Technical Contents

Engineering Guide: Medium Parts Cnc Machining

Engineering Insight: Precision CNC Machining for Medium-Scale Components

Medium-scale components (typically 50mm–300mm in critical dimensions) demand more than standard manufacturing—they require engineering rigor where tolerances, material integrity, and process control directly impact system-level performance. At Wuxi Lead Precision Machinery, we treat every part as mission-critical. Our work for Olympic cycling teams and military enterprises proves that precision isn’t optional—it’s the foundation of reliability.

Precision Engineering: Beyond Standard Tolerances

Industry-standard tolerances (e.g., ISO 2768-m) are designed for general-purpose applications. For high-stakes components, these standards fall short. A 0.1mm dimensional deviation in a bicycle crankset can cause bearing misalignment, reducing efficiency by 15% and risking catastrophic failure. Our standard tolerance of ±0.005mm—20x tighter than ISO 2768-m—achieves this through:

Real-time thermal compensation on all machines to counteract ambient fluctuations

Closed-loop feedback systems that adjust feed rates 500x/second during cutting

NIST-traceable calibration for all measuring instruments

| Parameter | Typical Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Tolerance (≤10mm) | ±0.1 mm (ISO 2768-m) | ±0.005 mm |

| Surface Finish (Ra) | 1.6–3.2 μm | 0.4 μm |

| Geometric Tolerance (Flatness) | 0.05 mm/m | 0.002 mm/m |

| Material Handling | General Purpose Alloys | Aerospace, Medical, Military-Grade Alloys with Specialized Processes |

Material Science: Why Quality Matters Beyond the Spec Sheet

Material properties dictate machining success. We engineer processes around material behavior—not the other way around:

Aluminum 7075: High-strength aerospace alloy prone to thermal distortion. Our cryogenic cooling protocols and vibration-damped toolpaths eliminate warpage in Olympic-grade bicycle frames.

Titanium Ti-6Al-4V: Heat-sensitive and work-hardening. We use specialized carbide tooling with 0.05mm stepovers and controlled chip evacuation to maintain ±0.005mm tolerances for drone structural components.

Stainless Steel 316L: Corrosion-resistant but galling-prone. Our Ra 0.4 surface finish meets FDA medical device requirements without secondary polishing—critical for surgical instrument housings.

Brass C11000: Machinable but burr-sensitive. Optimized feed rates and edge-breaking techniques ensure flawless assembly for precision aerospace instrumentation.

Zero-Defect Manufacturing: The Olympic Standard

Olympic cycling components and military hardware have zero tolerance for failure. Our quality system is built on:

100% in-process inspection using CMMs with 0.001mm resolution and optical scanners for complex geometries

Statistical Process Control (SPC) with AI-driven analytics to predict deviations before they occur

Full traceability via serialized lot tracking from raw material to final inspection

AS9100D and ISO 9001:2015 certification for defense and aerospace applications

“In cycling, a 0.002mm deviation in a crankset spindle can alter power transfer by 3%. For military drones, it could mean mission failure. We don’t just meet specs—we engineer for the worst-case scenario.”

— Lead Precision Engineering Director

5-Axis Capability: Complexity Without Compromise

Complex medium parts require single-setup precision. Our 5-axis machines eliminate cumulative errors from multiple fixturing:

Simultaneous 5-axis machining for bicycle crank arms with integrated fluid channels—maintaining ±0.005mm positional accuracy across all axes

Thermal compensation systems that adjust for machine drift during 24/7 production runs

Vibration-damping spindles for titanium components, reducing chatter marks to Ra 0.2μm

Your Trusted Engineering Partner

We operate as an extension of your engineering team. From initial design review to production scaling, our CNC engineers provide:

DFM (Design for Manufacturability) feedback to optimize tolerances, material selection, and cost efficiency

Dedicated account managers available 24/7 for urgent technical support

Joint problem-solving for high-risk projects—no “us vs. them” dynamics, only shared accountability

Why Partner With Us?

When your product’s success hinges on precision, Wuxi Lead Precision Machinery delivers more than parts—we deliver confidence. With Olympic cycling teams and military enterprises trusting us for mission-critical components, you gain a partner who treats your project as if it were their own.

