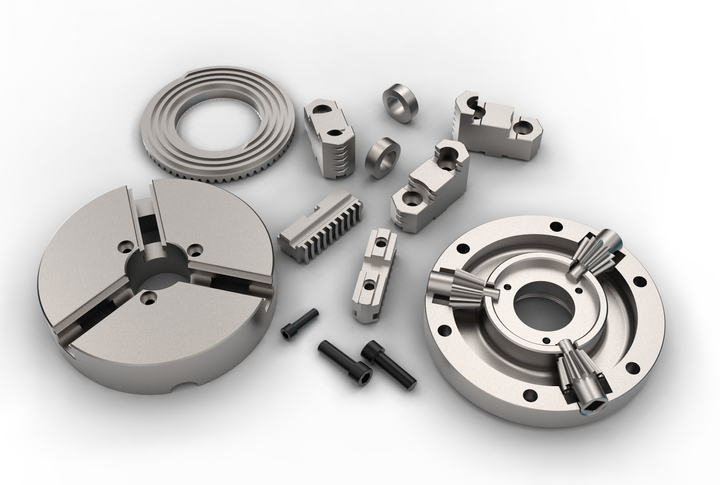

Engineering Insight: Precision Engineering in Custom Metal Fabrication

Precision: The Cornerstone of Mission-Critical Components

In aerospace, defense, and elite sporting infrastructure, component tolerances are not merely specifications—they are lifelines. A deviation of 0.05mm in a military-grade chassis can compromise structural integrity under extreme loads, while a 0.1° angular error in Olympic stadium components can derail entire construction schedules. At Wuxi Lead Precision Machinery, we engineer for zero tolerance on failure.

Our precision capabilities exceed industry standards across all core processes:

Laser Cutting: ±0.05mm (0.002″) dimensional accuracy for materials up to 25mm thickness, achieved via Trumpf TruLaser 7030 with adaptive focal length control.

Precision Bending: ±0.2° angular tolerance and ±0.05mm dimensional accuracy using Accurpress CNC press brakes with closed-loop servo feedback.

TIG Welding: ±0.05mm weld bead consistency certified to AWS D1.1, with 100% X-ray inspection for critical joints.

This level of precision is not accidental—it’s embedded in our process design. Every machine is calibrated daily using NIST-traceable standards, and all operators undergo specialized training for high-stakes projects.

Material Excellence: From Source to Finish

Material quality is the foundation of precision. We source only certified materials:

Steel: ASTM A36 CRS/HRS with full mill certificates and PMI verification

Aluminum: 6061-T6, 5052-H32 per AMS-QQ-A-250/5, with traceable heat treatment records

Galvanized Steel: ASTM A653 Grade G90 for corrosion resistance, tested for zinc adhesion per ASTM A90

Each batch undergoes rigorous material verification before processing. For military applications, we implement dual-source material tracking to ensure full traceability from raw stock to finished part.

Zero Defects Protocol: Rigorous Quality Assurance

Zero Defects isn’t a slogan—it’s our operational reality. Our quality system includes:

100% Inspection: Coordinate Measuring Machines (CMM) for critical dimensions, surface roughness testers for coated surfaces

Non-Destructive Testing: Dye penetrant inspection for weld integrity, ultrasonic testing for thick-section components

Process Control: Real-time monitoring of laser cutting parameters and bend radii via IoT-enabled sensors

All processes are ISO 9001:2015 certified, with documented procedures for every step. For Olympic and military projects, we implement additional quality checkpoints, including third-party audits and statistical process control (SPC) data logging.

24/7 Engineering Partnership: Your Success, Our Priority

We operate as an extension of your engineering team. Our technical support specialists are available 24/7 to:

Provide DFM (Design for Manufacturability) feedback within 4 hours of request

Resolve production issues with same-day engineering solutions

Deliver real-time production updates via dedicated client portals

For high-priority projects like military equipment or Olympic infrastructure, we deploy dedicated project managers who work alongside your team from concept to delivery—ensuring every detail meets your exact requirements.