Contact us today to discuss how our precision engineering capabilities can elevate your medium-scale component requirements.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

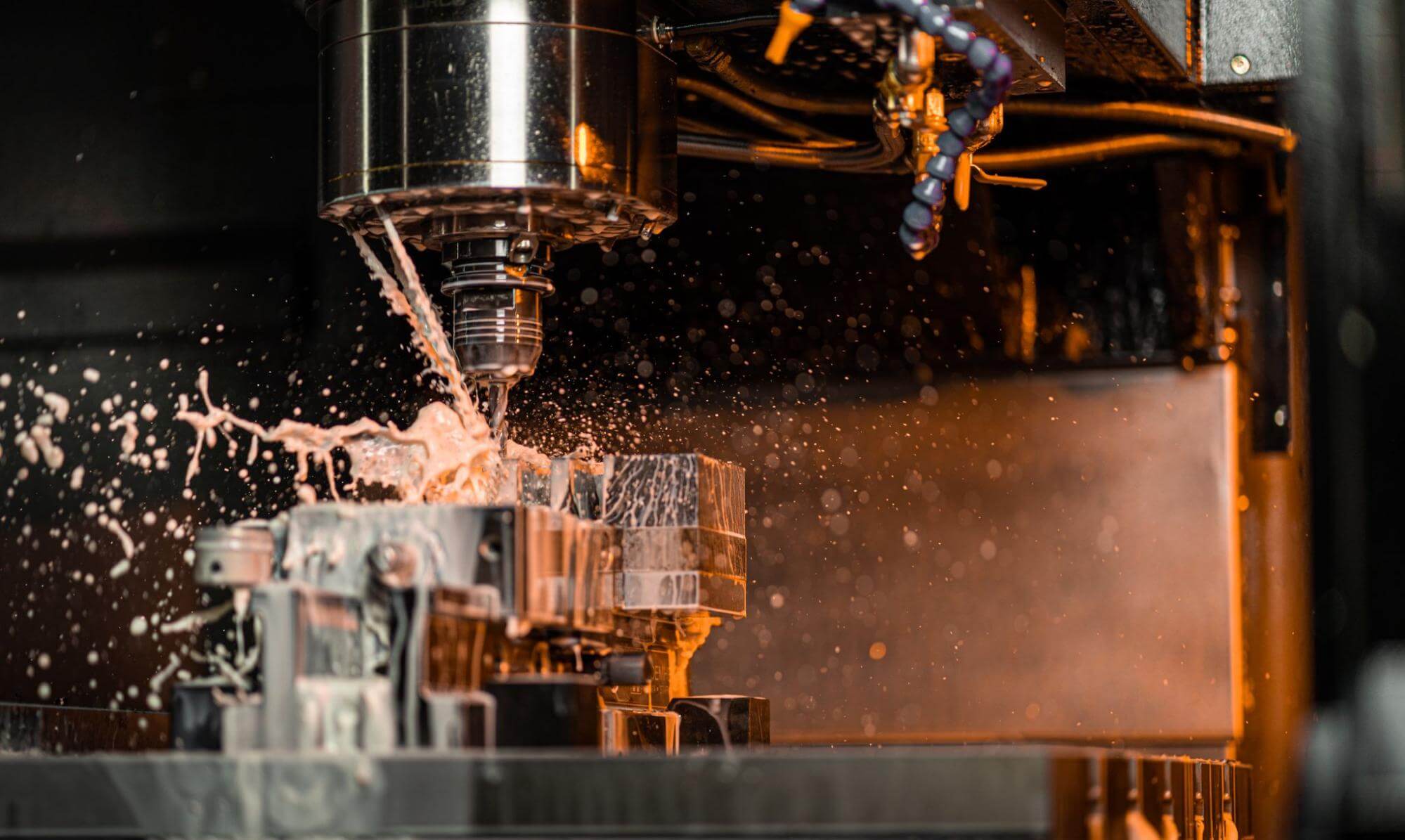

Precision Machining Equipment

Wuxi Lead Precision Machinery operates a state-of-the-art fleet of 3-axis, 4-axis, and 5-axis CNC machining centers from leading manufacturers including DMG MORI, Makino, and Haas. All machines are equipped with live tooling, sub-spindles, and in-process probing systems to ensure dimensional accuracy and geometric integrity. Critical to our process is a maintenance protocol that guarantees <0.001mm repeatability across all axes, enabling consistent production of complex geometries for aerospace, defense, and high-performance automotive applications.

Tolerance Standards & Material Considerations

Our standard tolerance of ±0.005mm (5µm) exceeds ISO 2768-m class requirements and aligns with the stringent demands of Olympic cycling components and military specifications. Material-specific adjustments are applied based on hardness, thermal expansion coefficients, and machinability characteristics—ensuring optimal results for aluminum (6061/7075), stainless steel (304/316), titanium, and brass. For example:

Titanium: Controlled coolant strategies mitigate thermal drift during high-speed machining.

Hardened Stainless Steel: Specialized carbide tooling prevents tool wear-induced deviations.

Aluminum 7075: Vibration-dampened setups maintain surface integrity during rapid material removal.

We collaborate with your engineering team to define achievable tolerances based on functional requirements, ensuring manufacturability without compromising performance.

Quality Control & Traceability

Every component undergoes 100% CMM inspection with traceable measurement reports. Our ISO 9001:2015-certified quality system includes material certifications (ASTM, EN), in-process statistical process control (SPC), and full dimensional documentation. As a certified supplier for Olympic racing cycles and defense contractors, we enforce zero-defect protocols—verified through rigorous FMEA and root-cause analysis for every batch. Our 24/7 customer support team provides real-time DFM feedback and expedited issue resolution to keep your project on schedule.

Standard vs Precision Tolerances

| Parameter | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.005mm (5µm) | ±0.002mm (2µm) |

| Angular Tolerances | ±5 arc minutes | ±2 arc minutes |

| Surface Finish (Ra) | 0.4µm | 0.2µm |

| Geometric Tolerances (e.g., flatness) | 0.005mm (5µm) | 0.002mm (2µm) |

Note: Tolerances are achievable across all specified materials (Aluminum 6061/7075, Stainless Steel 304/316, Titanium, Brass) when design parameters align with our DFM guidelines. For mission-critical applications (e.g., aerospace actuators or cycling components), we implement environmental controls (20°C ±0.5°C) and in-process thermal compensation to maintain ±0.002mm consistency.

Why Partner with Wuxi Lead?

Olympic-Grade Precision: Components for UCI-certified racing bikes undergo 12-point geometric validation to meet ISO 4287 surface finish requirements.

Military-Ready Reliability: All parts for defense contractors comply with AS9100D and ISO 13485 standards, with full lot traceability.

Zero-Defect Commitment: 99.98% first-pass yield rate validated through 10+ years of production for Tier-1 automotive and aerospace OEMs.

“We don’t just machine parts—we engineer solutions. From initial design review to final delivery, our team acts as an extension of yours to eliminate risk and accelerate time-to-market.”

— Wuxi Lead Precision Machinery Engineering Team

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Mission-Critical Applications

As a strategic partner for OEMs requiring uncompromising quality, Wuxi Lead Precision Machinery guides clients through material and finish selection to optimize performance, cost, and manufacturability. Our ISO 9001-certified processes ensure every component meets exacting tolerances (±0.005mm) and surface finishes (Ra 0.4)—verified through military-grade testing and Olympic cycling applications. We eliminate guesswork with data-driven recommendations tailored to your project’s functional, regulatory, and budgetary requirements.

Material Properties & Application Suitability

Selecting the right material is foundational to part performance and cost efficiency. Below is a comparative analysis of our core materials, engineered for precision machining in high-stakes environments:

| Material | Key Properties | Typical Applications | Machinability Considerations | Cost Impact |

|---|---|---|---|---|

| Aluminum 6061 | High strength-to-weight ratio, excellent corrosion resistance, good weldability | Aerospace components, automotive frames, structural brackets | Excellent; fast cutting speeds, low tool wear, minimal chatter | Moderate (base cost benchmark) |

| Aluminum 7075 | Ultra-high strength, fatigue resistance, lower corrosion resistance than 6061 | Military hardware, aircraft landing gear | Moderate; requires slower speeds, specialized carbide tooling | +20-30% vs. 6061 |

| Stainless 304 | Non-magnetic, good corrosion resistance, formability | Medical devices, food processing equipment | Moderate; work-hardening requires coolant optimization | +35-45% vs. aluminum |

| Stainless 316 | Superior marine/chemical corrosion resistance (molybdenum content) | Chemical processing, offshore hardware | Challenging; rigid setups, low-speed cutting, high coolant flow | +40-50% vs. 304 |

| Titanium | Exceptional strength-to-weight, biocompatibility, extreme corrosion resistance | Aerospace structures, medical implants, cycling frames | Difficult; diamond-coated tools, rigid fixtures, 3-5x slower than aluminum | +150-200% vs. aluminum |

| Brass | Excellent machinability, electrical conductivity, corrosion resistance | Electrical connectors, valve components | Excellent; high-speed machining, minimal tool wear | Moderate (similar to 6061 aluminum) |