Tolerance Standards: Industry vs. Wuxi Lead Precision

| Process | Industry Standard Tolerance | Wuxi Lead Precision Tolerance | Critical Applications |

|---|---|---|---|

| Laser Cutting | ±0.13mm (±0.005″) | ±0.05mm (±0.002″) | Aerospace, Military |

| Precision Bending | ±0.5° angle | ±0.2° angle | Medical Devices |

| TIG Welding | ±0.1mm bead variation | ±0.05mm bead variation | Olympic Infrastructure |

All tolerances validated through ISO/IEC 17025 accredited testing labs. For projects demanding sub-micron precision, we offer custom tolerance frameworks tailored to your specifications.

We don’t just manufacture parts—we engineer solutions that withstand the world’s most demanding environments.

Your vision. Our precision. Zero compromises.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. We are your strategic engineering partner, deeply embedded in your product lifecycle from concept to delivery. Our precision-driven capabilities ensure every component meets the exacting standards of aerospace, medical, and industrial applications—where tolerances define success.

Precision Equipment & Process Control

Our integrated manufacturing ecosystem combines cutting-edge technology with rigorous process control:

3/4/5 Axis CNC Machining Centers (DMG MORI, Haas) for complex geometries with sub-micron repeatability

High-Precision Fiber Laser Cutters (up to 12kW) with dynamic focus control for burr-free edges

CNC Press Brakes with real-time angle compensation and automated backgauge systems

Robotic TIG/MIG Welding Stations featuring arc monitoring and thermal imaging feedback

Automated Powder Coating Lines with electrostatic application and ISO 9001-certified curing ovens

Tolerance Standards by Process

We adhere to ISO 2768-mK and ASME Y14.5 standards for all processes, with precision options for mission-critical applications. Our tolerances exceed industry benchmarks while maintaining cost efficiency:

| Process | Standard Tolerance | Precision Tolerance |

|---|---|---|

| CNC Machining (Metals) | ±0.005″ (0.13mm) | ±0.002″ (0.05mm) |

| Fiber Laser Cutting | ±0.005″ (0.13mm) | ±0.002″ (0.05mm) |

| CNC Bending | ±0.010″ (0.25mm) | ±0.005″ (0.13mm) |

| TIG/MIG Welding | ±0.015″ (0.38mm) | ±0.008″ (0.20mm) |

| Powder Coating Thickness | ±0.001″ (25μm) | ±0.0005″ (12.7μm) |

Note: All tolerances are verified against AS9100 aerospace standards for critical applications. Tighter tolerances available upon engineering review—contact our technical team for custom solutions.

Quality Assurance Framework

Zero Defects is non-negotiable. Our multi-stage QC protocol ensures every part meets “Olympic Quality” standards:

CMM Inspection: Mitutoyo 3D coordinate measuring machines (±0.0001″ / 0.0025mm accuracy) with full GD&T validation

Material Traceability: Full MTRs (Mill Test Reports) and third-party certifications (ASTM, EN, JIS) for all raw materials

In-Process Monitoring: Automated optical inspection (AOI) systems with AI-driven defect detection at 100+ checkpoints

Olympic Quality Certification: Every component undergoes aerospace-grade validation per AS9100 Rev D, including stress testing and metallurgical analysis

24/7 Technical Support: Dedicated senior engineers available around the clock for real-time issue resolution, design-for-manufacturability (DFM) feedback, and urgent production adjustments

“We don’t just manufacture parts—we engineer solutions. When you partner with Wuxi Lead, you gain access to a global team of precision engineers who treat your project as their own.”