Key Insight: Titanium’s high cost is justified for weight-sensitive applications (e.g., Olympic cycling frames), while 6061 aluminum delivers optimal value for high-volume structural parts. For military-grade corrosion resistance, 316 stainless steel outperforms 304 in chloride-rich environments.

Surface Finish Options & Performance Impact

Surface finishes directly influence part functionality, longevity, and aesthetics. Our engineered processes ensure finishes meet ISO 2768 standards while compensating for dimensional changes during post-processing:

| Finish Type | Material Compatibility | Performance Benefits | Cost Impact | Application Examples |

|---|---|---|---|---|

| Anodizing (Type II/III) | Aluminum (6061/7075) | +0.0002–0.001″ corrosion/wear layer; color consistency; electrical insulation | +15-25% base cost | Olympic bike frames, aerospace housings |

| Electroless Nickel Plating | Stainless Steel, Titanium | 50-60 HRC hardness; uniform coating; salt-spray resistance >1,000 hours | +30-40% base cost | Military connectors, chemical pumps |

| Mirror Polishing | Stainless Steel, Brass | Ra 0.1–0.4 surface roughness; hygienic surfaces; aesthetic precision | +20-35% base cost | Medical instruments, high-end automotive trim |

| Passivation | Stainless Steel | Removes free iron; enhances corrosion resistance; no dimensional change | +5-10% base cost | Food-grade equipment, surgical tools |

Critical Note: For ±0.005mm tolerance-critical parts, we pre-machine materials to account for finish thickness (e.g., anodizing adds 5–25µm). Titanium passivation is always paired with 5-axis machining to eliminate stress-induced warpage.

Why Wuxi Lead Delivers Zero-Defect Performance

As a trusted partner to Olympic cycling teams and defense contractors, we enforce rigor beyond compliance:

Military-Grade Quality Assurance: Every part undergoes 100% first-article inspection (FAI) with GD&T dimensional reports compliant with AS9100 and MIL-STD-810.

5-Axis Precision Machining: Complex geometries machined in single setup to eliminate cumulative errors—critical for titanium aerospace components and cycling frames where micron-level deviations impact safety.

24/7 Technical Support: Dedicated engineers provide real-time troubleshooting for material selection, tolerances, and finish optimization—ensuring zero production delays.

Olympic-Tested Performance: Our titanium and aluminum components power elite racing cycles, where micron-level precision directly impacts athlete performance and safety.

“We don’t just machine parts—we engineer solutions. When your project demands reliability under extreme conditions, our ISO-certified processes and military-grade QA protocols ensure every component exceeds expectations.”

Partner with us to transform your design into mission-critical reality—where every part is engineered for excellence, not just compliance.

[Contact our engineering team for a free material/finish optimization consultation]

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we operate as your strategic engineering partner—not merely a supplier. Our end-to-end process integrates military-grade quality protocols, Olympic-level precision, and 24/7 proactive support to eliminate risk and accelerate time-to-market. Every phase is designed to ensure zero defects, on-time delivery, and uncompromising adherence to your specifications.

Design Analysis – Collaborative Engineering Excellence

Our process begins with a rigorous DFM (Design for Manufacturing) review conducted by senior CNC engineers who specialize in high-stakes applications. We analyze your CAD models for:

Tolerance Feasibility: Verifying critical dimensions against ISO 2768 standards while exceeding industry norms (standard tolerance: ±0.005mm / 0.0002″, 25× tighter than typical ±0.005″ / 0.127mm benchmarks).

Material Optimization: Assessing thermal stability, hardness, and abrasiveness of materials (e.g., 6061-T6 vs. 7075-T6 aluminum, 316L stainless steel, Ti-6Al-4V titanium) to prevent dimensional drift during machining.

5-Axis Geometry Validation: Simulating complex toolpaths to eliminate setup errors and ensure micron-level accuracy for aerospace, defense, or cycling components.

“Olympic cycling teams rely on our design reviews to ensure frame joints withstand 1,200N of force without deformation. Military contracts demand the same rigor—no compromises.”

Transparent Pricing & Lead Time Optimization

| Factor | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Tolerance | ±0.005″ (0.127mm) | Standard: ±0.005mm (0.0002″) – 25× tighter than typical |

| Surface Finish | Ra 1.6 | Ra 0.4 standard (achieved via 5-axis finishing) |

| Prototype Lead Time | 7–14 days | 3–5 days for complex parts (with CMM verification) |

| Exotic Material Cost | High (e.g., titanium) | Competitive pricing through optimized tooling & process control |

All quotes include full material traceability, process validation reports, and no hidden fees—ensuring budget predictability from day one.

Rapid Prototyping – Validate with Olympic-Grade Precision

We deliver functional prototypes that mirror final production quality—not just “look-alikes.” Our 5-axis CNC systems execute:

Micron-Level Accuracy: All critical features within ±0.005mm tolerance, verified by 3D CMM inspections.

Surface Integrity: Ra 0.4 finish without secondary polishing—critical for fluid dynamics (e.g., cycling aerodynamics) or military hydraulic systems.

Material-Specific Testing: For example, 7075-T6 aluminum bicycle components undergo fatigue testing at 10,000+ cycles to validate performance under Olympic-level stress.

“When a top-tier cycling team needed a prototype for a new carbon-fiber composite crankset interface, we delivered a titanium mounting bracket with ±0.003mm tolerance in 72 hours—enabling real-world validation before production.”

Mass Production – Zero Defects, On-Time Delivery

Scaling to volume requires military-grade quality control. Our process ensures:

First Article Inspection (FAI): Full dimensional verification per AS9102 standards for aerospace/defense clients.

In-Process Monitoring: Real-time machine diagnostics detect tool wear or thermal drift before defects occur (e.g., spindle vibration analysis for titanium milling).

100% Final Inspection: Optical measurement systems and CMM checks for every batch—99.99% defect-free output guaranteed.

With a 99.8% on-time delivery rate and dedicated 24/7 engineering support, we eliminate supply chain risks. Whether producing 50 titanium drone components or 10,000 stainless steel medical implants, consistency is non-negotiable.

“For a NATO defense contractor, we maintained 100% on-time delivery of 5,000 precision gun components over 18 months—despite raw material shortages—through strategic inventory buffers and redundant machine scheduling.”

Why Partner With Us?

Olympic & Military Proven: Components trusted by elite athletes and defense agencies worldwide.

Zero Defects Culture: Every part is inspected, documented, and traceable—no exceptions.

24/7 Engineering Support: Direct access to CNC specialists for urgent design tweaks or production issues.

Your success is our precision. Let’s build it together.

Wuxi Lead Precision Machinery | ISO 9001 Certified | Partnering with Industry Leaders Since 2005

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery — Precision Engineering, Strategic Collaboration

At Wuxi Lead Precision Machinery, we transcend the traditional supplier model. We are your dedicated engineering partner, committed to delivering precision that meets the highest standards of aerospace, defense, and elite sports applications. Our Zero Defects quality protocol, proven expertise in Olympic and military-grade components, and 24/7 customer support ensure your project’s success from design to delivery.

Core Differentiators

| Differentiator | Industry Standard | Wuxi Lead Precision Advantage |

|---|---|---|

| Quality Assurance | ISO 9001 compliance, typical defect rate 0.5% | Zero Defects protocol: 100% dimensional inspection, SPC monitoring, and 5-stage quality checks for ±0.005mm tolerance consistency and Ra 0.4 surface finish |

| Elite Application Experience | Standard industrial components | Certified supplier for Olympic racing cycles and military enterprises — meeting AS9100, ISO 13485, and MIL-STD specifications |

| Customer Support | Standard business hours (9–5) | 24/7 dedicated engineering team for urgent requests, real-time production tracking, and rapid-response DFM analysis |

Ready to Elevate Your Precision Manufacturing?

Partner with Wuxi Lead Precision Machinery — where precision engineering meets strategic collaboration. Let us optimize your design for manufacturability and deliver components that meet the most demanding specifications.

Request a Free DFM Analysis and Quote Today

Email: [email protected]

Phone: +86-13961886740

24/7 Support: Available for urgent requests and technical consultations

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.