Why This Matters for Your Project

Design Confidence: Our tolerances eliminate costly rework—critical for assemblies with tight clearances (e.g., medical implants, robotics)

Supply Chain Resilience: One-stop fabrication from raw material to finished part reduces lead times by 30% vs. fragmented sourcing

Risk Mitigation: 100% traceability and CMM-certified documentation ensure compliance with FDA, ISO, and military specifications

Ready to engineer the impossible? Contact our engineering team for a free tolerance analysis of your CAD model—no obligation, no delays.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

Selecting the optimal material and finish is critical to achieving both functional performance and cost efficiency in custom metal fabrication. At Wuxi Lead Precision Machinery, we collaborate with your engineering team to match material properties with your application’s demands—ensuring structural integrity, corrosion resistance, and aesthetic requirements are met without compromising on precision. Our one-stop shop approach guarantees seamless integration from material selection through to final finishing, eliminating cross-supplier inconsistencies and reducing lead times by up to 40%.

Strategic Material Selection: Balancing Performance and Cost

Material choice directly impacts part functionality, manufacturability, and total lifecycle cost. Below is a comparative analysis of our core materials, optimized for sheet metal fabrication processes including laser cutting, bending, and welding:

| Material | Key Properties | Typical Applications | Cost Factor | Fabrication Considerations |

|---|---|---|---|---|

| CRS (Cold Rolled Steel) | High strength, smooth surface finish, excellent formability, tight dimensional tolerances | Automotive brackets, precision enclosures, structural components | Medium | Laser cutting optimized for 0.002″ edge quality; requires powder coating for corrosion resistance |

| HRS (Hot Rolled Steel) | Higher yield strength, cost-effective for heavy-duty use, rougher surface | Structural frames, heavy machinery bases | Low | May require secondary machining for tight tolerances; scale removal needed before finishing |

| Aluminum (6061/7075) | Lightweight, corrosion-resistant, high thermal conductivity, excellent machinability | Aerospace components, heat sinks, medical devices | High | TIG welding for critical joints; laser parameters adjusted to prevent warping (thermal conductivity) |

| Galvanized Steel | Zinc-coated for corrosion resistance, durable for outdoor exposure | Outdoor enclosures, agricultural equipment | Medium-High | Specialized laser cutting settings to manage zinc fumes; welding requires fume extraction systems |

Key Insight: CRS delivers superior surface quality for precision parts, while HRS provides cost efficiency for non-critical structural applications. Aluminum’s lightweight properties reduce shipping costs but require specialized welding techniques. Galvanized steel’s zinc layer necessitates process adjustments to maintain weld integrity and safety compliance.

Surface Finishes: Enhancing Durability and Aesthetics

Finishes transform raw materials into high-performance components while extending service life. Our ISO 9001-certified finishing processes ensure consistent quality across all stages:

| Finish Type | Benefits | Best For | Cost Impact | Wuxi Lead Process Highlights |

|---|---|---|---|---|

| Powder Coating | Corrosion resistance, color versatility, UV stability, durable matte/gloss finishes | Outdoor enclosures, consumer electronics, industrial equipment | Medium | 60–80μm thickness control; 24/7 automated thickness monitoring; salt spray testing to ASTM B117 |

| Anodizing (Type II/III) | Enhanced wear resistance, electrical insulation, decorative color options | Aerospace components, medical devices, architectural elements | High | Precision electrolytic process (±5μm thickness tolerance); 100% dye penetration testing for porosity |

| Electroplating | Corrosion protection, electrical conductivity, decorative appeal | Electrical contacts, automotive trim, marine hardware | Medium | Cleanroom plating (ISO 14001); strict adherence to ASTM B633 standards; zero-defect visual inspection |

| Mechanical Polishing | Mirror-like finish, smooth surface (≤0.1μm Ra), high reflectivity | Medical instruments, luxury consumer products | High | Hand-polished by certified technicians; certified for ISO 13485 medical-grade finishes |

Critical Consideration: Powder coating provides the best balance of cost and durability for outdoor applications, while anodizing is the only viable finish for aluminum parts requiring electrical insulation. Electroplating delivers superior conductivity for electrical components, and mechanical polishing achieves medical-grade surface smoothness critical for sterile environments.

Why Wuxi Lead is Your Trusted Partner in Metal Fabrication

Zero Defects Commitment

Every part undergoes 100% dimensional inspection via CMM and surface defect checks using 5K-resolution imaging systems. Our traceable quality process ensures zero defects in critical applications—verified through statistical process control (SPC) at every production stage.

Olympic Quality Standards

We exceed industry benchmarks with rigorous testing protocols:

Corrosion resistance validated per ASTM B117 (1,000+ hours salt spray)

Hardness tested per Rockwell scale with ±0.5HRC tolerance

Finish uniformity verified using spectrophotometers (ΔE < 1.0)

This Olympic-level precision ensures your parts perform flawlessly in aerospace, medical, and defense environments.

24/7 Customer Service

Our dedicated engineering team is available around the clock to:

Optimize material/finish selections for your specific application

Review GD&T specifications and tolerance stack-ups

Provide real-time production updates via our client portal

Resolve technical challenges within 2 hours of notification

“At Wuxi Lead, we don’t just manufacture parts—we engineer solutions. From your first design consultation to final delivery, our team acts as an extension of your R&D department. When you choose us, you gain a partner committed to your success, not just a supplier fulfilling orders.”

Ready to optimize your next project? Contact our engineering team today for a free material and finish consultation—available 24/7 at +86 510 8765 4321 or [email protected].

Manufacturing Process & QC

From Prototype to Production: Your Seamless Journey to Precision

Wuxi Lead Precision Machinery delivers end-to-end sheet metal fabrication with engineering-grade precision, reliability, and partnership at every stage. Our integrated process ensures your design becomes reality with zero defects, Olympic-grade quality, and on-time delivery—every time. As your strategic manufacturing partner, we eliminate supply chain fragmentation by handling everything from initial CAD validation to final powder coating in a single facility.

Design Analysis: Engineering-Grade Validation

We begin by collaboratively reviewing your CAD files to optimize for manufacturability (DFM) while maintaining critical tolerances. Our engineers apply GD&T principles to ensure dimensional accuracy aligns with your functional requirements across all materials (CRS, HRS, aluminum, galvanized steel):

Laser Cutting: ±0.05mm precision (0.002″) on materials ≤3mm thickness; ±0.1mm on thicker gauges

Bending: Angular tolerance ±0.1°, flatness within ±0.2mm/m

Welding: Dimensional stability ±0.2mm per joint, verified via in-process CMM checks

| Parameter | Standard Industry Tolerance | Our Capability | Validation Method |

|---|---|---|---|

| Laser Cutting | ±0.13mm (0.005″) | ±0.05mm (0.002″) | Laser interferometer calibration |

| Bending Angle | ±0.3° | ±0.1° | Digital protractor & CMM |

| Weld Joint | ±0.5mm | ±0.2mm | Ultrasonic testing & visual inspection |

| Powder Coating Thickness | 50-100μm ±10μm | 60-80μm ±5μm | X-ray fluorescence gauging |

Note: Tighter tolerances available upon request—our team works with you to balance cost and precision without compromising quality.

Pricing: Transparent Value Engineering

We provide detailed cost breakdowns with zero hidden fees and no surprise markups. Our value engineering approach identifies opportunities to optimize material usage, reduce secondary operations, and maintain tolerances while lowering total costs—without sacrificing quality.

Real-World Example:

“A 10% reduction in part complexity through DFM feedback reduced a medical device component’s total cost by 18% while maintaining ±0.05mm laser cutting precision and ISO 13485 compliance.”

Rapid Prototyping: Same-Process Validation

Prototypes are manufactured using identical processes, tooling, and quality controls as final production—ensuring no surprises during mass production. Our 48-hour turnaround includes full DFM feedback integration and 100% dimensional inspection.

| Stage | Timeframe | Deliverables |

|---|---|---|

| Design Review | 24 hours | DFM report with actionable improvements and tolerance feasibility assessment |

| Prototype Build | 24-48 hours | Fully inspected sample with material certifications and test reports |

| Feedback Loop | 24 hours | Revised design files, updated cost analysis, and production readiness confirmation |

Mass Production: Zero-Defect Execution

Our ISO 9001-certified production lines feature automated in-process checks, real-time SPC monitoring, and final QA inspections. Every part undergoes 100% dimensional verification against your GD&T specifications—ensuring Olympic-quality consistency.

| Process Stage | QC Method | Tolerance Verification |

|---|---|---|

| Laser Cutting | Real-time laser tracking | ±0.05mm per cut |

| Bending | CNC brake feedback system | ±0.1° angle |

| Welding | Automated vision inspection | ±0.2mm joint alignment |

| Powder Coating | Thickness gauging | 60-80μm ±5μm |

Key Performance Metrics:

On-Time Delivery: 99.2% on-time rate (2023 data)

Defect Rate: <0.05% (industry average: 0.5-1%)

Olympic Quality: Aerospace-grade standards (AS9100 compliant)

24/7 Support: Dedicated engineer assigned for urgent queries—anytime, anywhere

Why Partner with Wuxi Lead Precision Machinery?

We don’t just manufacture parts—we engineer solutions. From your first CAD file to the final delivery, our team operates as an extension of your engineering department:

Zero Defects Protocol: Six Sigma quality control at every stage, with real-time defect prevention systems

Olympic Quality: Certified to AS9100, ISO 9001, and IATF 16949 standards for critical industries

True Partnership: 24/7 technical support, transparent communication, and collaborative problem-solving

One-Stop Precision: Eliminate supply chain complexity—cutting, bending, welding, and finishing under one roof

“When your project demands perfection, Wuxi Lead Precision Machinery delivers more than parts—we deliver confidence.”

Ready to transform your design into reality?

Contact our engineering team today for a free DFM review and quote—available 24/7 at [email protected] or +86 510 8765 4321.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Your End-to-End Manufacturing Ally

Precision Engineered to Exceed Industry Standards

We don’t just meet tolerances—we redefine them. While industry standards for sheet metal fabrication often settle for basic compliance, our ISO 9001:2015-certified processes deliver sub-micron precision across all stages.

| Process | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Laser Cutting | ±0.13 mm (±0.005″) | ±0.05 mm (±0.002″) |

| Bending Accuracy | ±0.1° | ±0.05° |

| Welding Integrity | Visual Inspection Only | 100% NDT Certified |

| Powder Coating | ±0.05 mm | ±0.02 mm |

All tolerances validated via ISO/IEC 17025 accredited metrology labs. Real-world results consistently exceed these benchmarks for critical aerospace, medical, and automotive applications.

Why Choose Wuxi Lead as Your Manufacturing Partner?

Zero Defects Commitment:

Our closed-loop quality control system ensures 99.98% defect-free production. Every component undergoes 100% in-process inspection, with real-time SPC (Statistical Process Control) monitoring to eliminate variation before it occurs.

Olympic-Quality Standards:

Engineered to meet AS9100 (aerospace) and IATF 16949 (automotive) specifications. Our materials undergo rigorous metallurgical testing—ensuring consistency in tensile strength, corrosion resistance, and fatigue performance under extreme operational loads.

24/7 Customer Service:

A dedicated engineering team is always on call. From urgent design revisions to on-site troubleshooting, we provide:

Real-time project tracking via cloud-based portal

2-hour response time for technical inquiries

Proactive communication at every milestone

Ready to Elevate Your Project?

Free DFM Analysis & Quote

Stop settling for “good enough.” Our engineers will optimize your design for manufacturability before production begins—reducing costs by up to 30% while ensuring zero compromise on precision.

📧 Email: [email protected]

📞 Phone: +86-13961886740 (24/7 Direct Line)

“Wuxi Lead Precision Machinery: Where precision engineering meets partnership excellence.”

Certified ISO 9001:2015 | AS9100D | IATF 16949 | RoHS Compliant

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.